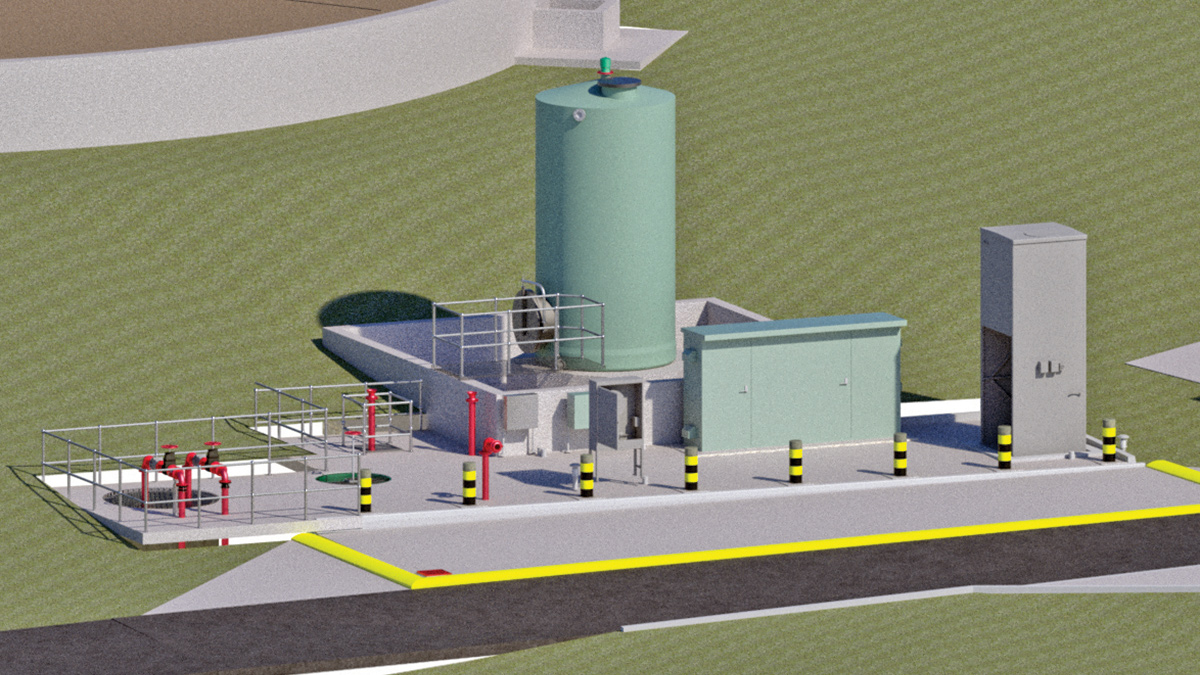

Bidford-on-Avon STW (2025)

Revit model of Bidford STW - Courtesy of Mott MacDonald Bentley

Bidford-on-Avon Sewage Treatment Works, located in southwest Warwickshire, is operated by Severn Trent. The site treats wastewater from a population equivalent of approximately 8,300 and ensures that the effluent is suitable for discharge into the River Avon. The AMP8 investment scheme is driven by both projected population growth within the catchment and the tightening of environmental permits. By 2038, Severn Trent Water projections indicate that the population equivalent figure will rise by roughly 20%, to around 10,140, and consequently, this has resulted in the introduction of several new effluent quality permits.

New permits

The new permits aim to safeguard the future operational capacity of the treatment works and enhance the quality of effluent discharged into the River Avon, thereby protecting sensitive habitats and preventing pollution of nearby designated wildlife sites.

Permitted full flow to treatment (FFT) to the site will be increased from 60.2 l/s to 87.0 l/s by December 2026, along with a new ammonia permit of 15 mg/l. Additionally, Total Phosphorus will be limited to 0.22 mg/l, and Iron to 4 (8UT) mg/l in December 2027. Biological oxygen demand (BOD) and suspended solids (SS) permits will remain the same at 25 mg/l and 45 mg/l, respectively.

