Amiblu Norway AS

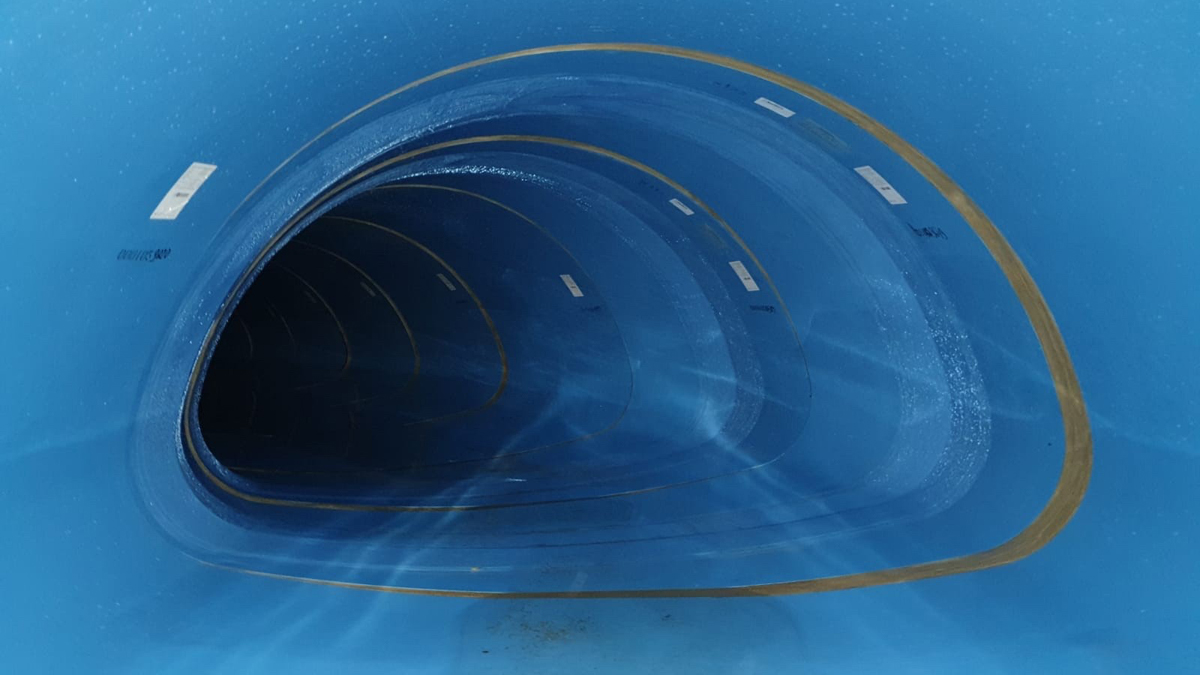

East Budleigh Culvert Re-lining

Completed installation of Amiblu NC Line - Courtesy of MDA Ltd

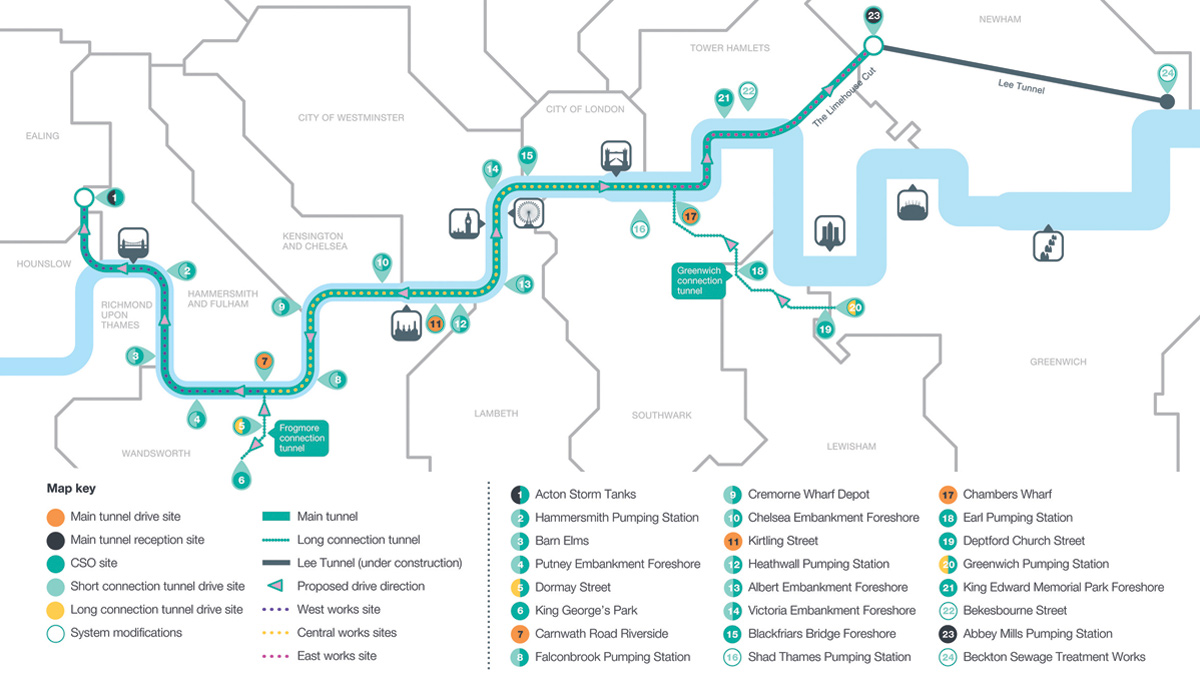

East Budleigh is a small village in East Devon, UK located about 2 miles (3.2km) north of Budleigh Salterton. The village features a bypass culvert, constructed in the 1970s. The culvert is approximately 280 metres in length, of Armco construction, oval shaped and constructed from corrugated metal sheeting (with a concrete floor laid over it during the last 10 years).

The existing culvert was in a poor condition, with joints failing and large voids appearing in the material outside the culvert structure. These failures led to a small localised collapse in the road above during flooding in 2012 and there were concerns that in the future that a larger collapse could occur, causing a failure in the highway surface.

It was decided that this culvert required structural strengthening due to minimal cover to the busy road above, and to maintain flows through the culvert in storm conditions.

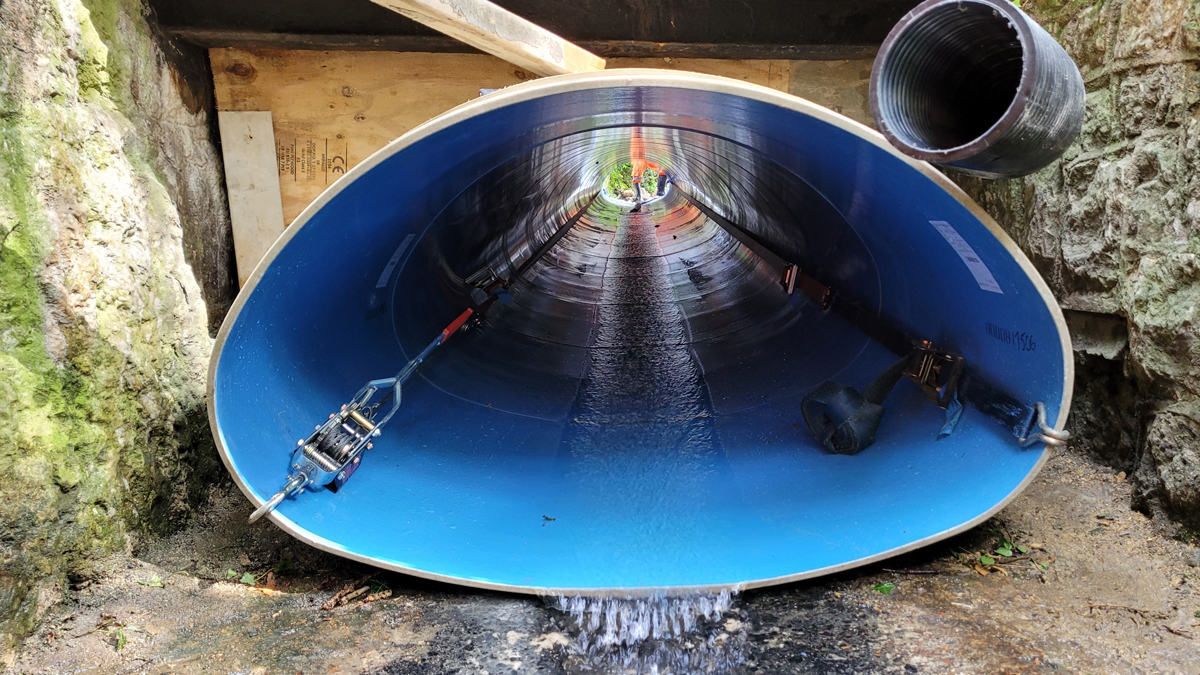

(left) Host pipe inspection and (right) site preparation – Courtesy of MDA Ltd

Project scope

The Environment Agency employed Atkins to design the culvert rehabilitation, with Kier appointed as main contractor who in turn appointed specialist contractor Matt Durbin Associates to consult on rehabilitation options and carry out the work. Given that the location was a highly trafficked residential area with minimum cover to the road, it was decided that lining with a structural GRP segment lining system offered the best solution and Amiblu‘s NC Line, non-circular GRP Structural Relining system was selected for the project. In total some 300 metres of Amiblu NC Line Arch Shape liner, 2360mm wide x 1350mm high was manufactured to the required WRC Type II standard and ISO 16611.

Amiblu’s application engineers worked in partnership with Matt Durbin Associates to understand specific performance criteria required in order to create the optimal shaped pipe to fit the needs of the project and production started in January 2022 at Amiblu’s Gdansk factory in readiness to commence February deliveries.

The culvert meandered with the local water course, and on inspection for the design of the linings was found to include long radius bends which were designed for pre-manufacture so that they would install without issue on site.

Despite the apparent loss of cross-section in the culvert the design and smooth internal finish of the linings ensured that the flow capacity requirements for the culvert would be met.

