Yorkshire Water P Schemes Portfolio (2024)

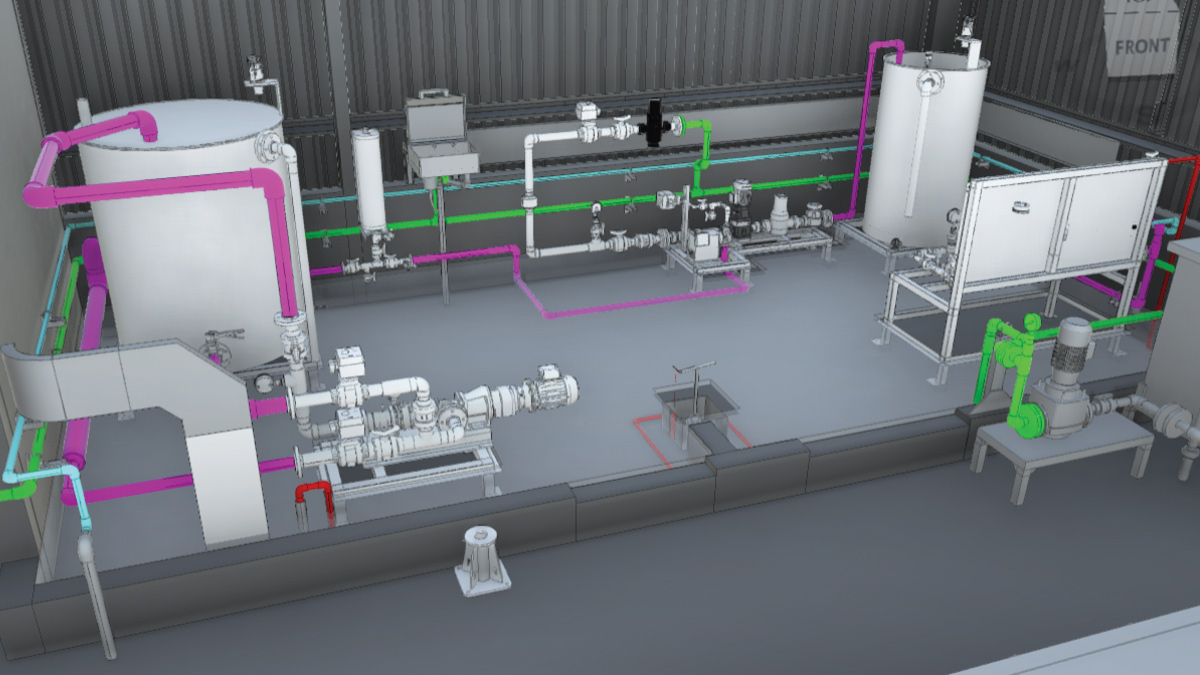

Thorne STW ferric sulphate dosing installation - Courtesy of Glanua UK

In response to stricter Environment Agency permits for phosphorus removal, the water industry has quadrupled the number of phosphorus reduction schemes since AMP5. This surge in efforts is widely regarded as one of the most significant challenges the industry has ever faced. The Water Industry National Environment Programme (WINEP) comprises a series of mandatory actions that water companies in England must implement. These actions aim to enhance the environment and ensure compliance with relevant environmental legislation. The consent date for these measures is 22 December 2024. Glanua Group was appointed to deliver four P removal schemes to help Yorkshire Water meet the requirements at Thorne, Aldwarke, Lundwood and Castleford STWs.

Supply chain selection

Due to the scheduling and repetition of work being undertaken within the four-project portfolio, there was a strategic approach to the appointment of specific sub-contractors to maximise programme benefits and acceleration across the projects.

The primary area that was focused upon was the supply of chemical dosing kiosks with a DfMA approach and the mechanical and electrical installation services.

Thorne STW, Doncaster: Contract value: circa £1.7m

The Thorne STW scheme has a quality driver to reduce phosphorus concentrations in the final effluent to 2.0 mg/l without exceeding iron concentrations of 4 mg/l.