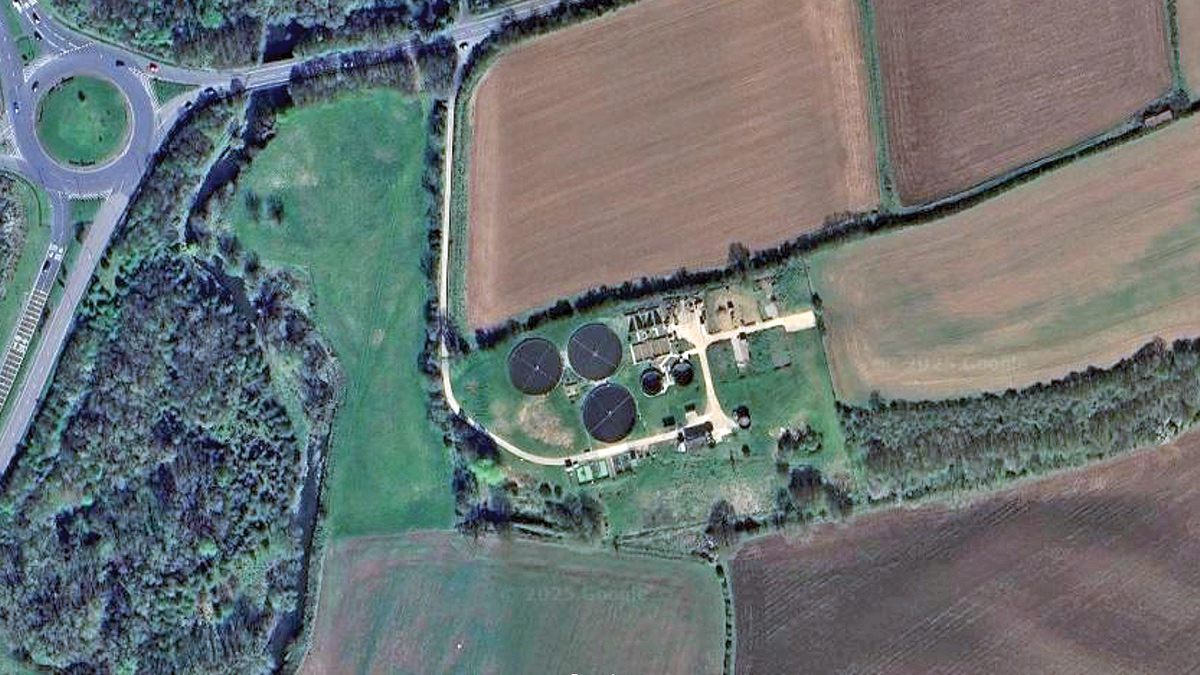

Google Maps image of existing Bidford site – Courtesy of MMB

Existing works

The current treatment works employs a biological treatment process. Flow enters the site and passes through the inlet works before proceeding to two 235m3 Dortmund-style primary settlement tanks (PSTs).

Here, sludge is settled out and directed to a dedicated 113m3 sludge storage tank, where it undergoes further thickening before being transported off-site for additional treatment. Partially treated effluent from the PSTs is then distributed evenly between three 28m diameter biological filters. Finally, three 235m3 Dortmund-style humus settlement tanks facilitate further sludge removal before the treated effluent is discharged into the River Avon.

Early engagement: Evaluating the received outline design

In 2023, Mott MacDonald Bentley (MMB) was appointed by Severn Trent, under an Early Contractor Involvement (ECI) agreement, to review the outline design for upgrading biological treatment at Bidford-on-Avon STW. The proposed scope included replacing the inlet works, constructing new primary and humus settlement tanks, enhancing sludge processing and storage, installing two biofilters, and integrating tertiary solids removal capabilities.

Initial site investigations highlighted major constraints, including topographical, ecological and spatial challenges within the site boundary, as well as potential difficulties in achieving regulatory permit dates. The scale and cost of temporary works were substantial, and there were significant health and safety risks associated with some elements of the scope.

Following a detailed review, MMB concluded that the original scheme presented excessive buildability and programme challenges, which could potentially result in failure to meet the regulatory date for the new consent.

To maintain project momentum, the design team considered alternative options. To support this, MMB undertook enabling works, including vegetation clearance, trial holes, and topographical and utility surveys. These actions ensured early service identification, allowed for safer construction methodologies to be considered, and helped mitigate programme risk.

