Newcastle WwTW (2025)

Aerial view of Newcastle WwTW - Courtesy of NI Water

Newcastle is a small seaside resort town in County Down, Northern Ireland. It has a population of 8,298 at the 2021 Census. It lies by the Irish Sea at the foot of Slieve Donard, the highest of the Mourne Mountains. Newcastle is known for its sandy beach, forests and mountains. The town lies within the Newry, Mourne and Down District and aims to promote itself as the “activity resort” for Northern Ireland. In recent years, the WwTW has required extensive operator intervention and considerable maintenance costs. The aim of the PC21 Capital Delivery project was to upgrade the existing treatment process at Newcastle WwTW to ensure that the effluent quality complies with the bacterial consent standard set by NIEA for discharge adjacent to the designated bathing water.

Existing treatment works

Inlet flows to the wastewater treatment works (WwTW) are pumped from the Harbour Wastewater Pumping Station (WwPS) and pass through a flow to full treatment (FFT) overflow chamber, with flows greater than Formula A (FA) being screened then spilled via the outfall pipe. Flows between FA and FFT are screened and spilled to the storm storage tanks and flows up to FFT are passed forward for treatment.

The existing Newcastle WwTW – Courtesy of NI Water

Following grit removal and two 6mm screens, flows then pass through ‘contact stabilisation’ activated sludge tanks with final settlement (four duty/one standby treatment streams) before the treated effluent is pumped to the discharge point via ultraviolet (UV) disinfection.

A sludge treatment facility uses drum thickening prior to the sludge being tankered off site, with supernatant returned upstream of the contact stabilisation tanks splitter chamber for treatment; stored storm water is also returned here when incoming flows reduce. Odour control is also provided at the works.

The storm handling facilities and the fifth treatment stream were added in an extension to the works in 2012, along with the replacement of the grit removal plant and screens, the settlement tanks scrapers, the aeration tank blowers, the standby generator, the sludge thickener, and modifications to the existing sludge storage provision, plus an upgrade of the ventilation and odour abatement systems.

In recent years, significant base maintenance works have been carried out at Newcastle WwTW. Major elements of work included the replacement of UV bulbs, quartz sleeves, wiper unit consumables and a full yearly overhaul of the UV process stream.

During the bathing season, the UV plant provides the disinfection required for the E. coli standard. However, the potential exists for high suspended solids carryover from the contact stabilisation process which can impact on the UV plant treatment efficiency. As a result, the UV plant has required considerable maintenance since its installation in 2012 and thus formed part of the recent project upgrade scope.

The initial ‘out-of-season’ storage of the UV equipment in the site’s saline environment resulted in deterioration, especially of the wiper blades, that in turn reduced the operational lifespan of the unit.

