Te-Tech Process Solutions

SAM50 – Ultra-efficient Reverse Osmosis (2023)

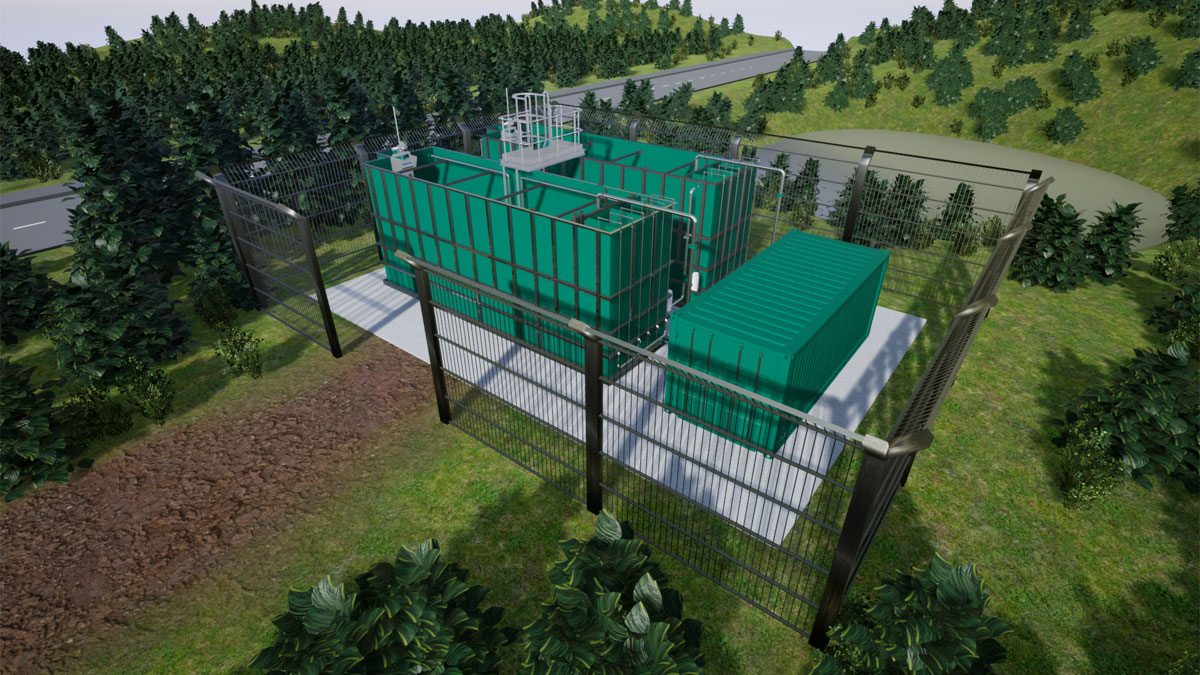

The SAM50 batch reverse osmosis unit - Courtesy of Salinity Solutions

Reverse Osmosis (RO) will play an essential role in helping the water industry tackle the numerous environmental and sustainability challenges it faces. Global climate change is causing increased stress on water resources around the world, and this means more reliance on desalination of brackish and sea water sources to provide drinking water security. The technology of choice for these applications is RO. Nutrient pollution of waterways is another problem, and effective technologies are required for the removal of nitrogen and phosphorus from sewage works final effluent. In the industrial sector, RO can remove toxic elements and recover valuable minerals and metals from wastewater as well as providing opportunities for water reuse and recycling. With such a diverse range of applications, RO has the potential to ensure a cleaner, greener, and more water secure future. But traditional RO is energy intensive. SAM50, using ultra-efficient batch RO technology, significantly reduces the energy requirements, and provides the ideal solution for a growing demand far more sustainably.

