Evergreen Water Solutions

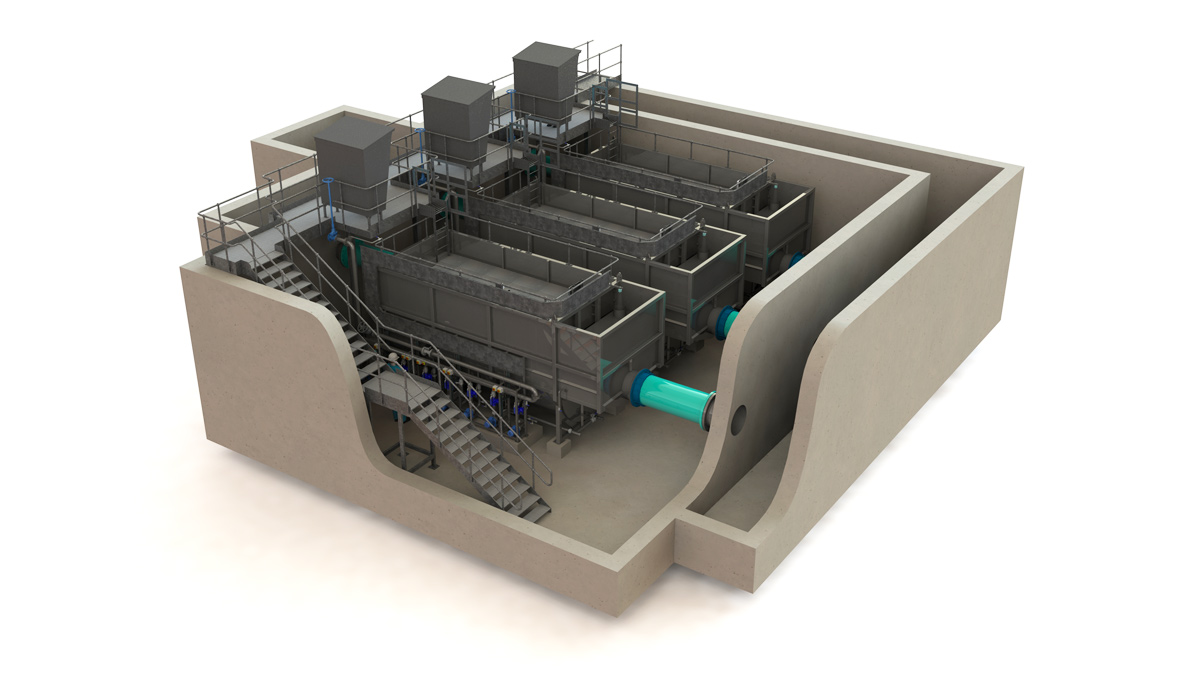

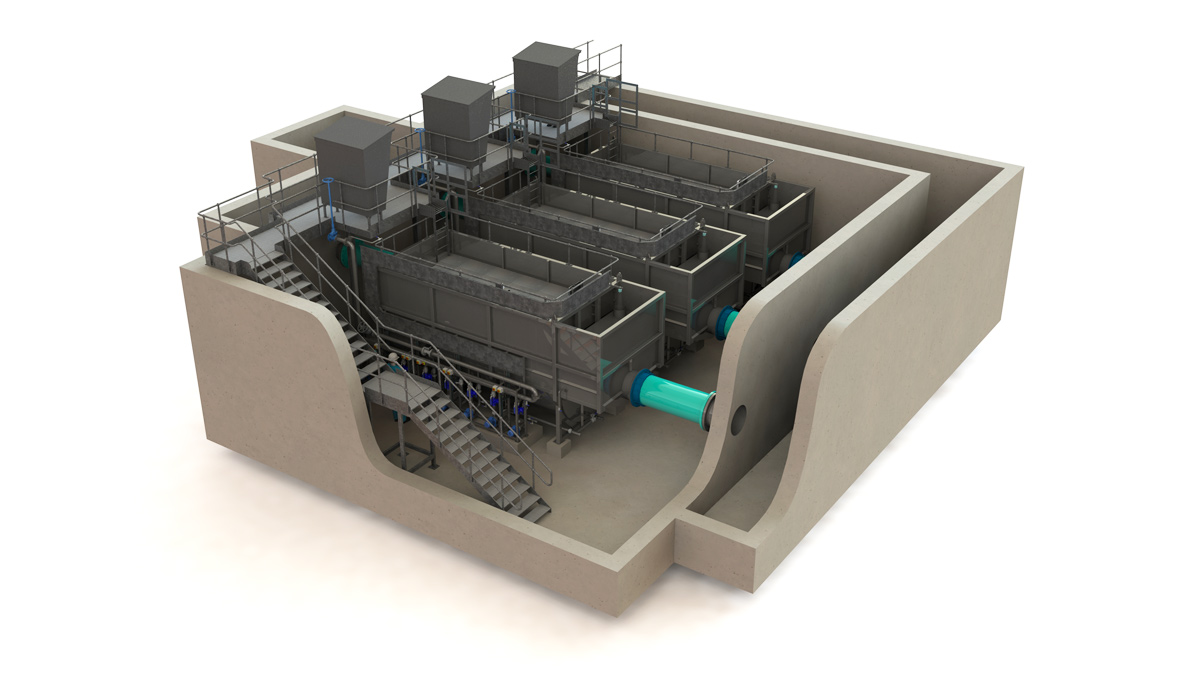

Evergreen Cloth Filtration Tertiary Treatment (Ellesmere Port 2021)