3D render of Thorne STW – Courtesy of Glanua Group

The new works has been carried out in the north-east corner of the site, adjacent to the sludge balancing tank. An existing concrete spur off the access road will be broken out and replaced by a new RC concrete tanker delivery bay with ferric dosing kiosk slab adjacent. A standard 7.5m3 ferric sulphate storage tank and dosing kiosk will be delivered and installed in a single DfMA off-site fabricated SR4 rated kiosk (due to site security classification).

The new ferric sulphate dosing unit will run automatically, and the operator will only be required to ensure that there is a constant supply of chemicals.

A new liquid polymer plant will be installed to replace the existing powder polymer system which feeds the existing gravity belt thickener. To facilitate the replacement a temporary containerised rig was installed and commissioned prior to the removal of the existing plant which removed the existing H&S risk associated with powdered polymer.

The scope also included a full clean up of the existing polymer plant to help facilitate the safe installation and construction works.

Thorne STW: Supply chain – key participants

- Principal designer & contractor: Glanua Group

- Outline design: Stantec UK

- Civils design: AtkinsRéalis

- Polymer dosing: Richard Alan Engineering

- Ferric dosing kiosk: NPS Engineering Group

- Systems integrators: Saftronics Ltd

- Mechanical installation: Staptina Limited

- Electrical installation: PLR Building Services Ltd

- Civil works: M Cooper Civils

- Safety showers: Aqua Safety Showers International Ltd

Aldwarke STW, Rotherham: Contract value: circa £2.5m

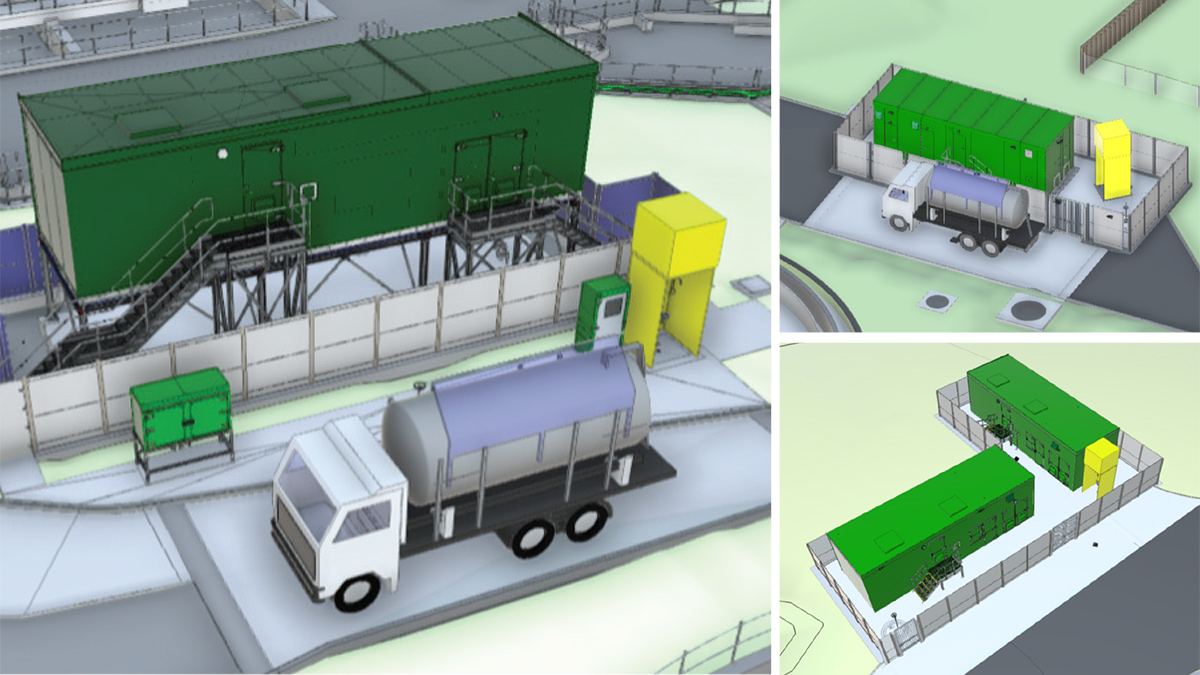

The Aldwarke STW P scheme project has a quality driver to reduce phosphorus concentrations in the final effluent to 0.7 mg/l without exceeding iron concentrations of 4 mg/l (2.5 mg/l Al).

