Alderney WTW (2025)

CeraMac® 37 ceramic membrane system following off-site integration - Courtesy of RSE

For over a century, Alderney Water Treatment Works in Bournemouth has been relied upon to provide safe, clean drinking water to the local community. As demands on the water network continued to grow, and the effects of climate change became more pressing, a major transformation of this essential facility was identified as a requirement. The large-scale infrastructure project is a key part of Bournemouth Water’s investment programme to modernise the water system, future-proof it against a changing climate and minimise the impact on the environment. The overall project goal is summarised in Bournemouth Water’s Strategic Objectives statement:

“Delivery of a world class drinking water supply solution for the supply network serving Bournemouth Water’s customers, providing excellent water quality and long-term water supply security for the region.”

Project scope

RSE (Ross-shire Engineering) was contracted for the design, manufacture, installation, commissioning and optimisation of a new modular water treatment plant at Alderney that combines advanced technology with a sustainable Design for Modular Assembly (DfMA) approach.

The new 84ML/day ceramic membrane treatment plant deploys a range of RSE standard product off-site modular solutions. This included the integration of ozone dosing up-front of the PWNT CeraMac® 37 ceramic membrane system which allows the plant to operate at a higher flux, with less chemical cleaning required, and within a smaller overall plant footprint.

Pre-build phase of the treatment unit in RSE’s Muir of Ord facility – Courtesy of RSE

The completed plant will deliver high quality water, whilst enhancing the overall efficiency and resilience of the site, and providing a barrier to Cryptosporidium.

This project is not solely centered around technology upgrades. It also serves as a showcase of RSE’s strengths in standardised DfMA construction, environmental awareness, and seamless project delivery. The Alderney upgrade demonstrates what is possible when innovation, collaborative planning, and sustainability are prioritised from the outset.

Alderney WTW: Supply chain: key participants

- Main process designer & contractor: RSE (Ross-shire Engineering)

- Ceramic membrane design: PWNT

- Ozone generation unit design/install: Nijhuis-Saur Industries

- Liquid oxygen vessels design/install: BOC

- Logistics & specialist transportation: GF Job

- Civil construction works: KIER

- Structural steelwork: Kloeckner UK

- Precast concrete tank: FLI Precast Solutions

- Precast concrete tank: A-Consult Ltd

- Overhead crane: Street Crane Co.

- MCCs, ICA & electrical: GPS Group

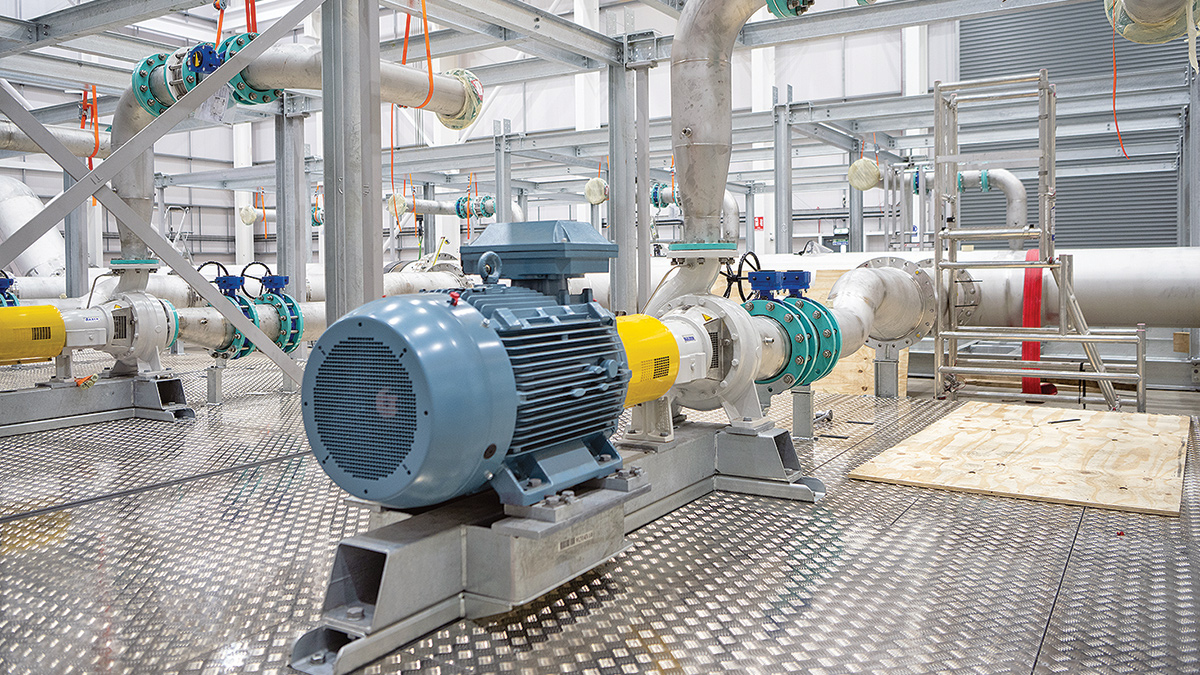

- Process pumps: Sulzer Pumps Wastewater Ltd

- CIP pumps: Xylem Water Solutions

- Backwash pumps: Grundfos Pumps Ltd

- Chemical storage tanks: Chem Resist Group Ltd

- Tanks: Forbes Technologies Limited

- PVC pipework: Georg Fischer

- Crimp-press pipework: Mapress

- Instrument pipework: Hylok

- Pipework materials: DH Stainless

- Valves & pneumatic actuators: Socla UK | Watts Industries

- Static mixers: Statiflo International

- Pneumatic control hardware: Burkert Fluid Control Systems

- Bellows: Elaflex | FlexEJ

- Large diameter flanges: JR Whitehead 2000 Ltd

- Quality instruments (turbidity): SWAN Analytical UK Ltd

- Quality instruments (pH/ORP): Endress+Hauser Group

- Quality instruments (UVT): Process Measurement & Analysis Ltd

- Quality instruments (ozone): Xylem Water Solutions (Evoqua)

