Bolnhurst Water Recycling Centre (2025)

First-of-its-kind algae-based photo bioreactor system installation at Bolnhurst WRC - Courtesy of @one Alliance

Bolnhurst Water Recycling Centre (WRC), located near Keysoe in Bedfordshire, is currently undergoing a major upgrade to comply with new phosphorus discharge limits introduced under the Water Industry National Environment Programme (WINEP). Anglian Water, working through its @one Alliance, has designed and constructed a novel treatment solution that is now approaching the commissioning stage. The project combines a first-of-its-kind algae-based photo bioreactor system in-between primary and final settlement. By doing so, it is expected to not only secure immediate compliance with the new 0.5 mg/l phosphorus consent but also provide a sustainable, low-carbon model for nutrient management across the wider region.

Non-traditional treatment option

Rather than relying on conventional chemical dosing or energy-intensive tertiary plants, the scheme has been designed to demonstrate how compact, modular, prefabricated technology can provide a chemical-free and carbon-efficient alternative. Once operational, the Bolnhurst system will act as a reference site for future phosphorus removal schemes in Anglian Water’s AMP8 programme.

Exterior view of greenhouse – Courtesy of @one Alliance

The challenge

Under WINEP, Bolnhurst WRC is required for the first time to achieve an effluent phosphorus concentration of 0.5 mg/l. This is a stringent limit, particularly for a rural treatment works with no existing phosphorus removal capability. The site’s existing assets were an inlet wet well, followed by a series of RBCs, that were at the end of their lifespan, and a small lagoon that provided settlement.

Without intervention, Bolnhurst would have been unable to meet the new consent, exposing Anglian Water to regulatory penalties and increasing nutrient loading in the receiving watercourse. Achieving the new standard required a complete wastewater treatment package, instead of just a tertiary treatment process. The challenges on site included:

- Restricted footprint: Little available space for conventional plant such as tertiary cloth filter packages and dosing units.

- Ageing assets: Existing assets were at the end of their design life and there was limited biological treatment and no inlet screen or primary settlement phase.

- Operational continuity requirements: Treatment must be maintained during construction.

- Carbon reduction commitments: The solution must align with Anglian Water’s net zero 2030 target.

