Central Borders Strategy (2024)

New Howden CWT under construction - Courtesy of ESD

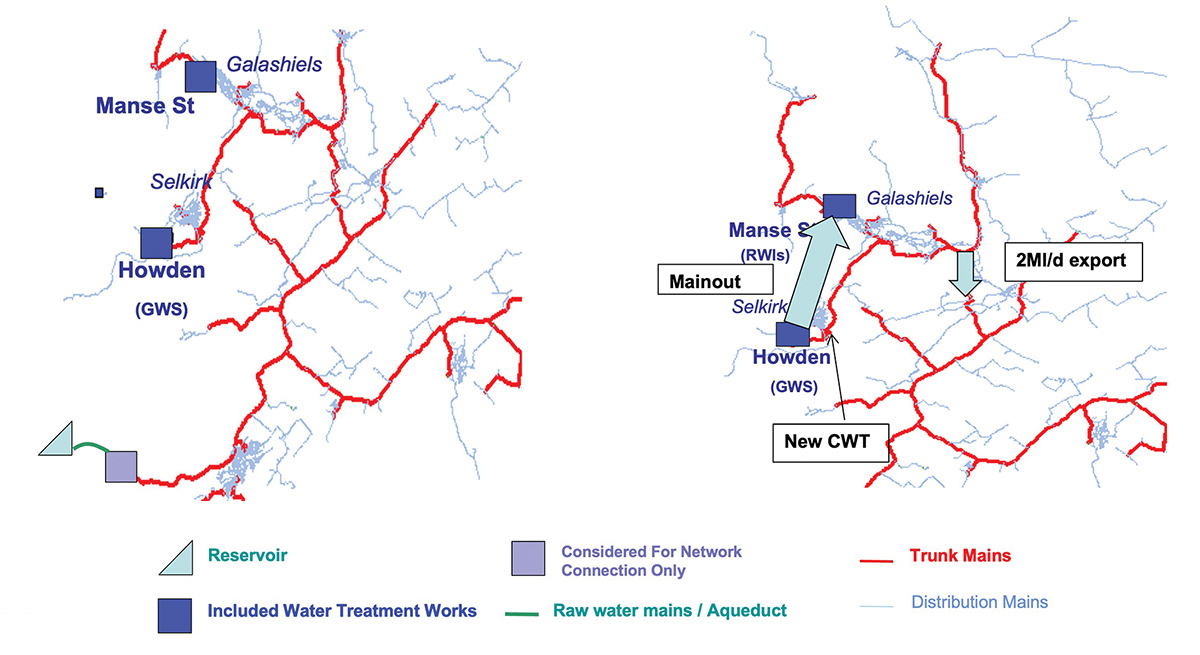

Located in the heart of the picturesque Scottish Borders, the towns of Galashiels and Selkirk are central to a significant upgrade of the region’s water infrastructure. Galashiels, situated approximately 38 miles south-east of Edinburgh, serves as a vital hub for the surrounding rural communities. In line with Scottish Water’s vision, the £30m Borders Central Strategy focuses on improving water quality and reliability in these communities by transforming Galashiels’ Manse Street Water Treatment Works into a Distribution Service Reservoir site only and enhancing Selkirk’s Howden WTW’s borehole supply and treatment output to serve over 20,000 houses and business premises. The construction includes a new 12 ML clear water tank, 7 miles of 400 mm HPPE main, and significant upgrades to Howden WTW; promising to support the region’s growth and resilience for years to come.

The need for improvement

Manse Street WTW was built in 1964 and has a capacity of 5 ML/D; equivalent to two Olympic sized swimming pools. The process consisted of an inlet clarifier, four RGFs and associated backwash equipment (backwash pumps, blowers and dirty wash water system), and poly, caustic and sodium hypochlorite dosing. Since the 1960s there has been no significant capital maintenance and plant operation is reliant upon significant manual and knowledgeable operator input. Manse Street WTW has eight outputs with risk concerns of contaminant breakthrough due to process issues with the filter backwashing, flocculation formation, and clarification.

Completed access road to new CWT – Courtesy of ESD

Howden WTW was built in 2000 and in 2009 a membrane stage was added. The setup is comprised of four abstraction boreholes (duty/assist/assist/standby), a membrane package plant including six membranes, CIP cleaning plant and equipment, sodium hypochlorite and orthosphoric acid dosing, contact tank and four high lift pumps. Howden’s design capacity was 16 ML/D although it only ever managed a peak flow of 12.5 ML/D due to issues with raw water quality and limitations of membranes performance.

The average demand is 8-9 ML/D and the clear water tank (CWT) was undersized at only 5 ML and required significant repairs.

The Central Borders Strategy Project aims to address these issues by upgrading Howden WTW to meet a demand of 16.2 ML/D that will enable a main out of Manse Street WTW in addition to providing additional capacity in the Central Borders Supply Network for the 25-year growth design horizon that is anticipated.

Scottish Water’s Non-Infrastructure Alliance Partner, ESD (a joint venture between MWH Treatment, Binnies, and Galliford Try), started the design of the £30m project started in June 2018 and work commenced on site in February 2020.