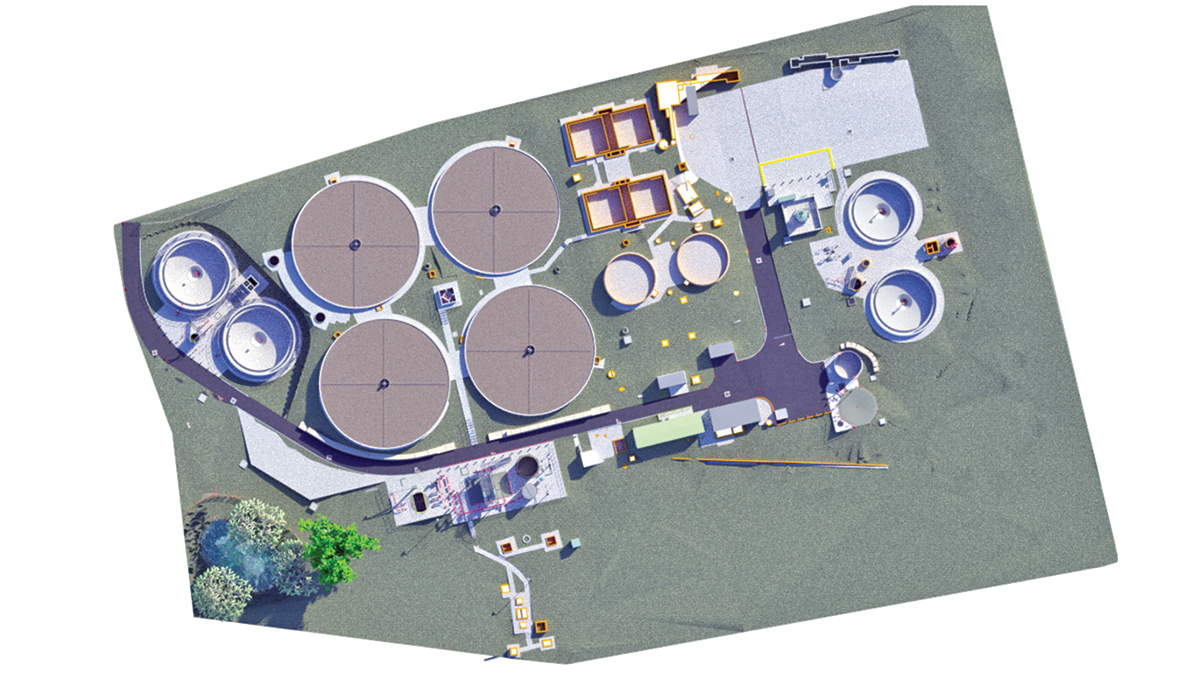

Revit model showing the proposed design whilst using a CDM area in the northern field – Courtesy of MMB

Optioneering & strategic re-assessment

A renewed optioneering phase was initiated to explore alternative solutions aimed at improving constructability whilst ensuring compliance with environmental and safety standards.

One key proposal involved constructing an offline solution in the northern field, replicating the assets outlined in the original design and connecting into the existing inlet works. Although this option would have mitigated many risks associated with the original design, it introduced new ones, such as delay in securing land ownership and planning permission.

Due to its complexity and the resulting uncertainty in the programme, this approach was ultimately deemed unfeasible.

However, the northern field remained in consideration as a potential location for the temporary working area. With the existing site too constrained to safely accommodate construction welfare alongside construction activities, this alternative offered a more practical solution. Yet, after several months of planning and evaluation, the proposal was ruled unviable, due to the inability to agree temporary access to the land.

Faced with land ownership constraints in the northern field, MMB and Severn Trent considered the option of a temporary working area in the field to the east of the site. Even though this initially appeared to be a workable alternative, the complex access strategy required, using the existing access road and new routes across the eastern field, came with its own ecological and archaeological hurdles. Mitigation efforts were expected to increase costs substantially and jeopardise the first regulatory permit deadline in December 2026.