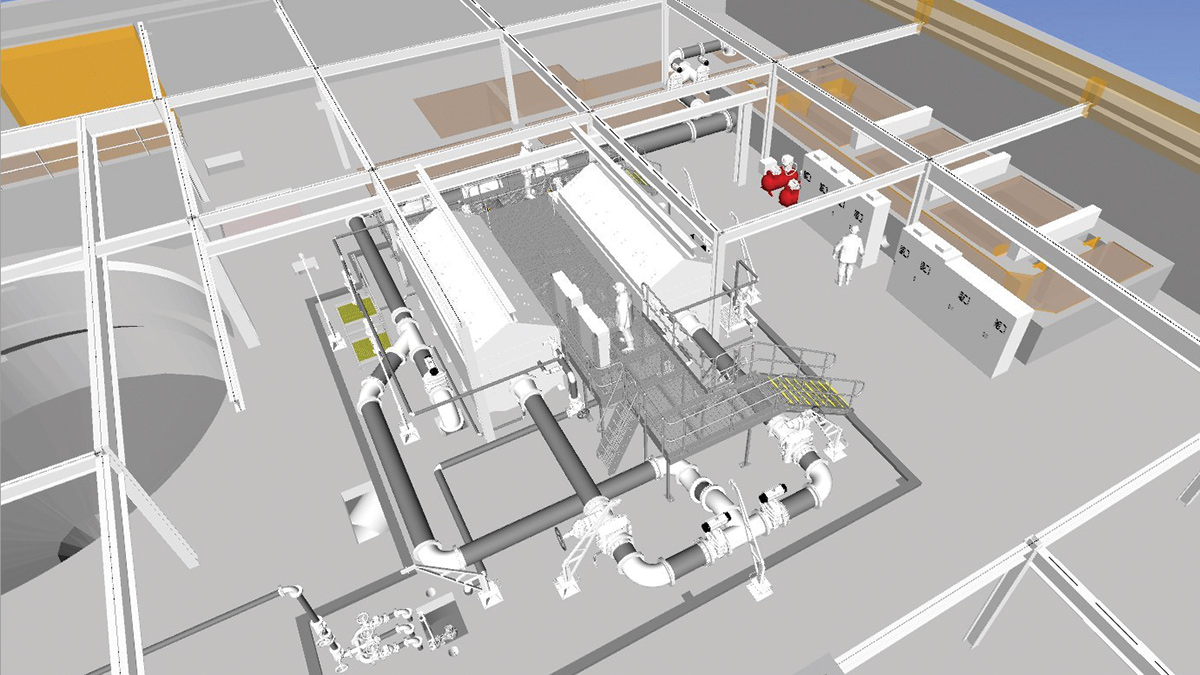

3D model view from the ECI design development stage – Courtesy of Murphy

Early contractor involvement & optioneering

Murphy/Dawson-WAM JV was appointed by NI Water in March 2023 under an Early Contractor Involvement (ECI) contract. The ECI phase allowed Murphy/Dawson-WAM JV to develop options with the project management team from McAdam and NI Water at an early stage.

Input from NI Water Operational staff during the ECI was paramount for the Design Team’s understanding of the problems experienced. This proactive, 3-stage approach, led to enhanced collaboration, value engineering and greater efficiency for the project. The recommended upgrade solution for Newcastle WwTW was as follows:

- Provide additional tertiary treatment to assist UV process (disc filters).

- Replace existing open channel UV system.

- Provision of pipework, valves, access arrangements for the new process streams.

- Automation and control improvements, for enhanced robustness, of the treatment works.

- Testing and commissioning.

After an intensive ECI design/investigative study was completed in August 2023, the Main Contract was awarded in December 2023 to deliver the works in accordance with NI Water’s Scope, comprising:

- Civils/structural and MEICA detailed design of proposed work.

- Procurement of materials, equipment and M&E plant, to align with the bathing season programme constraints.

- Civil construction: Concrete apron, side opening for tertiary disc filter installation and UV channel modifications.

- MEICA installations and commissioning: Tertiary disc filter plant, UV disinfection units, automated valves, pipework and process control.

(left) Lifting of tertiary disc filters to below road level for transferring into existing treatment building and (right) Transferring of tertiary disc filters into existing treatment building via a purpose-built opening in the outer wall – Courtesy of Murphy

Project team delivery

As principal designer/contractor, Murphy’s had overall responsibility to deliver the project on time and within budget. They were also responsible for designing and delivering a full turnkey MEICA, process design and build solution for the new works.

Dawson-WAM provided civil and structural services. Their design, supported by RPS, included the initial enabling and investigatory works carried out at the ECI stage, as well as the detailed design for construction.

The Murphy/Dawson-Wam JV team collaborated closely with NI Water, McAdam (NIW’s project managers) and key suppliers and subcontractors to provide a resilient, efficient, and modern treatment solution. This solution supports future growth within the catchment area and safeguards the environment by meeting stringent discharge consent requirements.

Newcastle WwTW: Supply chain – key participants

- Client project managers: McAdam

- MEICA & process designer/contractor: Murphy Ireland

- Civil contractor: Dawson-WAM Ltd

- Civil, structural & geotechnical design: RPS

- Electrical design: Murphy Ireland

- Tertiary filters package: Huber Technology

- Valves, penstocks & actuators: Flow Technology Services

- Actuators: Rotork

- Pipework: APP Fusion Group

- MCC upgrades: Pronto Automation Systems Ltd

- UV disinfection & return liquors pumps: Xylem Water Solutions

- Lifting equipment: Columbus McKinnon Ltd

- Access platforms: SMP Fabrications Ltd

- Flow & level instrumentation: Park Electrical Systems

Project description & main MEICA scope

Tertiary disc filters: Two RoDisc® 16 disc filter units from Huber Technology were installed, featuring an in-tank design and including all essential ancillary equipment, such as a chemical cleaning skid, backwash pumps, and instrumentation. This setup necessitated a custom portable support frame equipped with castor wheels for the installation and removal of the disc filters, along with access platforms that included davit sockets and lifting arms. Additionally, a permanent lifting system was required for the maintenance of the plant. An emergency eye wash station and an automatic chemical cleaning package were also necessary and turbidity instrumentation was installed to monitor the flows exiting the tertiary filters.

The disc filter specifications are:

- Design flow for each machine: 630m3/hour.

