Alderney WTW (2023)

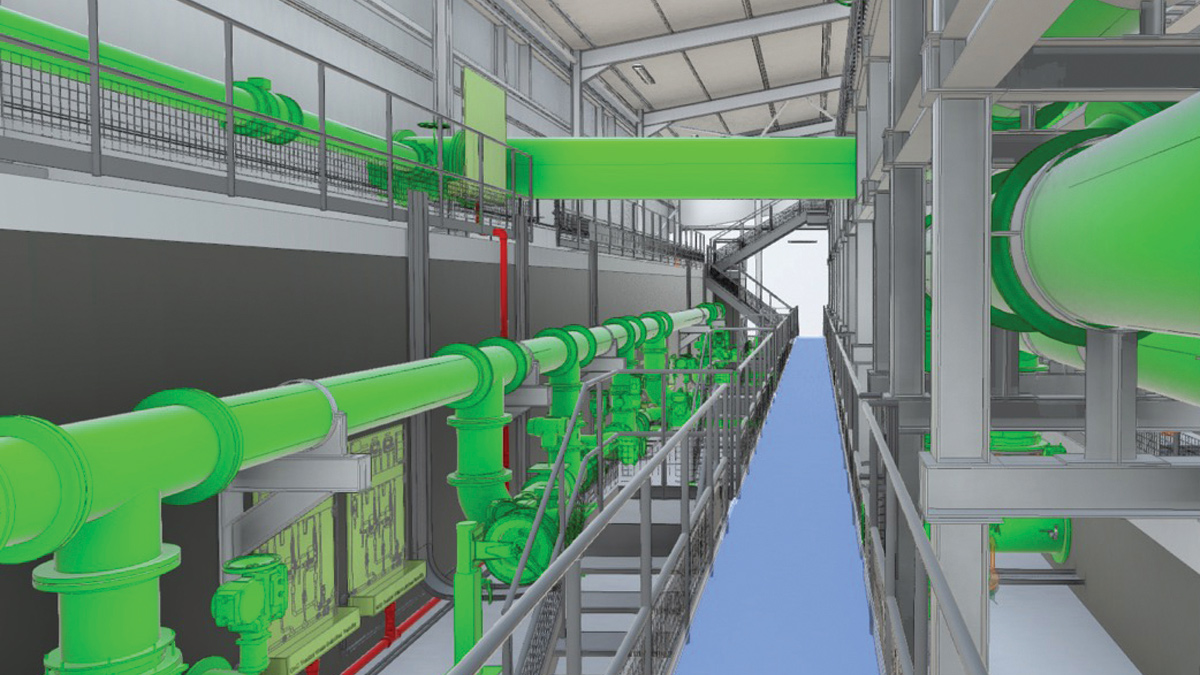

3D model of the new Alderney WTW - Courtesy of South West Water

In 2015, Bournemouth Water was acquired by Pennon Group, who already owned South West Water (SWW). Alderney WTW, located in the north of Bournemouth, is a strategically important water treatment works that supply high quality drinking water to approximately 375,000 customers – nearly 75% of the homes and businesses in Bournemouth Water’s operational area. Alderney WTW was served DWI notices requiring replacement of the current treatment process with agreed milestones and delivery timelines. The investments at these works are the most significant pieces of infrastructure in South West Water’s AMP7 plan and will secure a long-term resilience by building on the innovative work carried out by South West Water at Mayflower WTW in providing industry leading water treatment facilities.

Existing works

Pre-treatment for Alderney is based at Longham. Raw water is drawn from Longham Lakes and passes through pressure filters. This pre-treated water is then pumped to the Alderney WTW. Treatment at Alderney consists of slow sand filtration (SSF) which combines a layer of granular activated carbon (GAC).

Disinfection is achieved via UV irradiation followed by super/dechlorination and finally chloramination. Treated water is pumped on site to the final water storage reservoirs before entering the distribution network.

Optioneering

Significant optioneering and value engineering work has been undertaken to evaluate the most cost-effective solution both in terms of OPEX (operational costs) and CAPEX (capital expenditure).

There was an early strategy investigated where a single ‘super works’ could provide opportunities for economy of scale savings in non-infrastructure costs but this would be offset by the need for more infrastructure and pumping, to convey both raw water from one or more abstraction points to the works and treated water back to the service reservoirs serving the respective demand areas.

One overriding factor to the ‘super works’ option was that resilience implications linked to the decision to move to a single location meant further options were developed.

This has included successful pilot trialing of ceramic membranes after the existing slow sand filters. This is an innovative approach and is the first time globally that ceramic membranes have been configured in this way. Through retaining more existing assets at the site and re-purposing them, the current proposed solution has reduced the OPEX costs significantly compared to a conventional membrane solution.