Given the small village size and the traffic management requirements for the installation works, coordination with local residents and parish councils regarding the large deliveries to site was essential and worked extremely well.

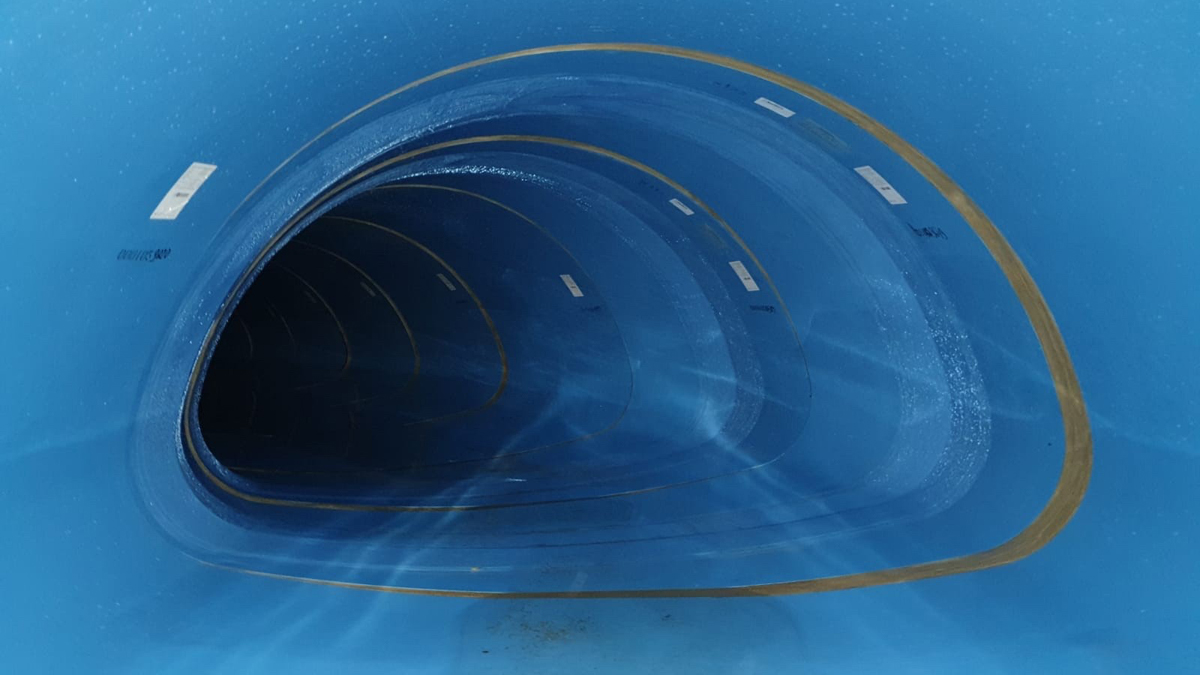

Amiblu NC Line 2360 x1350mm ready for installation

Work commenced on site on 14 February with site preparation works. Installation into the culvert commenced in March. In total, all installation and annulus grouting operations were completed in just 8 weeks.

Amiblu’s NC Line provides structural rehabilitation to existing non- circular culverts and host pipes that have reached a point in their service life where the asset owner must decide to renovate or replace.

GRP pipe systems made by Amiblu maintain excellent long-term stiffness, corrosion and abrasion resistance and are engineered for 150 years‘ service life.

Project parameters

- Country: UK

- City: East Budleigh

- Year: 2022

- Application: Culvert reline

- Installation: Trenchless

- Technology: Amiblu NC Line

- Total length of pipe: 300m

- Nominal Diameter DN (mm): 2360 x 1350mm

- Nominal Pressure PN (bar): PN1

- Nominal Stiffness SN (N/mm2): As per design criteria

Supply chain

- Client: Environment Agency

- Contractor: Matt Durbin Associates Ltd

- Consulting engineer: Atkins

- Structural GRP pipe liner: Amiblu

Completed installation – Courtesy of MDA Ltd

What they said

Daniel Gay, Project Manager for the Environment Agency:

“From a client perspective, the GRP liner solution has provided a cost and time-effective approach to prolonging the asset life. We were hopeful to avoid any requirement for open cut solutions to minimise the impact to the local community and meet delivery deadlines. We also needed to ensure that the flood risk standard of protection was not altered to upstream or downstream receptors. The structural GRP liner allowed for a bespoke unit to be installed which optimised the culvert capacity to retain the flow performance and extended the life. The outcome of improvements to the culvert have reduced flood risk to 27 residential properties, significantly reduced future maintenance costs and health and safety risks to the public.”

Adrian Parker, Senior Project Manager, Kier:

“This project is a great example of how accelerated delivery can be achieved under the Environment Agency’s Collaborative Delivery Framework. From identification of the scheme for fast tracking in June 2021, the scheme was on the ground in February 22 and complete by June 22. MDA have done a great job and thanks also to Amiblu.”

For more information: Amiblu UK | +44 (0)7786 013574 | www.amiblu.com