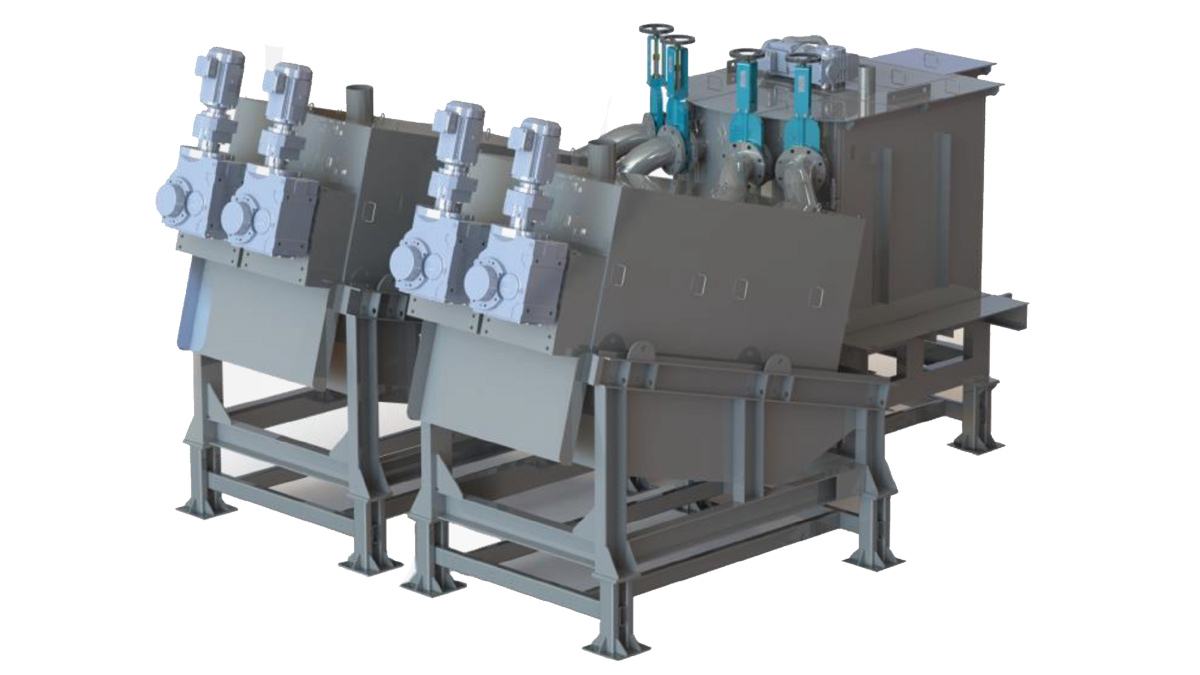

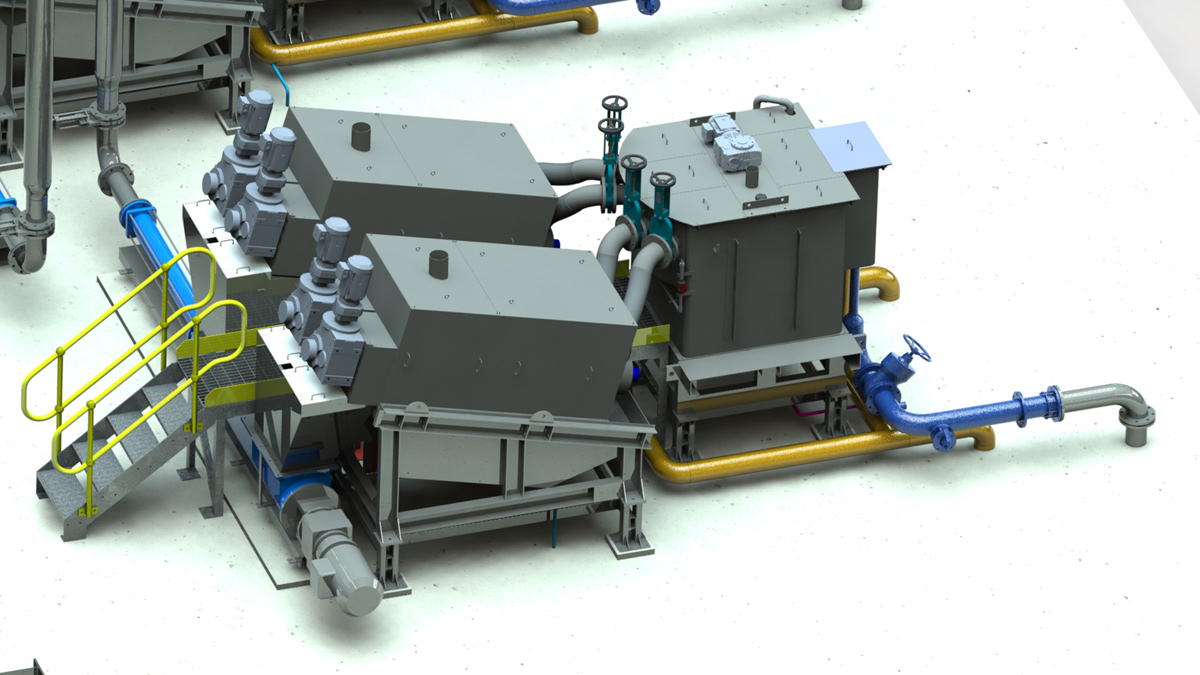

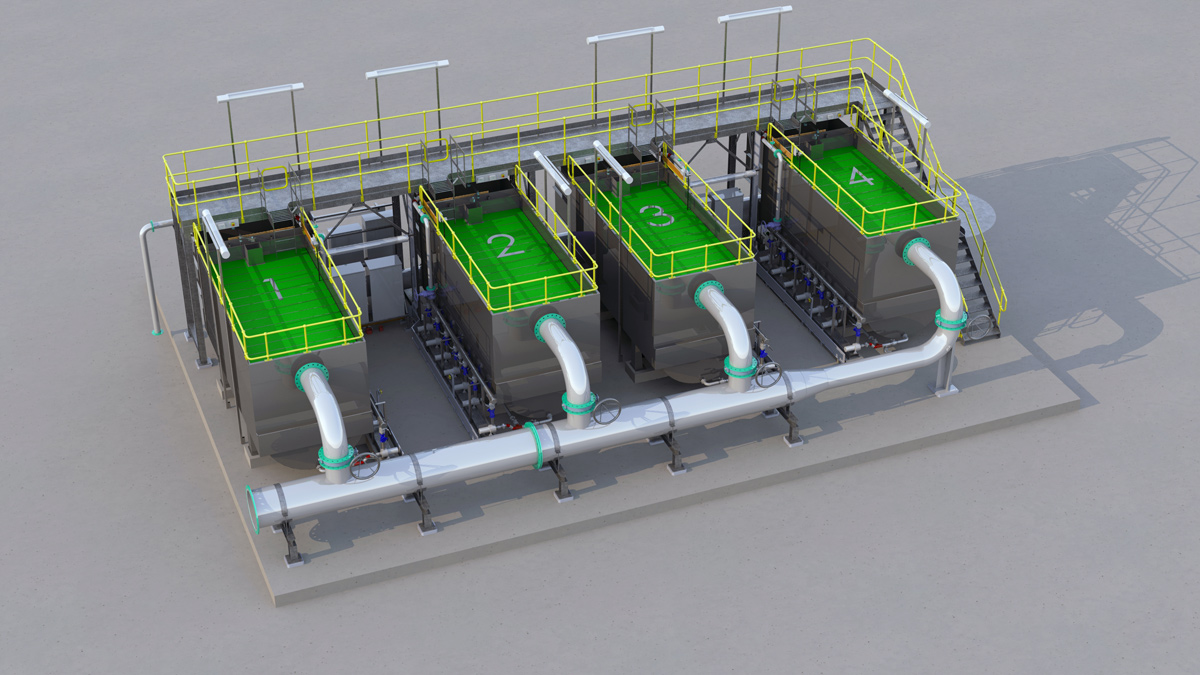

3D model designed in-house by EWS - Courtesy of Evergreen Water Solutions

Tertiary treatment processes have been used for many years to polish effluent, reducing concentrations of suspended solids (TSS), BOD and ammonia in wastewater and effluent treatment plants. Changes in UK legislation including the introduction of the Water Framework Directive and Shellfish Directive has led to increased interest in nutrient removal (P+N) technology and increasing demand for tertiary treatment in the wastewater treatment process. Tertiary treatment is essential to maintain future compliance with ever tightening Environment Agency standards. Tertiary treatment options available for the municipal and industrial wastewater markets include: cloth filtration, sand filtration, membrane bioreactors and UV disinfection. All offer similar end results, but cloth filters have a number of advantages including a small footprint and online backwash during operation without reduction in hydraulic capacity.