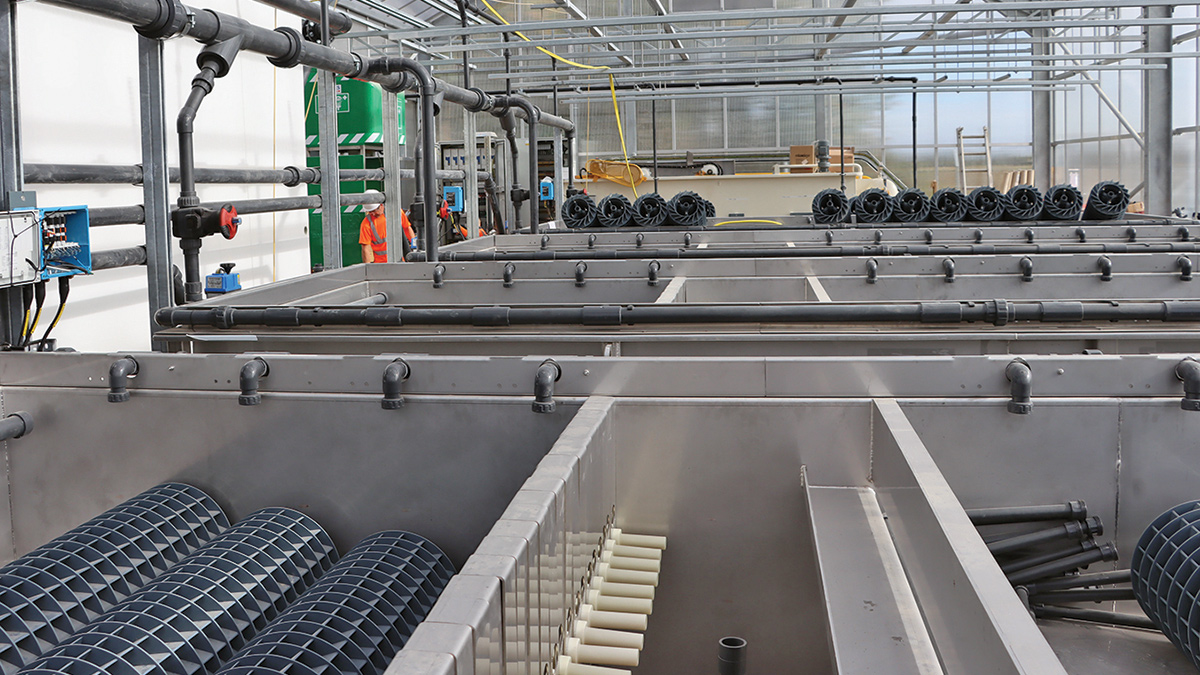

Photo-bioreactor tanks installation phase – Courtesy of @one Alliance

Optioneering

Anglian Water tasked the @one Alliance to provide a robust solution that provides a variety of benefits to the local communities and environment. Initially, a range of potential treatment options were considered during the feasibility design, however following a multi-criteria assessment covering cost, carbon, footprint, operability and resilience, an innovative algae-based photo-bioreactor technology was selected as the preferred option.

The solution

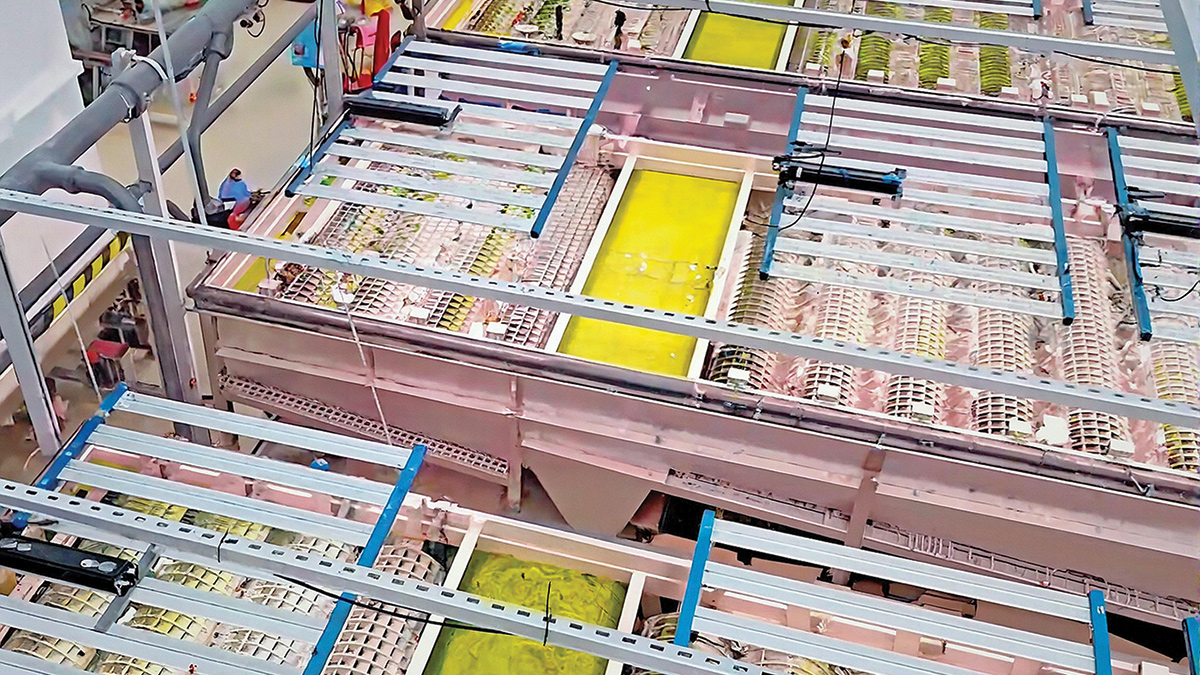

Supplied by ALGAESYS S.A., the central feature of the upgrade is the 200m2 algae-based photo-bioreactor system. This is a low energy, chemical-free system for primary, secondary and tertiary treatment, capable of removing solids, organic matter, nitrogen and phosphorus, as well as reducing pathogens. At Bolnhurst WRC, this robust decarbonised technology harnesses naturally occurring algae to capture dissolved phosphorus and other nutrients from secondary effluent. The algae assimilates phosphorus as it grows, enabling P-removal without the need for chemical precipitation.

