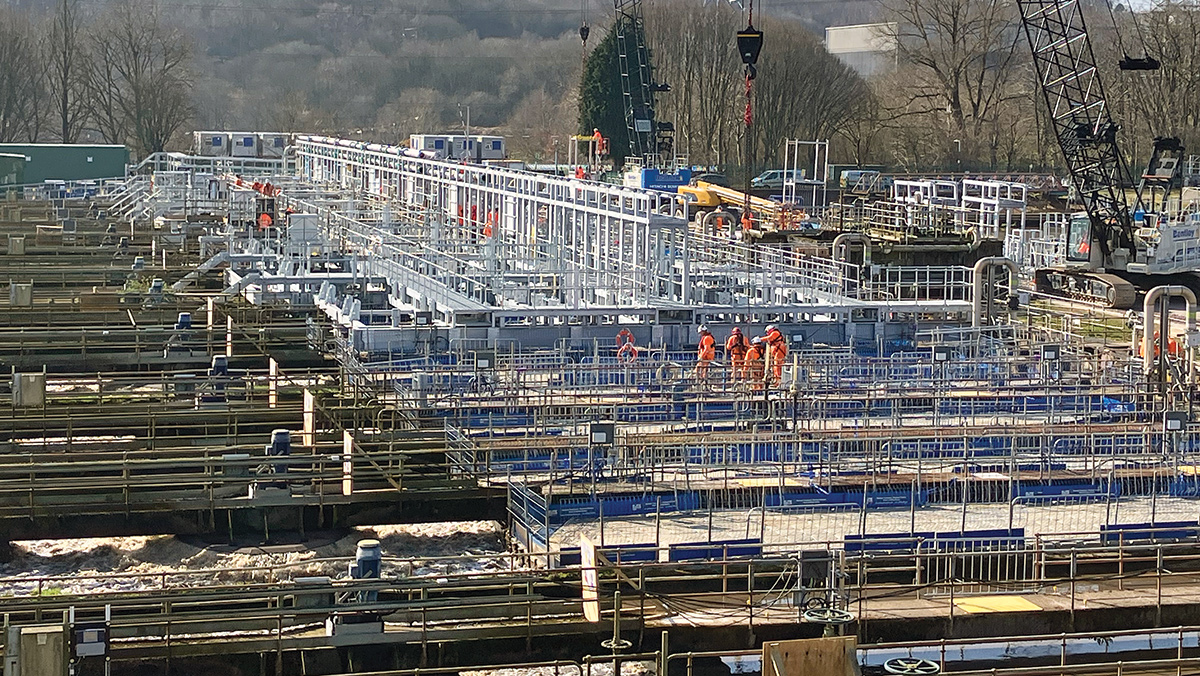

Bolton WwTW (2025)

MABR nearing completion - Courtesy of MMB

United Utilities’ Bolton Wastewater Treatment Works (WwTW) serves a population equivalent (PE) of around 436,000 in the town of Bolton and areas of northern Manchester; treating a flow to full treatment (FtFT) of 2800 l/s. As part of the AMP7 programme of work, a substantial project has been undertaken at Bolton WwTW to meet tightened permits and change the route of the existing storm flows to improve the quality of the River Irwell to ‘Good’ standard, as defined by the Environment Agency. Alongside nearby treatment works in the same catchment, United Utilities has invested £100m in these upgrades.

Existing works

The works was last subject to significant expansion in 2009, with an additional four radial final settlement tanks (FSTs) to complement the existing five-screen inlet works, eight radial primary settlement tanks (PSTs), 12-lane surface aerated activated sludge process (ASP) and eight radial FSTs. The works also contained a primary digestion plant that processed waste solids before pumping to secondary digestion off site at a central processing facility.