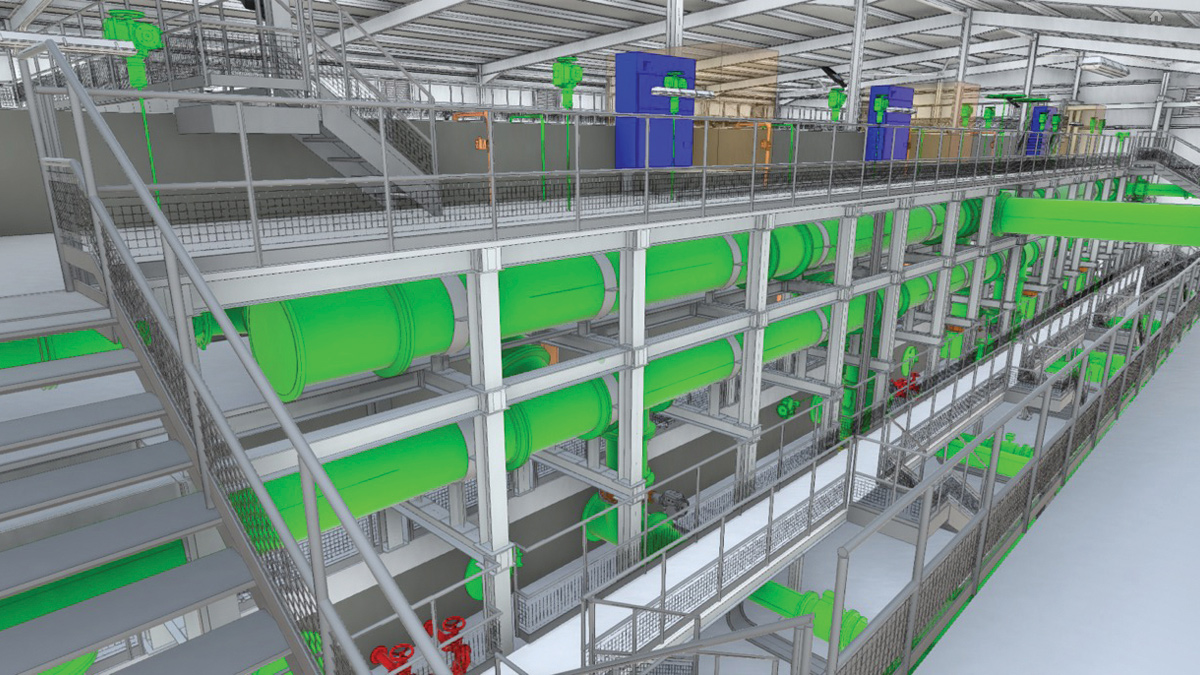

3D model inside the new Alderney WTW – Courtesy of South West Water

Project scope

The project will deliver a treatment process that will be installed after the existing slow sand filters in order to provide an effective barrier to cryptosporidium and other quality parameters. The design capacity of Alderney WTW is 81.2 MLD (output), with a sustained production output of 59.9 MLD.

The scope of the proposed works includes the following:

- Ceramic membranes: 10 (No.) PWNT C37 membrane units (with sufficient space in the building to install two additional units if required).

- Ozonation.

- Granular activated carbon (GAC) filters.

- pH correction when needed.

- Chlorination using chlorine gas.

- Dechlorination using sulphur dioxide.

- Chlorine contact tank.

- Pumping into on-site service reservoirs.

- Ammoniaton using ammonium sulphate solution.

- Final site water quality monitoring.

- Connection pipework to the existing process

- Management of waste from the new treatment process.