Evergreen cloth filtration system

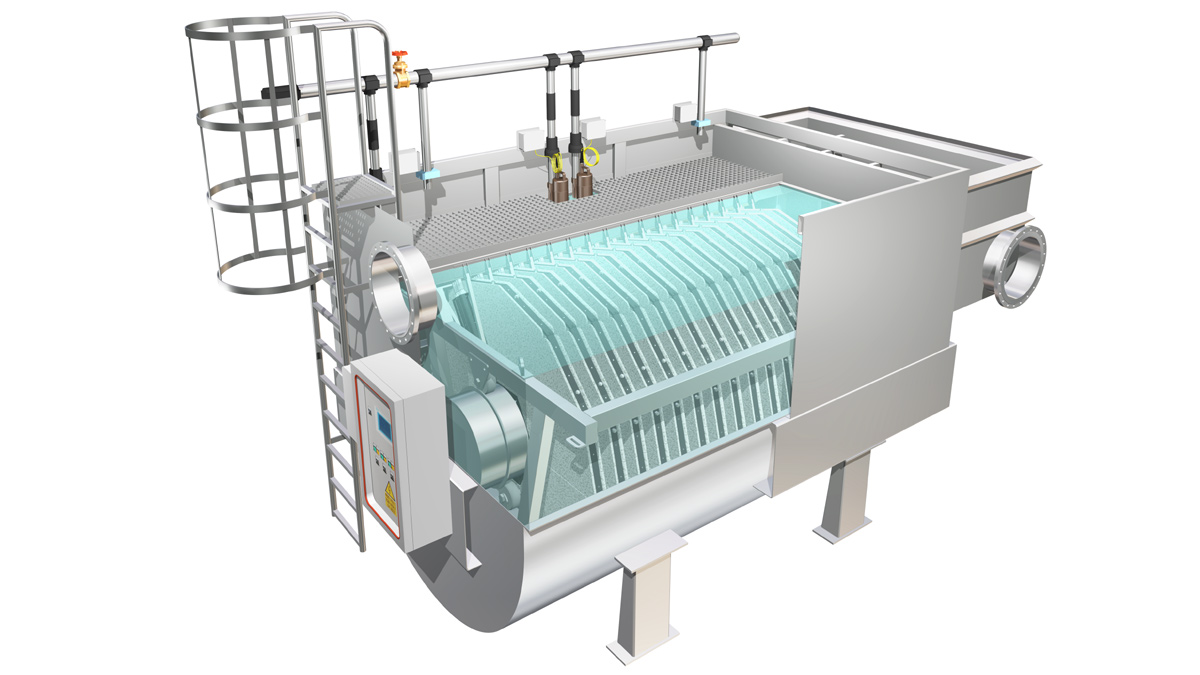

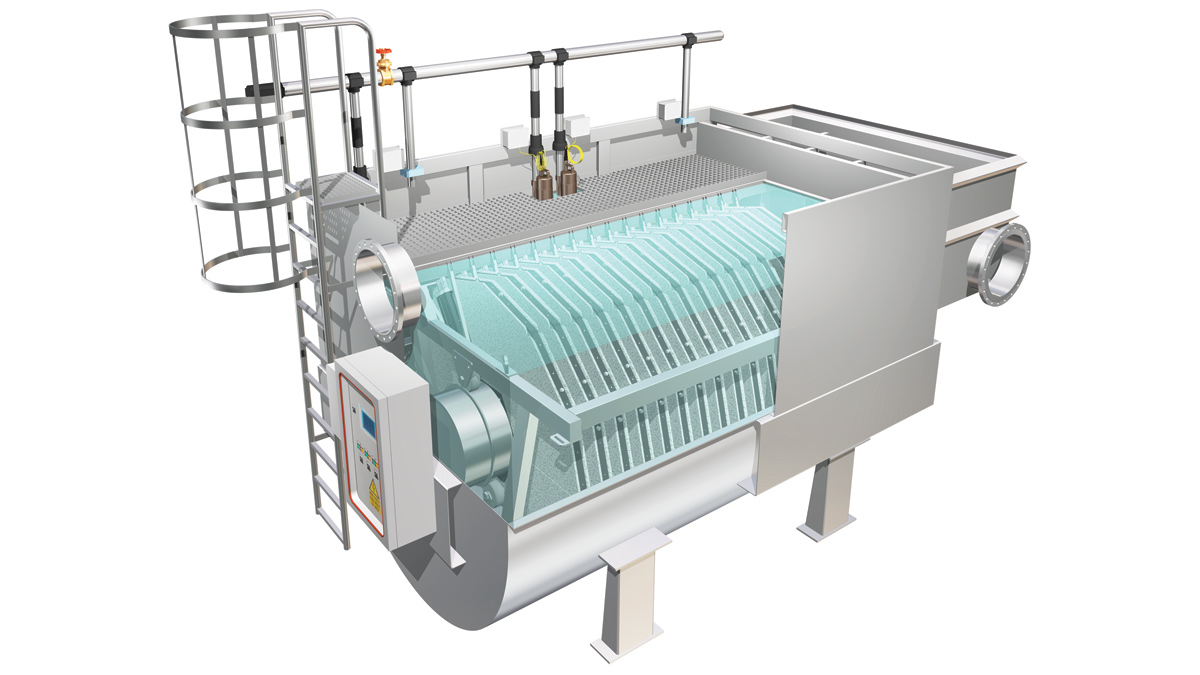

The Evergreen Water Solutions Ltd pile cloth filtration system allow efficient TSS removal in tertiary phases of wastewater treatment works, which is an efficient way to remove phosphorus as particulate. The filters can be used with or without upstream chemical dosing. The system provides solid separation using a deep pile cloth which combines the characteristics and advantages of surface filtration with that of deep bed filtration. The Evergreen cloth filter is made up of a series of filter discs mounted on an inner tube making it a very compact design. Evergreen cloth filters are sold in the UK and Ireland by Evergreen Water Solutions Ltd.

There are two types; drum and disc. For the drum type, the filtration cloth is fitted on a stainless-steel drum operating in vertical/horizontal orientation, whereas for the disc type, a central drum supports up to a maximum of 32 discs; each disc comprises six sectors made of reinforced plastic and each covered with an individual deep pile cloth.

