Burnley WwTW Catchment Strategy (2025)

Overview of Burnley WwTW - Courtesy of United Utilities

The requirement of the Burnley Integrated Catchment Scheme is the River Water Quality Improvement for the Water Framework Directive (WFD) driver identified in the Water Industry National Environmental Programme (WINEP) to achieve a ‘Good’ status in the defined reaches of Pendle Water and the River Calder. The project, which commenced in 2020, is one of United Utilities’ largest AMP7 investments and is being delivered by Advance-plus, a joint venture between MWH Treatment, J Murphy & Sons (JMS) and Stantec UK. In previous articles published by Water Projects, United Utilities has shared the project journey from concept, solution design development, and construction. This case study focuses on the project team’s experience in achieving effective project outcomes.

Project requirements & summary

To meet ‘Good’ status in Pendle Water and the River Calder, the treatment capability at Burnley Wastewater Treatment Works (WwTW) had to be enhanced to achieve compliance with the new treated effluent permit standards, coupled with management of storm discharges in the defined reaches, to achieve compliance with the WFD 99%ile wet weather intermittent standards. There are eight regulatory drivers attached to this WFD element of the scheme.

The project also includes two additional regulatory drivers for U_MON3 spill monitoring and U_MON4 flow monitoring.

Through complex river water quality and network modelling, the lowest whole life cost integrated catchment solution was determined and developed.

The Integrated Catchment Solution comprised four sites, which are all inter-dependent in delivering the regulatory outputs.

Modification of existing PSTs 6, 7, 8 and 9 – Courtesy of United Utilities

Burnley WwTW

Serving a domestic population equivalent of approximately 107,000 plus trade load, Burnley WwTW has undergone a significant upgrade during this AMP7 project with the scope comprising the design, construction, and commissioning of:

- A new Evoqua BioMag® activated sludge plant (ASP) from Xylem Water Solutions. The BioMag® system enhances conventional biological wastewater treatment by using magnetite (an iron oxide powder) to ballast the microbiological floc, creating an increase in mixed liquor suspended solids (MLSS) in the ASP and enhanced performance in the final settlement tanks (FSTs).

- A new 64-panel, 12,000m3 detention tank constructed by A-Consult Ltd with associated feed pumping station.

- A new additional (4th) primary settlement tank.

- A new 2500 l/s interstage pumping station (pass forward of FtFT and RAS flows).

- Refurbishment of the four existing FSTs.

- A new surplus activated sludge (SAS) thickening process.

- A new ferric and caustic chemical dosing plants.

- New MCCs, SCADA upgrade and power upgrade.

- U_MON3 event duration monitoring on spills to storm tanks.

- U_MON4 flow monitoring.

The final effluent quality for the new works at Burnley WwTW is to comply with both WRA (spot samples) and UWWTD (composite samples):

| Design Permit WRA | |||

| Parameter | Average | 95% ile | Upper Tier Limit |

| BOD | 9 mg/l | 50 mg/l | |

| Solids | 40 mg/l | ||

| Ammonia | 2 mg/l | 12 mg/l | |

| Total P | 0.25 mg/l | ||

| Iron | 4 mg/l | 8 mg/l | |

| Design Permit UWWTD Composite Samples | |||

| Parameter | Compliance Requirement | Upper Tier Limit | |

| BOD | 25 mg/l (or 70% removal) | 50 mg/l | |

| COD | 125 mg/l (or 75% removal) | 250 mg/l | |

| Total P | 2 mg/l (or 80% removal) | ||

Evoqua BioMag® activated sludge plant – Courtesy of United Utilities

Burnley WwTW Catchment Strategy: Supply chain – key participants

- Client: United Utilities

- Construction Delivery Partner: Advance-plus JV

- MWH Treatment (Advance-plus jv)

- J Murphy & Sons (Advance-plus jv)

- Stantec UK (Advance-plus jv)