Process selection

Studies to assess and identify potential solutions to tackle the issues and optimise delivery demand were undertaken, with each scenario also considering the optimum solution for neighbouring areas. The following were considered for Howden and Manse Street:

- Maintain and enhance Manse Street and Howden.

- Main out Manse Street from upgraded Howden.

- Main out of all WTWs from new Peebles works.

- St Mary’s Loch.

- Main out Howden from new enhanced Manse Street.

Options 1 and 5 were deemed too costly and had significantly more risks for a successful outcome, while Option 3 was discounted due to negative impact on Edinburgh and Lothian yield. Option 4 had a lower yield of only 13 ML/d versus demand of 16 ML/d for Howden and Manse Street.

Option 2 was selected as it best fit the demands of Scottish Water’s SR15 framework drivers, being able to deliver the capacity needed with a lower anticipated cost.

(left) Geographic extent overview and (right) Option 2: the chosen solution – Courtesy of Scottish Water

Central Borders Strategy: Supply chain – key participants

- Client: Scottish Water

- Principal designer & contractor: ESD

- Pipeline & tunnel design: Caledonia Water Alliance

- MGroup

- AECOM

- Excavation works: RJT Excavations

- Construction: Careys

- Pipe construction: AG Wilson

- Borehole pump changeover & pipework: Dustacco Engineering Ltd

- Pipework: Alpha Plus Ltd

- Borehole pumps: Wilo

- Actuators: Rotork Controls

- Air compressors: Kerr Compressors

- Membranes: DuPont Water Solutions

- Membrane feed pumps: Grundfos

- Systems integrator: IDS

- Systems integrator: Lintott Control Systems

- Systems integrator: Saftronics

- Electrical: ICL

- Electrical: Main Electrical Ltd

- Pipework & metalwork (Howden CWT): AJ Engineering & Construction Services Ltd

- Cryptosporidium unit: Watercare Systems Ltd

- GRP kiosks: Kingsley Plastics

- MCC: Lintott Control Systems Ltd

- PE pipes: FPP Ltd

- Gate valves & pipe fittings: AVK UK Ltd

- Metalwork (Howden WTW): Archibald McAulay & Son Ltd

- Metalwork (Manse Street): GT Fabrications

- Metalwork (Manse Street): Homer Burgess Ltd

- Security & fire systems: Pointer Ltd

Overview of process and scope

The existing treatment works at Manse Street, Galashiels is to be closed and decommissioned to create a Distribution Service Reservoir (DSR) site only. Meanwhile an increased borehole and treatment output being installed at Howden WTW, means larger sections of the customer network will be fed from the Howden WTW into a new clear water tank to replace the 5 ML Thornbush Quarry tank. This project will be supported by upgraded infrastructure, including new main laying from Howden-to-Howden new tank to Manse Street.

New water tank at Howden WTW – Courtesy of ESD

The Borders strategy was split into 4 key projects outlined below:

Galashiels WTW

At Galashiels, the existing works, including the raw water source, will be decommissioned and abandoned along with the nearby Thornbush CWT once the new upgrades at Howden and Manse Street are operational and fully integrated. The following tasks to accomplish this at Galashiels, undertaken by ESD, are outlined below:

- New MCC and standby power generator to replace ageing asset.

- Construction of a new twin compartment 12 ML CWT nearby Galashiels and Howden replacing Thornbush CWT, known as the new Howden CWT. With the CWT compliant with all security requirements.

- Installation of associated valves and overflows, scour pipework, flow meters, and connections into three transfer/distribution mains.

- Installation of a new kiosk housing quality instruments, level instruments, flowmeter display, telemetry

- Install a new power supply to the instrument/telemetry kiosk.

- Decommission the existing Thornbush Quarry CWT, TWS power, instrumentation and existing security

- Conversion of Manse Street WTW to a DSR within the existing treatment site a new standby, decommissioning of the supply transformer, generator and telemetry.

Improving resilience of supplies

The pipework installation to tie all the works together and deliver the Central Borders Strategy was led by Caledonia Water Alliance; Scottish Water Alliance’s Partner. The works included:

- Pipelaying 11.55km of 400mm HPPE main from Howden to Manse Street Clear Water Tank/Distribution Service Reservoir.

- Upsize 400m of the Central Borders Trunk Main from upstream of Melrose DSR to 350mm HPPE.

- Lay new gravity fed 400mm HPPE main to cater for a 5.56 ML/D (3.24 M/LD from current Manse Street site plus an additional 2.12 ML/D for the re-zoned).

- Abandon the existing 300mm supply pipe from Manse Street.

(left) Borehole set up and (right) CWT valve chamber – Courtesy of ESD

Howden WTW upgrades

At Howden WTW, the following improvements to upgrade the existing WTW capacity from 12.5 ML to 16.2 ML were undertaken by ESD:

- Replacing a pump in Borehole No. 2 with a 10 ML/D pump.