Some special features of the Evergreen cloth filters include:

- Externally mounted backwash pumps.

- Fully decked filter with small panels for safe maintenance.

- Variable speed drive motor.

- Double chain drive.

- Heavy duty backwash mode.

- PLC control.

Energy consumption (W/m3 of effluent treated) for the Evergreen filter is extremely low, which is a fundamental driver in process selection. On a recent plant this was <1W/m3. Additionally, a head loss of <250ml is considered for normal operation at all flows and load.

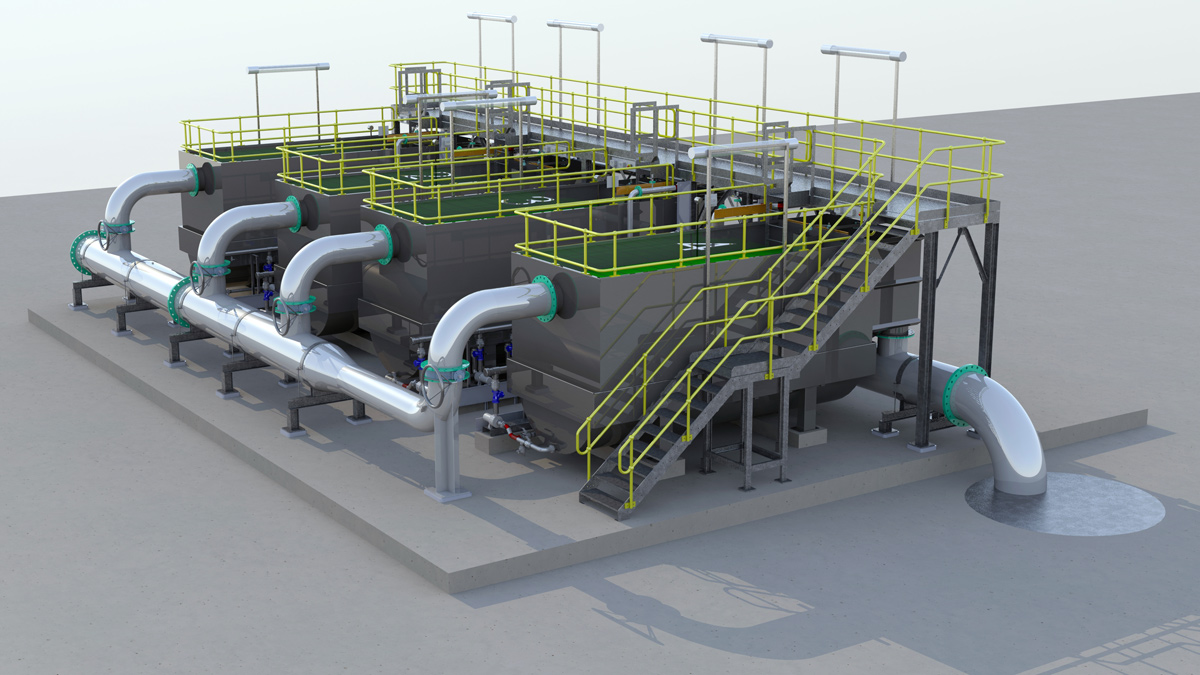

Wastewater flows to each filter either though a piped manifold or an inlet channel. The liquid level in the filter chamber is typically just above the cloth covered discs. The level is controlled by the outlet weir. The entire area over the filter is covered by open grid removable GRP decking. The decking panels are specifically designed to facilitate easy maintenance. The influent (post-secondary clarification) passes through the filter cloth whilst the solids are retained on the cloth pile/fibres.