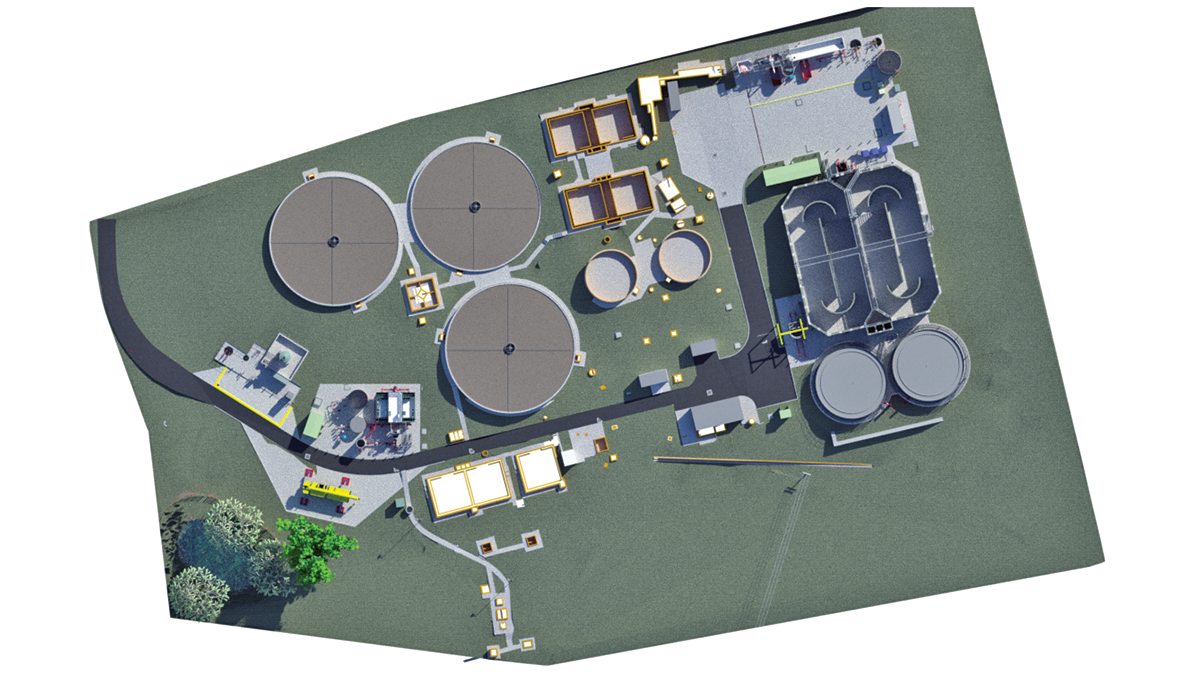

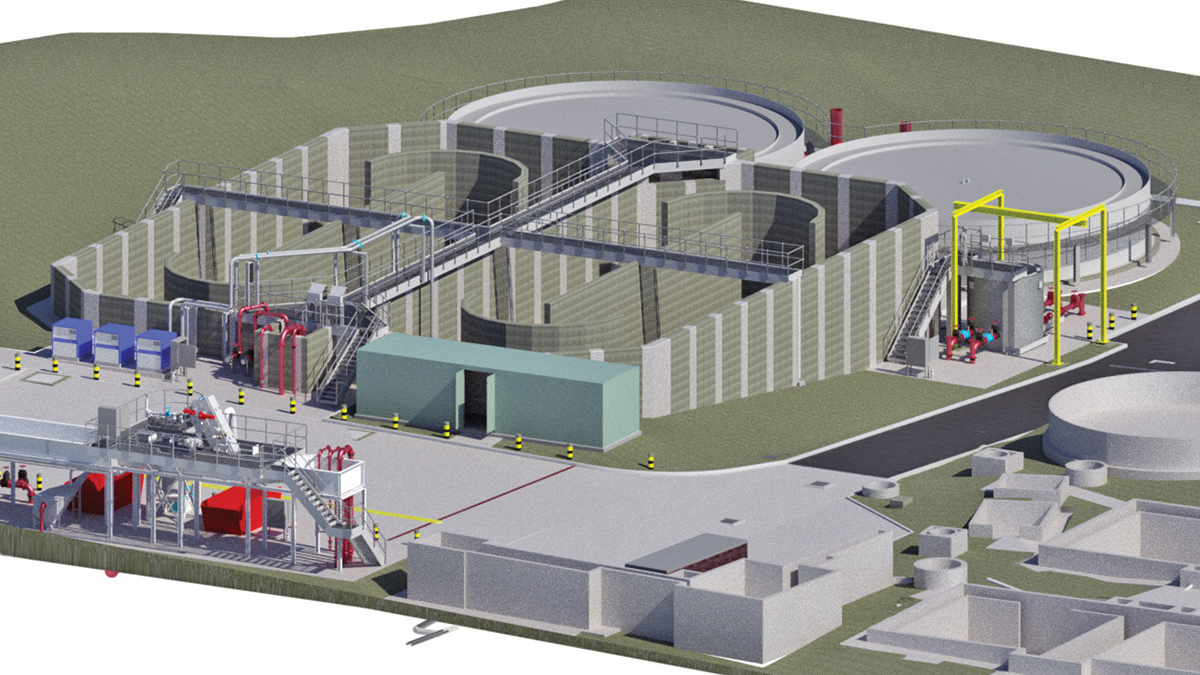

Revit model showing MMB’s latest oxidation ditch solution – Courtesy of MMB

Enabling success: Proposed scope change

In order to address the above challenges, MMB proposed a strategic shift in scope to Severn Trent, replacing the originally proposed biological filtration (fixed film) approach with an activated sludge (suspended growth) system.

