Ballycastle Wastewater Project (2018)

The works is located near local residents - Courtesy of NI Water

The picturesque coastal town of Ballycastle is located on Northern Ireland’s scenic North Antrim Coast. This popular tourist spot attracts many visitors, who come to take in the beautiful scenery, as well as passing through on their trip along the famous Wild Atlantic Way. Visitors come from all over the world to see the nearby UNESCO World Heritage Site at the Giants Causeway, as well as other unique historical, cultural and built heritage at Dunluce Castle and Bushmills Distillery in this area of outstanding natural beauty. Recognising the importance and sensitivity of the area and increase in tourism, Northern Ireland Water (NI Water) has made a major investment to improve the wastewater treatment facilities of the Ballycastle catchment and bring about a significant improvement to the local water quality and bathing water standards. The project involved the construction of a new coastal wastewater treatment works on an extremely confined site with some very difficult archaeological, ecological, social and time related challenges.

Drivers

The project at Ballycastle was driven by the accelerated growth of the town and tourism as well as regulatory requirements to meet the European Commission Urban Waste Water Directive and EC Bathing Water Directive.

The Waste Water directive set out requirements and goals that detailed the need for secondary treatment of some form to be in place at Ballycastle, as the existing site constructed in 1985 only provided screening and storm storage before pumping 2 miles to a sea outfall.

The town of Ballycastle for much of the year has a population equivalent (PE) of only 8000; however, following a boost to tourism to the area and the expansion of several local holiday caravan parks, the summer population would exceed that and would peak during the hugely popular annual ‘Ould Lammas Fair’ in August to approximately 13,500 PE.

The European Commission Bathing Water Directive created significant drivers for the project to move towards significantly increased storm storage capacity. The Bathing Water Directive limited the storm overflow to no more than 3 spills per bathing season and following a detailed drainage area assessment period, which looked at the entire catchment network and the storm water entering the system, this indicated a storm storage capacity requirement of 2300m3 during bathing season.

Storm tanks 440m3 concrete pour – Courtesy of NI Water

Appraisal and planning

The appraisal phase for this project was one of the most complex undertaken in recent years by NI Water as it had to meet the specific objectives set out in the EC Directives, but also the limited availability of land in the area meant that all options to relocate the works to another site were exhausted. NI Water then moved to vesting a small area of land adjacent to the existing works and to adhere to the strict landscape designations and planning restrictions associated with the town.

The vesting process had to follow the extensive period of appraisal and outline design. Only the minimum amount of land required could be vested, so planning permission was granted and the design was completed to a very detailed stage to ensure the works would operate within the smallest footprint possible.

To support the planning process, detailed assessments were completed to ensure all attributes of the social and environmental impacts of the new works were assessed. A landscape and visual impact assessment, noise and vibration impact assessment and a flood risk assessment were completed as the works would sit alongside the sensitive Tow River. A detailed odour modelling assessment was also completed due to the close proximity of several properties and holiday rental apartments.

A tree preservation area was in place at the southern boundary of the new works, so ecology surveys and tree survey reports were completed as several ageing trees were at risk of falling into the completed works. An archaeology suvey was also carried out, along with some exploratory trench excavations as the location next to the river was thought to have possible historical significance.

At the final effluent outfall, a detailed marine modelling exercise was carried out to determine if the outfall location needed to be moved or extended further out to sea. A model predicting outfall plume and effluent dispersion was completed which showed that tidal flows were effective at dispersing the final effluent plume away from the primary bathing water beaches around the town.

Phase 1 construction – Courtesy of NI Water

The Water Research Centre carried out an audit of the model and presented the results, along with close stakeholder engagement with the Northern Ireland Environment Agency, which brought huge economic gains to the project.

Throughout the planning process, the project team prioritised a close working dialogue with the planning officials and the local residents. Regular correspondence was issued to residents and a number of information events were hosted in the nearby council offices. Local residents’ concerns were taken on board and subsequent changes were made to the designs of the site lighting and inlet pumping arrangements.

The use of new virtual reality technology was also a key innovative tool, which was used to great effect with local councillors and residents. RPS Consulting Engineers used a 3D model of the works along with an HTC Vive 3D virtual reality headset, which was transported to the residents’ information evenings.

Locals could be ‘placed’ virtually on the public paths or at their own house and view a fully 3D view of the works in its final position. This gave residents the opportunity to see the design in 3D and the landscaping efforts that were planned to minimise the visual impact of the works.

Inlet pumping station – Courtesy of NI Water

Design

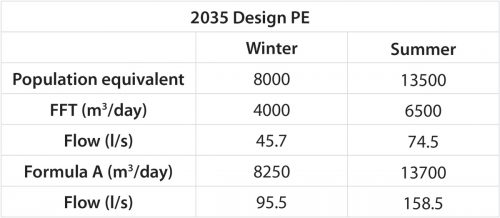

The design for the new works needed to be flexible to overcome the significant difference between winter and summer flows anticipated for the works. A 70% increase in the winter flow from 8,000 PE to 13,500 PE needs to be treated to the 30 BOD (biological oxygen demand), 50 suspended solids standard.