- Civil design detention tank: COWI UK Ltd

- Physical modelling: Hydrotec Consultants Ltd

- Dewatering design: OGI Groundwater Specialists Ltd

- Dewatering: Alba Dewatering Services Ltd

- Concrete construction: STAM Construction Ltd

- Detention tank shaft: Joseph Gallagher Ltd

- Pump station shaft: EJ Kelly

- Sheet piling: Sheet Piling (UK) Ltd

- PCC driven piling: Van Elle

- Concrete cutting: Holemasters

- Temporary works/shoring: MGF Ltd

- Precast post tensioned tanks: A-Consult Ltd

- Precast roof sections: Macrete (Ireland) Ltd

- Precast shaft segments: FP McCann

- Blower building: Saredon Steel Buildings Ltd

- BioMag® building: Gallaway Construction Ltd

- Access metalwork: Tushingham Steel Fabricators

- Evoqua BioMag® process: Xylem Water Solutions

- BioMag® mechanical installation: Alpha Plus Ltd

Detention tank water test – Courtesy of United Utilities

- Civils & pipework: SGC Civil engineering Ltd

- Pumping station mechanical installation: Fluid Sealing & Engineering (FSE)

- Transformers: Winder Power

- Electrical installation: PICOW Engineering Group

- MCCs: Technical Control Systems Ltd

- Systems integration: Tata Consultancy Services

- SAS glass coated steel tank: Stortec Engineering Ltd

- Dosing systems: NPS Engineering Group

- PST fixed scraper bridge: EPS Water

- Epoxy coated carbon steel pipework & wall starters: Freeflow Pipesystems Ltd

- SAS drum thickeners: Huber Technology

- Odour control system: Air-Water Treatments Ltd

- PST odour covers: Corporate Engineering

- Ductile iron pipework: Saint Gobain PAM UK

- Ductile iron pipework: Electrosteel Castings (UK) Ltd

- FST scraper bridge refurbishment: Jacopa Ltd

- Blowers: Sulzer Pumps Wastewater Ltd

- Aeration system: Suprafilt Ltd

- SAS tank air mixing system: Utile Engineering

- Submersible pumps: Xylem Water Solutions

- Valves: AVK UK Ltd

- Standby generators: DTGen

- Kiosks: Industrial GRP

- Ventilation: Air Technology Systems Ltd

Lindred Road CSO (PEN0056)

Work at this existing combined sewer overflow (CSO) site comprised the construction of an online 1,950m3 detention tank to store storm waters during times of heavy rainfall and reducing discharges to the watercourse. New pumps within the tank return the effluent to the sewer for onward treatment at Burnley WwTW. A new MCC and power supply were installed for this facility.

Lindred Road detention tank during construction – Courtesy of United Utilities & Advance-plus

Altham Outfall Fennyfold CSO (BUR0026)

This existing CSO site is located in the local town of Padiham and on the sewer network that transfers flows to Hyndburn WwTW for treatment. The solution at this site was to construct a new chamber over the downstream sewer, install a new ‘real time’ controlled actuated penstock valve that regulates and optimises flows passed forward to Hyndburn, whilst reducing spills from the existing CSO. A new control kiosk was also provided.

Hyndburn WwTW

Value engineering and engagement with the Environment Agency enabled a no-build solution to be accepted at Hyndburn WwTW site, with only the optimisation of existing storm tank emptying system necessary for compliance.

Process optimisation: update to previous report

New primary settlement tank No. 4

- New primary settlement tank (PST) No. 4 desludge pump run/dwell timers have been optimised to provide primary sludge concentration to a target of ~3.5% ds w/w.

- Daily PST No. 4 sludge blanket dips are undertaken by ADP and UU Operations undertook routine measurement of primary sludge concentration to inform any occasional minor changes to desludge pump run/dwell timers.

- The set-points for the run/dwell timer of the PST No. 4 desludge pumps typically range from 9-12 minutes for the run phase and 45-60 minutes for the dwell phase. These set-points will be adjusted in the future to accommodate changes in operational conditions at the site, including those related to the current sludge treatment center.

PST4 with odour control cover – Courtesy of United Utilities

Interstage pumping station

- The new interstage pumping station (IPS) has been commissioned with close consideration of the operating level set-points as determined during detailed hydraulic design.