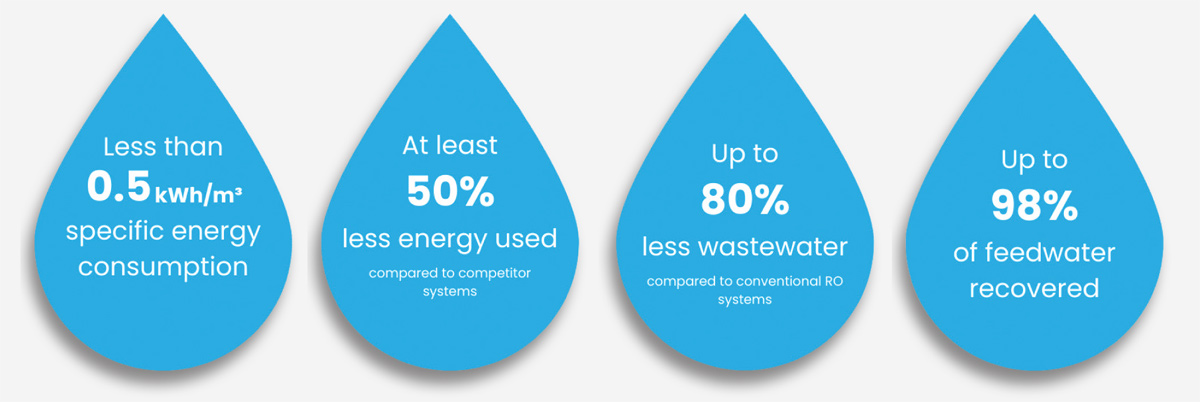

Benefits of the SAM50 batch RO system – Courtesy of Salinity Solutions

Compact batch reverse osmosis technology

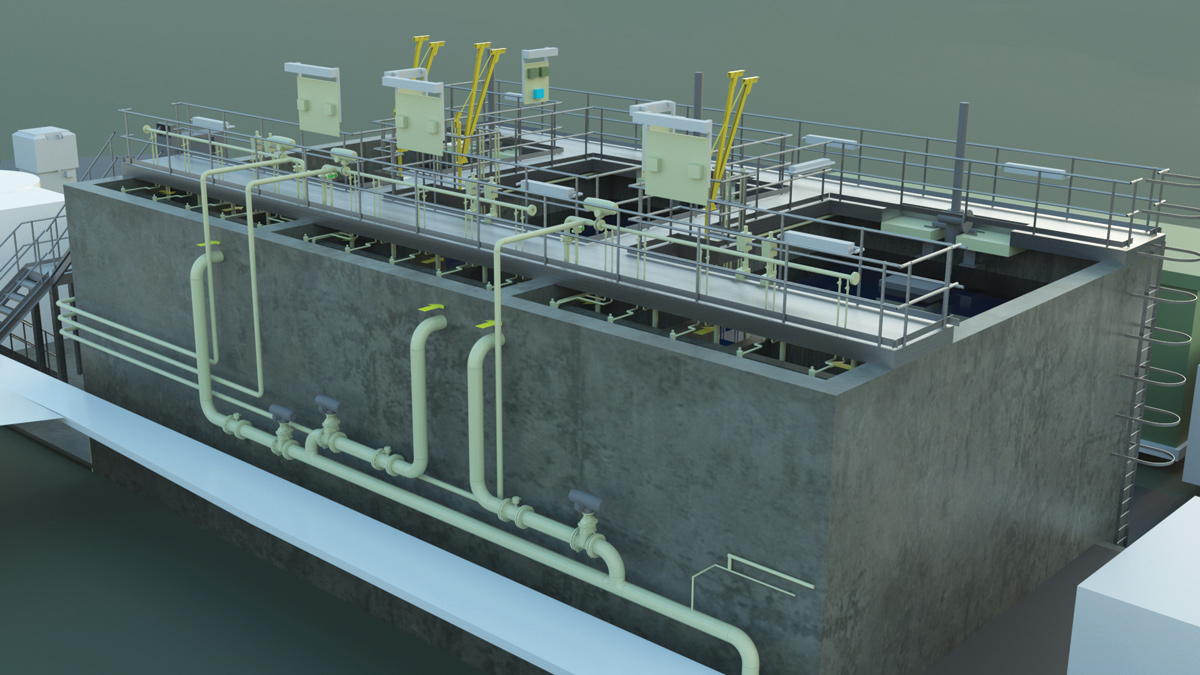

The SAM50 Batch RO system uses a pressure exchange vessel and valve control, both patented, to minimise the pressure in the system and therefore reduces energy requirements by 50% whilst purifying up to 98% of the water, producing 30% more clean water and generating 80% less waste than conventional RO systems. The compact system is containerised and easily transportable, and is the first batch RO product in the world to be manufactured commercially. SAM50 offers a sustainable, low energy water treatment solution that reduces both carbon footprint and operating costs. The technology, for which a European Patent Application has been granted, is suitable for desalination, wastewater treatment, water recovery, and industrial process and utility water treatment. Designed by Salinity Solutions the ultra-efficient batch RO system is manufactured by Te-Tech Process Solutions, part of Trant Engineering.

The technology was co-developed over the past 10 years at the University of Birmingham and Aston University, by Tim Naughton, co-founder of Salinity Solutions, alongside Professor Philip Davies, Head of Water Technology Research, University of Birmingham.