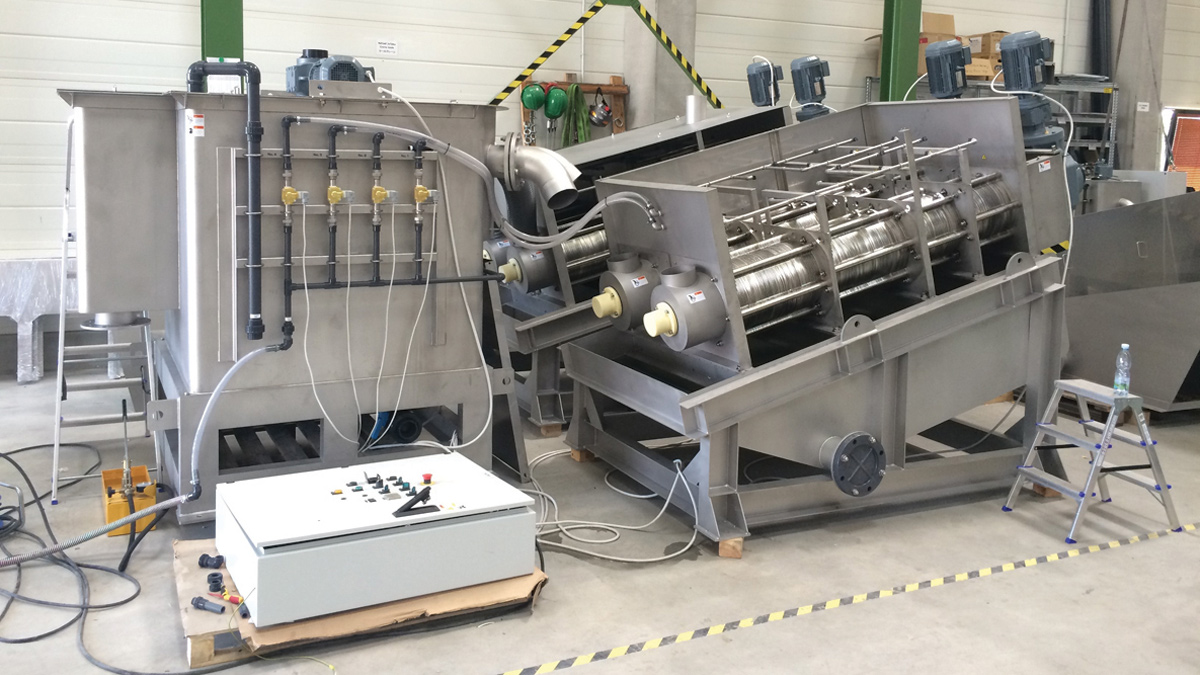

Example of an Evergreen pile cloth filtration system installation – Courtesy of Evergreen Water Solutions

Cloth filtration occurs under gravity flow, with all discs completely submerged. The discs will be stationary unless the solids collected on the cloth has resulted in a head loss sufficient to generate a backwash cycle. As only a small percentage of the total filter area is cleaned at any instant, the remainder or the filter cloth can continue to filter the wastewater stream as normal.

The disc segments are covered with a removeable cloth, which is a woven ‘pile’ fabric. During the filtration phase, the direction of flow causes the fibres to lie flat against the support panels. This results in a fine filtration matrix of overlapping piles. This creates an extremely efficient layer for the separation and retention of suspended solids in a similar manner to sand filters. Each segment of the cloth filter disc has its own individual cloth membrane that can be easily and quickly replaced. The design life of the cloth is up to 8 years depending on the influent load. The Evergreen deep pile cloth is supplied in two sizes: standard pile cloth (10 micron equivalent) and microfibre cloth (5 micron equivalent). The microfibre pile cloth is made of thinner fibres, but more densely installed on the lower woven polyester supporting fabric, than the standard pile cloth.

The footprint of a deep pile cloth filter compared with that of a deep bed sand filter is significantly reduced.

The online backwashing of each filter means that all filters are permanently operating and the use of the filtered water from within the filter itself eliminates the need for a backwash water reservoir. This results in considerable capital and operational cost savings. For example; a sand filter surface area of 100m2 would require a filter cloth tank of approximately 20m2 plan area.

Evergreen cloth filtration unit – Courtesy of Evergreen Water Solutions

Operation

During normal operation, solids are deposited on the cloth, causing the water level in the filter basin to rise, compared to the height of the exit weir. When a preset differential level is reached, the cloth backwash sequence is activated: a unique pumping system, connected to a series of suction nozzles, removes the solids retained on the cloths, resulting in lower operating head loss.

During the backwash process the fibres are raised inside the backwash nozzle, in such a manner that the solids, previously captured, can be readily removed by the counter-current water flow. The backwash water is supplied by the filtered water contained within the filter disc drum. The backwash water (including retained solids) are returned upstream. Any solids settling in the bottom of the filter tank are removed by a pump controlled by a timer.

This filtration technique with free-fibres filter cloth allows the use of very fine fibres and the attainment of optimum separation efficiencies, even in cases of high hydraulic loading or of load peaks and with minimum backwash water flow rates.

Applications

- Tertiary treatment: Cloth filters are used with great success for tertiary filtration downstream of secondary settling tanks in biological wastewater treatment plants, both municipal and industrial. The rate of removal of suspended solids is very high and the concentration downstream of the filter can be as low as 1mg/l.

- Phosphorus reduction: Reduction of the solids bound phosphorus content when discharged into bodies of water from existing or new build wastewater treatment plant.

- Pre-filtration upstream of UV disinfection: The cloth filter can be included upstream of the UV treatment, ensuring the quality of the water typically specified by UV suppliers and required for good operational efficiency of the disinfection system.

- Alternative to traditional secondary clarifiers: Separation of excess sludge downstream of biological wastewater treatment with RBC, trickling filters or other fixed growth processes.

Case study – Tertiary treatment for United Utilities

Ellesmere Port in Cheshire has experienced exceptional growth in the past few years with improved infrastructures and industrial companies continuing to expand their business in the area. The population is expected to increase by 10% to ~75,000 by 2036. The Essar Oil UK’s local Stanlow Oil Refinery forms part of the catchment.

