Ballykelly WwTW (2022)

Ballykelly WwTW - Courtesy of BSG Civil Engineering Ltd

Built in the 1970s, Ballykelly WwTW was designed to serve a population of just under 8,000. However, the closure of the nearby army barracks in 2008 meant the population was halved to around 3,600, leaving the works both biologically and hydraulically oversized. A hybrid solution, comprising conventional and natural wastewater treatment processes, was designed for Ballykelly which would not only deliver a robust long-term solution for the village, but also provide an area rich in biodiversity to enhance the local land/water environment. Additional lands were purchased adjacent to the existing site to facilitate the implementation of a greener, sustainable solution while keeping the existing WwTW operational and compliant during construction works.

Primary drivers

Ballykelly WwTW required upgrading to meet the current and projected loadings and to ensure compliance with the discharge consent. The drivers for this project were:

- Compliance with EU Water quality standards.

- Accommodating the current and future population.

- Compliance with the Northern Ireland Environment Agency discharge standards.

- NI Water’s long-term strategy.

Construction works progressing at Ballykelly WwTW – Courtesy of BSG Civil Engineering Ltd

Scope of works

The WwTW is located south of the former Shackleton Barracks. The inlet works, which was constructed in 2018, formed part of the design for the new WwTW. The remaining elements consisted of the following new structures and relevant process equipment:

- Activated sludge plant (ASP) consisting of two lanes with anoxic and aerobic zones with process monitoring and control.

- Two final settlement tanks with automatic de-scum and de-sludge.

- Return activated sludge/surplus activated sludge pumping station with flow and level control.

- FST scum pumping station with storage transfer option.

- Sludge holding tank, storage with agitation and decant facilities.

- Tertiary treatment; comprising two free-water surface wetland cells to provide a final polish with quality monitoring.

- Process flows, levels, and quality monitoring.

- Ancillary processes to support the main process units.

- Intelligent motor control centre (MCC) with telemetry.

- Programmable logic controller (PLC) and SCADA system using HMIs, (MCC No.1 and inlet works MCC).

- 91.20kWp 75KW AC solar farm.

- Extensive demolition of existing WwTW.

- Standby generator Installation.

(left) ASP tank stone placement, (middle) piles cropped, and mud mat poured for the base ready for reinforced concrete and (right), base was poured in 2 sections; photo shows pour 1 – Courtesy of BSG Civil Engineering

Main process structure construction

Two aeration tanks sized 24m long x 6.1m wide with a 4.5m water depth provided a total volume of 1,318m3. The depth was limited to 4.5m to minimise the depth of excavation at the site where the water table was very high.

During early contractor involvement (ECI), the ground investigation report showed low bearing capacity at tank formation level. As a result, a piled solution was adopted to provide the required bearing capacity. The piles were designed to achieve a safe working load of 100 ton. The piles were spaced to minimise bending in the slab and ensure the 100-ton safe working load was not exceeded.

Each aeration tank was excavated at a face-to-formation level using 21t/5t excavators. This included placing 4” clean stone to assist with ground water control, pile cropping and mudmat placement. All the straight wall sections of the aeration tanks were prefabricated outside of the tank, then set in place using a spreader beam and crane. This was more time and cost effective than in situ tying for this specific job. The aeration tank walls were constructed in 17 different concrete pours and included L-shaped, straight, and cross-sectional pours.

(left) base pour 2, (middle) one of 17 wall pours and (right), finished constructed tank with piles being removed and backfilled – Courtesy of BSG Civil Engineering

MEICA installation

The screened Formula A/influent flows downstream to the selector tank. In the selector tank the influent is mixed with the RAS flow by mixers, before gravitating via two adjustable flow splitting weirs to ASP Lane No. 1 and ASP Lane No. 2. Included are facilities for bypassing the selector zones allowing these zones to be isolated and drained for cleaning. The ASP lanes are identical in design and equipment. Each lane comprises an anoxic zone and two aeration zones. Each anoxic zone is equipped with a mixer. Each aeration zone is equipped with an aeration grid, air control actuator, air flow meter transmitter and dissolved oxygen probe. ASP Zone No. 2 is also equipped with an MLSS probe. Each aeration zone is connected to a central manifold which connects to the ASP blowers.

Flow from the ASP lanes gravitates to the FST flow split chamber with adjustable weirs where the flow is split to the two settlement tanks: Final Settlement Tank No. 1 and Final Settlement Tank No. 2. Each tank is identical and is equipped with a half bridge scraper, sludge blanket detector and a proximity switch. The tanks ‘de-scum’ and ‘de-sludge’ are controlled via actuated valves located in/at their respective pumping stations. Each tank’s settled effluent hydraulically discharges into the tank’s outlet launder channel to the outlet manhole.

Duty/assist/standby blowers from Aerzen Machines – Courtesy of BSG Civil Engineering Ltd

The RAS/SAS pumping station is equipped with two sets of pumps. RAS pumps and SAS pumps. A level ultrasonic and low-level and high-level probes are used to control both sets of pumps.