- Process instrumentation: IFM Electronics

- Large bore flow meters: Siemens

- Safety showers & eyebaths: Aqua Safety Showers International Ltd

Aerial view of Alderney WTW site (RSE modular building in centre)- Courtesy of RSE

Delivering a smarter approach

RSE recognised that a modular construction approach offered the best path to meet both the technical and environmental goals of the project. By fabricating and assembling major elements of the new plant off-site at RSE’s manufacturing facilities across the UK, civil engineering works could proceed on-site in parallel; shortening the project delivery timeline by 12 months and minimising disruption at the existing live treatment site. At the same time, the CeraMac® systems from PWNT were being fabricated in Italy and the Netherlands.

By progressing all aspects in tandem, RSE was able to procure all long-lead items immediately after order placement, and release work packages to production facilities to allow commencement of fabrication activities exactly when required. This allowed the project to be delivered at an unmatched pace.

Achieving major project milestones

RSE started work in April 2023, focusing first on critical path design and long-lead procurement items. Full-scale fabrication works started within five months, followed by off-site modular assembly starting in early 2024. The first modular units arrived at the site in October 2024, already commissioned off-site, ready for integration. The final unit was delivered in December 2024, marking the end of the off-site delivery phase.

In total, 70 modular units were safely transported to site and reassembled across just eight weeks. With the commissioning phase scheduled for completion in 2025, the RSE contract will be delivered both on time and to specification. This will stand as the largest modular-built ceramic membrane plant in the UK, and was completed in half the time of a conventional build.

Precision planning with digital tools

The scale of this project required careful and coordinated logistics. RSE’s in-house Building Information Modelling (BIM) team developed a detailed 4D animation using Autodesk Construction Cloud models, enabling every stakeholder to visualise and understand the delivery sequence in real time.

This step-by-step animation mapped out how each modular unit would be delivered and reassembled, ensuring a smooth process for the installation teams, hauliers, and on-site crews.

The digital planning also provided the client full visibility into every stage of the build.

Early stages of modular building fabrication – Courtesy of RSE

Built for performance & sustainability

Environmental efficiency is a core focus throughout the Alderney upgrade. Rather than demolishing and rebuilding the facility from scratch, the project team have retained key parts of the existing infrastructure and integrated new treatment processes within them. This approach has reduced carbon emissions and environmental impact.

The RSE DfMA approach brought additional benefits by reducing time on site, minimising vehicle traffic, and cutting construction waste. The use of ceramic membranes also contributes to long-term operational savings, thanks to their durability and lower energy requirements.

Proven delivery model

The key programme dates for the Alderney upgrade were:

- April 2023: Contract award.

- May 2023: Procurement start.

- September 2023: Start of fabrication.

- March 2024: Start of modular off-site assembly.

- October 2024: First modular unit delivered to site.

- December 2024: Final modular unit delivery to site.

On-site at Alderney WTW during build up phase – Courtesy of RSE

The Alderney project showcases the reliability of RSE’s integrated delivery model. With in-house capabilities across design, automation, and installation, RSE are able to control every aspect of delivery with precision. Supporting the successful outcomes were:

- Over 40,000m2 of factory-controlled production space.

- Automated manufacturing processes with built-in assurance.

- A national network of 26 facilities supporting regional mobilistation.

- Self-delivery across mechanical, electrical, and control (MEICA) disciplines.

- 4D modelling and real-time delivery tracking.

- Standardised, repeatable product solutions tailored to each project

- Dedicated teams focused on safety, compliance, and technical excellence.

This integrated approach allows RSE to meet commitments with certainty, delivering a high-quality product, within the agreed budget and schedule.

Recognition through innovation: The King’s Award

In June 2025, RSE was honoured with the King’s Award for Enterprise, the highest accolade available to UK businesses, in recognition of our contribution to innovation in the water industry. The award specifically acknowledged the groundbreaking work behind the off-site build methodology and the development of the modular m-CTU product; both of which were instrumental to the successful delivery of the Alderney WTW project.

The Alderney upgrade exemplifies the very innovation that the award celebrates. By embracing a DfMA, factory-built approach and integrating advanced treatment processes into standardised units, the project delivered significant gains in efficiency, quality, and sustainability. These same principles formed the foundation of King’s Award submission and ultimately secured this national recognition.

The success of the Alderney project stands as a real-world demonstration of why RSE received this honour, showcasing how innovation, when applied with purpose, can help transform the water industry and set new standards for delivery.

Modular treatment unit leaving RSE workshop for delivery to Alderney

Courtesy of RSE

Summary

The upgrade at Alderney WTW stands as a benchmark for modular delivery in the water industry. It demonstrates how innovative thinking and modern construction methods can respond to the challenges facing water networks today, while also laying the foundation for more sustainable infrastructure in the future. It demonstrates what can be achieved in partnership with innovative clients who are committed to providing high levels of engagement and collaboration, to secure best outcomes for their end customers.

From early design through the final commissioning, RSE’s team are delivering a complex, high-value project with precision, speed, and care. The successes at Alderney not only highlights RSE’s technical capabilities but also the company’s ongoing commitment to supporting the UK’s water industry with solutions that are smarter, faster, and cleaner. It is testament to Bournemouth Water and the respective teams who have underpinned the delivery of the overall project.