- Further optimisation of the recycled activated sludge (RAS) control flow rates was undertaken following an exceptionally dry and warm weather period during April-June 2025 which has then resulted in supplementary further optimisation of the IPS control set-points.

- To maintain a stable hydraulic gradient for control of RAS (via gravity) from the final settlement tanks, the IPS top water level has been further optimised at 2.5m set-point with an operating level set-point control band optimised across a 0.5m depth (as per design).

- The IPS pumps minimum/maximum operating speeds (32.5Hz and 50Hz respectively) have been further optimised to provide stable control to level set-point across the 0.5m operating level band and avoiding, as much as possible, pump start/stops during dry weather flow periods where pump minimum performance exceeds received flows into the pumping station.

- The IPS has operated generally in accordance with the initial duty/assist/assist cascading level control with PID control loop tuning set-points remaining generally unchanged since original turn of flows in early October 2024.

- Further optimisation of the IPS process control set-points is not envisaged in the future.

Interstage pumping station – Courtesy of United Utilities

Process air blowers: The new process air blower package was initially commissioned with support from the supplier, Sulzer Water & Wastewater. The majority of operational set-points within the blower package system are standard defaults and did not require further optimisation. The assist blower start/stop changeover set-points were optimised during a subsequent Sulzer site visit to ensure stable operational transition, avoid unnecessary noise and prevent nuisance under/over pressure process trips.

The process air blower discharge header control set-point has been further optimised to 640 mbarg in attempt to minimise dissolved oxygen depletion during storm events. The occasional depletion of dissolved oxygen remains an issue during the extraordinary rate of change of incoming flows and loads often associated with these storm events.

The addition of alternative ‘Storm Mode’ process control may ultimately be required to fully remedy the situation. Further optimisation of the process air blower process control set-points may therefore be required in conjunction with implementation of future ‘Storm Mode’ process control philosophy.

New primary ferric sulphate dosing: Extensive and routine jar-testing to monitor the optimal primary ferric dose molar ratio dose to achieve target residual orthophosphate and Total Iron concentrations was undertaken during May and June 2025.

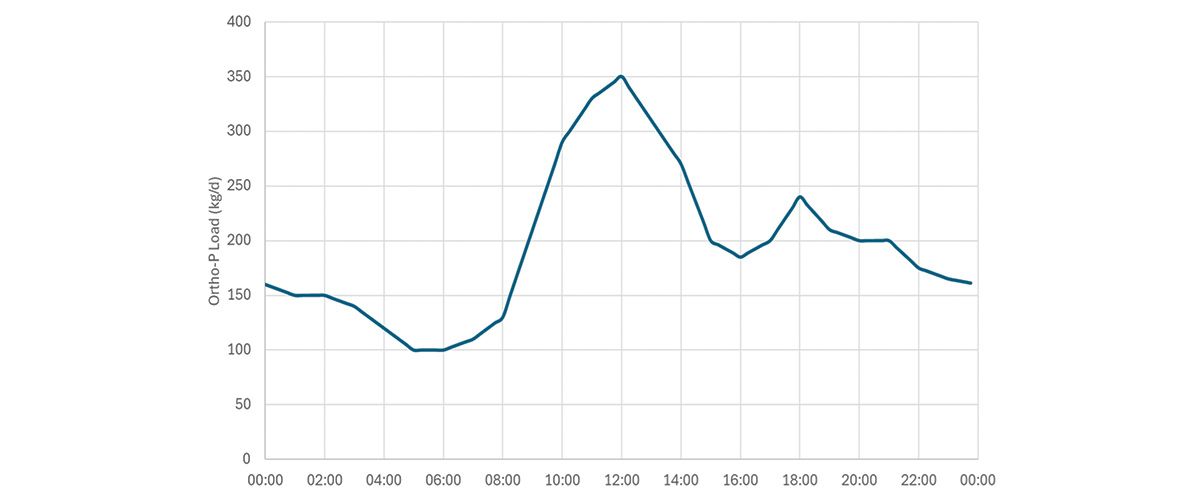

The primary ferric molar ratio dose providing optimal phosphate and iron control (~1mg/l orthophosphate and <20mg/l Total Iron concentrations in PST effluent), as determined during the Summer Completion Test, was 4.15 MR. For reference, the ‘as-commissioned’ diurnal orthophosphate base load profile is shown below.