The sludge holding tank is equipped with an external mixer for the blending of the tank’s contents. The tank is also equipped with a decant tree valve arrangement, including overflow. The decant arrangement consists of four hand valves and an actuated valve. The actuator will operate to aid decanting at certain times. The tank is also equipped with a tanker point for the removal of the tank’s contents when required.

The upgraded plant is designed to run fully automatically with control enacted by a single PLC housed in a common control panel/MCC of a newly installed ASP MCC. The new ASP MCC is located inside a new kiosk routed adjacent to the ASP plant. The panels are controlled by SCADA-enabled human machine interfaces (HMIs) providing access to and displaying data from the PLC. Plant control and monitoring may also be accessed from either MCC. Plant status, alarms etc. are relayed by radio telemetry links to the NI Water central monitoring station.

FFT flow meter and pipework – Courtesy of BSG Civil Engineering

ICW construction

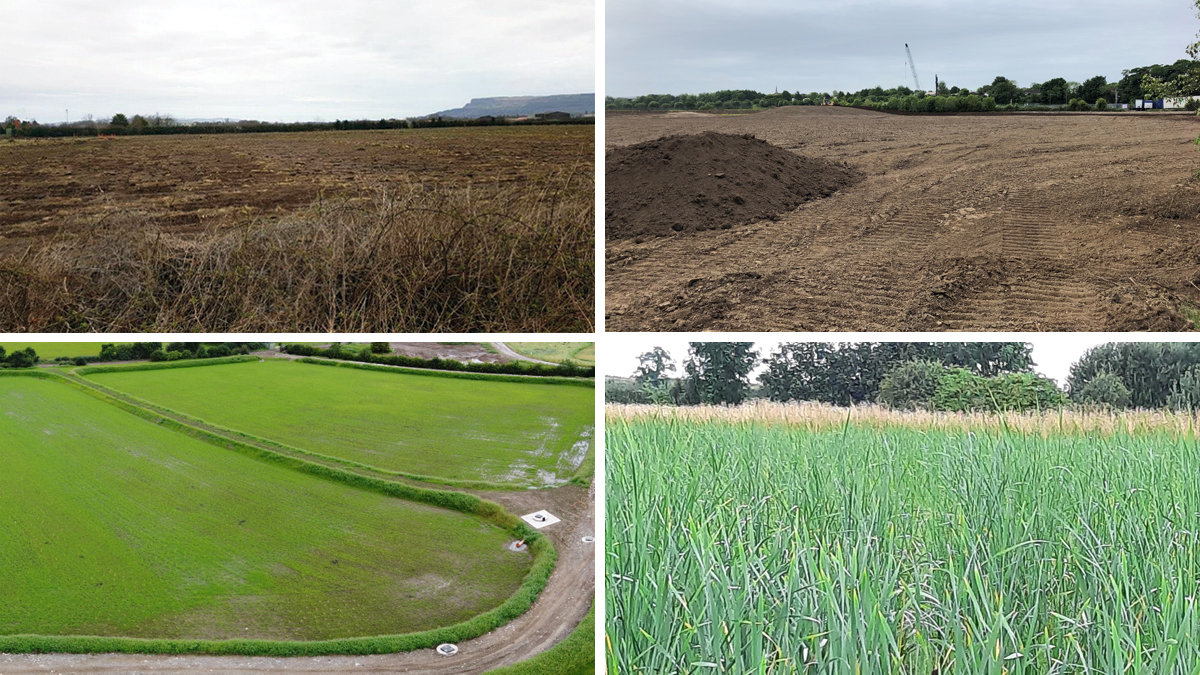

The flow from the WwTW outlet manhole gravitates to a series of effluent discharge chambers, before discharging to the first of two integrated constructed wetlands. The ICWs have a combined surface area of 16,010m2 with a covering of suitably selected vegetation which provides a finish polish to the final effluent before it discharges to the local watercourse.

ICWs are designed, built and operated through human technology but are based on processes that occur naturally as it is the plants themselves that support the water treatment process. At 1.6 hectares in surface area carbon sequestration, it is estimated that the ICWs achieve in excess of 5 tonnes of elemental carbon per hectare per annum. Any carbon footprint will be negative over the lifespan of the ICW as the amount of carbon sequestered is far greater than that used in the construction.

The land the wetland cells are built upon was previously used for agricultural use. A bulldozer was used to remove the topsoil to stockpile to lower levels to formation and then pushed back over the two ICW ponds. Once the cells were formed the ground was then power harrowed to allow for easy planting of reeds.

Around 75,000 reeds were planted out over both cells with the vegetation used being common wetland species that are native to Ireland and specially grown for the Ballykelly site. Vegetation includes bulrushes, sedges and water grasses.

(top left) The wetland cells were previously used for agricultural use, (top right) bulldozers were used to remove topsoil to stockpile to lower levels to formation and push back over cells, (bottom left) finished cells with berms and (bottom right), July/Aug 2021 vegetation growth during 28-day process trial – Courtesy of BSG Civil Engineering

The effluent from the conventional side of the works gravitates through the ponds and together the plants, micro-organisms, sun, substrate and air interact naturally to polish the wastewater and produce a high-quality effluent.

