Queens Bridge Siphons (2019)

Construction of new siphon chamber reinforced concrete base - Courtesy of DAWSON-WAM Ltd

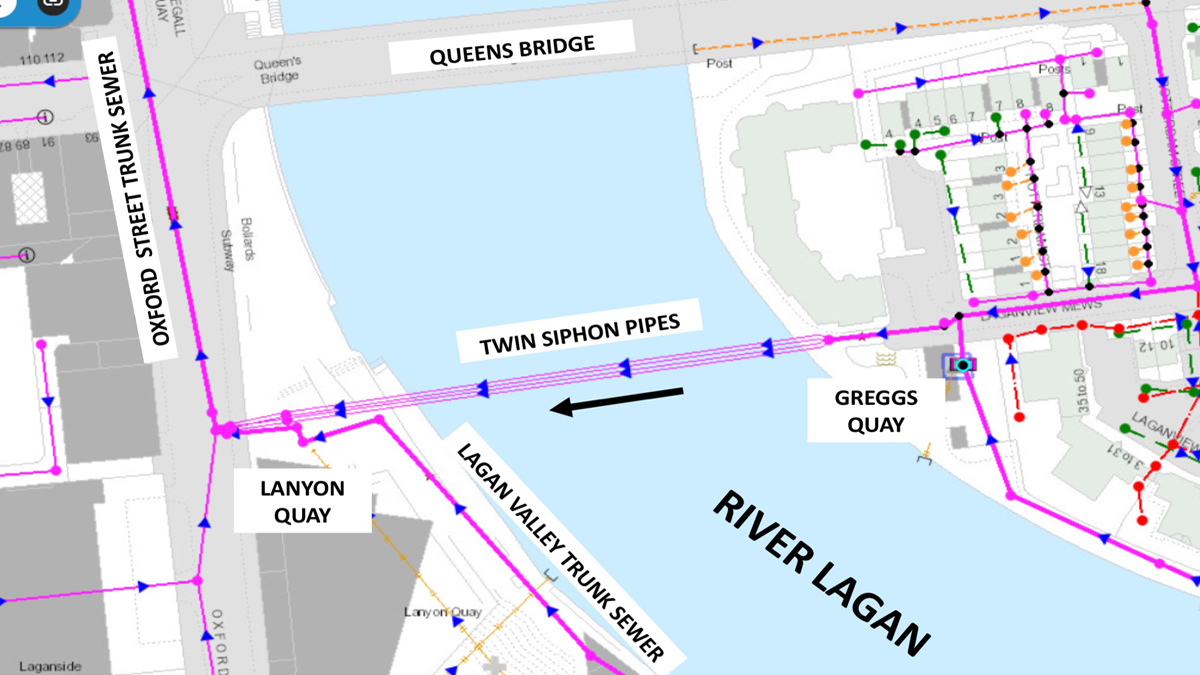

During 2018, NI Water commenced refurbishment work to one of its critical assets, twin sewerage siphons, known as the Queens Bridge Siphons, in Belfast. The siphons transfer wastewater from a substantial proportion (circa 40,000 population) of the east of the City under the River Lagan to the Oxford Street Trunk Sewer for onward transfer to the Belfast Wastewater Treatment Works. The siphons, and their associated chambers, were constructed c1910 during the Titanic era. Historical maps of the locality show that the Lanyon Quay area had once been a dockyard served by a railway line. NI Water was fortunate enough to be in possession of copies of the siphons’ original construction drawings, which showed they had been tunnelled below a railway underpass that served the old dockyard. The drawings also showed that temporary works of the time had been in the form of substantial wooden piled cofferdams, driven into the underlying strata. It was therefore suspected that the old underpass structure and remains of the original cofferdams might be encountered during any proposed construction works.

Background

The siphon pipes themselves comprise twin 1.14m diameter (45”) cast iron/brick pipes. Three brickwork chambers provide access to the siphon pipes, the locations of which are:

- On Greggs Quay, in a pedestrian area adjacent to a modern apartment development on the east riverbank.

- On Lanyon Quay, in a pedestrian area close to Belfast’s Waterfront Hall (a premier concert venue) on the west riverbank.

- On Oxford Street, within a busy bus lane.

Penstocks within the chambers allow closure of one, or both siphons for maintenance purposes. Wastewater flows enter the siphon system via the 9m deep Greggs Quay chamber where they descend vertically, flow through the siphon pipes under the river and then ascend vertically within the Lanyon Quay chamber and on to the Oxford Street chamber and trunk sewer.

Project location and schematic – Courtesy of NI Water

Inspection

In 2013, a cleaning and inspection operation on the siphons identified structural deficiencies within the chambers, including infiltration and acrow props in the Greggs Quay chamber, which appeared to be lending structural support. The existing flow control penstocks also no longer operated or sealed effectively.

