Stromness Wastewater Network (2019)

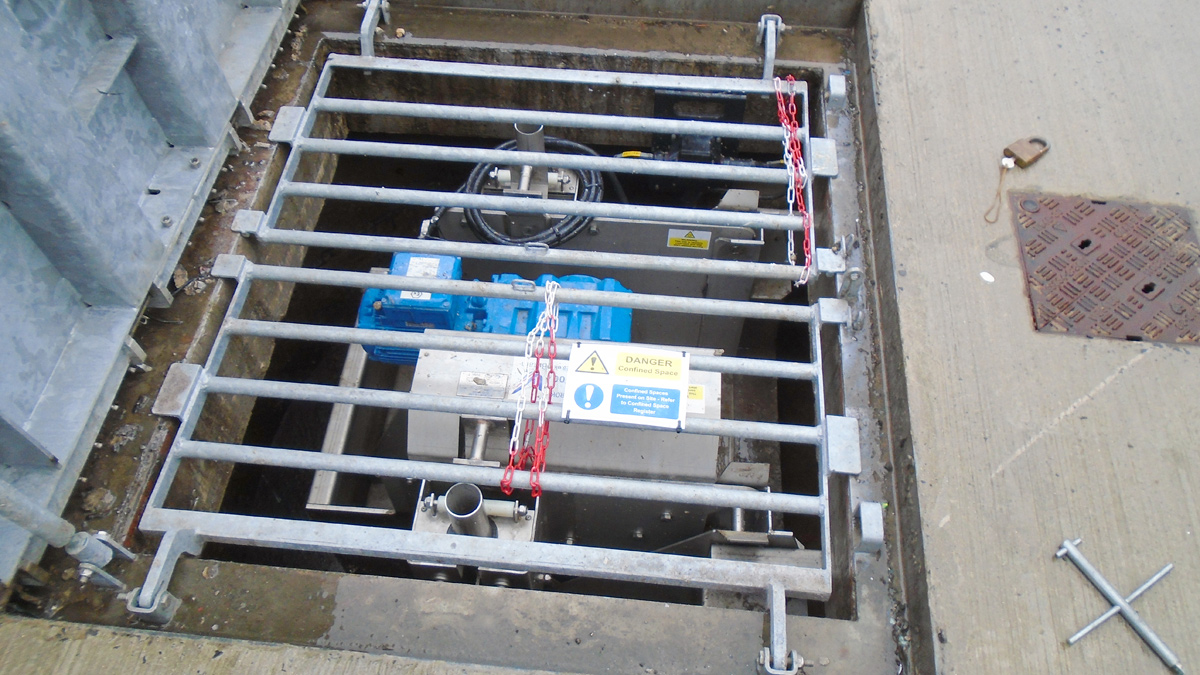

Login’s Well during CSO/EO installation - Courtesy of aBV

Stromness is a town situated around the sheltered bay of Hamnavoe on the west of Orkney’s mainland. It has a population of approximately 2200 inhabitants and a population equivalent (PE) of 2,600, due to the local industry; which is expected to grow to 3,600 in the years ahead. The town has a dramatic and unique vista because of the tightly packed traditional stone buildings that are orientated gable-end on between the adjacent main street and sea front. Situated between the buildings are numerous narrow roads and walkways which allow people to access from the winding main street to the small piers and cobbled boat slips (nousts) which make up the stunning Stromness harbour front.

Background

In the 1980s and 1990s, work was undertaken to reduce the undesirable discharge of raw sewage to this harbour. This initially led to a number of wastewater pumping stations (WwPSs) being built and these new WwPSs served to pass a large majority of the town’s wastewater along the harbour front to the terminal pumping station at Garson, where flow was then pumped over the headland to a new WwTW situated at Bu Point.

The latest phase of the improvement works, Phase 3, as part of the Urban Wastewater Directive, is required to further reduce the pollution from the existing Wastewater Network to the surrounding recreational waters within Stromness Harbour. The scope of work required to meet this need consists of:

- Removal of 6 (No.) uncontrolled, unscreened wastewater discharge points.

- The installation of 4 (No.) new WwPS along with associated rising and gravity mains.

- Installation of 6mm 2D screens for 11 (No.) PS emergency outfalls and combined sewer overflows (CSOs) – 4 (No.) at new WwPSs and 7 (No.) at existing WwPSs.

