Dewsbury WwTW (2025)

The three new 45m diameter primary settlement tanks nearing construction completion - Courtesy of SkyCam®

Dewsbury WwTW is located to the south-east of Dewsbury, approximately 10 miles south of Leeds and services a population equivalent of 286,527 (including trade effluent). The treatment works has undergone a major upgrade as part of the AMP7 WINEP programme to provide suitable wastewater treatment for the predicted population growth to 289,234 by 2035. In addition, the works has been upgraded to implement enhanced biological phosphorus removal to ensure compliance to a new phosphorus consent limit of 0.5mg/l in the final effluent; improving 5.8km of the River Calder.

Existing works

Dewsbury WwTW receives catchment area raw water flows via low lift screw pumping station, where flows in excess of Flow to Full Treatment (FtFT) enter two storm tanks through the screen chamber, grit removal chamber, and storm pumping station. Storm returns are pumped upstream of preliminary treatment.

The preliminary treatment consists of an inlet works with coarse screening, storm tanks, fine screens, and bridge-driven detritors. There are three waste compactors installed at the inlet works, with one compactor for the two duty/standby 25mm 1D coarse screens and two compactors for the four duty/assist/assist/standby 6mm 2D travelling fine screens.

Screenings are transferred to the screening handling unit via one of two screw conveyors, and flows continue to the primary settlement tanks (PSTs). The existing works utilised 12 rectangular and two circular primary settlement tanks, activated sludge plant (ASP) lanes and humus tanks. There are also trickling filters and a biological aerated flooded filter (BAFF) plant; both of which are to be abandoned as part of the project upgrade.

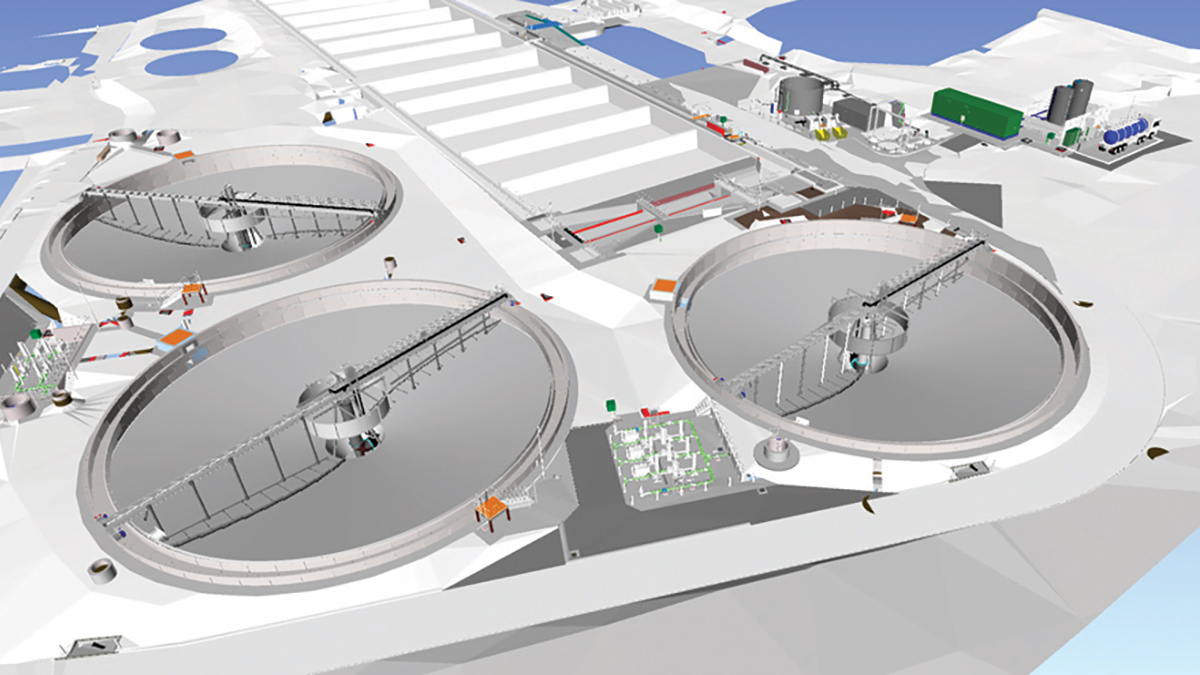

BIM model of Dewsbury PSTs – Courtesy of Barhale Enpure JV

Undertakings

In May 2023, Yorkshire Water awarded the contract for the £20m Dewsbury STW Upgrade Project to BEJV (a joint venture between Barhale and Enpure Ltd). The process, mechanical, electrical and ICA design was undertaken in-house by Enpure Ltd. The civils design was carried out by Barhale’s internal design team and their external civils consultancy, Pick Everard.

