Scunthorpe WFD Programme (2025)

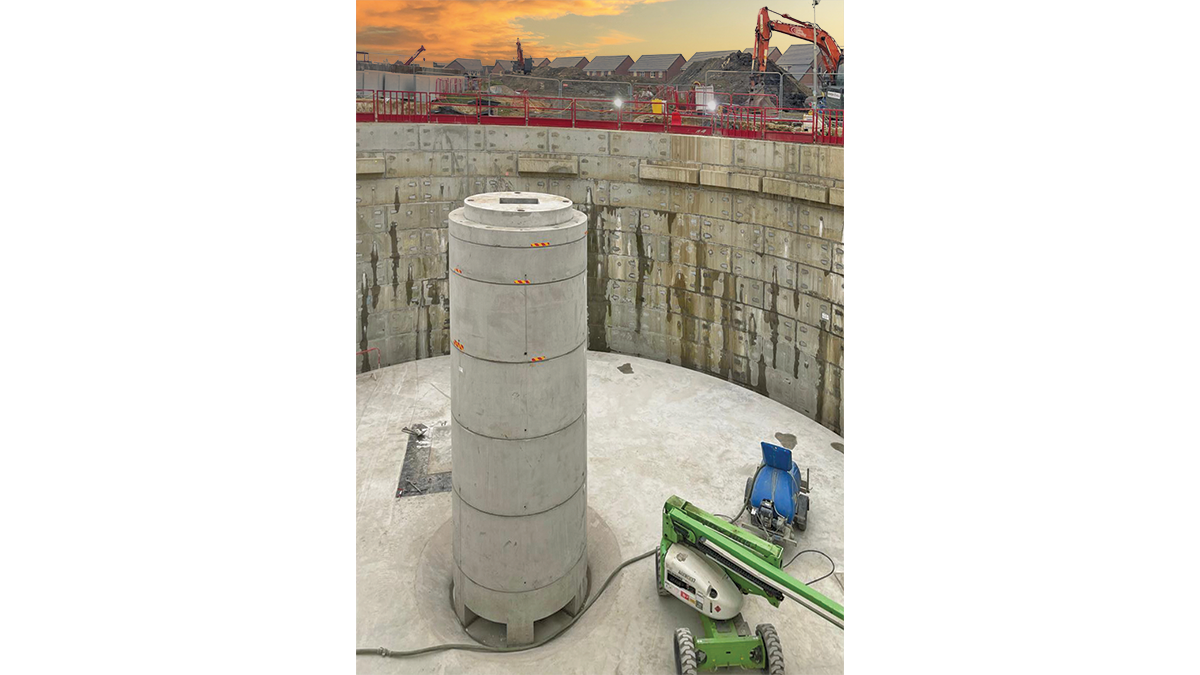

Inside the stormwater storage tank - Courtesy of Active Tunnelling Ltd

The Scunthorpe Wastewater Flooding Defence (WFD) Programme aims to reduce the number of spills from key combined sewer overflows (CSOs) during periods of heavy rainfall. For the South Grange, Brigg Road and Grange Lane North CSOs, a sustainable stormwater management solution was required to retain excess water and reduce intermittent storm discharges at all three CSOs, improving the biological oxygen demand (BOD) concentration in Bottesford Beck. As part of Severn Trent’s commitment to environmental compliance and improving water quality, an effective and efficient delivery was critical.

Challenges

Tasked with reducing storm discharges to local watercourses, Avove developed a robust delivery model that ensured a seamless process to achieve key project objectives, whilst minimising disruption to residents. To overcome the project challenges, required blending collaboration and innovation in a way that unlocked measurable long-term benefits for Severn Trent and these included:

- Location adjustments: At Brigg Road, the proposed shaft tank location was adjacent to an old building with limited space and difficult access. Following a thorough site review, an alternative location was agreed, delivering significant Health, Safety, Environment and Quality (HSEQ) benefits.

- Confined space: The confined nature of the site at Grange Lane North presented challenges for construction and operations. These constraints were resolved through the utilisation of an empty building, which was repurposed to provide temporary accommodation and a laydown area for materials.

- Risk Management: A comprehensive risk register was created to outline potential risks and mitigation strategies. For example, infrastructure risks when crossing a gas pipeline were identified, and through careful planning, were addressed by the Avove project delivery team.

All risk reduction meetings and planning phases were underpinned by collaboration, as the combined expertise of the project team played an important role in strategising an effective response to ensure that the project did not deviate from the scope.

