Amiblu Norway AS

Using cutting edge technology to meet the toughest challenges, Amiblu manufactures GRP pipelines and storage systems that last for generations and do not corrode. GRP is a resilient, composite material utilised in many aspects of construction and civil engineering to deliver long lasting infrastructure.

The history of Amiblu’s GRP systems starts with the first production of centrifugal cast (CC) pipes in Basel in 1957 and continuous filament wound (FW) pipes in 1969 in Norway using top quality raw materials combined with glass fibres to create robust pipes and storage solutions.

Over the past 60+ years, research and development, growth and investment now puts Amiblu at the forefront of GRP pipe production, with seven state of the art manufacturing facilities and a global network of licensed partners producing the two market leading names in GRP pipes – Flowtite (FW) and Hobas (CC).

Amiblu takes environmental responsibility very seriously by developing systems that offer a number of benefits to asset owners who are faced with aging networks, growing cities, climate change and increases in demand. Challenging traditional materials, our products are corrosion and abrasion resistant, with excellent hydraulics, can be bespoke made to meet project requirements, are low-maintenance and engineered for 150 years’ service life.

Products are manufactured for:

-

-

-

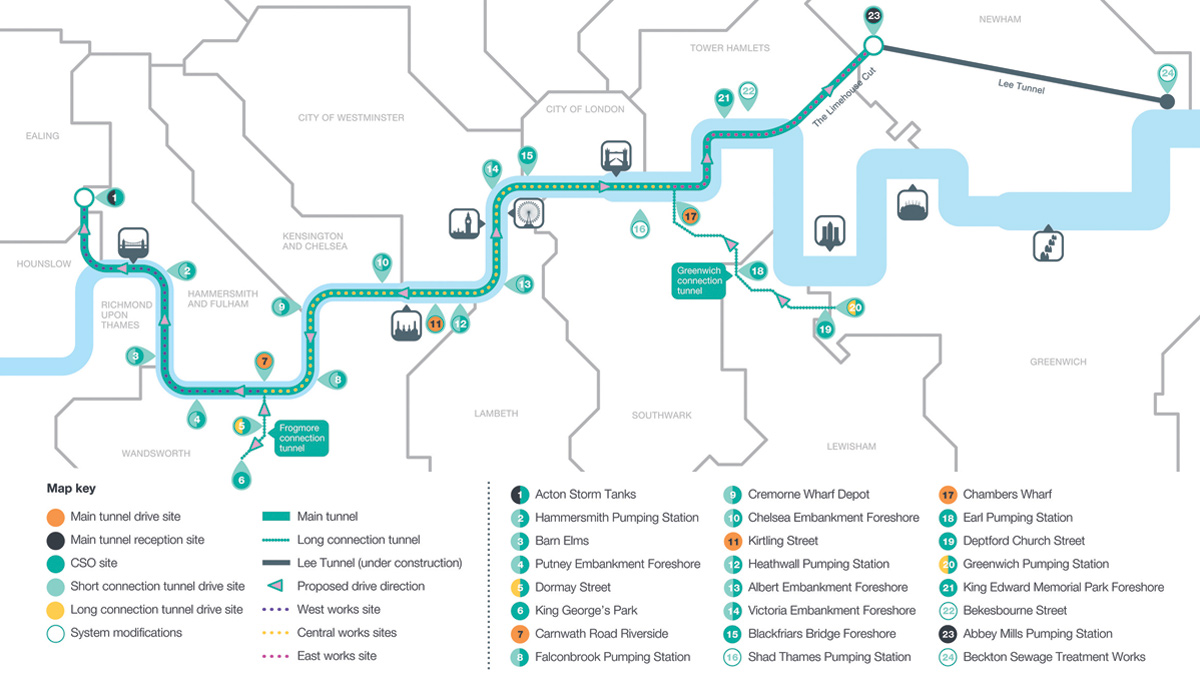

- Sewage & stormwater

- Hydropower

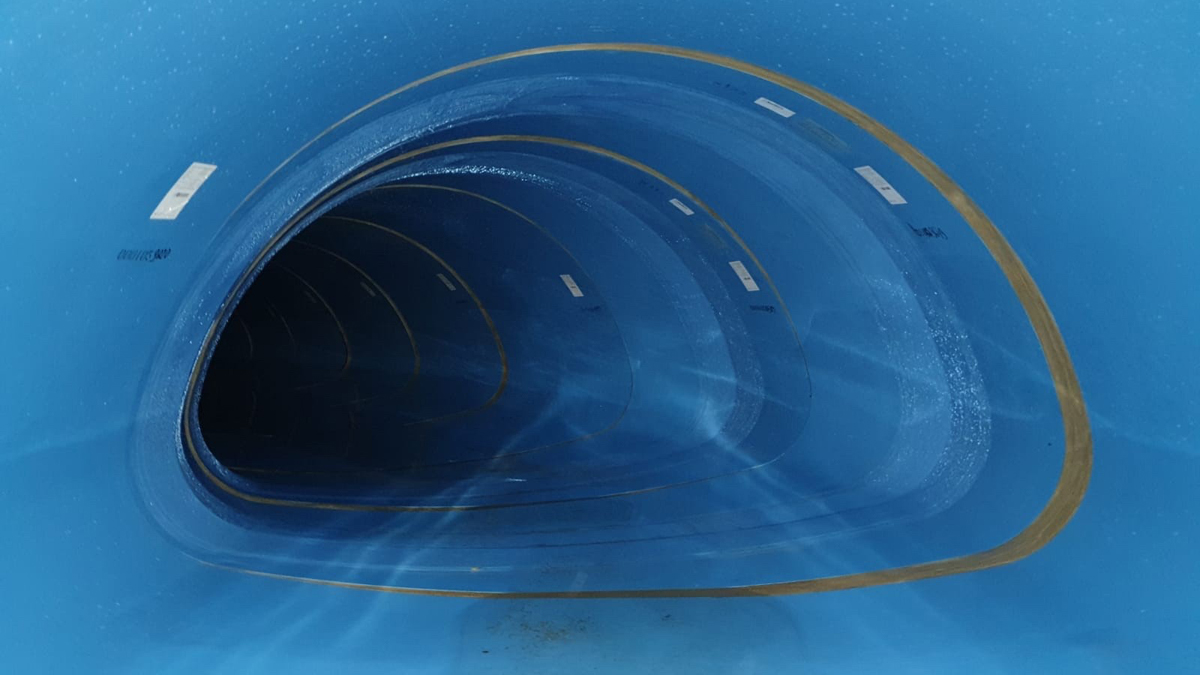

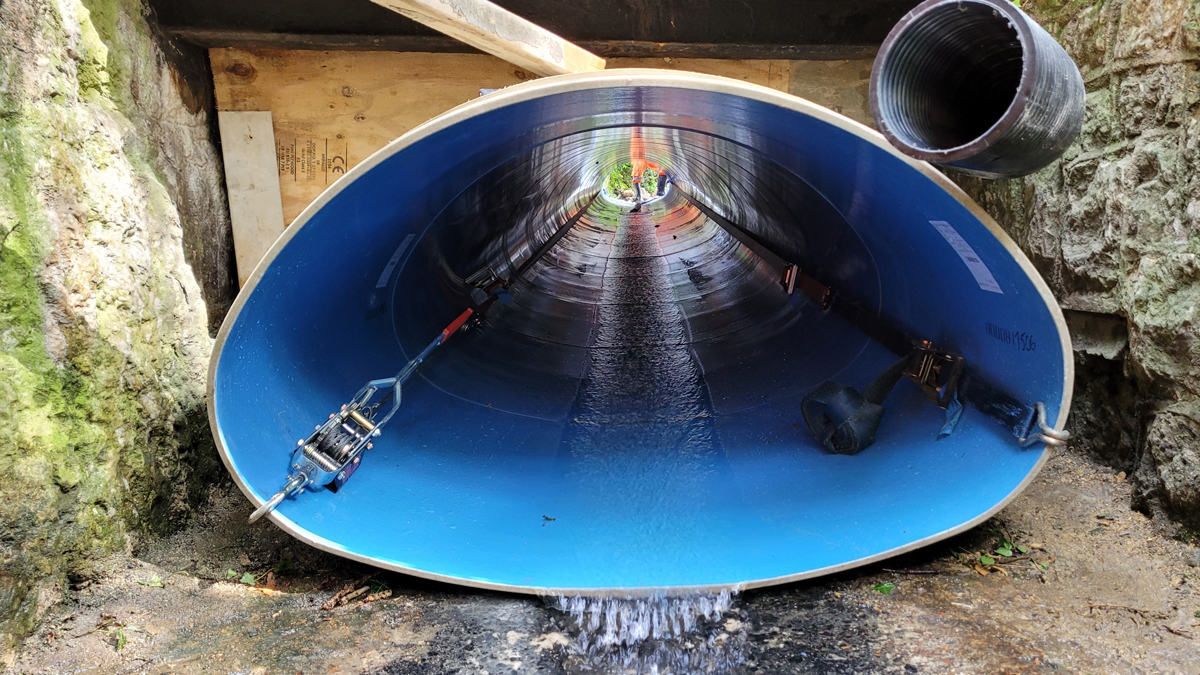

- Circular & non-circular pipeline rehabilitation

- Potable & raw water delivery

- Industrial processes

- Micro-tunnelling applications.

-

-

The greenest product is the one you don’t have to replace.