Dereham WRC (2025)

Newly installed MBBR tanks - Courtesy of @one Alliance

Dereham Water Recycling Centre is one of over 1,100 Anglian Water WRCs and is located in North Norfolk, approximately 20 miles from Norwich within the Wensum Nutrient Neutrality catchment, serving an estimated population in excess of 25,000. The existing works was built in the 1980s and consists of two main treatment streams made up of traditional process blocks namely, primary settlement tanks, biofilters and humus tanks. Previous work undertaken on the site by Anglian Water included six new tertiary sand filters, which were installed in 2003.

The challenge

The key driver for this project was Anglian Water’s obligation to meet new Compliance Flow to Full Treatment (cFFT) standards introduced under the Water Industry National Environment Programme (WINEP). Without intervention, Dereham WRC did not have sufficient hydraulic capacity to meet the new legal FFT requirement of 130.8 litres per second (up from 114 l/s) by 31 March 2025, which could have led to breaching permit conditions and facing significant penalties.

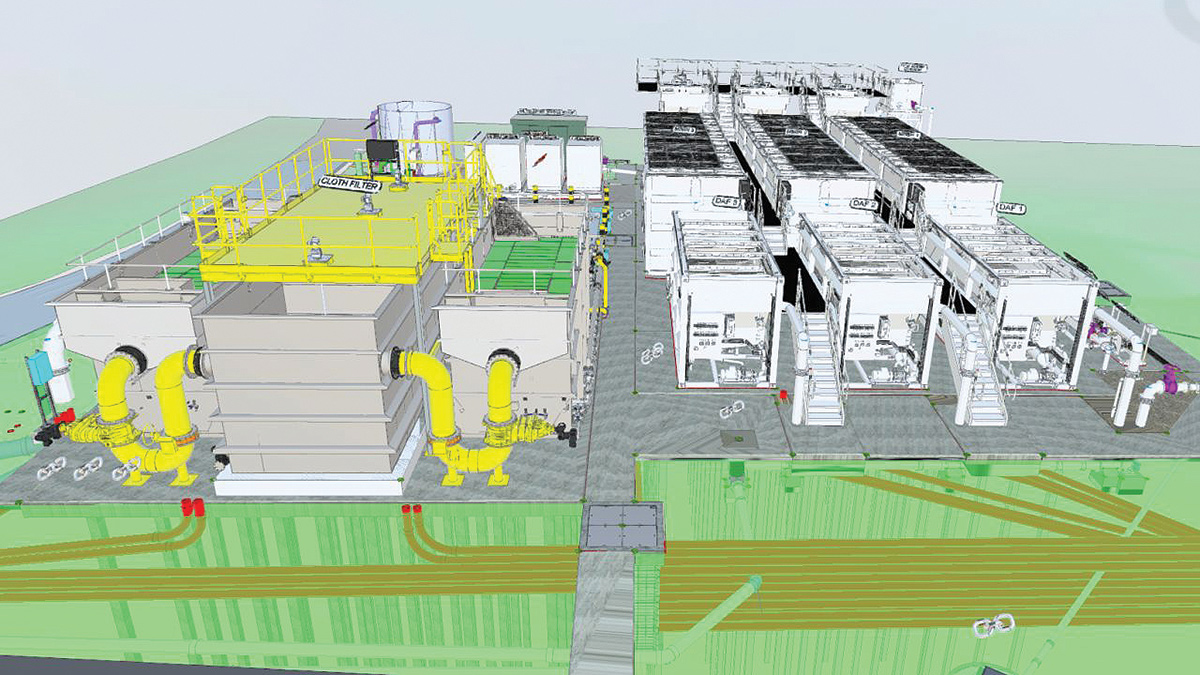

BIM model of works – Courtesy of @one Alliance

Design

Anglian Water tasked the @one Alliance and its supply chain partners to fullfil the scope, and to undertake a complex engineering challenge. Initially, the design centred around a traditional sidestream solution including primary settlement tanks (PSTs), submerged aerated filters (SAFs), and high-rate sedimentation tanks (HSTs). However, it quickly became clear that this approach would not work due to the limited site space, the need for extensive enabling works, and potential delays from planning approvals and environmental assessments; all of which presented major hurdles.

