Te-Tech Process Solutions

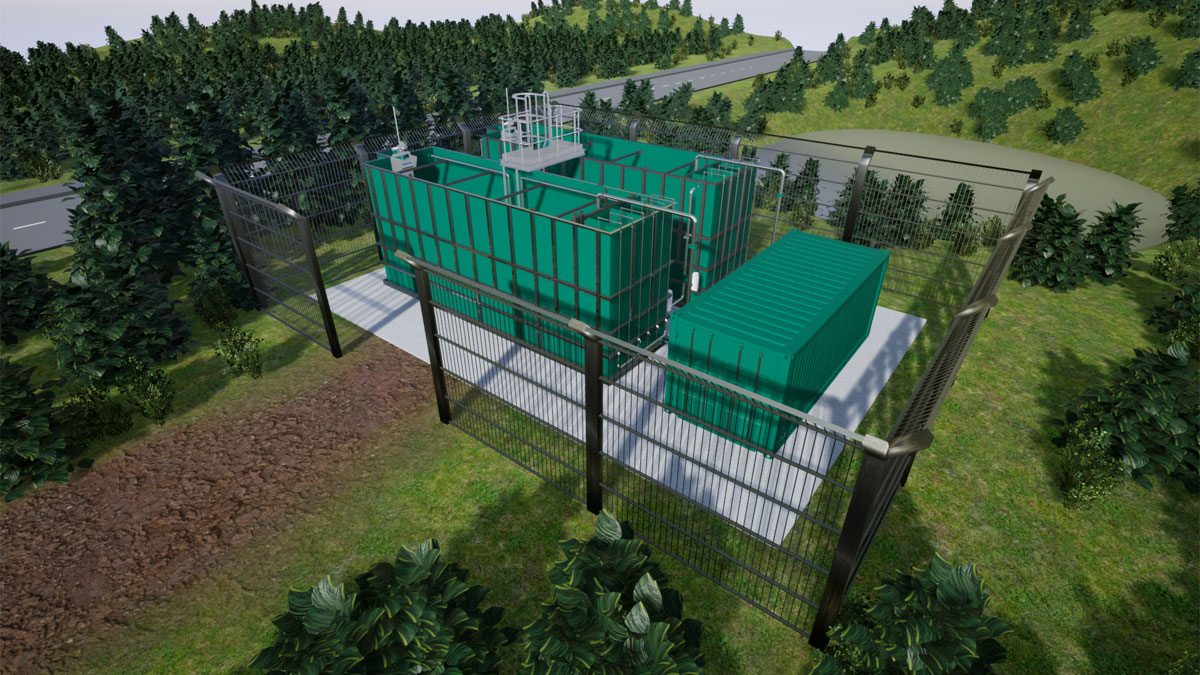

te-ion™ Treatment (2022)

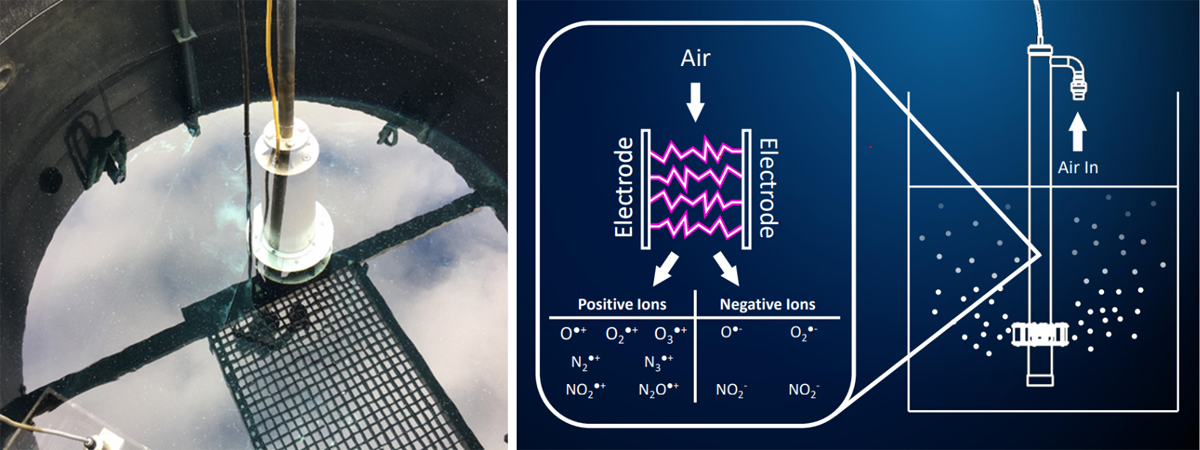

(left) te-ion™ advanced oxidation technology - Courtesy of Te-Tech Process Solutions and (right) electrical glow discharge generating a non-thermal plasma - Credited to Zita/Shutterstock.com