- Works at Bu Point WwTW to allow for any increase in screenings and loading.

- The construction of 6 (No.) new outfall pipes.

- Approximately 300m of 125mm water main re-routing/enabling works.

Graham Place WwPS – Courtesy of aBV

Phase 3 improvements

The extent of the Phase 3 improvement works to improve the water quality in Stromness Harbour was developed by Scottish Water (SW), and their associated design consultants. After the final scope of improvement works was fully defined, the project was handed over to SW’s Wastewater Infrastructure Alliance partner, aBV, a joint venture between Amey and Black & Veatch (now Binnies). aBV then went about undertaking the final design, estimating and delivery of the project in 2015.

Process, hydraulic modelling & design work

Network design: The main design work associated with the upgrading of the Stromness Wastewater Network relates to the sizing on the new CSOs and new WwPSs. With the inclusion of 4 (No.) new WwPSs installed, and the existing WwPSs upgraded to include the newly combined CSO structures, the system can transfer most of the foul, and some of the storm flow, along a chain of WwPSs to the termination WwPS at Garson.

To establish the storage volumes required of each of the new and upgraded WwPSs, and to calculate pump sizing and screen selection in compliance with the required specifications and environmental regulations, InfoWorks database modelling was undertaken. This was carried out by SW’s sub consultant Jacobs in 2014, and by using the PE for each of the local sub-catchments, the modelling data was able to establish the new storage volumes required at each of the WwPSs and CSOs. The modelling works were also undertaken to confirm the frequency and spill volumes expected from each CSO, as well as being used to establish the screen type (static or mechanical) required at each site.

Bu Point WwTW with new inlet screen and grit system – Courtesy of aBV

Mechanical electrical & inter-site connectivity design: Additional power supplies were provided by the DNO to the new control kiosks built at the 4 (No.) new WwPS sites. At the existing WwPSs where the new powered CSO screens were to be installed, the existing MCC kiosks were too small, and didn’t provide enough space to accommodate the new CSO panels. This resulted in the aBV design team developing a design solution of removing the existing MCC panels and installing new separate and smaller panels to act as starters for both the existing pumps and the new CSO screen drives. The MEICA installation and replacement works required the use of temporary over pumping to manage the flow during electrical changeover and the work were undertaken by RS Merriman.

To maintain compliance with SEPA regulations relating to the emergency storage provided within each of the WWPSs and associated CSO structures, a control system had to be developed and installed which would inhibit the transfer of flow from any of the upstream WwPS, when the receiving WwPS had failed. Working alongside aBV’s MEICA design team and SW’s Telemetry Team, a Private Wire system using BT’s M2M is to be installed so that connectivity between all sites can be maintained.

Navigation School storm screen and access cover – Courtesy of aBV

Civil infrastructure: With the storage volumes and screening requirements established, the design teams undertook the challenging work of designing combined WwPS and CSOs structures at several of the sites. This part of the design work was made difficult due to the tight spatial constraints that existed on the small nousts and piers where the new structures were to be built. The design challenges were further exacerbated at each site because of the narrow pathways and limited access available, which greatly reduced the size and type of machinery which could be used to excavate and aid general construction activities throughout.

Due to these unique challenges, the aBV design and delivery team undertook in-depth buildability reviews to establish the optimum design arrangement at each site, factoring in:

- The risk of damage to adjacent and historic structures.

- The ability to install appropriate temporary works.

- The ability to transfer the required materials and install appropriate temporary over pumping.

Construction of Well Park WwPS – Courtesy of aBV

The design and delivery teams also worked closely with Huber Technology, who developed 3D drawings of the new CSO structures. This allowed the screens and support metalwork to be adequately designed based on the space available, with the information then passed to SW’s framework cover supplier EJ, who developed covers designs which removed any possibility of clashes occurring between the 6mm 2D storm screens, and some of the drop-down support beams of a number of the new covers.

Transfer of flows and upgrade to WwTW

Due to the increase in flow generated in the catchment with the inclusion of the 4 (No.) new WwPSs, process calculations were undertaken to establish the capacity of the existing WwTW to treat the additional flow and load. Although the works’ process was assessed as being capable of dealing with this increase, SW’s specifications confirmed that the current inlet works’ single screen was no longer compliant and that a new mechanical screen, along with a grit removal system would have to be installed.