This recommendation stemmed from a robust desk study, highlighting gains in programme efficiency, affordability, and process performance. To meet the increased flow from population growth and tightening environmental permits, the revised design comprises of a new prefabricated inlet works, a racetrack-style double oxidation ditch, steel final settlement tanks, chemical dosing, and tertiary solids removal capabilities, supported by containerised sludge thickening plant and a sludge holding tank.

Following detailed collaboration and review with Severn Trent, the scope change was approved, with MMB instrumental in driving the transition. The solution exemplifies how Severn Trent, as part of AMP8, is championing small-to-medium sized oxidation ditches for their operational benefits and how MMB is at the forefront of their delivery, setting a new benchmark for process excellence.

The revised solution is now positioned to meet the regulatory date whilst also providing a safer construction environment. This is to be achieved by maximising the available working area within the existing site, by minimising the footprint of the proposed assets.

Crucially, it does so whilst eliminating the need to build over existing assets, significantly reducing risk during construction. This approach also enables the establishment of a compliant CDM setup on-site, delivering substantial health and safety benefits and supporting efficient project delivery.

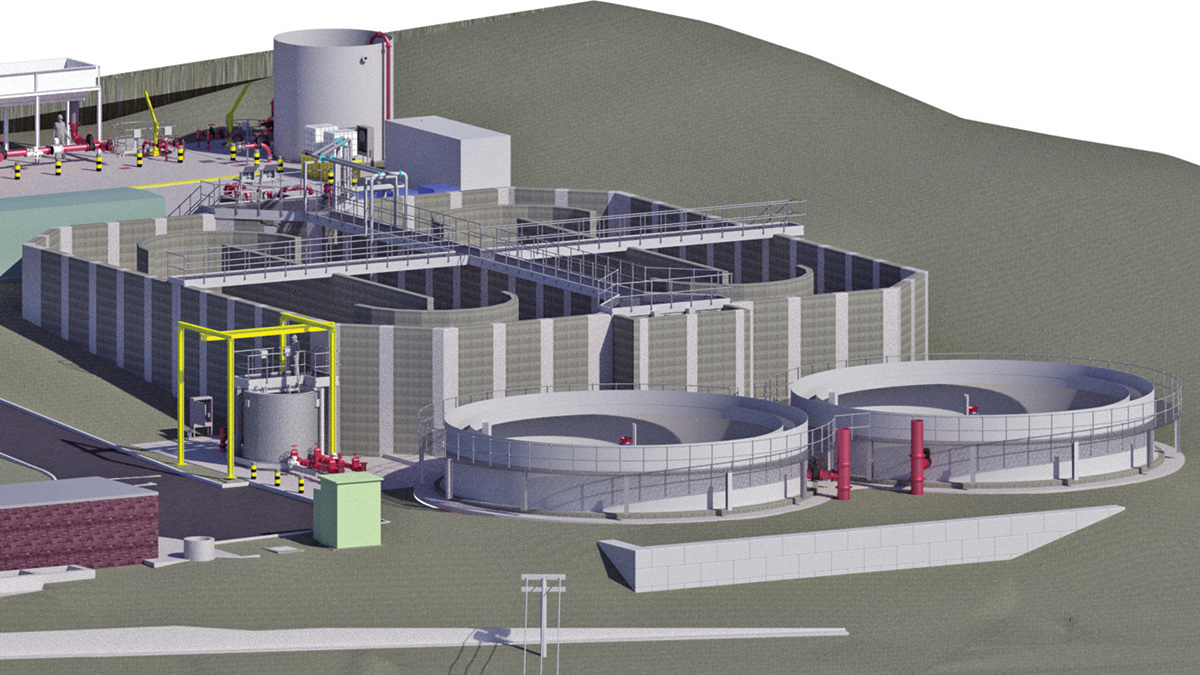

Revit model showing the inlet works, oxidation ditch and FSTs, looking north – Courtesy of MMB