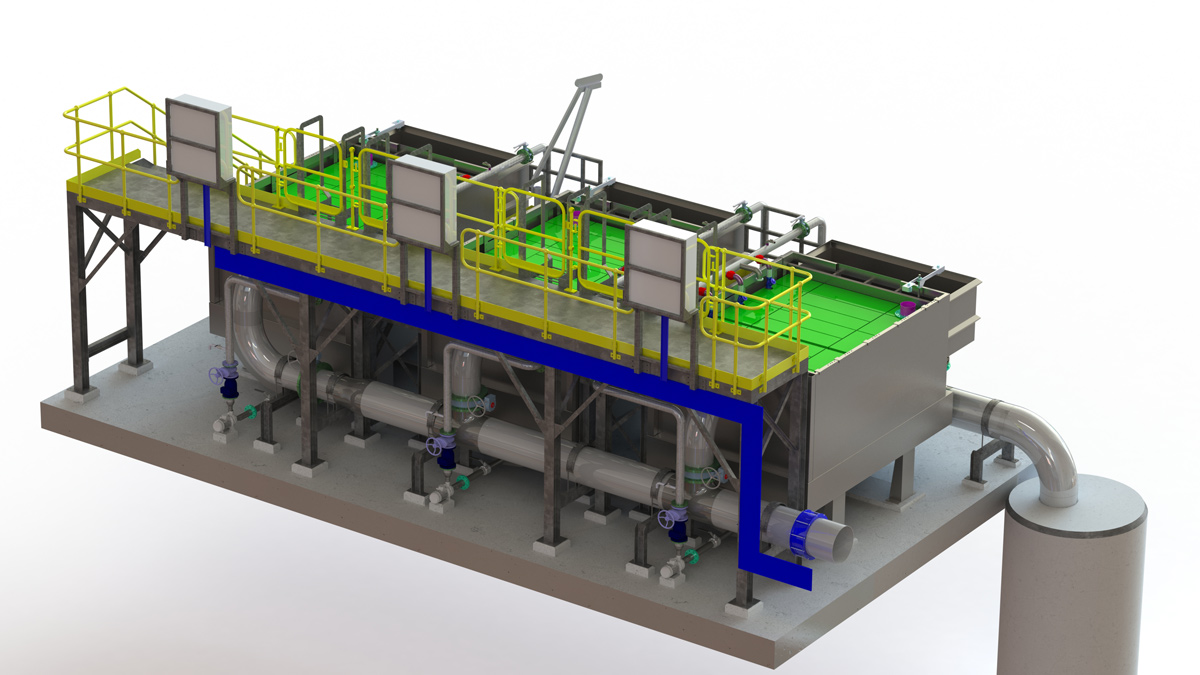

Evergreen tertiary treatment plant – Courtesy of Evergreen Water Solutions

Ellesmere Port WwTW is being upgraded with the installation of a new integrated fixed-film activated sludge (IFAS) plant followed by a tertiary solids removal process. Working in partnership with the delivery contractor C2V+ (a Jacobs/VolkerStevin joint venture), Evergreen Water Solutions Ltd was tasked to provide and innovative design and build tertiary treatment solution (FFT: 988 l/s and TSS: 5 mg/l on average, 10 mg/l at the 95%ile).

Coming at the back of an upgraded ASP process, Evergreen selected the cloth disc filter with microfibre as it was the most compact and robust tertiary technology available to meet the United Utilities future discharge consent, with the capacity to reduce TSS to less than 5mg/l and in so doing achieve a low TP concentration. Based on the hydraulic capacity of the plant, 3 (No.) Evergreen MSF 24/120 horizontal units were selected providing a total filtration area of 360m2. The units are installed in an above ground concrete bund operating duty/assist/standby and included backwash pumps, control panel and PLC control.

The benefit of the selected system was a small footprint, low head loss, and low energy. This enables a gravity flow from the upgraded ASP plant. Using the Evergreen microfibre cloth filtration process it is possible to achieve an ultra-low total phosphorus (TP) concentration. Compared with other technology the high hydraulic capacity of the units makes it an economical option with a small footprint and low operating and maintenance costs.

EWS, along with its manufacturing partners, adopted for off-site construction techniques in a bid to improve quality, reduce the carbon footprint, reduce health and safety risks during installation, reduce capital costs, reduce waste and speed up delivery of project.