Burnley WwTW: Orthophosphate diurnal load profile – primary ferric LUT set-points (as commissioned November 2024) – Courtesy of United Utilities

A summary of initial and subsequent primary ferric dosing MR dose ‘optimisation’ is provided below:

| 28 November 2024 | Dosing commences at 5MR | ||

| 11 December 2024 | Dosing increased to 6MR to target 1mg/l orthophosphate in PST effluent | ||

| 20 December 2024 | Dosing reduced to 5MR in response to ASP ammonia breakthrough spikes | ||

| 24 December 2024 | Dosing reduced to 4MR in response to ASP ammonia breakthrough spikes | ||

| 2 January 2025 | Dosing paused in response to observed ASP ammonia breakthrough spikes | ||

| 9 January 2025 | Dosing recommenced at 2MR | ||

| 11 February 2025 | Dosing increased to 3MR to target 1mg/l orthophosphate in PST effluent | ||

| 25 February 2025 | Dosing increased to 3.5MR to target 1mg/l orthophosphate in PST effluent | ||

| 6 March 2025 | Dosing increased to 3.75MR to target 1mg/l orthophosphate in PST effluent | ||

| 17 March 2025 | Dosing reduced to 3.5MR in response to ASP ammonia breakthrough spikes | ||

| 24 April 2025 | Dosing increased to 3.75MR to target 1mg/l orthophosphate in PST effluent | ||

| 30 April 2025 | Dosing paused in response to observed FST iron breakthrough spikes | ||

| 3 May 2025 | Dosing recommenced at 4.5MR following jar testing | ||

| 8 May 2025 | Dosing reduced to 4.15MR in response to jar test results | ||

| N/A | No primary ferric MR change since 8/5/25 | ||

Routine, minor, operational changes to the primary ferric dosing set-points will remain a business-as-usual activity associated with normal wastewater treatment works operation in the future; and most notably, in response to envisaged seasonal variation and catchment characteristics.

Caustic dosing: An initial set-point of 7.1 pH units was adopted for interstage pH process control upon commencement of the Summer Completion Test. This control set-point has been further optimised on occasion and in agreement with/request by United Utilities Operations to 7.15 pH units to either reduce chemical consumption or in consideration of prevailing final effluent alkalinity measured value.

Routine, minor, operational changes to the interstage pH setpoint considering prevailing final effluent pH and alkalinity will remain a business-as-usual activity associated with normal wastewater treatment works operation in the future.

Chemical dosing area – Courtesy of United Utilities

Liquid polyelectrolyte dosing: The ‘sweetening’ dose set-point of 25 l/h per FST has been retained and a storm event %FtFT trigger setpoint of 75% (in line with Evoqua recommendation). During periods of low FtFT, the 25 l/h ‘sweetening’ dose set-point results in the liquid poly system batching around four times per day; ensuring that a fresh, but matured, make-up solution is available at all times in readiness for flash increase in FtFT or prolonged storm event.

The poly dose proportional set-point has been gradually reduced to the current value of 0.6 mg/l as active product. It is noted that the product selection and amount of liquid polyelectrolyte dosed is subject to EA permitting and, as such, strict limits on maximum poly dose rate applies (currently 3.2 mg/l maximum as active product).

Further optimisation of the liquid poly ‘proportional’ dose process control set-points is not envisaged as necessary in the future.

