Flood Control International

Carpenter Technology

Courtesy of Flood Control International

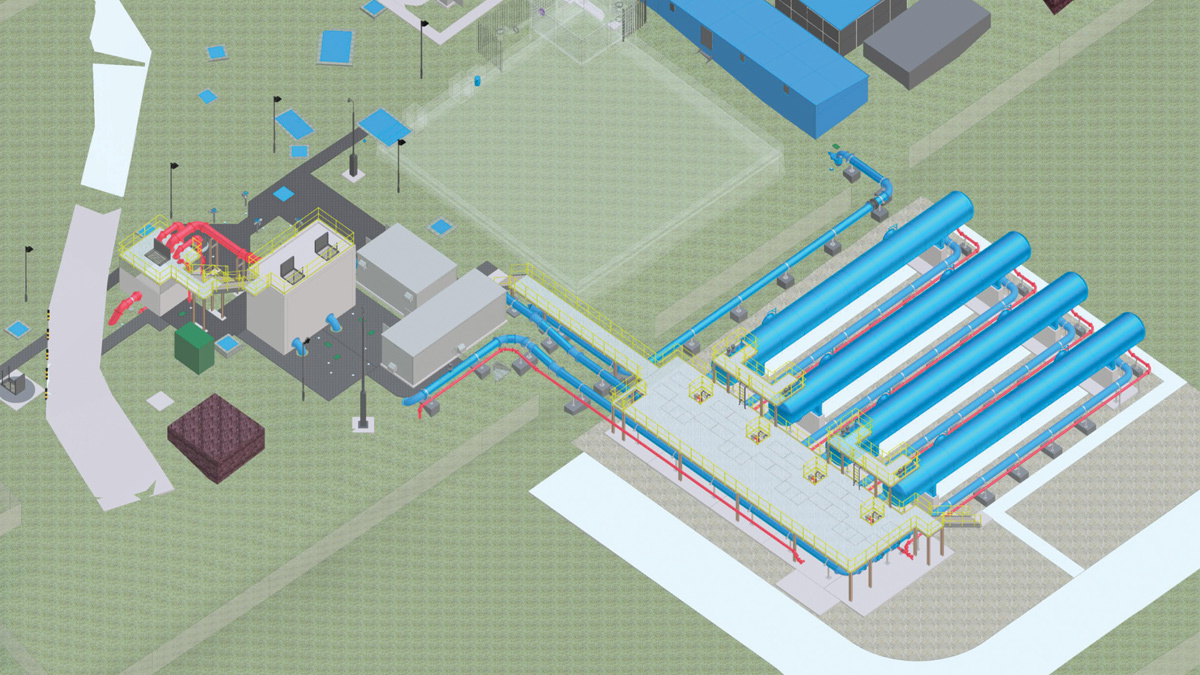

Carpenter Technology Corporation is a global leader in high-performance speciality alloy-based materials and process solutions, for critical applications in aerospace, transportation, defence, energy, industrial, medical and consumer electronics markets. Established in 1889, the company’s main plant in Reading, Philadelphia, has a wastewater treatment facility designed to treat Volatile Organic Compounds (VOCs) and metals, which is critical to all production on the site.

The requirement

FM Global, Carpenter Technology’s insurer, identified that there was a 1% chance of flooding each year at the Philadelphia site. What was particularly concerning was the value of potential losses as a direct result of any production downturn. Officials acknowledged that significant and certified flood protection was needed, ultimately prompting executives to explore flood defence solutions which protected the facility from flood heights of up to 6ft.

The solution

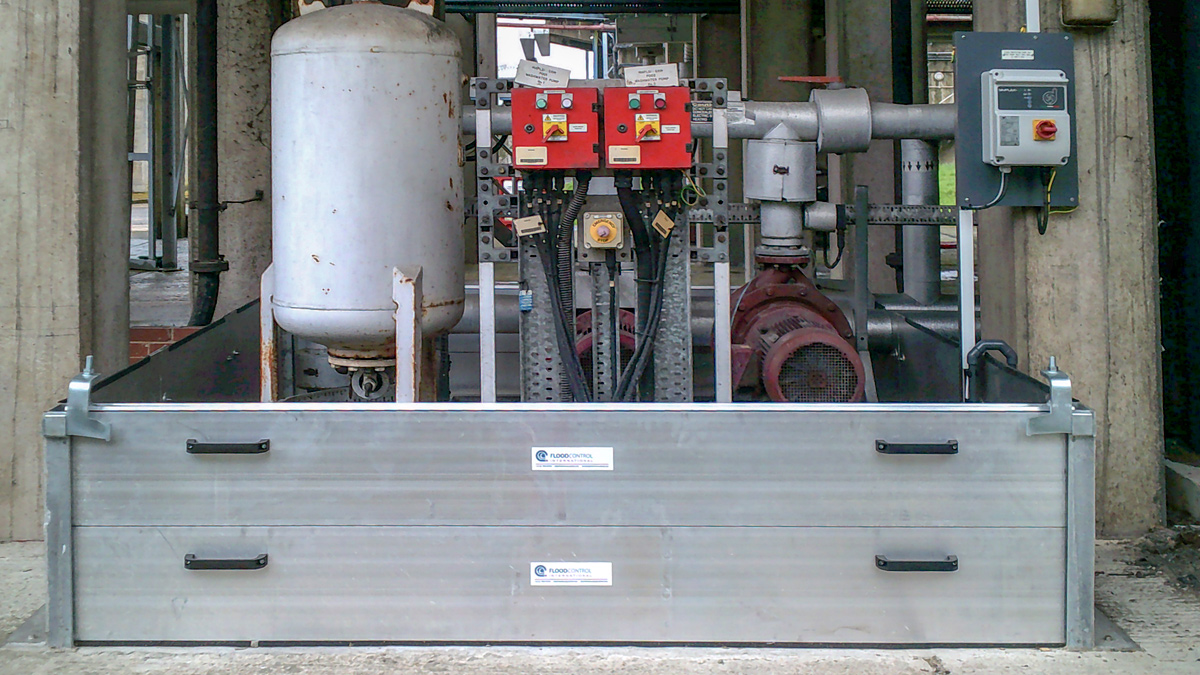

A huge advantage of working with Flood Control International is the custom design service, which allowed an efficient system solution that fitted seamlessly to the different levels of concrete; The site included existing accessways, raised troughs, plus steps and covers that needed a special layout with alterations to the standard system. Once the design process was completed, the systems to be supplied were 98ft x 6ft high, and 28ft x 6ft high retrospectively.

Courtesy of Flood Control International

The installation of the system was carried out by the plant’s local general contractors, with the anchors and receivers for the concrete foundations being delivered to site early.

Once fully installed, FM Global, the insurers of the site, requested an erection of the flood barrier, and a full height water test. Flood Control International attended the site with the installers and Carpenter Technology employees, who would be managing the equipment, along with two field engineers from FM Global.

The water test was an overwhelming success, with leakage well below the specified levels, leaving a happy customer, with a protected facility and reduced insurance premiums.

|

For more information: Flood Control International | +44 (0)1822 619730 | https://floodcontrolinternational.com/