How it works

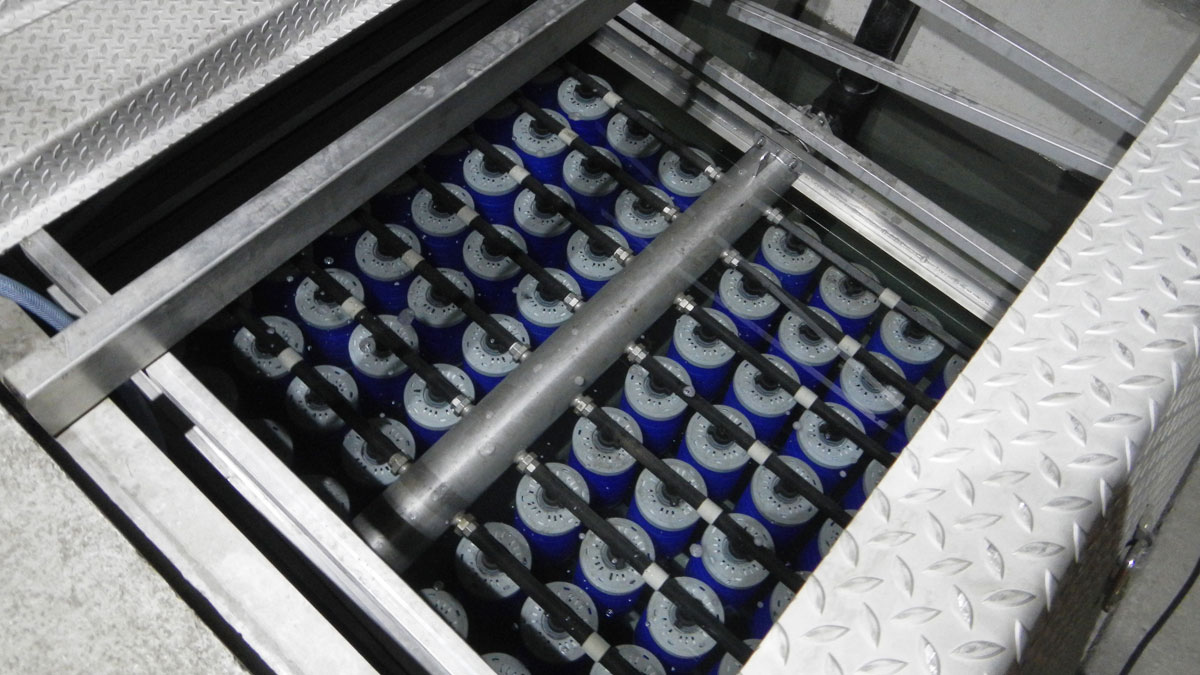

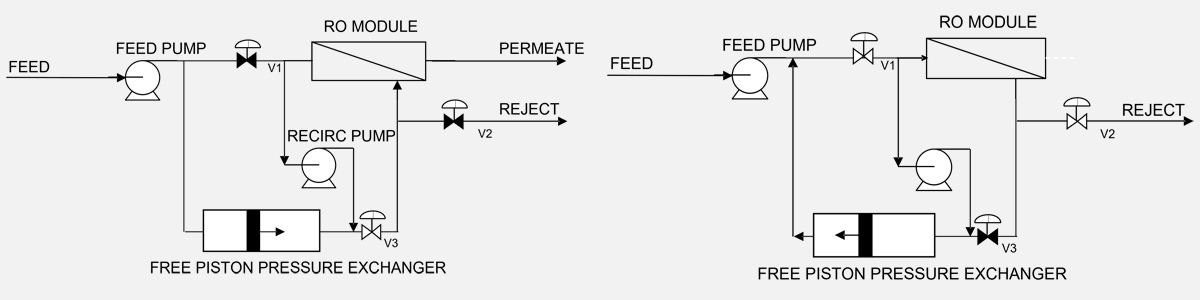

SAM50 is a fully automatic batch RO system. It consists of a high-pressure feed pump, a recirculation pump, industry standard RO modules and a free-piston pressure exchanger that operate in a cyclic manner using only three automatic valves as shown in the flow diagram:

SAM50 pressurisation phase (left) and purge and refill phase (right) – Courtesy of Salinity Solutions

In the first phase of the cycle, the pressurisation phase, the feed pump applies pressure to the feed side of the pressure exchanger, matching the minimum osmotic pressure of the water in the batch. This pressure is transferred to the batch of water that is being processed via the free moving piston. The batch then passes through the membrane module, producing permeate and a reject stream. The reject stream is then recirculated into the pressure exchanger via the recirculation pump. During this process no additional feed is added. This causes an increase in the concentration of the recirculation loop.

As the concentration inside the recirculation loop increases over time, the feed pump will generate a higher pressure to overcome the increasing osmotic pressure, causing the piston to slide to the right. This allows for the average pressure of the cycle to be lower than any competing RO technology, thus reducing the energy demand. When the piston reaches the end of its travel, the pressurisation phase ends, the automatic valves change position and the purge-and-refill phase begins. During this phase, concentrated reject brine is discharged to waste and the free piston moves to the left back to its original position.

This cyclic operation not only reduces energy consumption but also allows a much higher water recovery and, hence, reduced waste. In one recent customer field trial on brackish water application, the SAM50 achieved a 95% recovery rate and a concentrated brine with a 13 x concentration factor while producing a permeate quality of less than 10μS/cm, at a specific energy consumption of 0.5 kWh/m3.

Case Study 1: Mineral extraction – Cornish Lithium

A successful field trial, in collaboration with Cornish Lithium, helped reduce the high carbon footprint of lithium extraction from shallow well geothermal waters in Cornwall – a previously untapped resource. The SAM50 system helped achieve x 7 lithium concentration.