The bioreactors are designed to operate in modular tanks, equipped with LED lighting to help out in the depths of winter, and controlled aeration to keep the algae alive. Once established, the algal biomass can be periodically harvested, with the potential for beneficial reuse as an agricultural soil conditioner. There is also potential for the wastewater to be used for data centre cooling, instead of precious potable water; as AI data centres grow in the UK.

Photo-bioreactor tanks installation phase – Courtesy of @one Alliance

Given the restricted site footprint, the bioreactor plant was designed as a compact, modular system. Prefabricated units were assembled off-site and delivered to Bolnhurst for rapid installation. This approach minimises site disruption, lessens health and safety risks, reduces construction carbon, and allows future expansion by adding additional modules if required.

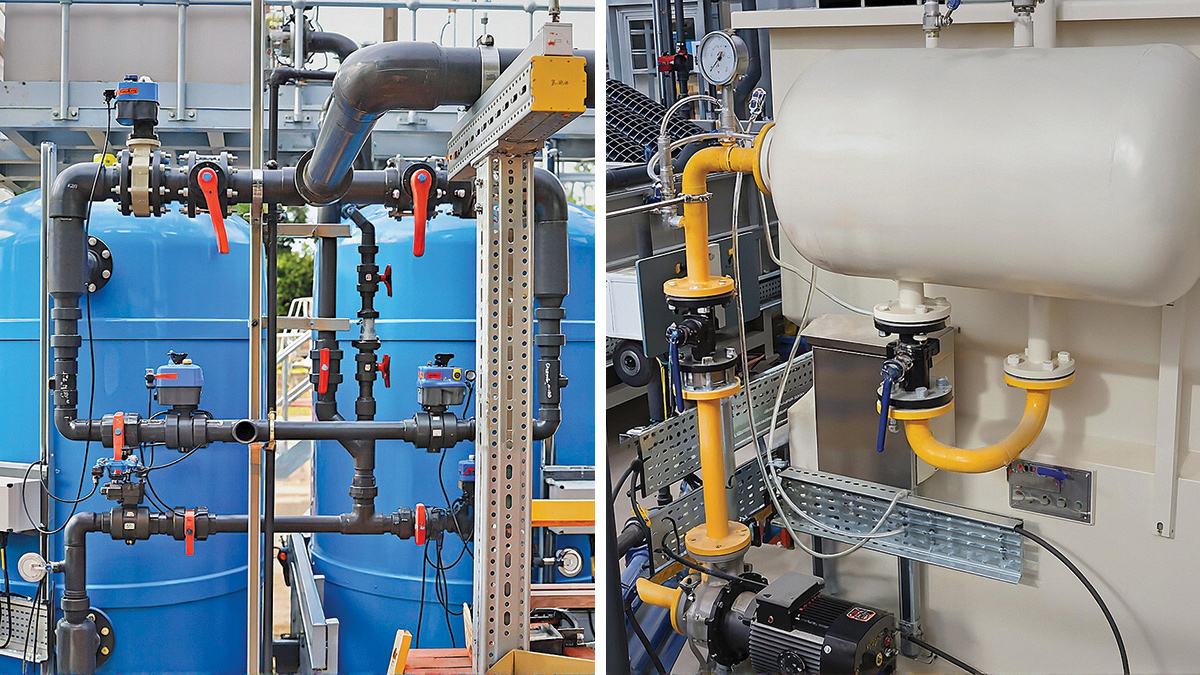

To integrate the algae system into the existing WRC, a number of supporting works were delivered:

- New inlet pumps and screens with an automatic duty/standby rotation and a safe maintenance access platform.

- Re-purposed RBC discharge tank, which is now used as a backwash attenuation tank.