Work area – Courtesy of Active Tunnelling Ltd

The approach

Collaborative planning and consistent communication was key to a successful delivery across all three sites. Avove prioritised early engagement with suppliers, particularly for precast items, to secure timely deliveries and reduce the likelihood of budget overruns caused by unforeseen delays. This detailed approach delivered important long-term benefits and facilitated open communication and mutual trust throughout the project’s lifecycle.

With overarching principles of communication and collaboration in place, the technical prowess of the project teams was enhanced. With confidence that key materials would be delivered on time, operatives could begin work, using their expertise to ensure an innovative and sustainable completion. This approach entailed:

- Early contractor involvement (ECI): Collaborative input from all stakeholders during the preliminary stages helped to develop innovative solutions and reduce later risks. This was particularly important in terms of design planning, as the Brigg Road shaft tank was relocated following an inspection.

- Multidisciplinary collaboration: Spanning civil, mechanical, electrical, geotechnical, structural and environmental engineering, multidisciplinary collaboration was facilitated through close engagement with sub-consultants. As such, all designs met the programme’s requirements, maintaining continuous alignment with Severn Trent’s team.

- Coordinated design process: This process enhanced buildability and reduced environmental impacts through a balance of cost, quality and carbon considerations. From minimising energy usage to cutting waste, the project achieved a significant reduction in emissions by removing the need for additional pumps.

- Effective programme management: Although it was a complex, multi-phase project, the structured approach comprised of regular project meetings to review progress against detailed schedules, ensuring activities were synchronised.

To complete this approach, Avove supported the communication process between the client and local stakeholders, with the project team assisting with land and planning matters. This involved the distribution of letters to residents, the negotiation of land access with owners and occupiers and following up on any concerns during the execution of works.

Construction continued throughout the night – Courtesy of Active Tunnelling Ltd

Scunthorpe WFD Programme: Supply Chain – key participants

- Client: Severn Trent

- Delivery contractor/main contractor: Avove

- Land & planning services: Dalcour MacLaren

- Shaft construction: Active Tunnelling Ltd

- Mechanical & electrical works: PJT Pumping Services Ltd

- VacFlush™ system: CSO Group Ltd

- Drainage works: VP Groundforce Shorco

- Core drilling: Matte Black Surfacing

- Plant: Trenchless Plant Ltd

- Concreting finishing: Overhall Contractors Ltd

- Concreting finishing: Groundtech (UK) Ltd

- Tarmac: Cemex

The solution

The Scunthorpe WFD project aligned with Severn Trent’s organisational goals of sustainability, biodiversity and environmental responsibility. By constructing large, off-line shaft tanks to manage stormwater flows from existing CSOs, the BOD concentration in Bottesford Beck was improved.

Effective Design & Delivery: Through effective design and delivery, the South Grange shaft tank (25m x 12m deep), Brigg Road shaft tank (12.5m x 14m deep) and Grange Lane North shaft tank (20m x 15m deep) were all successfully installed along with supporting infrastructure.

Technical Expertise: The tanks were connected to the existing combined sewerage system through 1,050mm diameter inlet pipes. A twin-pumped return system was activated by telemetry from Yaddlethorpe Sewage Treatment Works, ensuring stormwater was returned, once permitted. Additionally, MCC kiosks, flushing systems, vent stacks, rising mains and sewers were all introduced as part of the comprehensive works.

Sustainable Technology: Sustainability was embedded into every stage of the project. For the South Grange scheme and the Grange Lane North scheme, the initially requested pumped washing facility was replaced with the patented VacFlush™ system from CSO Group Ltd. Not only did this reduce maintenance and operational costs, but it lowered power requirements and cut carbon emissions at two of the three shafts.

VacFlush™ system installation – Courtesy of Active Tunnelling Ltd

The VacFlush™ system is an automated vacuum flushing system designed to clean storm tanks, holding tanks, and sewer networks without requiring manual entry into the tank. It utilises a vacuum pump to draw wastewater into a flush chamber, which is then rapidly released by a diaphragm valve, creating a powerful surge that cleans the tank floor and removes sludge. Key benefits include safe operation without man entry, efficient cleaning of large tanks, minimal maintenance, and automatic operation, often using the stormwater itself for flushing

Landscape Preservation: Through effective programme management and the utilisation of design and construction expertise, we avoided tunnelling under the A1029 highway and crossing strategic assets, preserving mature trees in the process.

Budget management: Integral to the project’s success and the feasibility of the solution was effective cost management. We maintained robust budget and cost control throughout the programme of works by implementing comprehensive Cost Value Reconciliation (CVR) reports, which were updated monthly to reflect expenditure and forecast completion costs.