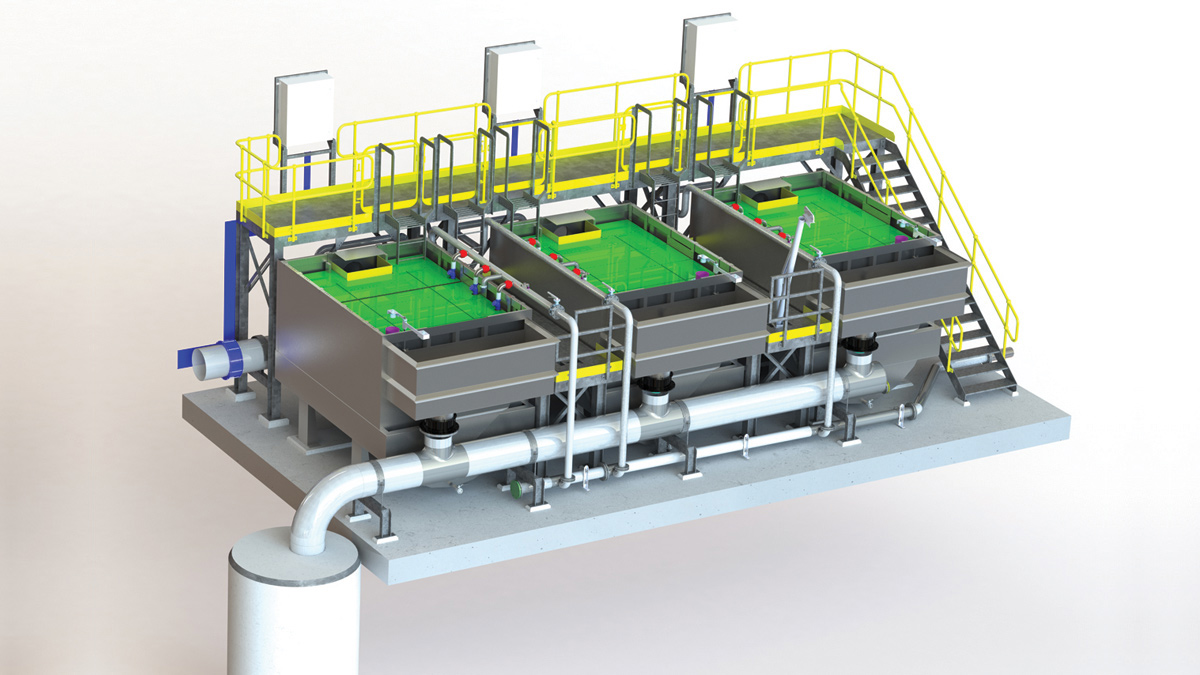

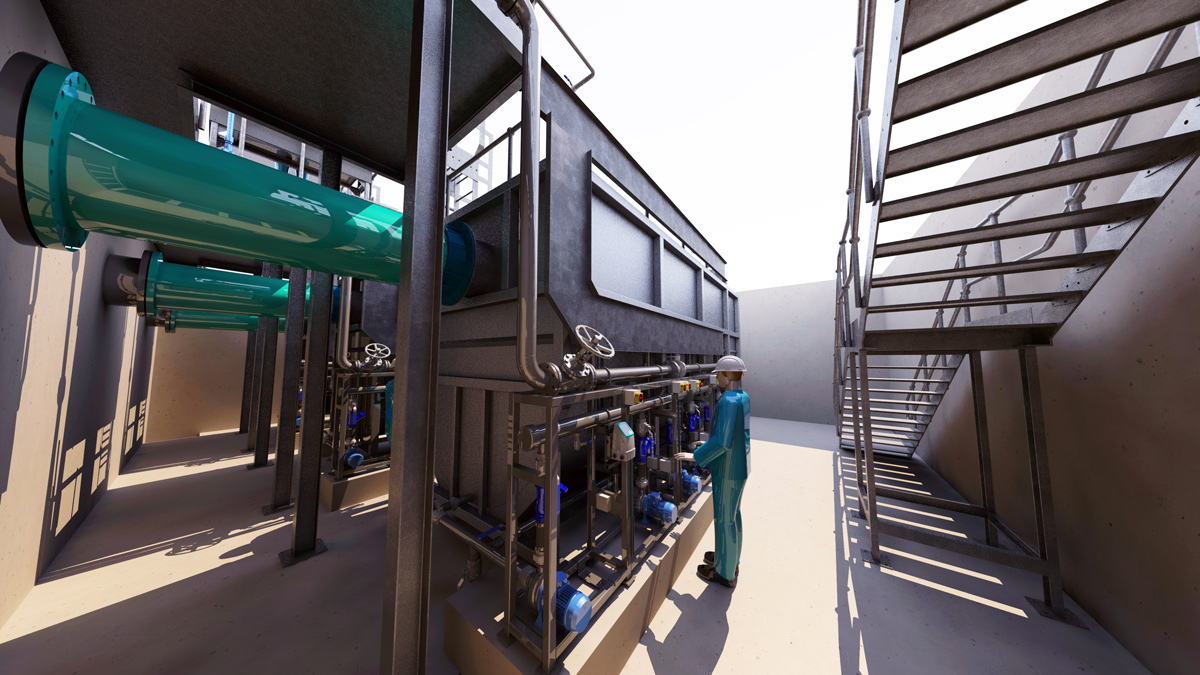

External mounted backwash pumps – Courtesy of Evergreen Water Solutions

Summary

For Ellesmere Port, EWS completed the design and fabrication of the stainless steel filter tanks and Evergreens manufacturing experience of cloth filters assembly and product design, allowed for the back wash pumps and drain pumps to be skid mounted and installed outside the Evergreen cloth filter tanks. The unique cloth filter design of external back wash pumps was agreed at a previous HAZOP with the client to improve access and maintenance for operations engineers on site.

The Evergreen MSF24/120 filter was supplied in a stainless-steel tank with an integrated removable access GRP platform and GMS handrail. All process equipment including the modular backwash pump skids and pipe works were pre-assembled off site and are pre-wired to reduce site wiring time on site.

Evergreen’s experienced project management team worked closely with C2V+ to safely deliver the Ellesmere Port WwTW Tertiary Treatment Project, with minimal disruption to the on-site infrastructure works.

For more information: Evergreen Water Solutions Ltd: +44 (0)1455 639760 | www.evergreenengineering.co.uk