Tightened permits

To improve the quality of the River Irwell, Bolton WwTW is required to meet the following tightened permits:

| Permit | Ammonia | Phosphorus | BOD | FtFT |

| Current | 6 mg/l | 1 mg/l | 20 mg/l | 2,800 l/s |

| New | 2 mg/l | 0.4 mg/l | 8 mg/l | 3,225 l/s |

Project team involvement

Mott MacDonald Bentley (MMB), along with other contract delivery partners, was invited to price for works at Bolton in early AMP7 as part of UU’s capital delivery programme. A collaborative team from across all parties including United Utilities engineers developed a number of initial solutions combining multiple technologies, schemes and flows. Initial efforts to find an affordable solution for UU were challenging which led to substantial changes in the overall scheme which started as a new side stream treatment process. The change consisted of radial settlement tanks and additional ASP lanes becoming a more innovative solution allowing existing assets to be enhanced to meet the project driver.

The process to find a solution took time and led to final contracts to complete the scheme being granted to MMB in late 2023 – noting that the Environment Agency compliance date for the tightened permits was 31 March 2025.

MABR steelwork under construction – Courtesy of MMB

In order to deliver the required outcomes for United Utilities, the £50m contract presented MMB with a unique challenge with the project programme being just 16 months from award of contract to compliance date. This amounted to a delivery rate comparable to or exceeding anything previously delivered by the company in its 25-year history.

What followed was 16 intense months of focused delivery for both MMB and United Utilities, concentrating heavily on collaboration to avoid delays in decision making. The team fully embraced a design and build methodology where design, commercial and operational colleagues operated in harmony to deliver the project in a cost-effective and timely manner.

United Utilities undertook the process responsibility under the contract, which empowered key client personnel located on site with the UU operations and MMB design teams to promptly take key decisions within a risk framework. This allowed a delivery rate (that many thought was unmanageable) to be achieved and the outputs met against the project driver by the EA compliance date.

Bolton WwTW: Supply chain – key participants

- Designer & contractor: Mott Macdonald Bentley

- Tunnelling: Active Tunnelling Ltd

- Electrical installation: Eric Wright Water

- Mechanical installation: Franklyn Yates Engineering Ltd

- Mechanical installation: Mectec Engineering (NW) Ltd

- System integrator: Tata Consultancy Services

- MABR: Veolia Water Technologies

- Steelwork fabrication: AJ Engineering & Construction Services Ltd

- Steelwork fabrication: Fluid Sealing & Engineering (FSE)

- MCCs: Lloyd Morris Electrical Ltd

- Drum thickeners: Alfa Laval

- Washwater pumping system: KGN Pillinger

- Polymer dosing plant: NPS Engineering Group

- Compressor system: Quantum Engineering Developments Ltd

- Progressive cavity pumps: NOV Mono Pumps

- Flow controls: AFFCO Flow Control (UK) Ltd

Solution proposed

To deliver the required outcomes, the site was split into 4 areas covering the following major scope items:

Area 1: Inlet & storm returns pumping station (PS)

- A new storm returns PS capable of returning up to 800 l/s.

- MCC and other control equipment to feed the storm returns pumping station and new FtFT and storm overflow monitors.

Storm returns pumping station under construction – Courtesy of MMB

Area 2: Membrane aerated biofilm reactor (MABR)

- A new MABR system situated in the anoxic zone of the existing ASP. The system comprises of 184 ZeeLung™ MABR cassettes, supplied by Veolia Water Technologies, 12 blowers providing mixing, scouring and process air, 24 mixers and two compressors providing high pressure instrument and condensate removal air.

- Ancillary steelwork and pipework to support the MABR equipment within the 130 x 20m space.

- MCC and other control equipment to feed the MABR and ancillary equipment.

- HV power connections to the existing site ring main.

Area 3: Surplus activated sludge (SAS) thickening

- Replacement of the former SAS co-settlement regime with three twin-drum thickeners and associated polymer dosing system.

- Hydrocyclone sludge separation to return good settling bacteria to the ASP whilst removing poor settling filamentous fractions.