In light of these issues, the project team undertook a high-level review and chose a smarter, modular route forward.

The solution

To manage the increased flow to full treatment and achieve compliance with tighter water quality standards, the @one Alliance team installed a state-of-the-art modular sidestream treatment system designed for performance, resilience, and minimal environmental impact.

Central to this system was the introduction of a new above-ground pumping station, purpose-built to efficiently transfer increased flows through the new treatment process. This strategic addition allowed for greater operational flexibility while helping to future-proof the site for further expansion should it be needed.

Installed lamella clarifiers – Courtesy of @one Alliance

The sidestream process featured three modular technologies which provided a robust, scalable, and energy-efficient treatment solution:

- Lamella clarifiers

Selected for their ability to deliver high-performance settlement within a compact footprint, the lamella clarifiers efficient solid-liquid separation capabilities significantly enhances treatment capacity without requiring major alterations to the existing site layout.

- Moving bed biofilm reactors (MBBR)

In addition to the lamella clarifiers, MBBRs were installed, which use specialist biofilm media to support biological treatment under increased loading. These reactors not only improve the quality of the final effluent but also offer improved reliability and easier operation compared to traditional systems.

- Dissolved air flotation (DAF) units

Completing the system were DAF units which are key to optimising solids removal and enhancing overall process performance.

Off-site fabrication

By prefabricating key system components off-site, the @one Alliance was able to significantly reduce on-site construction time, lower embodied carbon, and minimise disruption to the surrounding environment and community. This approach also reduced the need for complex groundworks, helping the team to stay on programme and adapt quickly to changing site conditions.

MBBR tanks & walkway – Courtesy of @one Alliance

Infrastructure upgrades

Delivering this advanced solution also required major upgrades to both the electrical and civil infrastructure on site. A ground-mounted kiosk was installed to replace the old pole-mounted substation, improving power resilience and safety.

The Press House building on site had previously been condemned due to safety concern but following an extensive refurbishment it was brought back into operational use to house a new, modern low voltage switchboard.

This upgrade has not only made the site safer but has also provided a more efficient and accessible control centre for Anglian Water’s operational teams, improving both maintainability and monitoring.

To support the new assets, an extensive network of underground ducting and cable management systems were installed ensuring seamless connectivity between each element of the treatment process. A robust concrete base slab was constructed to support the weight and vibration of the Siltbuster Ltd sidestream units, as well as associated blowers from AERZEN Machines and de-sludge pumps from NOV.