Due to the perceived poor condition of the chambers and the defective penstocks, incoming flows could no longer be managed and routine inspection and maintenance had become difficult and disproportionately costly.

The Lagan Valley Trunk Sewer, discharging to the Oxford Street chamber, also frequently surcharged and had no means of isolation. The condition of the underlying chamber on Oxford Street had led to partial failure of its large heavy-duty cover, resulting in traffic safety risks.

At the time of project development, the City’s flagship Belfast Rapid Transit (BRT) project, entailing special bus lanes and bus upgrades, was under construction and programmed to be fully operational by September 2018. The Department for Infrastructure (DfI) Roads (Northern Ireland’s national roads authority) directed NI Water to complete all work on the Oxford Street bus lane before August 2018. Due to this, and other constraints, NI Water decided to deliver the project in two phases:

- Phase 1: Addressing deficiencies in the Oxford Street and Lanyon Quay chambers.

- Phase 2: Deferring rehabilitation of the Greggs Quay chamber, and the siphon pipes themselves to a later date.

Existing Lanyon Quay siphon chamber – Courtesy of DAWSON-WAM Ltd

Project appraisal

NI Water appointed Doran Consulting in 2015 to provide professional services and complete a Capital Investment Appraisal for the project. The appraisal confirmed the project needs and drivers, identified as Base Service Provision, to enable safe, routine maintenance and cleaning of the siphon sewers. Assessment of a number of options confirmed constructing new siphon chambers, providing new penstocks and relining the siphon pipes as the preferred solution.

Early contractor involvement and enabling works

Doran Consulting managed the Early Contractor Involvement (ECI) stage of the project, preparing the ECI specification and contract as well as project managing and supervising the enabling works. Enabling works involved the gathering of site information to help define the scope of the works and, in conjunction with the ECI contractor, DAWSON-WAM Ltd (one of NI Water’s leading framework contractors), developing the construction methodology.

ECI works comprised:

- Ground investigation works.

- CCTV sewer condition surveys.

- Sonar pipeline surveys.

- Topographical surveys.

- Ground penetrating radar surveys.

The site at Lanyon Quay showing close proximity to multi storey buildings – Courtesy of DAWSON-WAM Ltd

The ground investigation works included geotechnical and environmental investigations, entailing boreholes, trial pits and slit trenches, with appropriate sampling and testing. Given the location of the site and its history, Doran Consulting oversaw the completion of a Preliminary Risk Assessment (PRA) and Generic Quantitative Risk Assessment (GQRA) in accordance with the Model Procedures for the Management of Land Contamination (CLR 11) 2004.

It was clear from the outset that the existing siphons would have to be taken out of operation to enable construction. Doran Consulting identified and assessed possible solutions for dealing with existing wastewater flows, a process that included network hydraulic modelling to identify feasible solutions and the potential impacts of any required temporary network modifications.

This confirmed that the Belfast Stormwater Tunnel and Terminal Pumping Station, the main elements of a major storm water interceptor project completed in 2010, could be utilised to convey diverted wastewater flows to Belfast WwTW. Modelling also confirmed temporary measures at strategic locations in the upstream network (e.g. temporary modifications to existing combined sewer overflows) necessary to mitigate increased out-of-sewer flooding risks during flow diversions.

An additional measure was the purchase of a spare low-flow pump and critical spares for the Belfast Stormwater Terminal Pumping Station, as the prolonged foul flow diversions risked increasing pump blockages and wear. All such measures were agreed in advance with NI Water’s Operations teams and the Northern Ireland Environment Agency and were implemented and monitored during construction.

The enabling works and ECI provided an early opportunity to identify and engage with key stakeholders. Discussions were held with affected landowners, DfI Roads, DfI Translink, Department for Communities, SUSTRANS NI Cycling and nearby businesses.

Refurbishment of the chamber on the Oxford Street trunk sewer in the bus lane of the Belfast Rapid Transit project – Courtesy of DAWSON-WAM Ltd

Project management

The NEC3 Engineering and Construction Contract, Option A: Priced Contract with Activity Schedule was chosen for the main construction contract and DAWSON-WAM Ltd was appointed by NI Water as design and build contractor for Phase 1 project delivery in May 2018.

Doran Consulting developed the scope of works and contract documentation and provided project management, site supervision and health and safety advisory services throughout construction.

