Flood Control International

Premier Foods (Ambrosia, Devon) Flood Protection

Courtesy of Flood Control International

Home to family favourites, including custard and rice pudding for over 100 years, Premier Foods’ Ambrosia site in Devon installed low level temporary floodgates many years ago to mitigate against the risk of flooding. It was decided that these flood protection measures required updating, reflecting both local and global environmental changes.

Just like Flood Control International, Premier Foods provide the highest quality products to their respective markets. In turn, they expect high quality equipment to be installed on their own sites, which is just one of the reasons we worked so well together to complete their flood mitigation programme.

The requirement

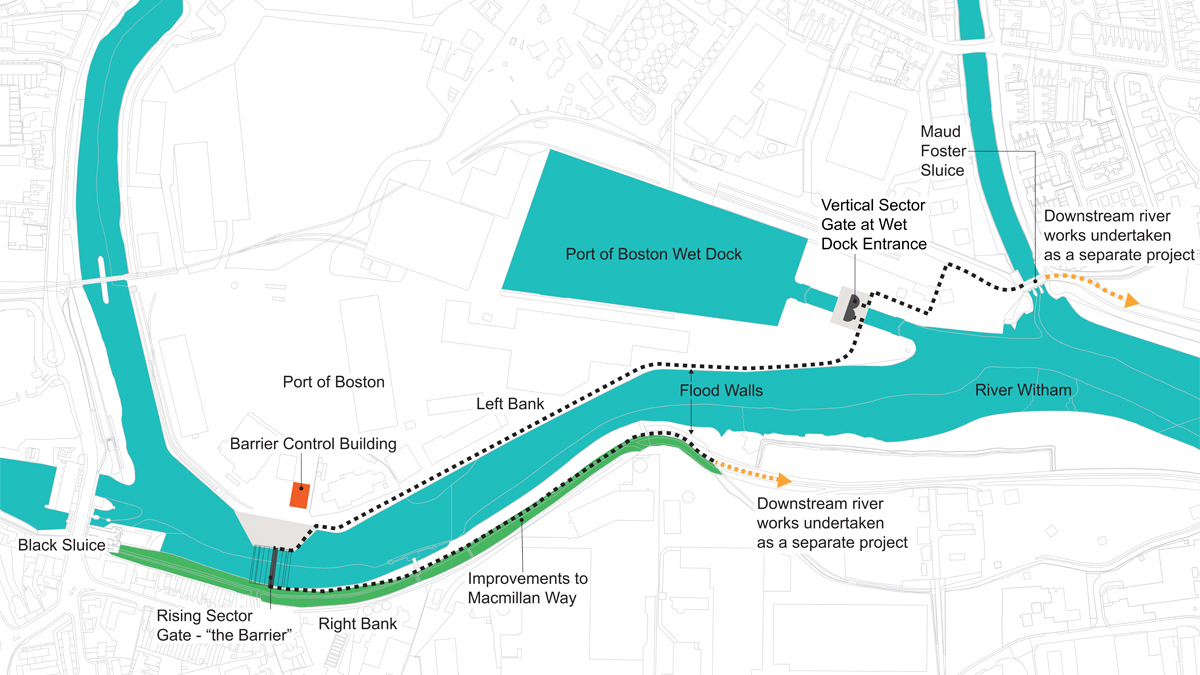

The clients’ objective, working closely with their insurance partner, was to find a way to protect key assets at the site, that would keep the plant running in the event the local river level rose such that the site becomes inundated. It was clear that it would have been uneconomical to protect the whole expansive site, so the team identified key areas and assets at risk of flooding and at what depth they needed to be protected to. A risk value versus cost outlay exercise was conducted on everything below the flood defence level, to help define the risks to factory output and provide a list of areas where options to prevent/mitigate exposure could be considered.