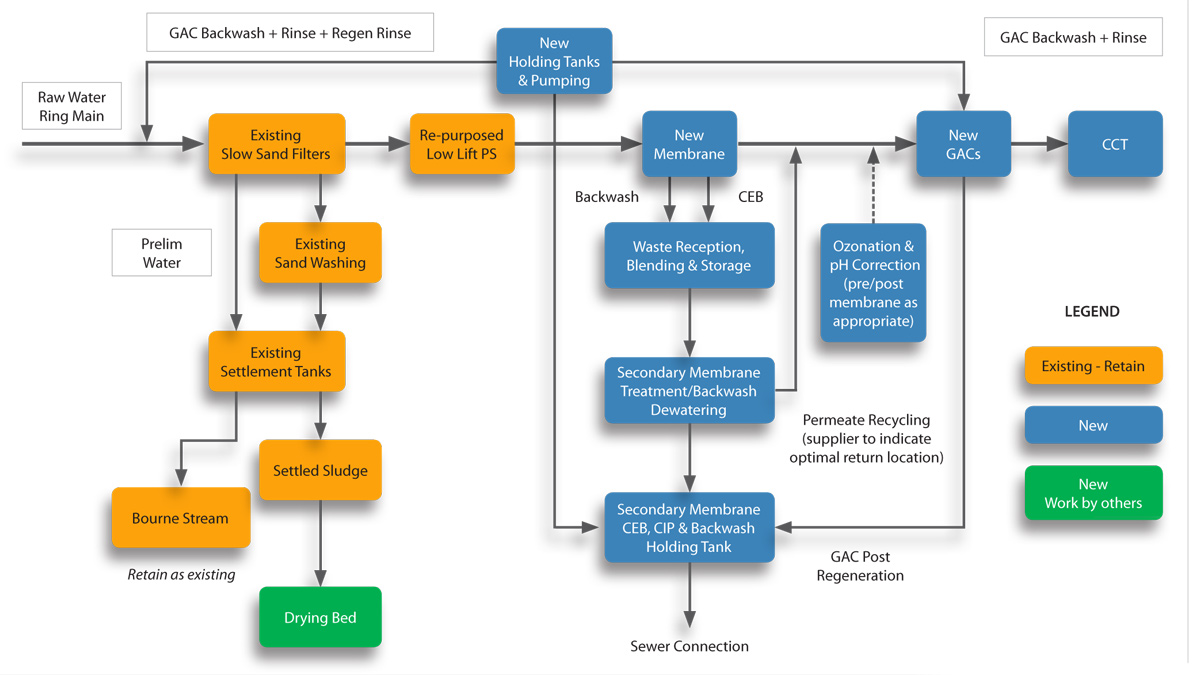

The flow diagram of the proposed works is below. Orange indicates existing assets, blue and green indicate new and refurbished assets.

Alderney WTW: Process flow diagram – Courtesy of South West Water

Progress (as of June 2023)

Feasibility Design: COMPLETE

This stage of the design included a substantial optioneering exercise, investigating different process technologies and potential locations for the new water treatment works.

Planning Design: COMPLETE

This stage has included extensive pilot testing on site which included two membrane units from different manufacturers and a lamella clarifier unit. This testing allowed the different process technologies to be evaluated over a range of different raw water conditions. The outputs from the pilot work allowed the team to confirm the water treatment process requirements, and to size the water treatment structures. Consultation also took place with the wastewater provider to determine a suitable route for wastewater discharge.

Spatial design of the building envelopes has also been undertaken for the purpose of the planning application. To facilitate this, a 3D model has been developed to optimise the general arrangement of the new works and the position and height of the different structures.

This model was then used to engage with BCP (Bournemouth, Christchurch and Poole) Council under a Pre-planning Agreement which allowed early consultation on the appearance of the building and to agree measures that can be taken to mitigate any impact of the construction.

As well as fixing the building appearance, this early engagement with the Council has been beneficial as it has allowed agreement to be reached on aspects such as landscaping requirements, SUDS measures, construction vehicle movements, environmental mitigation measures and the location of construction compound areas. A public consultation exercise has also been undertaken to ensure that local residents and interest groups are kept informed, and so that their comments can be taken into account as the design develops. Planning Approval for the scheme was received in October 2021.

3D model inside the new Alderney WTW – Courtesy of South West Water

Outline/detailed design: ONGOING

Further progression of the detailed design well progressed to provide greater definition of the proposed works. This includes refinement of the process design to ensure an optimised whole life cost and carbon footprint, and development of the 3D model to finalise civils structures.

Engagement is also ongoing with various equipment manufacturers (for example, the chosen membrane supplier) to confirm plant layouts, control philosophy and power requirements.

Construction: ONGOING

Construction activities have been progressing on site over the last year. The enabling works have included ground clearance and demolition of old buildings over the construction area. Foundation/piling work is also now complete in preparation for the above-ground structures which will progress on site at the back end of 2023.

Alderney WTW: Supply chain – key participants (July 2023)

- Client cost consultants: Chandler KBS

- Principal contractor: KIER

- Process designer: Arcadis

- Civils designer: AECOM

- Membrane process plant: Ross-shire Engineering

- Membrane technology supplier: PWNT

- Precast concrete tanks: FLI Precast Solutions

- Precast concrete tanks: A-Consult Ltd

(top right) Final stage of demolition and the start of the large diameter pipework buried below the GAC contactors and process buildings and (left & bottom right) temporary works: installation of sheet piles prior to the excavation of the regen tank and chlorine contact tank – Courtesy of KIER

Delivering for customers

Delivery of this project is seen as part of South West Water’s 25 year+ vision and commitment to customers in the Bournemouth Supply Zone. South West Water are confident that these plans can deliver on customers’ expectations and their number one priority of receiving a reliable supply of safe, clean drinking water. By continually looking to optimise the plans to balance any service improvement with affordability and target the timing of investments to minimise changes to the price that customers pay for their water and to protect vulnerable customers. Fundamental to this approach is the stewarding of water treatment assets to ensure the long-term resilience of the water supply and to minimise the impact that external pressures such as climate change or new legislation might have.

All South West Water schemes are designed and delivered with this in mind, and this large investment represents the company’s commitment safeguarding assets and the quality of water delivered for future generations.

The investment at Alderney WTW will have a significant impact on customers in the Bournemouth area, delivering a much-improved supply to this area once complete at the end of 2024.