Trant Engineering Ltd

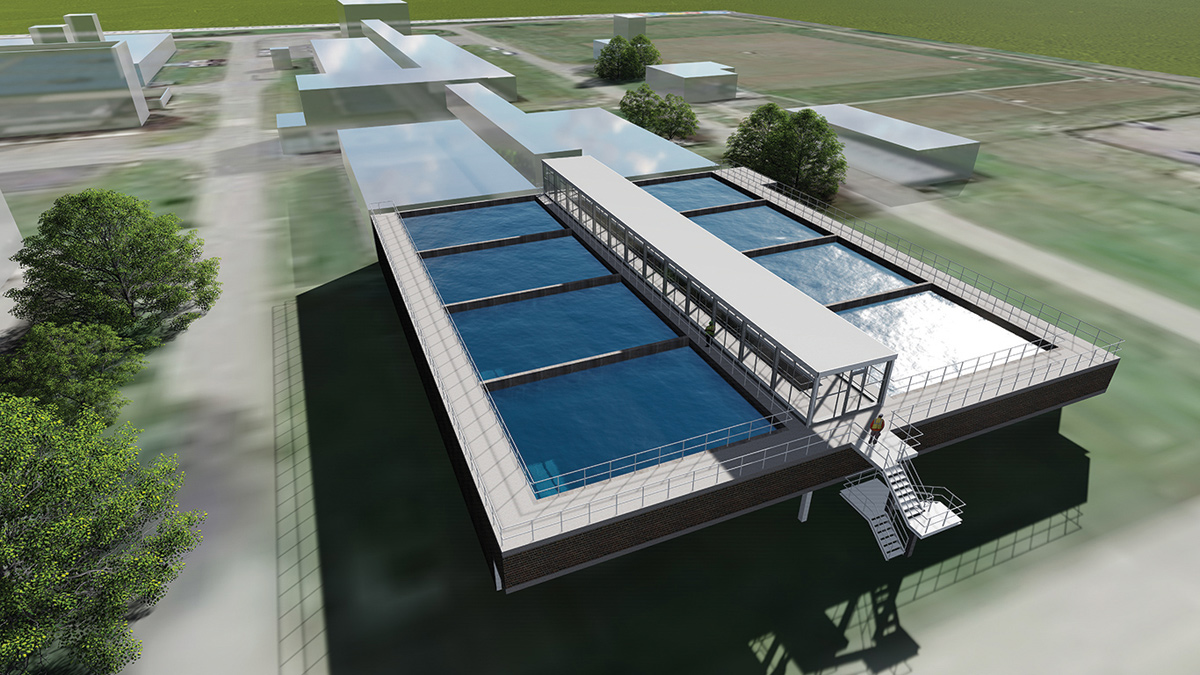

Hardham WSW

Hardham WSW

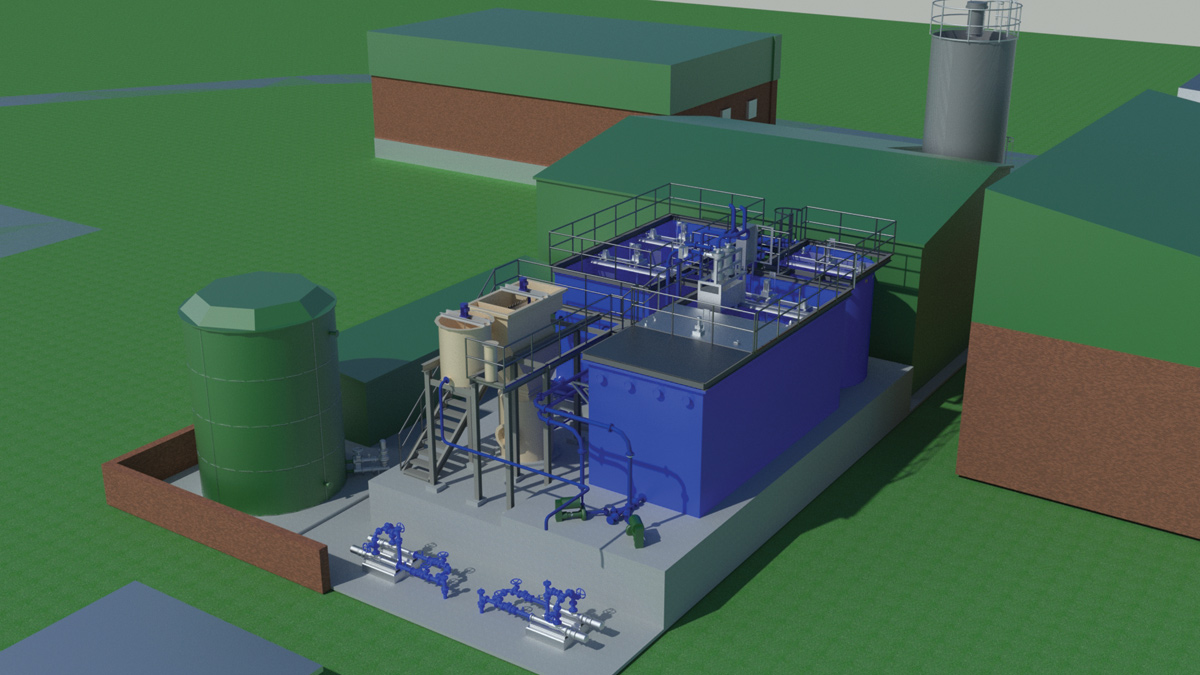

The upgrade scheme, undertaken by Trant Engineering, includes refurbishment and replacement of existing assets and improvements to treatment process unit operations, and will improve water quality and secure the water supply for years ahead.

The site had to remain “live” throughout the improvements, so Trant and Southern Water worked closely to develop a plan that would avoid interruptions to supply using Southern Water’s Safe Control of Operations (SCO) procedures backed up by risk assessed method statements.

Environmental considerations

The works is located in an environmentally sensitive area, so Trant’s Environmental Team carried out environmental audits covering aquatic wildlife, birds of prey, bats, rabbits as well as livestock on the adjacent farmland at key stages throughout the project. In addition, working alongside Southern Water’s ecology team to install bat boxes and rescue and relocate newts, eels and lampreys.