With a variety of native planting, the ICW creates a wide range of habitats for creatures large and small. The shallow water depth throughout the ICW allows for a wide variety of macro-invertebrates to find suitable areas within the wetland to survive, as well as a wealth of vegetated areas within which wildfowl can nest.

By integrating the Ballykelly ICW solution the site is enriched with biodiversity. The paths around the ICW have been planted with wildflower and in subsequent years, NI Water plans to cover over 7,500m2 of unused space around the site with trees. The ICW also has the potential to deliver on a substantial range of other ecosystem services, including flood attenuation, amenity and recreation.

As built site layout – Courtesy of BSG Civil Engineering

Ballykelly WwTW: Supply chain – key participants

- Project management: RPS

- Principal designer/contractors & MEICA design: BSG Civil Engineering Ltd

- Structural, hydraulic & process design: Doran Consulting

- Pumps & mixers and aeration equipment: Xylem Water Solutions

- Aeration blowers: Aerzen Machines

- MCC: Motrol Ltd

- Photovoltaic solar farm: Solmatix Renewables Ltd

- Flow meters & ultrasonics: Siemens

- DO/MLSS & turbidity instrumentation: Hach Lange

- MCC kiosk: Carn Plastics

- Half bridge scrapers, access flooring & metalwork: Graham Steelwork & Engineering (GSE) Ltd

- Aeration lane pipework instrumentation: Endress+Hauser

Demolition

Apart from the inlet works, the existing WwTW was decommissioned and demolished in June 2021. Reusable assets were removed for future NI Water use, while the 2500m3 of effluent (the contents of the existing structures) was carefully settled before being transferred by gravity to the ICWs. This sustainable approach allowed the reuse of higher load effluent to provide the ICWs with a boost in growth while negating the need for expensive tankering of the left-over contents. Demolition of the existing structures provided room for extensive groundworks in preparation for the installation of 240 solar panels with all materials reused as part of the groundworks.

Aerial view of completed solar farm – Courtesy of BSG Civil Engineering Ltd

Solar farm

The normal source (mains) power supply to the WwTW was upgraded for the new site loads to a MIC 154KVA and is synchronised with a new 91.2kWp 75 AC solar PV plant from Solmatix Renewables Ltd. During daylight hours the solar PV will generate power to supply the WwTW’s energy requirements. The amount of solar radiation each day will directly correlate with the energy generated, hence during part or all of the daylight hours the amount of energy generated will vary. The G99 Zero Export Board synchronises with the utility’s supply to make up any shortages in the WwTW’s energy demand. As dusk approaches each day, the utility’s supply will increase as the Solar PV generation slopes off, until the utility is supplying all required energy. At dawn the inverse will exist, and the solar PV generation slope will increase until its maximum generation occurs, depending on that day’s solar radiation.

Across an expected 25-year lifetime, NI Water expects the solar energy system to save the business over £400,000 (based on 2020 prices). Additionally, based on the current electricity generation mix feeding the Northern Ireland grid, it is estimated that the renewable electricity generation on the Ballykelly site will prevent the emission of over 41,000kg of CO2 per year.

NI Water have also installed a lithium battery system to augment the solar PV at the site to maximise the zero carbon energy use and enable the treatment works to operate on 100% solar energy for most of the year. During darker winter months the battery will charge from the grid during off peak hours and enable additional energy cost savings into the future.

The WwTW is also equipped with a 200 KVA packaged electrical generator, refurbished from another NI Water site. The generator has the facility of automatic change-over during a power failure and will return to the utility supplier source once power has been restored. The facility to use a portable generator is also available.

3 (No.) 25A invertors – Courtesy of BSG Civil Engineering Ltd

Conclusion

A collaborative, forward-thinking approach between NI Water, BSG Civil Engineering and RPS has produced whole-life cost, programme and carbon savings in the delivery of this project. The upgraded Ballykelly WwTW is ensuring that high-quality effluent is being discharged to Lough Foyle; helping to improve the water quality in the lough in line with the project objectives.

Sustainability lay at the heart of the project and through the introduction of ICWs the team has created thriving biodiversity areas, with solar energy allowing the WwTW to become fully self-sufficient in the summer months. A successful commissioning and 28-day performance trial was completed in November 2021 with excellent results achieved.

Innovation has also played a key role in the upgrade of Ballykelly WwTW and in a bid to trial other innovations, and help shape the future of sustainable wastewater solutions, a dedicated innovation test area has been established at the site.

The former infrastructure Minister and NI Water CEO visit the site – Courtesy of NI Water

The custom-designed facility provides NI Water and their suppliers the opportunity to test innovative new processes and equipment in a safe environment, as any outputs can be safely returned to the head of the main treatment works. To accommodate a ‘plug-and-play’ type design, the facility includes access to raw sewage entering the works, a power supply and an area of hard standing, suitable for containerised trial systems to be located.

The team was delighted to welcome the former Infrastructure Minister and NI Water CEO to Ballykelly in October 2021 to showcase the sustainable solutions and innovation area implemented at the site.