- Tertiary sand filters, located externally to the greenhouse, which improves access and maintainability.

- Bespoke MCCs, control panels and SCADA integration.

- New TSFR flow meter & final effluent sample point.

- Backfilling of existing lagoon.

With the regulatory deadline preceding full commissioning of the algae plant, a temporary lamella clarifier with ferric dosing from Siltbuster Group was installed. This interim system is already in place and is expected to secure compliance ahead of the statutory deadline, ensuring Anglian Water avoids permit breaches while final commissioning of the permanent works is completed.

Installed bioreactor tanks prior to seeding – Courtesy of @one Alliance

Once fully commissioned, the Bolnhurst phosphorus removal project is expected to deliver a broad set of benefits:

- Regulatory compliance: Consistent achievement of the 0.5 mg/l phosphorus consent, protecting local water quality and Anglian Water’s environmental performance.

- Carbon reduction: A more detailed carbon analysis is currently underway, and should verify that it is on track to make a more than 50% carbon reduction against baselines.

- Resource recovery: Captured phosphorus, stored in algal biomass, can be harvested for reuse in agriculture, supporting circular economy principles.

- Energy efficiency: Optimised pumping and modular process design are expected to reduce energy consumption by up to 80% compared with conventional systems.

- Resilience and flexibility: Modular units can be adapted or expanded in future, while prefabrication simplifies replacement or upgrade activities.

- Knowledge transfer: Lessons from Bolnhurst will inform the wider roll-out of algae-based phosphorus removal in Anglian Water’s AMP8 programme.

Algae photo-bioreactors being seeded – Courtesy of @one Alliance

Bolnhurst WRC: Supply chain – key participants

The constrained nature of the site necessitated careful planning of construction logistics, lifting operations, and traffic management. Prefabrication was central in reducing working at height, hot works, and confined space entries.

Project delivery relied on a wide network of supply chain partners coordinated through the @one Alliance:

- Project delivery: @one Alliance

- Principal contractor: Mott MacDonald Bentley

- Civil engineering: Hercules PLC

- MEICA: Waveneys

- Photo-bioreactor & PSC design: ALGAESYS S.A.

- Sludge tank: Stortec Engineering Ltd

- MCC requirements: TES Group

- Emergency safety shower: Hughes Safety Showers

- MCERTS: SIRIS Environmental

- Pumps: Xylem Water Solutions

- Temporary lamella plant hire: Siltbuster Group

Surplus biomass tank – Courtesy of @one Alliance

Commissioning

During commissioning, strict controls are in place to manage the co-existence of temporary and permanent treatment streams, ensuring no risk of environmental non-compliance. Operator training is being carried out in parallel to ensure that the new processes are understood and embedded before handover.

Expected outcomes

Once the algae-based system is fully operational, Bolnhurst WRC will be one of the first sites in the UK to meet phosphorus consents through a large-scale, chemical-free process. The project is expected to demonstrate the feasibility of algae systems as a mainstream alternative to chemical dosing, while provide real-world performance data for AMP8 phosphorus removal planning. This will also potentially reduce Anglian Water’s dependency on chemical supply chains & finally, showcase how modular prefabrication can overcome footprint constraints on small rural works.

The broader significance lies in proving that regulatory drivers can act as catalysts for innovation, driving adoption of lower-carbon and more sustainable wastewater technologies.

(left) Sand filters and (right) DAF – Courtesy of @one Alliance

Conclusion

The Bolnhurst Water Recycling Centre Phosphorus Removal Project represents a landmark step towards sustainable nutrient management. As it moves into final commissioning, the scheme is poised to deliver compliance with stringent phosphorus limits, while simultaneously advancing Anglian Water’s goals on carbon reduction, circular economy, and resilience.

By combining an innovative photo-bioreactor system with conventional treatment, the project demonstrates how small, space-constrained WRCs can meet demanding environmental standards without reliance on chemicals or energy-intensive processes.

Once operational, Bolnhurst will stand as a reference site for the industry, providing valuable insight for future projects and reinforcing the role of the @one Alliance in delivering innovative, low-carbon infrastructure that safeguards both communities and the environment.