Courtesy of Flood Control International

The solution

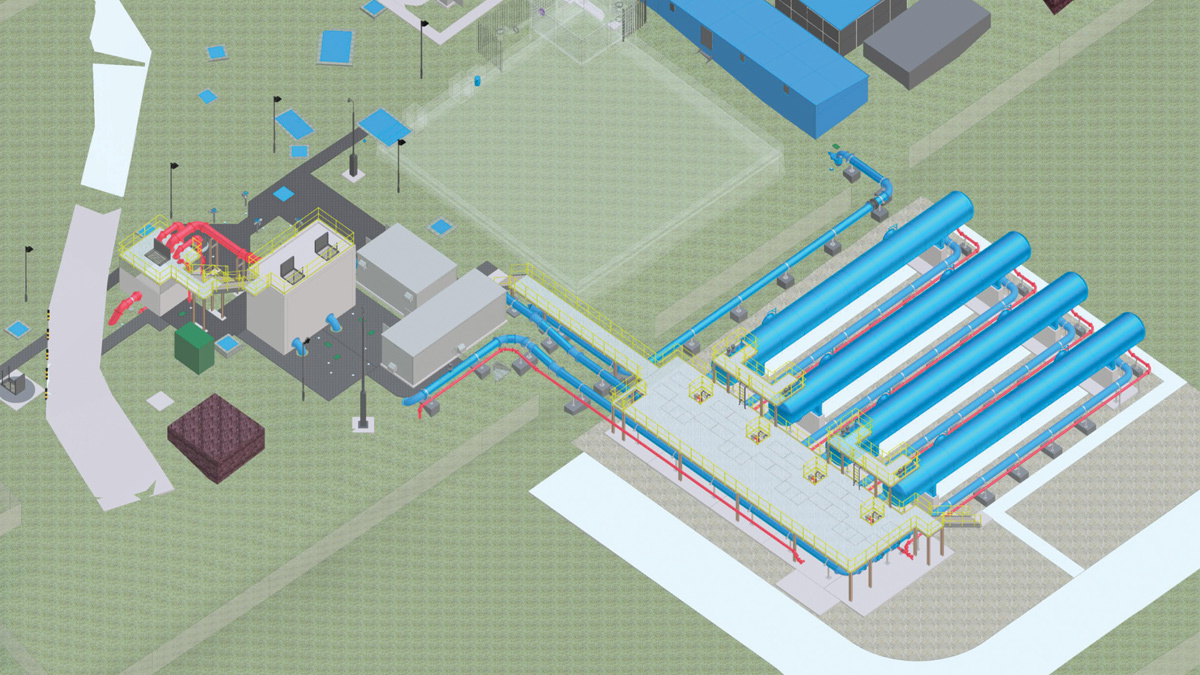

Due to the varied and complex processes on site, much time was spent assessing and understanding what was important and where the operational pinch points were, in order to develop a plant criticality list.

In some areas, at risk equipment was already on raised platforms or plinths, so the additional further benefit of raising or protecting these items for the 1:500-year (0.2% chance) flood depths was assessed, against the business interruption of not using that particular production line.

Following this thorough review process, a series of measures were proposed and implemented, including:

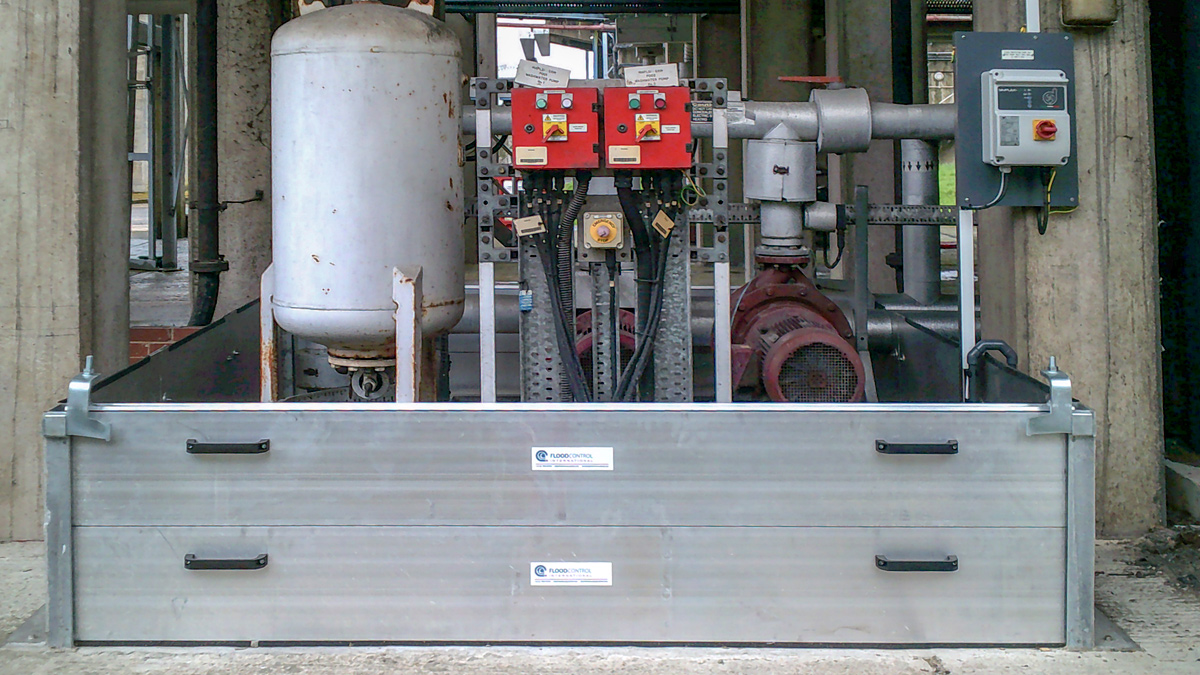

- Distribution boards and control panels inside production areas were protected by a mixture of removable and permanently installed FM Approved demountable barriers.

- The main pump room and site sub-stations needed doorways protecting, so that the power supply is kept intact; therefore, secure flood doors were the obvious choice to provide flood protection up to almost 2m height.

- At the boiler house and R&D department, FM Approved slot-in barriers were installed, to protect perimeter roller shutter and access doors, protecting key equipment and also ensure continuity of steam supply to factory.

To overcome often difficult installation positions, a number of bespoke designs and components were necessary, including posts with angled bases to sit on ramps, stainless steel parts for humid, steamy food production areas, plates to cover drains for barriers to sit on and floor mounted end channels sealed to walls.

The project was awarded in May 2021 with works completed in February 2022. It was extremely helpful to work with such a well engaged insurer and client, who took on board advice and recommendations, allowing us to do what we do best; provide expert advice, bespoke engineering solutions and above all, dependable flood defences.

|

For more information: Flood Control International | +44 (0)1822 619730 | https://floodcontrolinternational.com/

Courtesy of Flood Control International