Among the many anthropogenic micropollutants being released into the aqueous environment, the effects of active pharmaceutical ingredients (APIs), including feminisation of fish, increasing susceptibility to predation and increasing antibiotic resistance, are a growing concern. Whilst there is currently no legislation in place in the UK to cover APIs and other emerging pollutants, studies such as Chemical Investigations Programme Phase 2 (CIP2), which ran from 2015-2020, have flagged up painkillers, antibiotics and hormone contraceptives excreted by users of these medications as being of potential concern. Research assessing the effects of APIs in the UK’s aquatic environment1 found a range of APIs including Ibuprofen, diclofenac, ethinyloestradiol, clarithromycin and azithromycin in the final effluent from wastewater treatment works and concluded that as many as 890 wastewater treatment works in the UK were releasing APIs in their effluents exceeding the predicted no effect concentrations (PNEC).

The API problem

The problem for the water industry is that most APIs are not readily biodegradable and, therefore, not easily removed in conventional wastewater treatment processes; indeed some can actually threaten the activated sludge bacteria on which treatment relies. The Water Industry National Environment Plan (WINEP) favours catchment and nature-based solutions to prevent pollution of watercourses, but APIs are so widely used that, unless there is a massive reduction in our dependence on medications, wastewater treatment works will continue to rely on technology-based solutions for their removal.

This is by no means a problem confined to the UK. A 2022 global study2 concluded that “Pharmaceutical pollution poses a global threat to environmental and human health, as well as to delivery of the United Nations Sustainable Development Goals.”

Process options

The most effective technologies for the destruction of these recalcitrant organic molecules are advanced oxidation processes (AOPs). Combinations of hydrogen peroxide with ozone and/or UV radiation have been successfully used in the treatment of industrial wastewater, but have not been cost effective on the domestic wastewater scale. AOPs generate a variety of ‘reactive oxygen’ species including O2+, O2–clusters, O-radicals, OH-radicals and ozone. These are all powerful oxidants that can break down recalcitrant APIs either into smaller molecules that are more readily biodegradable or even completely oxidise them to carbon dioxide and water.

Non-thermal plasma solution

One AOP that is demonstrating effective API removal in trials is non-thermal plasma (NTP), which works by passing atmospheric air through an electrical glow discharge, generating an ambient temperature plasma containing reactive oxygen species.