Bidford-on-Avon: Supply chain – key participants

- Principal designer: Mott MacDonald Bentley

- Principal contractor: JN Bentley

- Specialist consultancy: Mott MacDonald

- Ecological consultancy: RammSanderson Ecology

- Archaeological fieldwork: West Yorkshire Archaeological Services

- Inlet works designers & contractors: SPIRAC Ltd

- Oxidation ditch precast concrete panel designers & suppliers: FLI Precast Solutions

- Tertiary treatment cloth filters: Eliquo Hydrok Ltd

- Landscaping: Holts Tree Care

Inlet works area: Design for manufacture & assembly

The site layout has been strategically engineered to optimise gravity flow, delivering long-term savings in operational expenditure. By eliminating the need for large pumping stations, the design significantly reduces energy demand and enhances sustainability, starting with flow management at the new inlet works.

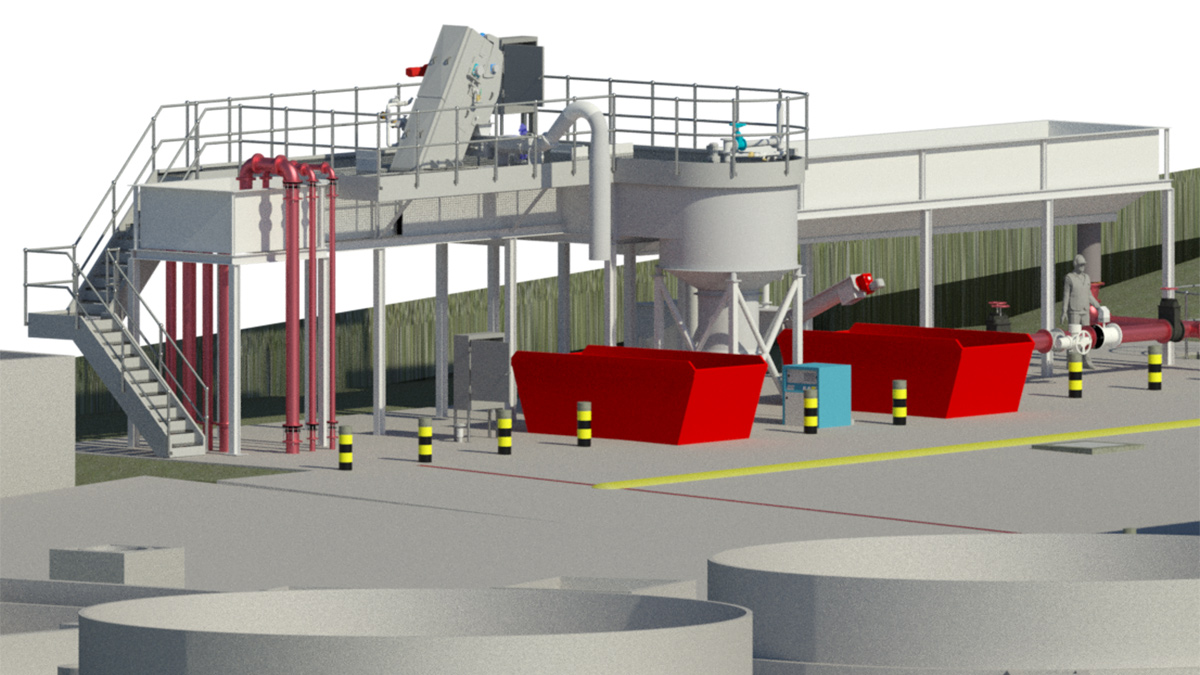

This inlet works, to be supplied as a complete prefabricated package by SPIRAC Ltd, represents another proposed installation of the SPIRAC package in the Severn Trent framework. Designed as a raised inlet works, it incorporates screening and grit removal at the initial treatment stage. Utilising a solution manufactured off-site will streamline the construction and commissioning process, leading to significant programme savings.

Revit model showing prefabricated inlet works from SPIRAC LTD – Courtesy of MMB

The solution also includes a suite of other critical assets in the vicinity of the inlet works. Using pre-assembled, containerised assets where appropriate enables rapid installation and health and safety benefits during construction.

The proposed containerised sludge thickening plant exemplifies a streamlined installation process that reduces labour requirements and minimises disruption to other construction activities.