New assets at Burnley WwTW – Courtesy of United Utilities

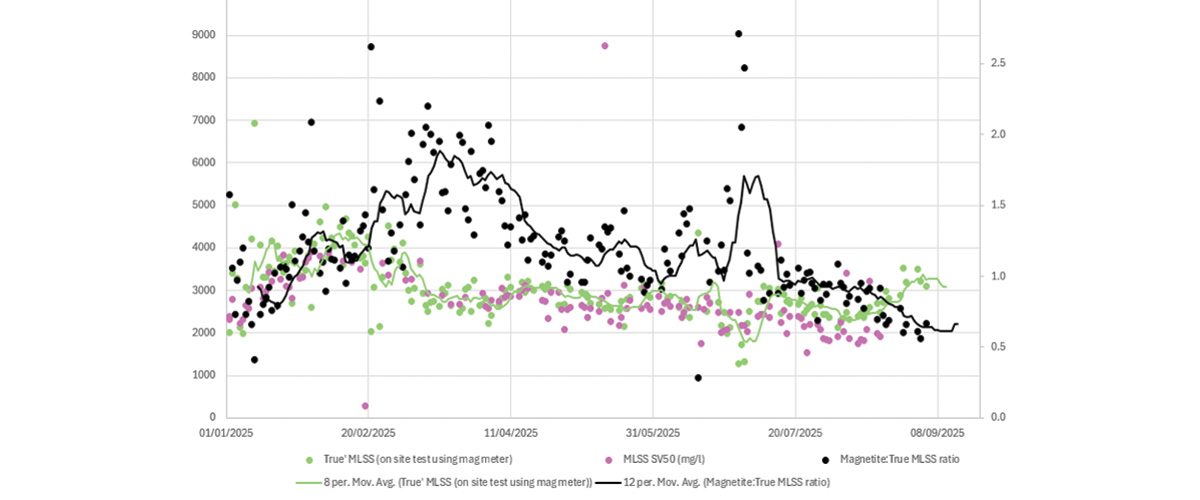

Magnetite addition & recovery: Magnetite, an iron oxide powder, is added to the activated sludge process via the BioMag® system to provide mixed liquor enhanced settleability in the final settlement tanks by microbiological floc ‘ballasting’.

The new works was operated during Q1 of 2025 to maintain the magnetite : MLSS ratio at the target of approximately 2:1, which was necessary to achieve the necessary mixed liquor settleability performance as measured by Specific Stirred Volume Index (SSVI).

Control to the target ratio is effected by management of magnetite ‘top-up’ addition, and in consideration of daily surplus activated sludge wastage volume, which relies upon having a disposal route for SAS. Mixed liquor settleability performance matured naturally during Q2 of 2025 and the magnetite : MLSS ratio was coincidentally reduced to target of 1:1 by the reduction of magnetite ‘top-up’ addition to the design anticipated amount of 500 to 600 kg/d.

The historic magnetite : MLSS ratio data is shown in the graph below. It can be seen that magnetite : MLSS ratio has trended down since the Summer Completion Test and as such, the ‘top-up’ magnetite loading set-point has been increased slightly to compensate.

Routine operational changes to the daily magnetite loading rate will therefore remain a business-as-usual activity associated with normal wastewater treatment works operation in the future.

MLSS minus magnetite (true MLSS) and true MLSS : Magnetite ratio on-site tests and laboratory results – Courtesy of United Utilities

Recycled activated sludge control: Further optimisation of the RAS control set-points was undertaken following the extended period of exceptionally dry and warm weather period during April-June 2025. During this dry weather period the RAS flow rate was maximised to design limitation of 1,040 l/s to best manage potential for denitrification within the FSTs and avoid rising sludge and scum formation where possible. RAS control to ‘FtFT Mode 1’ was adopted for control of RAS flows during the Summer Completion Test in accordance with a three-tiered banded philosophy as follows:

| FtFT flow (l/s) | RAS flow (l/s) |

| <600 | 400 |

| >600 <1000 | 600 |

| >1000 | 750 |

The RAS control system has operated stably for many months, and no significant further optimisation is envisaged. However, routine operational changes to the RAS control rate or mode of operation will remain a business-as-usual activity associated with normal wastewater treatment works operation in the future.