Queens Bridge Siphons: Supply chain – key participants

- Professional services & project management: Doran Consulting

- Design & build: Phase 1 project delivery: DAWSON-WAM Ltd

- Mechanical & electrical contractor: Murphy

- Precast MH rings & pipes: FP McCann

- Builders Merchant: McBlair

- Traffic management contractor: HBS

- Jetting & cleaning contractor: Environmental Techniques

(left) Excavation within secant piled cofferdam with 3 levels of temporary props and (right) completed siphon chamber walls at Lanyon Quay with Greggs Quay in the background, on the far riverbank – Courtesy of DAWSON-WAM Ltd

Construction

One of the most difficult constructional aspects to overcome was the confined nature of the site. Due to the deep excavations entailed, the works required careful phasing to minimise the impact on the surroundings and minimise construction traffic movements.

DAWSON-WAM Ltd first implemented the agreed temporary network modifications, which included the lowering of certain CSO weir levels and the installation of inflatable bungs in accordance with network model recommendations, to mitigate out-of-sewer flooding risks elsewhere in the network. When this was completed, flows to the siphon system were diverted to a nearby CSO to spill to the Belfast Stormwater Tunnel by fitting an inflatable bung in the incoming sewer at Greggs Quay.

At early design stage, it was decided to relocate the new Lanyon Quay chamber from the Oxford Street bus lane to the adjacent pedestrianised area, which would significantly improve access to the siphons and the new penstocks for future maintenance. The new chamber, which was in excess of 9m deep, required the installation of extensive temporary works. Taking into consideration the risk of encountering buried wooden temporary works from the initial construction back in the early 1900s, and the close proximity of existing high-rise buildings, the option of using traditional sheet piled cofferdam temporary works was quickly eliminated.

Installation of temporary props to support brickwork prior to installation of steel frame temporary works – Courtesy of DAWSON-WAM Ltd

Cofferdam

Achieving watertightness of the cofferdam was of paramount importance, as the excavation works were less than 30m from the river Lagan and formation level of the new structure was 2.5m below the riverbed. Failure to achieve a watertight cofferdam would have been detrimental to the overall construction process and works programme.

DAWSON-WAM Ltd implemented a secant piled cofferdam design for the installation of the new siphon chamber and connection pipework. This ‘hard/hard’, relatively silent and vibration free installation solution was ideal to overcome the identified risks. Watertightness between the secant piles and the existing structures was achieved by coring the 450mm dia. secant piles into the existing brick structure to form a watertight seal, using DAWSON-WAM’s cased auger system.

Temporary props were installed at three levels to support the secant piled cofferdam to enable excavation and construction of the permanent works. To minimise the footprint of the cofferdam, the secant piles were incorporated into the permanent works design, where they interfaced with the new siphon chamber. The secant piles were cleaned and the new, in situ reinforced concrete structure was cast against the piles to form the chamber perimeter walls.

Steel frame temporary works installed to facilitate connection of existing siphon pipes to the new chamber. Holes cored for temporary ‘pin’ supports are visible in brickwork and inflatable bungs visible at back of existing chambers – Courtesy of DAWSON-WAM Ltd

Linking the siphon pipes

Linking the existing siphon pipes to the new chamber proved challenging as they were separated by a brick wall in an existing intermediate chamber. As this formed one side of the cofferdam wall, DAWSON-WAM Ltd developed a temporary works design that involved the installation of timber needles and acrow props, to pin and temporarily support the overlying brick structure, before installing a steel frame to provide an adequate opening to allow installation of the new connecting pipes.

Diversion of incoming flows afforded the opportunity for a rigorous inspection of all the chambers and the siphon pipes below the river. It was discovered that the northerly siphon was almost fully blocked with an accumulation of debris, including silt, rags and grease (essentially a dreaded ‘fatberg’), which had to be removed.

Installation of new 1200mm dia interconnecting pipes between Oxford Street and Lanyon Quay – Courtesy DAWSON-WAM Ltd

Detailed structural inspection of the Greggs Quay chamber revealed that its structural integrity was such that complete reconstruction would not be required. It was therefore decided to carry out any work necessary to address minor infiltration and deteriorated brickwork pointing, apply a lining to the chamber and replace the defective penstocks, thereby realising the full benefits of the project, in terms of restoration of functional flow controls, within Phase 1.

Sika Poxitar F was chosen as the preferred product for lining the chamber as it would provide a hard wearing, easily maintainable surface and will adhere effectively to damp substrates.

Conclusion

At the time of writing (June 2019) work is about to commence on refurbishment of the Greggs Quay chamber with project Phase 1 completion anticipated by September 2019. The completed project will provide the benefits of improved operational effectiveness and safety and ensure this critical asset of the Titanic era is in a fit condition to serve the City of Belfast for years to come.

Early contractor involvement from the outset, and choice of design and build procurement route, ensured the supply chain’s experience and capabilities were drawn on and brought to the fore. This approach was fundamental in ensuring successful delivery in terms of meeting the physical and time constraints imposed, as well as providing a product that will be fit for purpose in terms of NI Water operational needs.