- MCC and other control equipment to feed the SAS thickeners and ancillary equipment.

- HV power connections to the existing site ring main.

Hydrocyclone racks under construction – Courtesy of MMB

Area 4: Storm outfall

- A new storm outfall installed adjacent to the existing works treatment outfall.

- Installation of diversion chambers and a 540m long 1-1.5m diameter mixed tunnel (constructed by Active Tunnelling Ltd) and open cut pipeline to feed the new storm outfall.

Innovation

MMB has been a leader in implementing MABR technology in the UK water sector; delivering the trial and full-scale plants at Severn Trent’s sites at Spernal and Monkmoor STWs respectively. Lessons learned from these projects were adopted by the Bolton team to expedite delivery of the scheme. Bolton WwTW represents United Utilities’ first use of both MABR and continuous sludge densification by means of gravimetric separation.

The design at Bolton WwTW allows the ZeeLung™ MABR technology to develop a hybrid system within the existing ASP.

The attached growth on the membrane allows for a high oxygen environment supporting dense nitrifier growth without the additional solids load to the FSTs that comes with high sludge ages in conventional systems. The membrane interface allows gas to solids mass transport of oxygen providing increased efficiency versus conventional suspended aeration.

Alfa Laval SAS drum thickeners – Courtesy of Mott MacDonald Bentley

Additionally at Bolton WwTW, in order to achieve the regulatory output date prior to the commissioning of all 12 lanes, the MABR cassettes were further enhanced with the zeeDENSE™ technology from Veolia Water Technologies. zeeDENSE™ delivers super-intensification of activated sludge by combining ZeeLung™ MABR for biological intensification and sludge densification.

This improves the settleability of the sludge allowing for greater mixed liquor suspended solids to be held in the system providing additional sludge age during the interim period. Post completion, the zeeDENSE™ hydrocyclones and associated plant will be retained to provide additional resilience for maintenance of assets.

Mott MacDonald Bentley has used several innovative digital technologies to deliver the scheme. This has included AI powered 360° imagery to map project progress, 3D model overlaying technology through Autodesk’s ACC platform and model based setting out, enabling Site Engineers to select their own setting out information from a 3D model (facilitated by Leica ICON software integrated with Autodesk Revit).

These tools have been critical in delivering the project right first time, in the timescales required, by highlighting issues to engineers that might not have been spotted as easily using manual methods.

Summary & conclusions

MMB and United Utilities successfully delivered the requirements for the project driver by the 31 March 2025. On commissioning, this installation became the largest MABR installation in the world. Works are ongoing to deliver the remainder of the project scope which aims to provide United Utilities with the necessary resilience to meet the required permits into the future. The works is now able to meet the tightened ammonia, phosphorus and biological oxygen demand permits thanks to the new treatment process equipment and ancillary plant.

Mott MacDonald Bentley has subsequently commenced work on an AMP8 Enterprise scheme at Bolton WwTW to provide permanent sludge dewatering. This project will utilise the knowledge and experience gained in the AMP7 scheme to accelerate progress and provide cost effective solutions to United Utilities.

Tunnel boring machine “Harriet” – Courtesy of MMB

Acknowledgements

Mott MacDonald Bentley acknowledges that this project would not have been deliverable without substantial efforts of the United Utilities Project Team (led by Project Manager, John Isaac), the UU Engineering Team (led by Project Engineering Manager, John Littlewood) and the UU Operations Team (led by Production Manager, Megan Johnson and Construction Supervisor, Martyn Hornby). An engaged and collaborative supply chain was another critical link in the project delivery chain.

MMB and United Utilities also acknowledge the input of Veolia Water Technologies (led by Project Manager, Stuart Waite) who have provided a significant proportion of the new process plant required to meet the tightened permits.

The Veolia Water Technologies team have worked collaboratively with both United Utilities and Mott MacDonald Bentley to deliver an affordable solution that has avoided the need to deliver a substantial new side stream for the treatment works.