Aldwarke STW ferric kiosk delivery and installation – Courtesy of Glanua Group

The proposed solution is to chemically remove the phosphorus with a primary and secondary ferric sulphate dose upstream of the primary settlement tanks and upstream of FSTs 1-4 respectively.

A new standard ferric dosing kiosk was provided with two dosing pumps and two 10m3 storage tanks complete with a remote fill point panel and remote wash system installed as a single DfMA off-site fabricated kiosk. This feeds two duty/standby POAs at the inlet works facilitated by a newly installed air mixing system as well as two duty/standby POAs at the RAS distribution chamber.

The project also included the decommissioning, removal and installation of like for like PST desludge ram pumps and pipework. During the removal of the existing ram pumps we had to run both the existing and the new pumpsets in order to maintain the resilience within the process. This was enabled by sequencing the pumps and pipework and inserting temporary pipework in order to run both systems.

The FST A & B scum removal boxes were also replaced as well as isolation penstock installation. The existing scum pump was replaced and new MLSS probes were installed on the ASP outlet channels.

Aldwarke STW: Supply chain – key participants

- Principal designer & contractor: Glanua Group

- Outline design: Stantec UK

- Civils design: Eastwood Consulting Engineers

- Ferric dosing kiosk: NPS Engineering Group

- Systems integrators: Lintott Control Systems Ltd

- Mechanical installation: Alpha Plus Ltd

- Electrical installation: PLR Building Services Ltd

- Civil works: Rack Construction

- Safety showers: Aqua Safety Showers International Ltd

Lundwood STW, Barnsley: Contract Value: circa £2m

At Lundwood STW the quality driver is to reduce phosphorus concentrations in the final effluent to 2.0 mg/l without exceeding iron concentrations of 4.0 mg/l.

The solution was to convert the existing secondary treatment activated sludge plant (ASP) to a RAS anoxic configuration. This process will change the existing ASP into an enhanced biological phosphorus removal (EBPR) plant. To limit recycling of phosphorus from the dewatering process back into the EBPR plant, the project will provide ferric sulphate for P removal and caustic soda dosing to the settled sewage to mitigate against the impact of ferric sulphate dosing on the final effluent alkalinity.

Lundwood STW sodium hydroxide kiosk delivery – Courtesy of Glanua Group

Standard 7.5m3 ferric sulphate and sodium hydroxide (caustic) storage tanks and dosing kiosks were to be delivered and installed in a single DfMA off-site fabricated SR4 rated kiosk (due to site security classification). Both chemicals are pumped to their designated POAs and dosed into the PST distribution channel via a bespoke designed V-notch brackets positioned above the top water level of the channel, with the mixing in the channel facilitated by air-mixing provided by newly installed blowers.

The project benefited from carbon savings and construction efficiencies by reviewing the original proposed site location and relocating it to an area which eliminated the demolition of existing assets.

Lundwood STW: Supply chain – key participants

- Principal designer & contractor: Glanua Group

- Outline design: Stantec UK

- Civils design: Eastwood Consulting Engineers

- Ferric dosing kiosk: NPS Engineering Group

- Sodium hydroxide dosing kiosk: NPS Engineering Group

- Systems integrators: Lintott Control Systems Ltd

- Mechanical installation: Alpha Plus Ltd

- Electrical installation: PLR Building Services Ltd

- Civil works: Indepth Civil Engineering

- Safety showers: Aqua Safety Showers International Ltd

Castleford STW: Contract value: circa £900k

The driver at Castleford is to reduce phosphorous concentrations in the final effluent to 2.0 mg/l without exceeding iron concentrations of 4.0 mg/l.

The proposed solution is to chemically remove the phosphorus by dosing ferric sulphate dose upstream of the final settlement tanks.

The primary ferric sulphate dosing system includes constructing foundations and support structures, installing a 7.5m3 storage tank with duty/standby dosing pumps, and integrating with the existing SCADA and telemetry systems. Civil works required modifications to access pathways and safety installations. Electrical installation works ensured the new plant was fully integrated into the existing works control systems.

