BRP – Elan Valley Aqueduct (Nantmel and Frydd Wood) – Birmingham Resilience Project (2018)

Downstream Nantmel site - Courtesy of Severn Trent Water, BNM Alliance & GHD

At the height of the industrial revolution, Birmingham’s population was booming. Between 1800 and 1900, the city had grown substantially. An innovative solution was needed to provide its residents and industries with safe drinking water. James Mansergh had identified the Elan Valley as a source for water. With Birmingham located so far in land, the city needed a viable way of transporting the water … enter the Elan Valley Aqueduct. The original aqueduct was built between 1893 and 1904. Fast forward over 100 years and the aqueduct still provides drinking water from the Elan Valley to Severn Trent Water’s customers in Birmingham. The aqueduct transports high quality water entirely by gravity.

Background to the works

Having supplied water for over 100 years, the aqueduct was beginning to tire in three key locations and Severn Trent identified the need to protect the structure. Severn Trent explored the possibility of internal repairs but the time available between aqueduct draining and restoring supply made this unfeasible.

The challenge

Having ruled out internal repairs, Severn Trent identified that the best option would be to replace three sections offline and use the planned shutdowns to drain the aqueduct and connect into the existing pipeline.

The Barhale/nmcn (now Galliford Try) PLC Alliance (BNMA) was appointed to deliver these new sections across three locations in Bleddfa, Nantmel, and Frydd Wood.

In 2016 and 2017, Bleddfa progressed well with the bypass successfully replacing a section of the ageing tunnel. In delivering this section, the team pioneered a number of innovative techniques that generated significant efficiencies for the project and protected supply reliability for Severn Trent’s customers.

These techniques have been adopted on the following Nantmel and Frydd Wood sections. Like the Bleddfa project, the Nantmel and Frydd Wood sections had to be bypassed using limited three-day shutdowns. This required efficient design and extensive collaborative planning to avoid customer impact.

Design and construction

The new aqueduct bypass sections are 3.05m diameter, segmentally-lined circular tunnels, constructed using an earth pressure balance tunnel boring machine (TBM).

- Nantmel: The new tunnel at Nantmel is now completed, and the existing section, including a masonry crossing, has been decommissioned. This replacement section was brought into operation in October 2017.

- Frydd Wood: The section in the town of Knighton replaces the Frydd Wood conduit and is 1.8km in length, nearly twice as long as the Nantmel section. The new tunnel runs under the Scheduled Ancient Monument of Offa’s Dyke. The project is located adjacent to a Site of Special Scientific Interest (SSSI) meaning it is crucial that environmental impacts are minimised. This is particularly important with the tunnel drive shaft located just metres from the SSSI area and the reception pit and new well-house located on the hillside above the town. The Frydd Wood project is due to be commissioned in March 2019.

Aerial photo of the downstream Nantmel Site, highlighting the scale of the temporary Earth Works. From this location the TBM was launched in 2017 – Courtesy of Severn Trent Water, BNM Alliance & GHD

Innovative design and construction

The project involved a number of innovative approaches in design and construction. These solutions reduced cost, time and environmental impact.

Nantmel

At Nantmel, a soil nail wall and reinforced soil wall were designed which enabled a flat platform to launch the TBM in an open cut excavation. This platform eliminated the need for any shafts to launch the TBM, improving the project’s efficiency by reducing the cost and programme.

Open cut launch solution: The steep topography at Nantmel proved a challenge for launching, servicing, and removing the TBM. The team resolved this challenge by introducing a substantial earthworks element to the project, namely a soil nail wall to support the cut face and a reinforced earth wall to support the fill material.

To reduce environmental impact, the cut material was reused to form the reinforced earth wall. The decision to expand the earthworks further allowed a larger launch area leading to a more efficient TBM launch.

The area was space-planned to provide areas for grout silos, and muck removal from the tunnel excavation. GHD designed the access road to ensure the TBM could be brought safely up the slope. This involved close collaboration with BNMA to identify transport and equipment sizes moving up the slope.

Connection solution: Having successfully pioneered an innovative approach for the connections at Bleddfa, the team delivered the same solution at Nantmel.

BNMA exposed the existing aqueduct, upstream and downstream, in discrete sections to protect the asset with a reinforced concrete wrap. The length of these discrete sections were dictated by analysis of the existing structure using scan data and laboratory tests of the concrete. This protected the aqueduct to keep it safely in operation during the process.

Where the connections were planned, the wrap was altered to make it easier to remove without affecting the rest of the aqueduct. Bolted steel sections and timber planks were added to facilitate the breakout works during the limited shutdown. The new connection walls and precast concrete transition sections were installed. These were shaped to maintain the hydraulic performance of the aqueduct as far as possible.

During the planned shutdown in October 2017, the existing aqueduct roof and walls were removed, precast concrete diversion blocks were placed and grouted in position, and a replacement roof added. The water was then turned back on with the flow diverted down the new bypass tunnel.