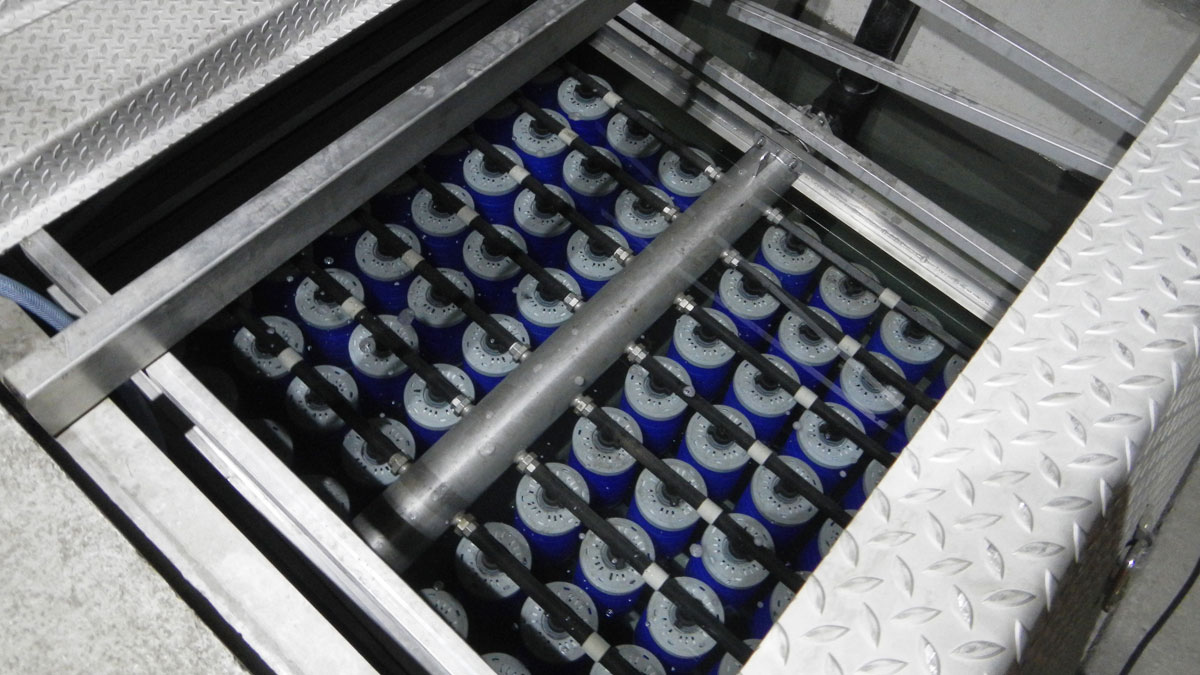

(left) The inside of the te-ion™ and (right) the process inside the ionisation cell which generates reactive oxygen species – Courtesy of Te-Tech Process Solutions

It is an established technology, having been used in medical, food and air purification applications and in textile bleaching. It has now been developed for use in the aqueous environment for the destruction of emerging pollutants. In this application, the plasma is formed separately by the te-ion™ process and introduced into the wastewater by a submerged turbine which avoids the clogging problems of other NTP systems such as thin-film reactors, in which water passes fine perforations before entering the reactor.

