Station Road (Queensbury) Sewer Flooding (2018)

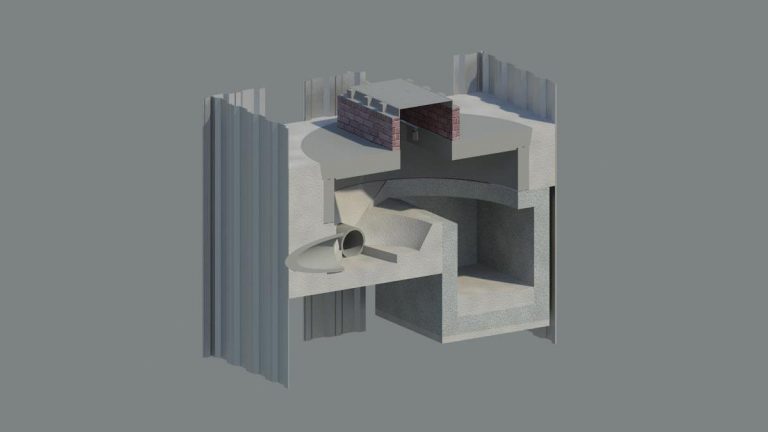

Construction of Station Road, Queensbury detention tank - Courtesy of VJ Donegan & Co Ltd

Mott MacDonald Bentley (MMB) carried out an investigation for Yorkshire Water Services into the flooding of five properties in Queensbury in West Yorkshire during periods of heavy rainfall. The investigation concluded that the combined sewer system in the residential cul-de-sac had insufficient capacity during a 1 in 10-year storm return event, resulting in overland flow and internal flooding to properties. The Early Contractor Involvement (ECI) report produced by MMB proposed a solution to construct a high-level overflow at the point of incapacity and a relief sewer to a 1400m3 off-line detention tank, with pumped return to the existing system. Under the AMP6 Framework Agreement, MMB was appointed as design and build contractor for the delivery of the £1.8m scheme. Delivery of the proposed solution within the confines of the residential cul-de-sac and the steeply sloping site of the detention tank presented challenges for the project team, but culminated in successful delivery of the scheme, resulting in 1 in 30-year flood resilience for the properties.

Existing system

A hydraulic model was used to assess the flooding mechanism in the existing sewer system which resulted in the flooding of five properties in April Gardens. The hydraulic incapacity was at the point where two sewers converged at a manhole chamber in the road, a 375mm diameter sewer from the east and a 300mm diameter sewer from the west. The 375mm diameter outgoing sewer from this manhole caused local incapacity, which was worsened by reverse flow from additional restrictions in the network further downstream.

Cul-de-sac street suffering from sewer flooding from manhole chamber located in the road on the uphill side – Courtesy of MMB

Solution development

In developing a solution, a number of different options were investigated for feasibility. Incapacity issues in the wider network meant that upsizing pipes or diverting flows locally was ruled out. A larger scale diversion was considered which required the diversion of flows from the west of the catchment, providing capacity in the network downstream of April Gardens. Construction of this option would have required closure of Brighouse Road, one of the main roads in Queensbury, and with no suitable diversion route, this option was also ruled out.

Surface water separation of the upstream system was modelled with an aim to promote a SuDS scheme, but this had minimal effect on the flooding at April Gardens. The extent of the surface water separation required to address the reverse flow from the downstream system was too widespread to consider as a potential solution.

Mitigation measures were considered including sealing manholes and the installation of flood gates, but this would have meant the flooding problem would only have been moved elsewhere or would have continued if the measures were not sufficiently robust due to reliance on manual operation, so these too were ruled out.

The use of online storage was investigated but the location and topography of the area meant that there was not the available space to store and gravitate flow back to the sewer network. There was, however, space in steeply sloping fields downhill of the properties. This meant that a storage solution would require a pumped return to the existing system.

Therefore, an offline storage solution was arrived at and modelled with the storage located in the field closest to the properties, minimising the length of connecting pipework required. The solution included a high-level overflow at the point of incapacity within April Gardens and a 525mm diameter overflow sewer to a detention tank with a pumped return to the existing system. The detention tank was sized at 1400m3 to store flows up to a 1 in 30-year storm event.

Design model of the overflow chamber – Courtesy of MMB

Solution development

The point of incapacity at the existing manhole within April Gardens, a single carriageway cul-de-sac, meant that the design and construction of an overflow chamber was challenging. The highly sensitive hydraulics of the existing system meant that a weir of minimum length 2.1m was required to relieve surcharge at the point of restriction and provide sufficient freeboard levels for the manholes upstream. The overflow system needed to convey a flow of 500 l/s for the design criteria of a 1 in 30-year storm event. The existing brick manhole at the restriction in the existing system was not of sufficient diameter or depth to accommodate the overflow weir and relief sewer.

Utility mapping was carried out early in design to locate existing services within the highway, including a telecoms cable over the cover slab of the existing manhole chamber. The narrow road and close proximity of private properties also meant the working area was very restricted, further constraining the design.

Forward planning by the design team meant that a temporary diversion of the telecoms cable could be implemented prior to excavation works commencing, removing the need for difficult excavation in close proximity to a service and potential for a service strike. This also improved construction access to the excavation which would otherwise have had a cable spanning it for the duration of construction and assisted in keeping the scheme on programme for beneficial completion by Christmas 2017.

Precast overflow chamber unit installed adjacent to existing manhole – Courtesy of MMB

The project team worked collaboratively to develop a solution within the constrained site, which also allowed the existing chamber to remain live throughout construction. By keeping the sewer live, this avoided the use of over-pumping, which would have caused additional disruption to residents. The solution was to construct an overflow chamber from a combination of precast concrete and in situ elements; utilising the existing manhole base.