Hardham WSW from the river – Courtesy of Trant Engineering

Raw water abstraction

Raw water is abstracted from the adjacent river and treated by a conventional multi-step process of clarification, filtration, adsorption and chlorination.

Pumps abstracting raw water had become blocked with silt, and so Trant installed flood defences and isolated each cell in turn. Because of the potential impact on the eel population, Trant’s confined space teams had to remove the silt – almost 500te – by hand between February and August 2024. Trant also repositioned the raw water sample line to improve the accuracy of sampling.

Eel screens at the river abstraction point – Courtesy of Trant Engineering

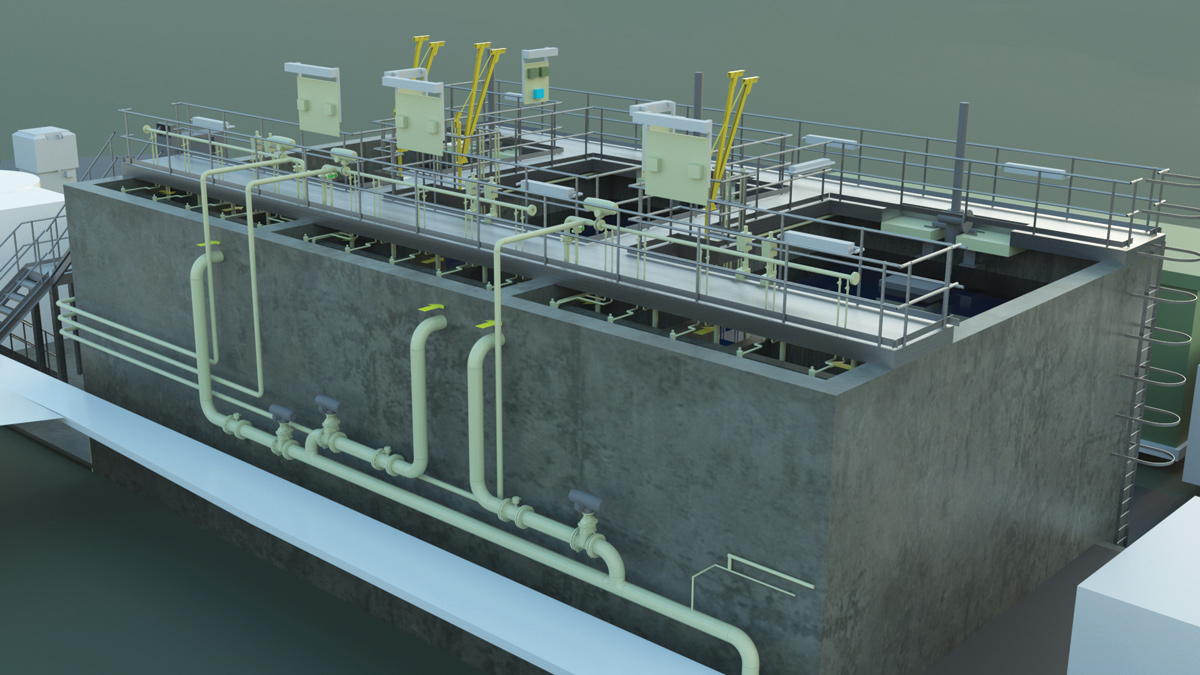

Dosing pumps & clarifier refurbishment

The dosing pumps were over 20 years old and so were replaced with state-of-the-art pumps with a new control system. The work was done in stages over a period of several months to ensure minimal disruption.