Dewsbury STW: Supply chain – key participants

- Main designer & contractor: BEJV

- Civils: Barhale

- Process & M&E: Enpure Ltd

- Civil design: Piick Everard

- Electrical installation: Circle Control & Design Systems Ltd

- Mechanical installation: Staptina Engineering Services Ltd

- Precast concrete PST tanks: Shay Murtagh Precast

- PST scrapers: JBF Group

- Sludge RAM pumps: EMS Industries Ltd

- Valves: Cotswold Valves Ltd

- Ferric dosing: IIES (Northern) Ltd

- Ferric storage tanks: Forbes Technologies Limited

- Hose reels: Arco Ltd

- Safety showers/eyebaths: Aqua Safety Showers International Ltd

- Trace heating & lagging: Jade Insulation

- SCADA & Telemetry: Saftronics Ltd

- MCC/PLC/HMI: Mitsubishi

- Flow meters & level transmitters: ABB Ltd

- Waste flow chamber & MCERTS: SIRIS Environmental

- Suspended solids transmitters: Hach

- Pressure instruments: IFM Electronics

New PST Inlet flow splitter chamber built within the existing redundant PST structure – Courtesy of Barhale Enpure JV

Scope of works

Works included the following upgrades and refurbishments:

Flow measurement

A new GRP U-MON4 and MCERTS compliant inlet flume/flow measurement system has been installed within the refurbished existing PST inlet channel that measures the FtFT to Dewsbury; considering pumped flows from both the Ossett Spa and Spenbrough catchments.

Primary settlement tanks

Three new 45m diameter radial primary settlement tanks have been constructed using precast concrete sections supplied and installed by Shay Murtagh Precast. At 6,500m³ capacity, the new PSTs are the largest in Yorkshire and among the largest in the UK.

Concrete was poured in concentric rings for precise curing and reduced carbon emissions – Courtesy of Barhale Enpure JV

Constructed using post-tensioned precast concrete walls, reducing the wall thickness from 300mm to 200mm cut concrete and steel volumes by a third and reduced embodied carbon by 48%.

Each tank was erected in just five weeks, with lessons learned from the first tank enabling a two-month programme reduction for the subsequent two.

New de-sludging and scum removal systems have been installed along with a new PST distribution chamber. A screened sludge rising main was designed as a dual-contained pipe to comply with the Industrial Emissions Directive. Developed in collaboration with Georg Fischer, this 280/450mm pipe was a UK-first for its size and specification.

Manufactured by JBF Group in Wrexham, the rotating scraper bridges were delivered in three modular sections for rapid and safe assembly. Installed within the newly constructed precast concrete tanks, at 45m the bridges are amongst the largest in the UK.

The scraper bridges operate continuously, scraping settled sludge towards the central hopper, from which it is extracted at a concentration of 3-6% dry solids. This process is initiated by the programmable logic controller (PLC) based on either time or the level detected by the sludge blanket detector, utilising five positive displacement RAM pumps.

The 45m full bridge scrapers from JBF Group – Courtesy of SkyCam®

The PST scrapers are full-bridge, rotating at approximately one revolution per hour. The bridges can be accessed by using a parking switch which docks the bridge at the fixed access platform (half-bridge access to the bridge-mounted local control panel). In the event that access to a PST scraper bridge is required more urgently, they are also equipped with the facility to attach a bespoke lightweight access ladder with a safety interlock that prevents to bridge from continuing to rotate.

A new primary settlement tank motor control centre (MCC) was supplied complete with PLC in a kiosk built off-site.

Sludge removal

The sludge removal RAM pumps have been supplied by EMS Industries Ltd. These pump settled sludge for further treatment via the site’s existing infrastructure (gravity belt thickeners and centrifuges); thickening the sludge to approximately 18-20% DS prior to removal from site by road.