The 3D model incorporating existing service information proved invaluable in designing both the temporary shoring and permanent works. Sheet-piled excavations surrounding the existing manhole chamber and adjacent precast chamber were installed. The deeper precast chamber was installed and backfilled, prior to demolition of the existing manhole chamber. The base of the chamber was retained and a standard 2.4m diameter manhole ring and cover slab were installed to complete the chamber.

Residents were unable to gain vehicular access to their properties during the construction of this section of works. Stakeholder engagement through intensive consultation, provision of alternative parking, and assistance to residents to minimise disruption as far as possible were all key in successful delivery.

Using the hybrid precast/in situ solution, the construction duration was kept to an absolute minimum and the existing chamber kept live, minimising the impact on the residents as much as possible.

Caisson shaft installation of detention tank – Courtesy of VJ Donegan Civil Engineering Ltd

Relief sewer

The 95m long 525mm diameter concrete sewer from the overflow chamber to the detention tank was constructed within the highway. The thrust block for a water main was encountered preventing the construction of a manhole in the original proposed location without substantial temporary works. Design alterations allowed the manhole to be relocated and the construction to continue without significant delays.

A penstock was required in the manhole chamber upstream of the detention tank to provide isolation. The design specified a precast concrete, off-site fabricated unit with the penstock ready installed to reduce the amount of work required in deep excavations and reduce the construction duration as much as possible.

Station Road (Queensbury) Sewer Flooding: Table of designers, contractors and suppliers

- Design investigation: Mott MacDonald Bentley

- D&B contractor: Mott MacDonald Bentley

- Caisson shaft D&B sub-contractor: VJ Donegan Civil Engineering Ltd

- Mechanical sub-contractor: VJ Donegan Civil Engineering Ltd

- Electrical sub-contractor: Circle Control & Design Systems

- Process control system: Saftronics

- Storm return pumps: Grundfos Pumps

- Ejectawash Pump: Xylem Water Solutions UK

- Precast overflow unit: Wolfenden Concrete

- Precast isolation chamber: Marshalls CPM

Storm storage

The site of the 1400m3 detention tank, provided by a 12.5m diameter, 14m deep shaft, in a steeply sloping field presented different challenges. The working area required for construction, within the restricted land envelope agreed with the landowner, was a challenge which benefited from the detailed 3D model developed for the scheme. Early engagement with the subcontractor enabled temporary works to be considered along with the permanent works to provide a sufficient working area to safely construct the storage shaft.

Excavation of material within caisson installation – Courtesy of VJ Donegan Civil Engineering Ltd

The solution to the steeply sloping site was to construct a 40m long, 6m high gabion basket retaining wall to allow the lower corner of the field to be raised to provide a large enough level area to site the detention tank. This aligned with the landowners’ requirements in terms of reducing the land-take of the scheme.

The 3D model allowed this solution to be visualised by both the design team, construction team and the client prior to works commencing.

Specialist subcontractor VJ Donegan Civil Engineering Ltd was appointed and confirmed the construction methodology prior to developing construction drawings for the civil engineering design of the detention tank. A jacked caisson shaft construction was selected due to the sandy clay ground conditions above a weak laminated sandstone.

MMB constructed the access road into site and stone working platform in the area surrounding the shaft for construction plant. The working platform was designed to be adequate for the three different cranes required during construction of the shaft, with the addition of outrigger pads for the 160-tonne mobile crane, required for installation of the precast concrete roof slabs.

VJ Donegan Civil Engineering Ltd then commenced with the shaft construction, installing a 1m thick concrete collar within the working platform from which to jack the precast concrete caisson shaft into place. A cutting ring on the base of the first ring of segments aided the driving of the caisson with excavation within the shaft footprint removing material to form the internal void.

At a depth of about 8m, the shaft installation encountered a laminar rock stratum to one side of the caisson and water ingress began to occur. The water was managed by pumping out from temporary sumps within the shaft excavation. Due to the close proximity to neighbouring properties, the pump was only operational during working hours.

Roof slab installation – Courtesy of VJ Donegan Civil Engineering Ltd

Following completion of the caisson installation, VJ Donegan Civil Engineering Ltd constructed the base slab with a 5m diameter, 1m deep sump for installation of duty/standby return pumps and a mixer pump to prevent sedimentation and septicity from the combined sewage. The shaft internal pipework was installed, followed by the roof slab which was made up of 11 (No.) precast concrete units with a maximum weight of 29 tonnes.

MMB installed the remaining pipework and ancillaries external to the shaft. The detention tank was reinstated with 0.5m of backfill above the cover slab to allow grass seeding and minimise the impact of the final installation.

Maintenance focus

The 3D model added significant value in the access, lifting and maintenance review with the end-user, and automatically updated all the drawings with any changes throughout the design process. Utilising the model to carry out cut and fill calculations enabled the team to reduce the environmental impact by maximising the volume of material reused on site for final re-profiling.

The landowners’ requirement to reduce the hard surfaces as much as possible was a challenge for the design team to develop innovative solutions, with operational health and safety at the forefront. The ventilation design for the shaft, all below ground level and including air filtration to reduce the possibility of odour, incorporated lifting points and reduced chamber depth to a minimum. The below ground valve chamber was also designed to minimise depth with removable covers across the whole chamber, improving the health and safety for future operability.

Final site landscaping with operational access – Courtesy of MMB

Conclusion

Beneficial completion of the scheme was achieved in December 2017 resulting in 1 in 30-year flood resilience for the properties in April Gardens. Site finishing, which included permanent access construction and landscaping, was completed in April 2018.

A collaborative approach has resulted in the installation of important sewer flooding alleviation infrastructure, constructed within a challenging site, with minimal final visual impact.