Efficient design & the oxidation ditch

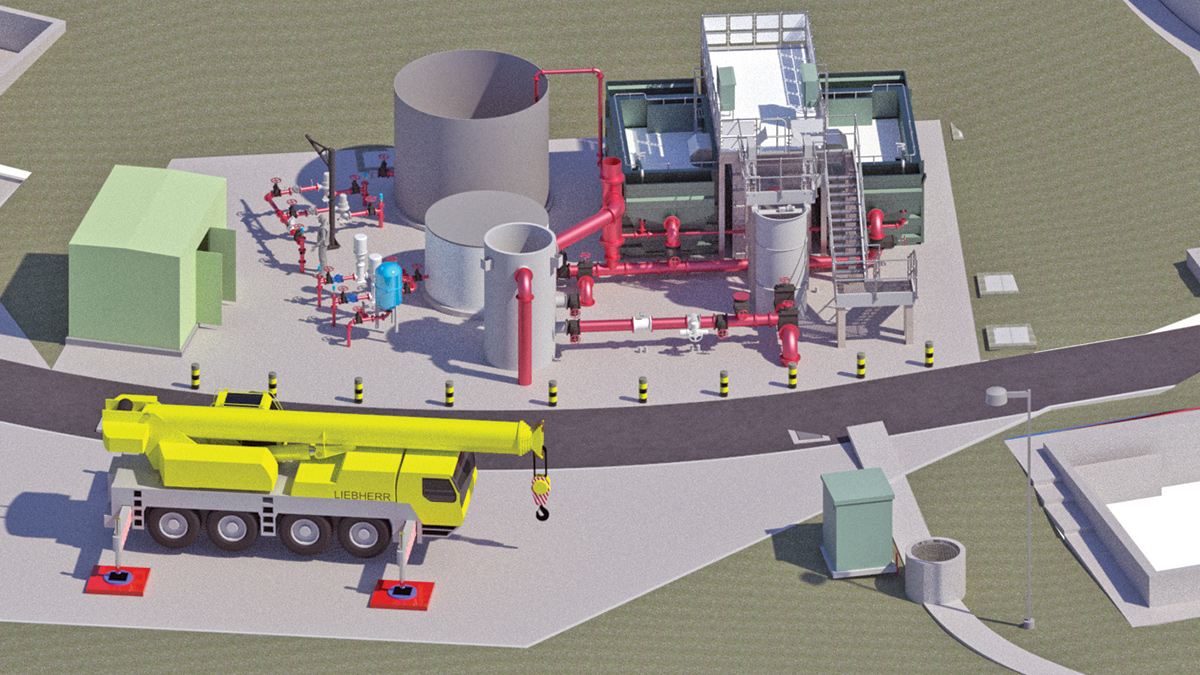

The oxidation ditch, measuring 32m in length, 28m in width, and with a capacity of 3,800m3 has been designed in a double-ditch ‘racetrack’ configuration. This layout enables efficient air distribution through an aeration grid, which is integral to the activated sludge treatment process. Following the scope change, MMB acted swiftly to engage subcontractors early, accelerating programme delivery through smart, efficient structural design.

FLI Precast Solutions, with support from MMB, has designed the precast wall units by using finite element analysis. This has enabled optimised structural design that allows the bending moments and shear forces to be calculated accurately. This approach has also allowed for the reduction of embodied carbon by reducing the amount of concrete used within the structure.

The position of the oxidation ditch has also capitalised on the natural topography that was once considered a constraint. Now, it acts as a strategic advantage to enhance flow dynamics by gravitating through the process and enhances construction efficiency by reducing the amount of excavation required.

Revit model showing the inlet works, oxidation ditch and FSTs, looking south – Courtesy of MMB

Secondary & tertiary treatment

The two 15m diameter final settlement tanks form a key stage in the treatment process, preparing flows for final polishing via tertiary solids removal. Having challenged conventional design standards, it is proposed to fabricate the final settlement tanks from stainless steel. This significantly reduces both the duration of construction and the carbon footprint.

A tertiary solids removal (TSR) stage will be delivered through Eliquo Hydrok TSR units; advanced cloth filters designed to remove suspended solids and ensure effluent quality. Once treated, the final effluent will be discharged into the River Avon.

As the site currently lacks chemical dosing infrastructure, a dedicated dosing area will be constructed as part of the upgrade. This will introduce controlled ferric dosing to promote particle coagulation, enhancing effectiveness of settlement and supporting overall process performance.