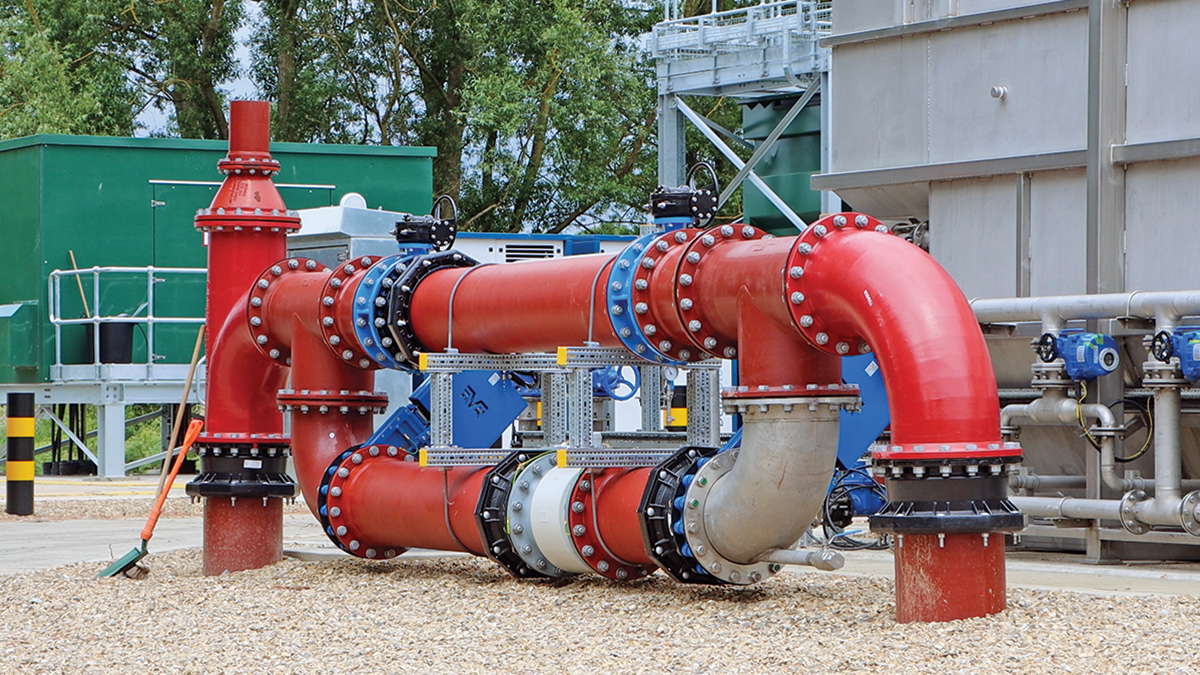

To ensure long-term structural integrity, piling operations were carried out to reinforce the site’s foundations. In addition, new underground pipework and flow distribution chambers were installed, enabling smooth and efficient transfer across the various treatment stages.

Delta blowers from Aerzen Machines – Courtesy of @one Alliance

Dereham WRC: Supply chain – key participants

- Project delivery: @one Alliance

- Principal contractor: Skanska

- Base slab & civil works: Bell Formwork & Civil Engineering Services Ltd

- Overpumping: Selwood

- Mechanical & electrical installation: Glasswell & Last Ltd

- MCC supply & integration: TES Group

- Modular treatment units: Siltbuster Ltd

- Ferric sulphate dosing system: EPS Water

- Access metalwork: Steelway

- Building refurbishment: Claret Civil EngineeringLtd

- Piling works: Roger Bullivant Ltd

- Valves: AVK UK Ltd

- Blowers: AERZEN Machines

- De-sludge pumps: NOV

- Pipework: Saint Gobain PAM UK

- Pipework: Wolseley

- Pipework: SC Pipelines Ltd

- Safe asbestos removal: Oracle Solutions Asbestos Ltd

Impacts & benefits

With the upgraded FFT capacity of 130.8 l/s, Dereham WRC now fully meets regulatory requirements, helping protect local rivers and wildlife from untreated discharges.

The modular design provides flexibility for future growth, enabling additional units to be added quickly and cost-effectively as needed.

The operational benefits are clear. The modular treatment system is easier to access and maintain, streamlining ongoing operations. The MBBRs and DAF units provide high performance while consuming less energy, ensuring long-term efficiency.

MBBR biofilm media: (top left) media ready for loading, (bottom left) crane lift, and (right) media installation – Courtesy of @one Alliance

Significant strides were made to reduce the environmental impact. By reusing the existing Press House, the carbon costs associated with new construction were avoided and off-site prefabrication played a key role in reducing on-site emissions and vehicle movements, contributing to a lower overall environmental footprint. Additionally, refurbishing the Press House eliminated legacy health and safety risks; creating a safer working environment for on-site personnel.

As Dereham continues to grow, the upgraded WRC now provides the necessary capacity for new homes and businesses, all while ensuring water quality remains protected.

Conclusion

Despite the complexity and scale of the works, the project team worked diligently to keep the water recycling centre fully operational throughout construction, and overcame tight lead times and site constraints to deliver a high-performing, future-ready solution.

Through meticulous planning and phased delivery, we successfully integrated the new sidestream system into day-to-day operations, delivering critical upgrades with zero unplanned disruption to service. This seamless transition showcases what’s possible when innovation, collaboration, and smart engineering come together with a clear purpose: to protect the environment and support our growing communities.

Overground pipework – Courtesy of @one Alliance

The Dereham WRC upgrade is a good example of how innovation, sustainability and collaboration can come together to solve complex challenges. By choosing a modular, low-impact solution, a compliant, efficient, and resilient water recycling centre was delivered.

Working together to protect the environment, support local growth, and deliver long-term value for customers, it stands as a blueprint for how Anglian Water and the @one Alliance will tackle similar challenges across the region throughout AMP8.

Valves and overground pipework - Courtesy of @one Alliance