Well Park WwPS complete – Courtesy of aBV

As part of the up-front design works undertaken to develop this new screening unit, it was established that a 250m section of the gravity sewer just upstream of the works, fed directly by the pumped flows from Garson, could be altered to act as a pressurised main. This would allow flows to transfer directly between Garson and Bu Point WwTW, without firstly having to pass through the WwTW’s inlet lift pumping station.

As part of the detailed design works, static state hydraulic calculations were undertaken, and HAZOP reviews were carried out with SW to confirm the validity of the overall proposal.

To physically change the existing 300mm dia gravity pipe into a smaller pressurised main capable of generating suitable self-cleansing velocities within the pipe, a 250mm diameter InsituMain® cured in place pipe (CIPP) liner was inserted into the host pipe. The liner was installed using water cure technology to provide enough head to invert the liner. Once fully inverted, water was circulated within the liner based on a pre-defined curing schedule for this specific project.

The overall Civil infrastructure mods required at the WwTW to facilitate the installation of the new screen were carried out by aBV’s sub-contractor Sinclairs. The new Ro9 6mm 2D screen and grit removal system was supplied and installed by Huber and the new CIPP was installed by Insituform.

The upgrade to the existing electrical installation to accommodate the new Ro9 plant was carried out by RS Merriman.

Stromness Wastewater Network: Supply chain – key participants

- Client: Scottish Water

- Wastewater infrastructure alliance partner: aBV (an amey-Black & Veatch (now Binnies) joint venture)

- CSO screening: Eliquo Hydrok Ltd

- 6mm screens: Huber Technology

- Sea outfalls design: Black & Veatch (now Binnies)

- Sea outfalls: Leask Marine

- Civil engineering: Andrew Sinclair Ltd

- CIPP Liner: Insituform

- MEICA: RS Merriman Ltd

- Telemetry: IDSystems UK

- M2M: BT

Merriman’s noust during construction – Courtesy of aBV

Emergency overflow & CSO spill pipes

To transfer intermittent storm spills to the harbour in compliance with SW’s new discharge licenses for all 11 new and modified sites, 6 (No.) new small-bore outfalls pipes with discharge points placed below Mean Low Water Springs were installed.

The outfall pipe designs were governed by a few factors including:

- The maximum allowable curvature of the PE outfall pipes.

- The need to limit excavation into the beach/sea bed.

- The invert start level in the landward manhole.

- The need to maintain a positive gradient to avoid silt accumulation and build-up of air in the pipeline.

The end of the outfalls needed to be positioned high enough to mitigate the risk of blocking by movement of beach material within the harbour but low enough to comply with the conditions of the environmental permit.

A key aspect of the outfall pipeline design was ensuring stability of the pipeline during storm conditions. This is often done by burying the pipe under the sea bed, but rock outcropping on the beaches within Stromness harbour made this difficult. Outfalls laid on the sea bed, protected and enclosed by rock armoury were first proposed as an alternative but these were viewed as too costly by the marine contractor. Concrete mattresses were therefore proposed as these could be placed on top of the outfall pipes in a more efficient and cost saving manner.

As part of the overall solution, the outfall pipeline designers from aBV designed the outfall pipe to include concrete collars which could be placed on the pipe such that it could be floated into position with the pipe full and then lowered to the sea bed by filling the pipe with water. Further concrete ‘kennel’ weight blocks were then included to be placed over the length of each pipe, together with concrete mattresses, which collectively provide the necessary weight for the stability of the pipe in storm conditions.

Finally, concrete scour protection was provided around the end anchor block of the outfall and diffuser to prevent subsidence and movement due to the natural scour on the sea bed. The scour protection also avoided erosion of the sea bed due to the discharge flow from each of the outfalls.

Ness Road – Courtesy of aBV

Conclusion

Community engagement was key to reduce the impact of the construction works on the local community where possible. SW and their alliance partner aBV, liaised with local community leaders and local residents prior to and throughout all the main construction activities, keeping overall disruption to a minimum. With the new wastewater infrastructure installed and commissioned, the cleanliness of the surrounding recreational waters has been improved to the benefit of all within the local community.