Due to the size of the primary settlement tanks, the five RAM pumps are split across two pumping stations, with two pumps dedicated to PST1 (duty/standby) and three pumps dedicated to PST2 and PST3 (duty/standby/standby). The floating scum is also scraped off the top of the PSTs into a scum hopper via scum draw-off chambers, that are also emptied (initiated on level) by these same RAM pumps. The PLC ensures that only one RAM pump ever runs at any one time in order to control and limit flows to the digester.

Positive displacement RAM pumps from EMS Industries – Courtesy of Barhale Enpure JV

PST distribution chamber

The newly designed primary settlement tank distribution chamber was modelled using computational fluid dynamics (CFD), and was designed and constructed within the boundaries of the redundant rectangular PST12. The new PST distribution chamber ensures an equal hydraulic flow distribution to each of the three PSTs through the implementation of weirs; allowing for future expansion to accommodate a fourth PST if required.

Chemical dosing

Two externally mounted 40m3 ferric storage tanks were installed in a new concrete bund along with a new chemical delivery area including interlocked loading points and a safety shower/eyebath from Aqua Safety Showers International Ltd.

To achieve the new phosphorus permit of the 0.5mg/l, ferric sulphate (12%) is dosed immediately downstream of the inlet flume and prior to the splitter chamber to the new PSTs. The new assets are typically achieving 75-80% phosphorus removal across the PSTs with the remainder of the P removal taking place in the ASP/humus tanks.

The chemical dosing system (excluding the external storage tanks) was all manufactured to the Yorkshire Water standard design by IIES (Northern) Ltd and brought to site pre-installed in an off-site manufactured building which was then craned into position onto the pre-prepared civils base with a cable trench below.

The new Mitsubishi motor control center (MCC), programmable logic controller (PLC), human machine interface (HMI) and telemetry system supplied by Saftronics Ltd) are also installed in this same kiosk in a dedicated MCC room; keeping it separate from the chemical dosing pumps.

Chemical dosing area: Off-site manufactured kiosks and storage tanks – Courtesy of Barhale Enpure JV

Digital delivery & safety

Digital tools played a central role in streamlining delivery and enhancing safety. A drone-conducted point cloud survey enabled the creation of the BIM and Digital Twin model, which was used to visualise construction sequencing and rehearse operations with stakeholders. Oculus virtual reality headsets facilitated immersive planning sessions, improving stakeholder engagement and operational readiness.

Artificially Intelligent Human Form Recognition (HFR) systems were integrated into machinery to provide real-time proximity alerts, significantly enhancing site safety. This innovation contributed to over 240,000 hours worked without a single injury, LTI, or RIDDOR incident.

Process optimisation

The treatment process was rationalised to divert 100% of flow to the existing activated sludge process (ASP), enabling the decommissioning of aging assets and reducing energy consumption by over 1,600 MWhr/year.

Digital hydraulic modelling supported this optimisation, allowing temporary flows to be managed without the need for carbon-intensive overpumping and saving thousands of tonnes of CO2 equivalent.

One of the complete 45m primary settlement tanks with full bridge scrapers – Barhale Enpure JV

Environmental gains

A 25,000m² biodiversity and rewilding area was created adjacent to the new assets, seeded with wildflowers and planted with woodland and shrubs. This initiative achieved a biodiversity net gain of over 100% and a significant linear unit gain. Instead of using gabion retaining walls, a vegetated wall was constructed to support a footpath and services for Tank 1, enhancing ecological integration.

Over 50,000 tonnes of site-won material, including nearly 8,000 tonnes of legacy conditioned material, were reused, avoiding more than 1,300 vehicle movements through Dewsbury town. Additionally, thousands of tonnes of concrete and steel were recycled on site.

Project status (July 2025)

The upgraded works successfully achieved the required WINEP compliance date of 22 December 2024 and the UMON4 MCERT flow measurement of 31 March 2025, despite extremely challenging weather conditions at Dewsbury during the civils construction stage throughout 2024. At the time of writing (July 2025) all assets are in service and operating well with formal takeover expected August 2025.

Recognition

The Dewsbury project was short-listed for the ICE Yorkshire and Humber Centenary Award for projects over £5m and won a Certificate of Commendation.

The completed PSTs with vegetated wall beneath Tank 1 - Courtesy of Barhale Enpure JV