- Polyester filter mesh size: 15µm.

- Maximum inlet solids concentration: 40 mg/l.

Huber Technology disc filters installed at Newcastle WwTW – Courtesy of Murphy

Open channel UV system: Specially engineered for use in wastewater from clarification plant processes the TAK 55 UV system from Xylem Water Solutions can be fine-tuned to match water quality, operating conditions and discharge requirements. The system is equipped with a pneumatic-driven automatic wiping mechanism. It includes air compressors, pipework, and instrument skids. Additionally, there is a fixed weir penstock at the UV outlet, along with chequer plate covers and flooring for the UV channel, as well as an upgrade for the handrail. Lifting equipment is provided for the maintenance of UV modules. The project also involves the decommissioning of the existing plant and instrumentation.

UV system specification are:

- Two channels with three banks per channel and two modules per bank.

- 96 low pressure UV lamps.

- 285W per lamp.

- Design UV transmittance: Minimum 45%.

Mechanical installation: The scope required a full suite of mechanical installation, including ductile iron, stainless steel and galvanised mild steel pipework, support brackets, strainers and Profibus-enabled actuated valves.

UV disinfection streams, local control panels and flooring upgrade – Courtesy of Murphy

Return liquor pumps, pipework & washwater: The scope of works included:

- Return liquors ductile iron pipework, isolation valves, non-return valves, brackets and fittings.

- Return liquors pumps and ancillary installation kit.

- Return liquors flowmeter and ancillaries.

- Service water provisions.

- Washwater pipework, solenoid valves, flow switches and lagging.

- Impeller upgrade on existing interstage pumps to ensure pumps suitably operate at the increased total head condition created by the new disc filters unit operations.

Electrical installation/panels: The electrical scope included upgrading the primary MCC starter sections and supplies of the current site to local control panels and local isolators. The proprietary panels (UV and tertiary) were networked to the existing PLC, and local isolators, e-stops and stands were also provided. The PLCs were interfaced with the new plant and the existing control functionality was upgraded. The electrical installation included plant wiring and containment for all new cable pathways.

Level testing, commissioning & acceptance period: This included functional tests, telemetry, SCADA interface, and demonstrations for new electrical installations. Training was for NI Water Operations personnel and extensive process proving period.

Disc filters, backwash pumps and return liquors pumping station – Courtesy of Murphy

Main challenges during design/construction

The limited headroom in the existing Newcastle WwTW plant room presented a hydraulic constraint, given that the tertiary filters had to be installed between two existing fixed-point levels. Murphy selected the Huber Technology plant as the preferred solution due to machine overall height, general layout for access and the inclusion of an internal bypass. Alternatives were considered, however access and maintenance concerns made them unviable.

During assembly, sequencing was key to allow for an efficient installation. Murphy designed a bespoke removable set of castor wheels as part of the Huber Technology structural base frame to facilitate manoeuvring the units into their final position, and lowered to bunker level via crane, transferred through the purpose-built side wall opening. With access a major constraint, 600/700mm pipework was then installed into position, fixing the levels of the Huber Technology filters between upstream pumps and downstream UV channel. Platforms were then installed in portable sections above the pipework, which provided access for the electrical containment and cable installations, local to the filters and other M&E plant, including pumps and actuators.

Successes

During ECI, Murphy made the decision to develop a 3D model for the works upgrade and engage the benefits of Murphy’s in-house BIM capabilities. The 3D model was key to the success of the project as it enabled the design team to simulate the installation of the disc filters, from road level to the bunker level, and aided the manoeuvrability of lift for entry into the building. This avoided the need to temporarily divert a below-ground storm pipe to create additional hardstanding at the new structural opening.

Tertiary filters inlet control valves – Courtesy of Murphy

The benefits of the 3D model were evident during the mechanical design layout, whereby large bore pipework, valves and platforms were designed for locating between and surrounding the new filters, whilst ensuring headroom for personnel access and also ensuring the bypass pipework was able to be supported at FFL underneath.

Bespoke overhead lifting beams and chain blocks were designed into the layout to facilitate removal of geared motors and equipment over 20kg in weight, that may require removal for maintenance in the future.

Clearance checks were carried out for same during the ECI model development to ensure all lifting provisions were functional.

The new process streams have been in operation since the end of April 2025 and are treating effluent to a high quality standard, protecting the Newcastle bathing waters for current and future bathing seasons. This latest NI Water investment will also contribute to supporting future population growth in the area.

Newcastle WwTW project team - Courtesy of NI Water