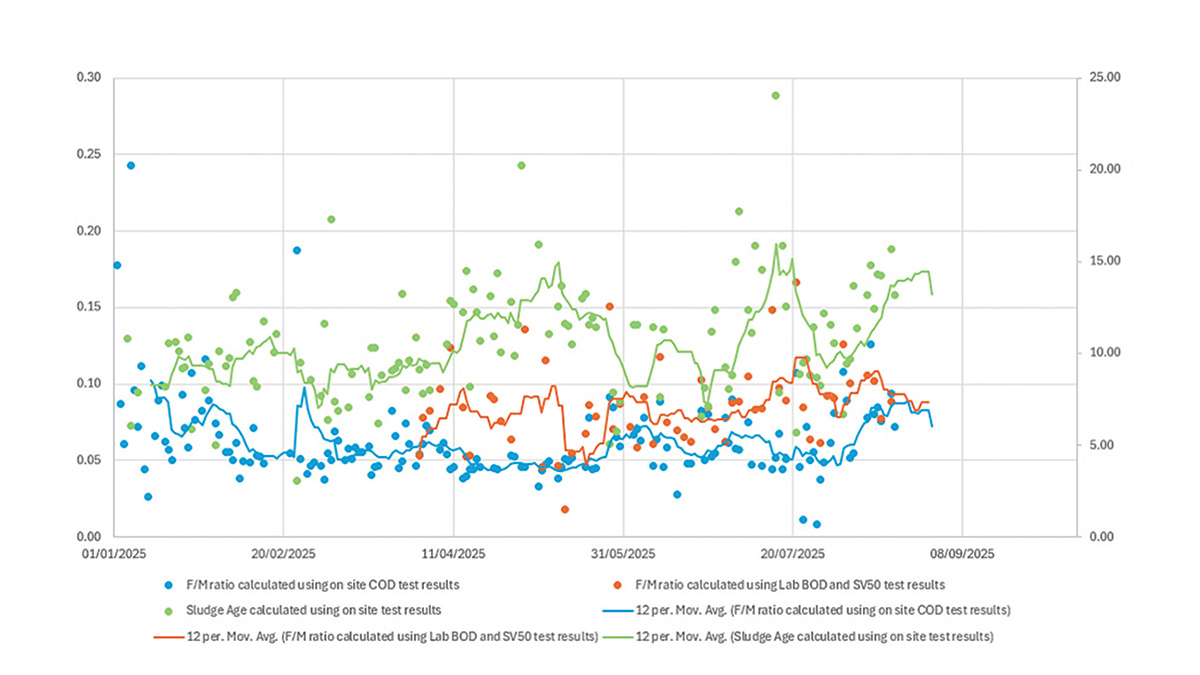

Activated sludge plant: Routine control of MLSS concentration has remained by the conventional method of monitoring food to micro-organism ratio (F/M) to the design target ~0.08d-1, by assessment of sludge age against target of ~14 days and then by manual adjustment of the surplus activated sludge daily wastage volume.

Routine monitoring of the biological load on the ASP and as-required operational changes to the daily SAS wastage volume to maintain F/M ratio and sludge age within an acceptable range will remain a business-as-usual activity associated with normal wastewater treatment works operation in the future. The historic F/M ratio and sludge age data is shown below.

F to M ratio and sludge age – Calculated using on-site tests and laboratory test results – Courtesy of United Utilities

Similarly, routine microscopic analysis has been undertaken by UU labs to monitor and track filamentous (and other indicator bacteria) abundance.

Summary/conclusion

The Summer Completion Test was carried out by Advance-plus over a 28-day period between 21 July and 18 August 2025. From the test results, it is concluded that the new works has successfully demonstrated compliance with the requirements of:

- CT1: Final effluent water quality compliance with site WRA Regulatory Permit limits for BOD, TSS, ammonia, Total Phosphorus, Total Iron and pH. The final effluent water quality adequate compliance with asset standard for alkalinity residual (noting routine pH set-point change made during completion test in response to slight reduction in background alkalinity).

- CT2: Final effluent water quality compliance with site UWWTD Regulatory Permit limits for BOD and COD.

- CT3: Final effluent water quality compliance with site UWWTD Regulatory Permit limits for Total Phosphorus.

- CT4: Magnetite recovery rate of the BioMag® process.

Landscaping work at Burnley WwTW - Courtesy of United Utilities