The process adopted for the works is an activated sludge plant with no primary settlement. Flows are pumped to a Huber Technology 6mm screening, grit and grease removal unit before a full flow to treatment (FFT) pumping station moves flows up to 3 (No.) above ground aeration lanes or a stormwater pumping station, pumping storm flows up to the 2300m3 storm tanks.

Following biological treatment flows flow to one of 2 (No.) final settlement tanks before entering the final effluent pumping station. Final effluent is then pumped for 2 miles to a sea outfall at Rathlin Sound. Sludge thickening is carried out by 2 (No.) Huber drum thickeners and is stored in a thin and thick concrete sludge storage tanks. Odour is managed on site by a network of odour pipework from process units connected to a carbon odour control unit.

2035 design PE

During the bathing season, the works inlet needs to prevent storm overflows from occurring to the adjacent Tow River. To manage this, the inlet pumping station has an instantaneous peak flow capacity of 500l/s. This peak flow capacity ensures that Formula A flows are screened and pumped to the storm tanks. The inlet pumping station also includes a smaller emergency storage tank for use in the event of a pump failure or during maintenance.

Inlet screening – Courtesy of NI Water

The winter and summer differences in flows are managed by utilising 3 (No.) independent activated sludge aeration lanes and 2 (No.) final settlement tanks (FST). To save energy during winter months, the works is designed to achieve compliance on 2 (No.) aeration lanes and 1 (No.) FST. In addition to this, individual parameters such as the dissolved oxygen levels and mixed liquor suspended solids (MLSS) are scaled to improve efficiency.

This project at Ballycastle was used as a trial by NI Water into the use of 3D BIM models (building information modelling). The rendered 3D model created by RPS, was viewable through the 3D virtual reality headset and not only proved useful for informing residents, but also gave operations staff the opportunity to view the completed works and advise on design changes or pinch points. Future versions of this model will be capable of containing supplier 3D CAD models of equipment with the ability to interact and view information which will prove to be an important tool in future design and HAZOP meetings.

Ballycastle WwTW: Table of designers, contractors and suppliers

- Client: Northern Ireland Water

- Client professional services: RPS

- Main contractor: BSG Civil Engineering Ltd

- M&E contractor: WIS Group

- Contractor design: Doran Consulting

- Process units: Huber Technology

- Tipping Buckets: CSO Group Ltd

- Structural steel: M Hasson & Sons

- Formwork: K&J Formwork Ltd

- Concrete: Creagh Concrete

- Precast concrete: FP McCann Ltd

- Construction sub-contract: Glenview Contracts

Causeway Coast Mayor is given a VR tour of the completed works – Courtesy of NI Water

Construction management

Pre-construction works began in late 2014 on the FE outfall, installing new air valves and hatch boxes for access to the pumping main. The entire pipe was CCTV surveyed and several sections of it were cut out for testing to check its condition for future use.

The main construction contract was awarded to BSG Civil Engineering Ltd in late 2015 and the local knowledge from the contracting team immediately highlighted risks regarding the temporary works and dewatering of the deep excavations. This led to an extended temporary works design period including trials for dewatering and the setup of boreholes with monitoring logs across the site and on the opposite river bank. This data fed into the temporary works design for the pumping stations and boundary retaining structure, which resulted in increased bracing for excavations and continual monitoring of sheet piles.

The load bearing concrete foundations under the tanks and pumping stations were on top of concrete driven piles. The site is at risk of flooding due to its riverside location so careful design consideration was required for the anti-flotation aspects of the structures.

Final settlement and FE pumping station – Courtesy of NI Water

The confined nature of the site was the most difficult challenge to overcome in the project. It required careful phasing of the works to manage movement of machinery and personnel. The storm tanks were constructed first to allow the existing tank to be removed. Following this first phase, it reduced the available working area on the site by 40% and created the toughest construction challenge of the project. Strict time restrictions meant the programme was tight to ensure operational start and compliance with the European Commission Enforcement Notice so there was no room for slippage in the programme.

The NEC3 Option A contract, tight programme and close supervision of the project was managed by an on-site project management team. The benefits of an on-site team ensured that quick discussions and resolutions could be made to overcome problems, which were then followed by accurate notifications or instructions.

The close working relationship between the project team and contractor allowed the programme to flow much more quickly and reduced the requirement for extended meetings off site.

Ballycastle Wastewater Project – Courtesy of NI Water

Legacy

The success of the Ballycastle WwTW project has proved to NI Water what can be achieved through careful appraisal and planning on a confined site. Further lessons learned from the effective public relations exercises and regular stakeholder engagement with the use of new 3D virtual reality technology will be carried forward into future projects.

The new plant, which will be officially opened in Autumn 2018 will bring many benefits for the local population and economy, meeting the needs of the growing local population and seasonal tourism increases, as well as greatly improving the coastal waters of this scenic area.