Frydd Wood

On the Frydd Wood project, designs were altered to generate time and cost savings by removing a deep intermediate shaft. The downstream connection at Frydd Wood also involves the construction of a well house complete with 5 (No.) complex connections to the existing siphon.

Challenging hydraulic philosophies: The initial design for the upstream Frydd Wood connections involved constructing a deep shaft to enable the tunnel to pass under a watercourse. The tunnel would then proceed to a reception shaft on the other side of the watercourse before continuing closer to the surface.

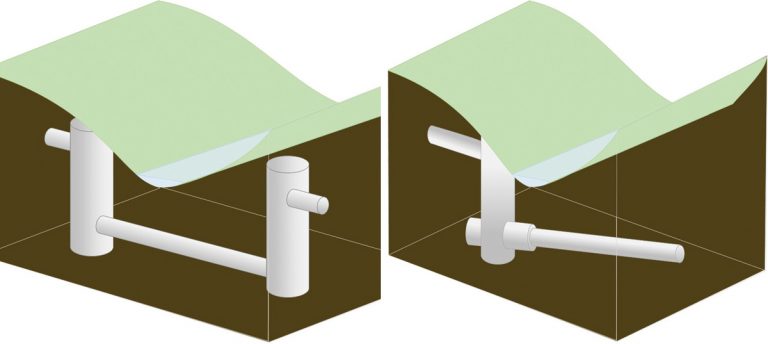

(Left) the initial solution involved driving the TBM between two shafts under a stream and (right) GHD’s solution challenged hydraulic philosophies to eliminate one of the shafts Courtesy of Severn Trent Water, BNM Alliance & GHD

GHD’s design team challenged hydraulic philosophies to design a solution that involved the tunnel gradually rising after passing beneath the stream. This eliminated the time, cost, and resources needed for the second deep shaft while also allowing the tunnel to be constructed in one continuous drive.

BNMA also identified that a front shunt and back shunt would increase the working area from which they could assemble and launch sections of the TBM.

The final design involves a part secant pile and part spray concrete circular shaft. This is excavated through the solid siltstone rock and allows the weight of the water to drive the flow underneath the changing topography.

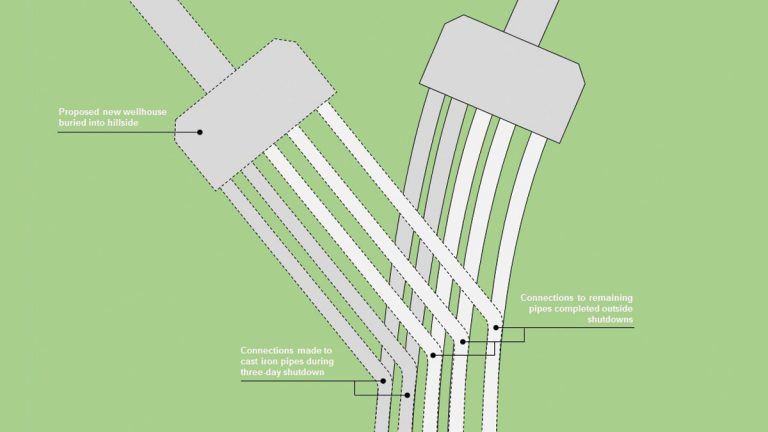

Downstream well house: Once the new structure is in place, the team need to connect the 5 (No.) syphon pipes from the new well house to the existing system.

The solution involves connecting and restoring flows through the two larger steel pipes during the three-day shutdown. BNMA will then connect the 2 (No.) cast iron pipes and overflow pipe, minimising disruption before restoring flows through the remaining pipes.

The proposed new wellhouse to be buried into the hillside with connections to the larger cast iron pipes to be made during a 3-day shutdown – Courtesy of Severn Trent Water, BNM Alliance & GHD

Summary

The EVA scheme forms part of Severn Trent’s Birmingham Resilience Project (BRP); an extensive programme of work to provide greater resilience of supply for over a million customers across the city of Birmingham and surrounding suburbs.

The creation of the three bypass tunnels on the EVA are an essential component of the overall project.

As the EVA is now over 100 years old it requires regular maintenance to keep it in service for the future. Severn Trent are therefore creating a new back up supply to keep water flowing for the city so that the EVA can periodically be taken out of action for inspection and repairs. The new back up supply will be sourced from across the region and includes laying a 23km pipeline from a new River intake on the Severn to a new treatment facility at Frankley.

Inside the new 3.05m diameter tunnel which will bypass an existing section of the EVA – Courtesy of Severn Trent Water, BNM Alliance & GHD

From the end of 2019, for the first time in history, Birmingham will have two water supplies, one from Wales via the EVA and a new back up supply. There is ongoing customer engagement helping customers understand what is happening and how this work ensures that future generation can continue to enjoy their ‘much loved’ water supply from Wales.