The POAs dosed into a splitter box upstream of the final settlement tanks which ensured even distribution of ferric sulphate within the FST distribution chamber.

Castleford STW: Supply chain – key participants

- Principal designer & contractor: Glanua Group

- Outline design: Stantec UK

- Civils design: Eastwood Consulting Engineers

- Ferric dosing kiosk: NPS Engineering Group

- Systems integrators: Lintott Control Systems Ltd

- Mechanical installation: Alpha Plus Ltd

- Electrical installation: PLR Building Services Ltd

- Civil works: Indepth Civil Engineering

- Safety showers: Aqua Safety Showers International Ltd

Google Maps images of the sites: (top left) Thorne STW, (top right) Aldwarke STW, (bottom left) Lundwood STW, and (bottom right) Castleford STW

Design

In order to best meet the needs of the four sites, the design team needed to develop the most efficient and effective solutions for each individual site and application. A collaborative multidisciplinary approach was taken to produce each solution whilst looking for the efficiencies in the standard elements of the portfolio.

The team engaged with Yorkshire Water in weekly collaborative planning meetings to review design; technical challenges and construction programme together with reviewing project Risk & Value (R&V). By adopting this collaborative approach, we achieved design and delivery consistency while utilising standard solutions delivered by a design team comprising of civil, mechanical, electrical, and process engineers.

Construction progress

At the time of writing (July 2024) the projects are progressing well:

Thorne STW: As the first project in the portfolio and therefore the most advanced, Thorne STW has progressed through to commissioning and the Glanua Group team are preparing to bring the plant online.

Aldwarke STW: Significant progress has been made with the completion of the civil works and installation of the ferric dosing kiosk. The delivery team have now moved on to completing the mechanical and electrical installation. This has included the potable water connections, installation of the secondary dosing lines to kiosk dosing rigs. The team has also installed three VSDs to provide a more flexible control of the replaced ram pumps and the blowers have been installed to facilitate air mixing at the point of application.

Aldwarke STW ferric sulphate dosing installation – Courtesy of Glanua Group

Lundwood STW: The civil works are complete and kiosks have been installed on site. We we have also progressed with the mechanical and electrical installation works including the installation of the point of application units as well as air mixing pipework. The electrical installation has progressed and cables are being pulled to allow for the second phase of installation prior to commencement of commissioning.

Castleford STW: The civil works are progressing in line with the programme and this includes the demolition of the roadway prior to piling and kiosk base construction, as well as the integration of the drainage and commencement of roadway reinstatement to form the chemical delivery bunded area.

Digital delivery

The primary Common Data Environment (CDE) and information delivery platform used programme is Autodesk’s BIM360 software. Utilising this, Glanua Group has been able to control the flow and dispersal of information throughout the project and delivery teams, enabling the information management workflow process and review to align with the ISO 9001 Quality Management Process.

The information management platform allows us to control how and when the various projects teams see and receive information ensuring the right information is delivered in the most efficient and effective way. This collaborative approach has ensured the right information is received at the right time.

3D renders (left) of Aldwarke STW, (top right) Castleford STW and (botton right) Lundwood STW – Courtesy of Glanua Group

Multiple digital tools were utilised to facilitate the safe design and construction process, this includes the Autodesk Revit suite for the civil structures and all mechanical and electrical equipment which was all modelled in 3D with subsequent sheets produced to facilitate a review and approval process as well as provide construction coordination, assessment, and as-built markups where required. Glanua Group utilised reality capture technology to establish baseline data and monitor progress against this.

Through the asset function of BIM360 Glanua Group has been able to replicate the client’s asset data requirements to collate data prior to submission on to their asset management database.

Within this function the procurement and construction/installation status could be tracked whilst assigning supplier and design information in preparation for the O&M and H&S file information.

Summary

Whilst significant progress has been made of all four projects, there is a number of key elements still need completing, a lot of work has been undertaken to help meet the project’s completion dates including completion of civil works, mechanical and electrical installation and wet and dry commissioning.