Revit model showing the tertiary solids removal and associated assets – Courtesy of MMB

Sustainable drainage & biodiversity enhancement

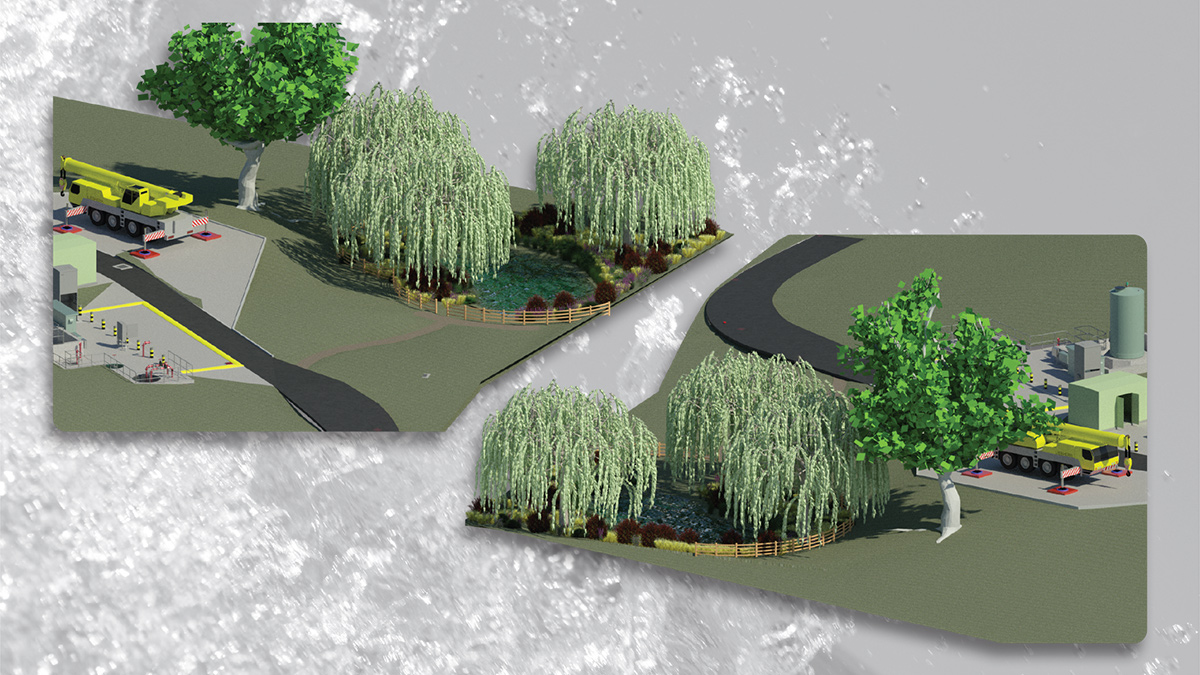

The site will benefit from a complete drainage upgrade, aligning with modern drainage standards. Potentially contaminated rainfall will be directed back to the inlet works, while clean runoff will flow into a sustainable drainage pond. Suspended solids will be captured through a cascade system at the outfall, before flows enter the pond.

The pond improves environmental resilience and presents an opportunity for Biodiversity Net Gain to be embedded into the design. It could potentially offer a new wetland habitat and provide an area for the planting of native trees and wildflowers. These areas will enhance the ecological value of the area, support local wildlife and promote long-term environmental sustainability.

Conclusions: delivering value

The design for the Bidford-on-Avon scheme demonstrates engineering excellence through robust optioneering processes. These have resulted in bold scope change that aligns the solution with Severn Trent’s operational, financial, programme and environmental objectives, without sacrificing engineering quality.

(left) Revit model showing the sustainable drainage pond, looking south and (right) looking north – Courtesy of MMB – Courtesy of MMB

The adoption of an activated sludge process, gravity-led flow and design for manufacture and assembly has transformed the scheme from a project at risk of missing regulatory deadlines into one on track to meet all key milestones. This turnaround has been driven by procurement-led design, early supplier engagement and a strong focus on construction efficiency. Financially, the revised design is set to deliver £multi-million savings without compromising quality or compliance.

Additionally, environmental stewardship has remained central to the design philosophy, with carbon reduction embedded across design elements and a strong emphasis being placed on Biodiversity Net Gain and sustainable drainage.

The design ensures that Bidford-on-Avon treatment works can accommodate future population growth and deliver high-quality final effluent to the River Avon.

Revit model showing the chemical dosing area - Courtesy of MMB