- Replacement of the existing scour and supply valves on each borehole wellhead and the installation of electronic actuators to enable automated scouring of the boreholes.

- Construction of new brick built walk-in enclosures over each wellhead to replace the existing chambers.

- Installation of a 300m3 raw water tank to buffer flows from the borehole pumps to the membrane plant. The borehole pumps are to operate on level control.

- Installation of three membrane feed pumps in a duty/assist/standby arrangement to feed the membrane plant from the raw water tank.

- Construction of a new membrane treatment building to house additional membrane units.

- Installation of three additional membrane units (3 x 48 (No.) L20N modules) to increase the current number of units to nine.

- Alterations to the membrane plants ancillary components to include increasing the capacity of the air system by installing an additional compressor, installing sodium hydroxide and sodium bisulphate for chemical neutralisation removal of the existing GAC neutralisation system, and increasing the heating capacity of the existing CIP tank.

- Installation of flow meters, relocation of the site boundary security fencing, alterations to power and control cabling PLC and SCADA modifications.

(left) Membrane feed pumps and (right) expansion to membrane plant – Courtesy of ESD

Howden WTW chloramination

Another project to ensure quality at Howden WTW was installation of an ammonia sulphate dosing skid. This system will be housed in a walk-in kiosk. The chemical will be dosed downstream of the chlorine contact tank (CCT) and upstream of the high lift pumps. The overall components of the chloramination dosing plant include:

- Storage tanks.

- Dosing pump skid.

- Fill point.

- Carrier water header tank.

- Carrier water pumps.

- Motor control center (MCC).

- Dual-contained dosing lines (duty/standby).

- Dosing static mixer.

- Sampling equipment.

- Chemical spill tank.

- Associated pipework and instrumentation.

Project challenges

Howden’s construction phase began just before the onset of the COVID-19 pandemic, which brought unprecedented challenges.

With the implementation of social distancing measures, lockdowns, and restrictions on workforce movement, the project faced significant delays and disruptions. The team had to quickly adapt to new health and safety protocols to ensure the safety of all workers, which included staggered shifts, remote coordination, and strict sanitation practices.

Implementing the SCADA system posed substantial difficulties as the existing chip needed to be replaced due to incompatibility issues with the new installations due to age. Ensuring seamless communication between various components and achieving real-time data acquisition was challenging. The technical intricacies and need for precise calibration and testing led to additional time and resource investments. Following this, there was a 12-month delay for the Siemens’ chip needed for the new system, due to the Ukraine-Russia war. This delay significantly impacted the project’s timeline, necessitating adjustments in the scheduling and prioritisation of other project activities.

New South Common CWT and valve chamber – Courtesy of ESD

Successes

- The new clear water tank stores water and monitors the quality before it goes into the supply. It also provides additional resilience to the network by providing additional storage to supply the area.

- The Howden Membrane upgrades increased membrane plant surface area allowing for increased treatment and production capacity from 12 ML/D to 16 ML/D.

- Leveraging off-site construction, when possible, allowed for precise, high-quality prefabrication of components in a controlled environment. This minimised on-site disruptions, reduced construction time and enhanced safety. Prefabricated elements were seamlessly integrated into the site, improving efficiency and sustainability by lowering emissions and waste.

- Weekly coordination meetings between Scottish Water (the client), ESD (for Galashiels and Howden WTWs), Caledonian Water Alliance (for infrastructure and pipe implementation) and other stakeholders were instrumental in ensuring the project’s smooth progression. These meetings facilitated effective communication, timely resolution of issues, and alignment of project goals, contributing to the overall success of the water infrastructure upgrade.

- The groundworks at the CWT site demonstrated exemplary resource utilisation. Materials excavated during construction were crushed, regraded into different sizes, and reused effectively. This not only reduced waste but also minimised the environmental impact and lowered material costs.

- At the Galashiels Manse Street site, the installation of a Hush Pod for the generator significantly reduced noise pollution. This implementation was particularly important for maintaining community relations and adhering to noise regulations. The Hush Pod ensured that the generator operated efficiently without disturbing the surrounding residential areas.

- Adherence to Scottish Water’s DOMS and TOMS Protocols, and working closely with Scottish Water’s Public Health Team ensured water quality compliance and avoidance of any issues while interfacing with a live water treatment works (Howden WTW) and distribution network (Howden CWT including inlet and outlet pipework).

The completed Howden CWT – Courtesy of ESD

Status

Howden’s chloramination project began in 2016 and was completed in 2019. The additional enhancements at Howden WTW, which commenced in 2020 alongside the Galashiels project, are both expected to be completed and operational by winter 2024.

The pipeline is currently undergoing the final stages of commissioning with the aim to commence the final flushing and sterilisation in November 2024 to allow the main out of manse street water treatment works.

- Client: Scottish Water

- Project delivery (WTWs, CWTs, pumping stations etc): ESD

- Project delivery (pipelines and tie-ins): Caledonia Water Alliance

- Project cost: £30m

- Design start date: June 2018

- Construction start: February 2020

- Completion: October 2024