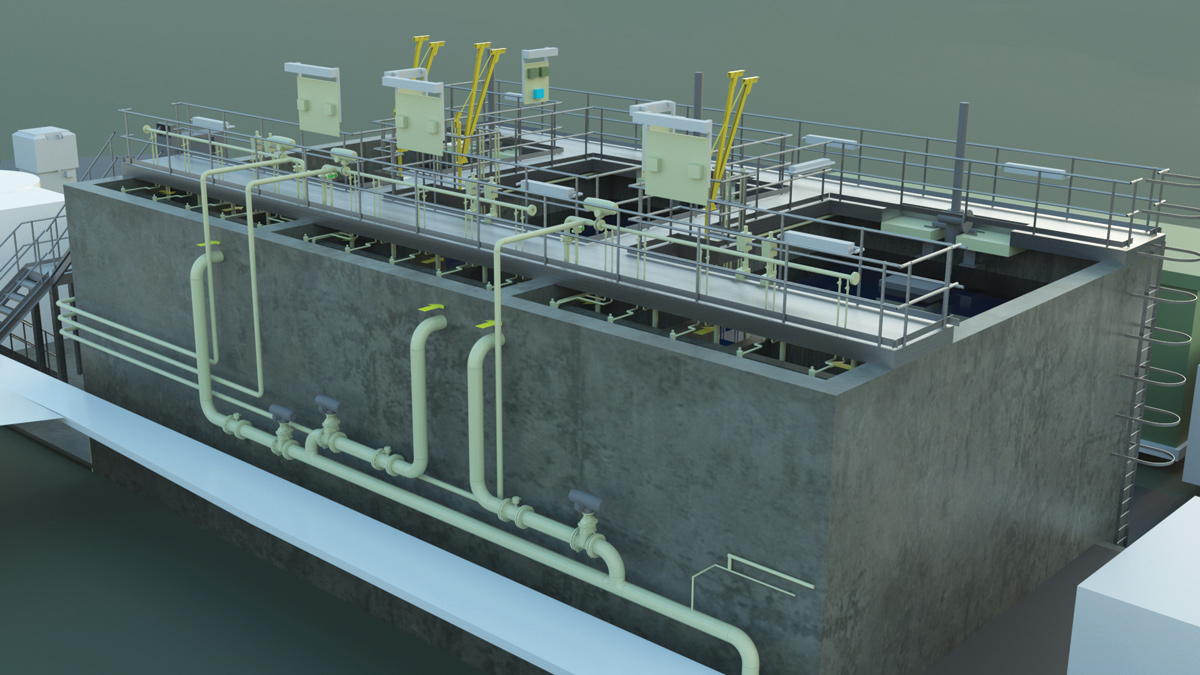

Case Study 1: Bad Reichenhall (Germany) – 90% removal of 3 target APIs achieved

A pilot scale tertiary treatment trial of the process investigated the effect of using the te-ion™ technology to remove three APIs from treated wastewater at the Bad Reichenhall municipal wastewater treatment works in Innsbruck. The results showed that it was possible to achieve 90% removal of the three target APIs – diclofenac, carbamazepine and sulfamethoxazole – well below the PNEC in the receiving watercourse. The results from the trials at Bad Reichenhall provided sufficient confidence in the efficacy of the technology to proceed with further trials, covering 23 APIs. These were undertaken as part of the Farmasense Project at a wastewater treatment works in Portugal.

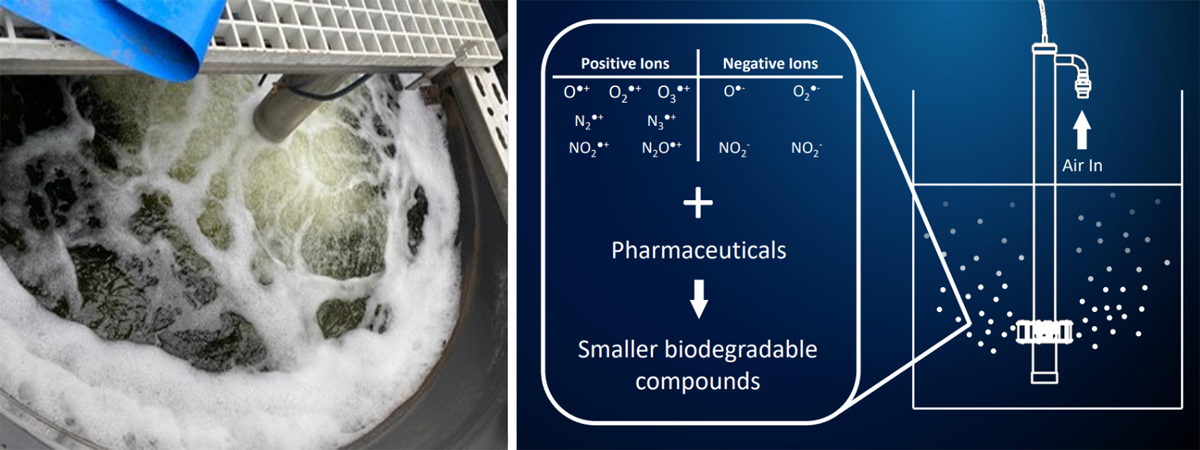

(left) The submerged turbine in action; used to introduce the plasma containing the reactive oxygen species into the wastewater and (right) the process of destroying APIs – Courtesy of Te-Tech Process Solutions

Case Study 2: Farmasense Project (Portugal) – 83% removal of 23 APIs achieved

The Farmasense trial has been fully reported but, in summary, two batch tests were carried out: the first treating the final effluent from the works and the second treating final effluent from the works which had been pre-treated by ultrafiltration (UF). In each test, the wastewater to be treated was delivered into a holding tank and subjected to treatment by bubbling the NTP through it. Samples were taken before treatment and then after 2, 6 and 21 hours of treatment, and analysed for a suite of 23 APIs. Using the combination of NTP with UF pre-treatment achieved 83% removal of the 23 APIs.

Unsurprisingly, some API’s were more susceptible to treatment than others: atorvastatin, trazodone, bupropion, fluoxetine, trimethoprim, azithromycin, venlafaxine and o-desmethylvenlafaxine were almost completely removed (better than 99%) after 2 hours of treatment without pre-treatment by UF, and the addition of pre-treatment resulted in negligible improvement. Atenolol, sulfapyridine, and sulfamethoxazole required much longer contact times and achieved 80% after 21 hours, although the addition of pre-treatment halved the required contact time. Even after 21 hours, gemfibrozil, diclofenac, acetaminophen, 2-hydroxyibuprofen and carbamazepine achieved only 40% removal, although this was improved for diclofenac and 2-hydroxyibuprofen when pre-treatment as introduced. The most recalcitrant of the API’s, Ibuprofen, naproxen, ketoprofen, ciprofloxacin, citalopram, topiramate and salicylic acid were poorly (less than 40%) removed with little improvement by pre-treatment.