It was through a careful combination of sustainability, innovation and collaboration that a highly effective solution was identified and implemented, helping us achieve a high degree of client satisfaction.

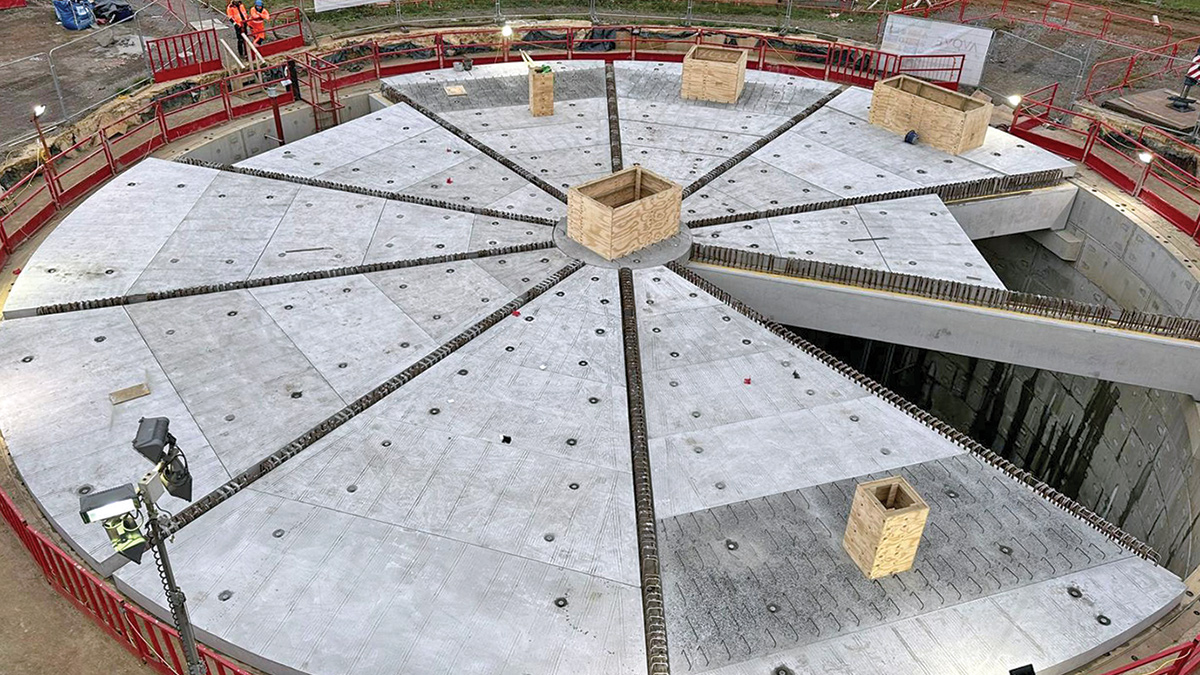

(left) Roof beams in place, and (right) start of the roof panel installation – Courtesy of Active Tunnelling Ltd

Benefits

The Scunthorpe WFD project delivered a range of long-term benefits, many of which were wide reaching, both in terms of compliance and structural integrity. Beneficial to both the client and their customers, the project achieved:

- Long-term compliance: The solution improved the BOD concentration in Bottesford Beck, meeting the Environment Agency’s ‘Good’ standard.

- Environmental enhancements: The project supported the improvement of nearby rivers, reducing the risk of pollution incidents whilst contributing to Severn Trent’s broader goal of improved watercourse health.

- Enhanced innovation: Collaborative working between Avove, Severn Trent and other key partners allowed for greater innovation and the successful delivery of robust off-site holding tanks.

- Future-proof design: The solution’s design ensures long-term compliance and operational effectiveness for years to come.

- Operational efficiency: Our team demonstrated technical excellence throughout the project’s delivery, ensuring the new solution was fit for purpose and operationally efficient.

- Time and cost-effectiveness: A proactive and highly collaborative approach streamlined the entire delivery, saving time and reducing costs.

- Improved safety: Best-in-class construction methods and thorough planning processes ensured the works were completed safely.

Installation of the roof slabs – Courtesy of Active Tunnelling Ltd

The results

Working diligently to achieve an expedited programme across all three sites, hard work and commitment ensured a seamless delivery, well within time and budget requirements. With regulatory deadlines to meet, it was imperative that a highly collaborative approach was adopted, with open communication and the implementation of a clear structure guiding the project.

The new off-line tanks effectively retain stormwater, reducing pressure from the existing network and improving water quality much to the benefit of the environment, Severn Trent and their customers.

Completed roof - Courtesy of Active Tunnelling Ltd