3D surveys and internal structural inspections of the clarifiers identified the need for repairs. They planned to carry out the work within strict “clarifier outage timeframes”. The construction teams had to maintain a constant temperature throughout the repair filler curing time by heating and encapsulating the clarifiers whilst ensuring the highest levels of water hygiene. The replacement resulted in improved chemical dosing accuracy and reduced risk of pump failure.

Rapid gravity filter refurbishments

The previous valves and actuators were replaced with eccentric plug valves with new actuators. The ageing PLC was also replaced, and the new one integrated into the existing site control system.

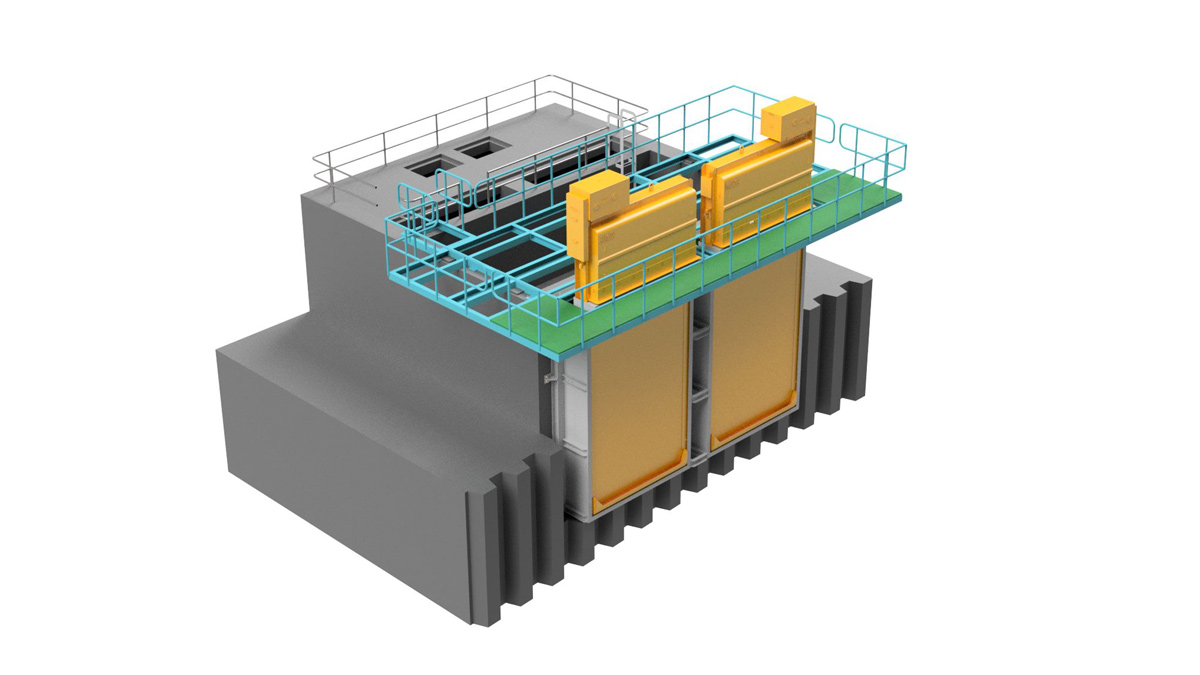

Granular activated carbon adsorbers refurbishment

Originally, the GAC adsorbers were designed to achieve a ten-minute empty bed contact time (EBCT) at the works design flow. Current Southern Water standards require a 15 minutes EBCT, to cope with the higher pesticide concentration now being found seasonally in the river water.

The solution was to raise the launder channels by 750mm to allow a greater depth of carbon. The adsorbers were taken out of service one by one, the carbon removed for regeneration and the structures, underdrains and plenum chambers inspected. During inspections, remedial works were identified and undertaken, including replacement of all nozzles, installation of closure plates and backing nuts to blank off old redundant connections and created new channel holes for the launders. The regenerated carbon was then installed followed by conditioning prior to putting back into service.

The adsorbers’ outlet flow modulating control valves were replaced with eccentric plug valves with new actuators.

GAC modifications to increase the empty bed contact time (EBCT) to 15 minutes – Courtesy of Trant Engineering

Regulating valve replacement

The replacement of the regulating valve was an important part of the project. Trant and Southern Water spent weeks carefully planning and reviewing, as well as carrying out “dress rehearsals” prior to commencing. The teams worked through the night to complete the work out of hours to avoid peak demand and customer interruptions.

Project delivery & successes

Work began in April 2022 and is due for completion by the end of 2026. The critical regulating valve replacement was completed in April 2025, some 2 years before the regulatory DWI date in September 2027.

Matthew Park, Hardham FEO Delivery Manager at Southern Water said:

“The installation of the regulating valve to ensure uninterrupted supply and meet the key DWI regulatory date has been the most impressive milestone. Given the importance of this part of the project, Trant’s management has been exemplary.”

Trant worked meticulously with Southern Water’s project and operations teams to achieve this.