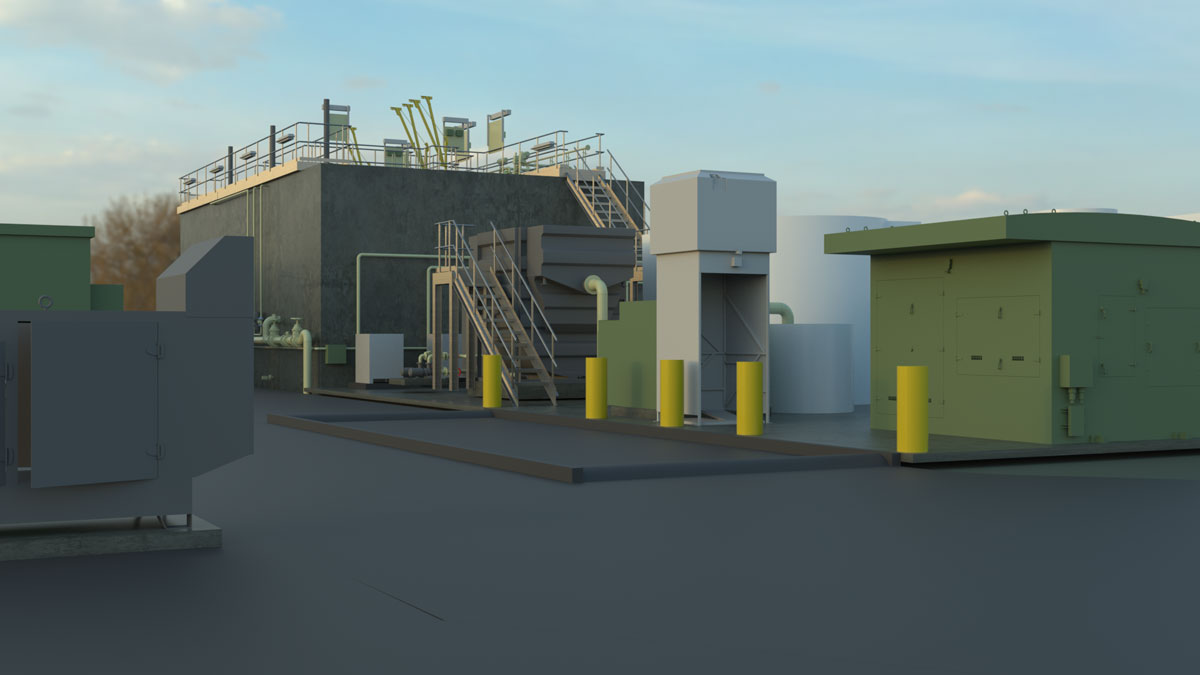

The te-ion™ (middle) and the results of the te-ion™ pilot trials at Bad Reichenhall WwTW (left) and the Farmasense Project (right) – Courtesy of Te-Tech Process Solutions

Conclusion

Whilst the Farmasense study was carried out in a batch treatment pilot plant rather than a continuous flow, it has identified the potential of the atmospheric non-thermal plasma technology for the treatment of pharmaceutical compounds present in treated wastewaters. The combination with UF improved further the overall quality of the wastewater effluent and, with power consumption typically around 0.5 kWh/m3, which makes this an attractive option for municipal plants. Although there are still challenges in the application of this NTP technology to real effluents, due to variable composition and complexity, development work is ongoing to optimise the process and improve its performance across a wider range of APIs. The te-ion™ process is available from Te-Tech Process Solutions for a number of applications including the reduction of sludge bulking as well as the removal of APIs.

References:

1 Comber S et al Active pharmaceutical ingredients entering the aquatic environment from wastewater treatment works: A cause for concern?, Sci Total Environ, 613–614 (2018) 538-547.

2 Wilkinson et al Pharmaceutical pollution of the world’s rivers PNAS 119 (8) 2022.

Acknowledgements:

The Farmasense Project (NORTE-01-0247-FEDER-039957) is funded by Sistema de Incentivos à Investigação e Desenvolvimento Tecnológico do Portugal 2020, Programa Operacional do Norte (NORTE 2020) and Fundo Europeu de Desenvolvimento Regional (FEDER).

This paper was prepared by Ben Hazard, Process Engineer at Te-Tech Process Solutions.

For more information: Te-Tech Process Solutions Ltd | +44 (0)2382 351600 | www.te-tech.co.uk