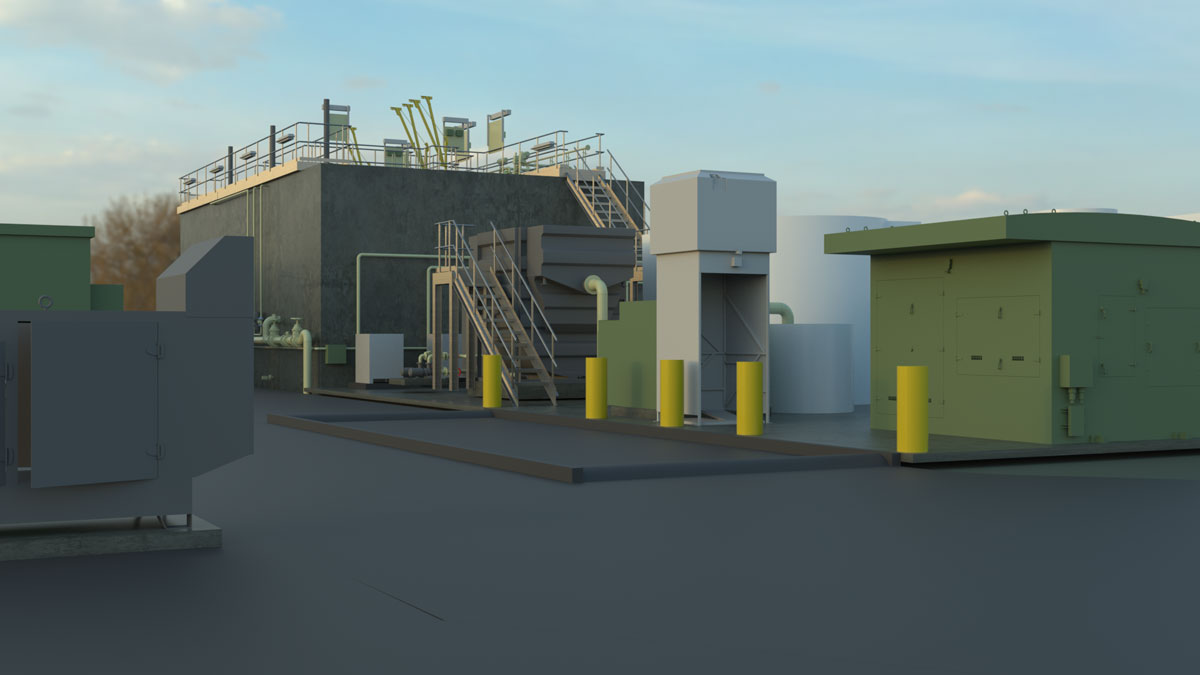

Case Study 2: Nutrient removal – Wessex Water

Salinity Solutions, Te-Tech Process Solutions and Wessex Water have delivered a no-cost trial for Somerset Council to demonstrate the efficacy of their modular water treatment units for nitrogen and phosphate mitigation.

A SAM50 system was placed at the Fivehead Water Recycling Centre near Taunton for two weeks allowing independent water sampling to be undertaken.

The trial demonstrated the effective removal of dissolved nutrients, nitrogen, and phosphorus, which are otherwise discharged into rivers, causing environmental contamination. Early indications show promising results with the first verified laboratory results showing over 98% of phosphates and 88% of nitrates removed.

Sarah Dyke, MP for Somerton and Frome, visiting the pilot trial at Fivehead Water Recycling Centre. Sarah’s visit follows Rebecca Pow’s ministerial visit, alongside representatives from various government departments – Courtesy of Salinity Solutions

Key features & benefits

- High energy efficiency (>0.5 kWh/m3).

- Up to 98% water recovery.

- Produces 30% more clean water and 80% less waste water compared to conventional RO systems.

- Modular and scalable.

- Small footprint.

- Up to 50x brine concentration.

- ‘Plug & play’ installation.

- Engineered in the UK.

- Uses any standard 8” RO membrane.

Award winning technology

Salinity Solutions won the 2023 Water Industry (WIA) Energy in Water Award and were also highly commended in the category of Wastewater Innovation Project of the Year. They were also awarded Manufacturing StartUp of the Year in the StartUp Awards (Midlands).

The containerised SAM50 unit arriving on site for the field trial at Cornish Lithium – Courtesy of Salinity Solutions

References

- Park K et al Design, modelling and optimisation of a batch reverse osmosis (RO) desalination system using a free piston for brackish water treatment Desalination 494 (2020) 114625.

- Hosseinipour E et al A free-piston batch reverse osmosis (RO) system for brackish water desalination: Experimental study and model validation Desalination 527 (2022) 115524.

This paper was prepared by Te-Tech Process Solutions and Salinity Solutions.

For more information: Te-Tech Process Solutions Ltd | +44 (0)2382 351600 | www.te-tech.co.uk