Amiblu Norway AS

Preston WwTW

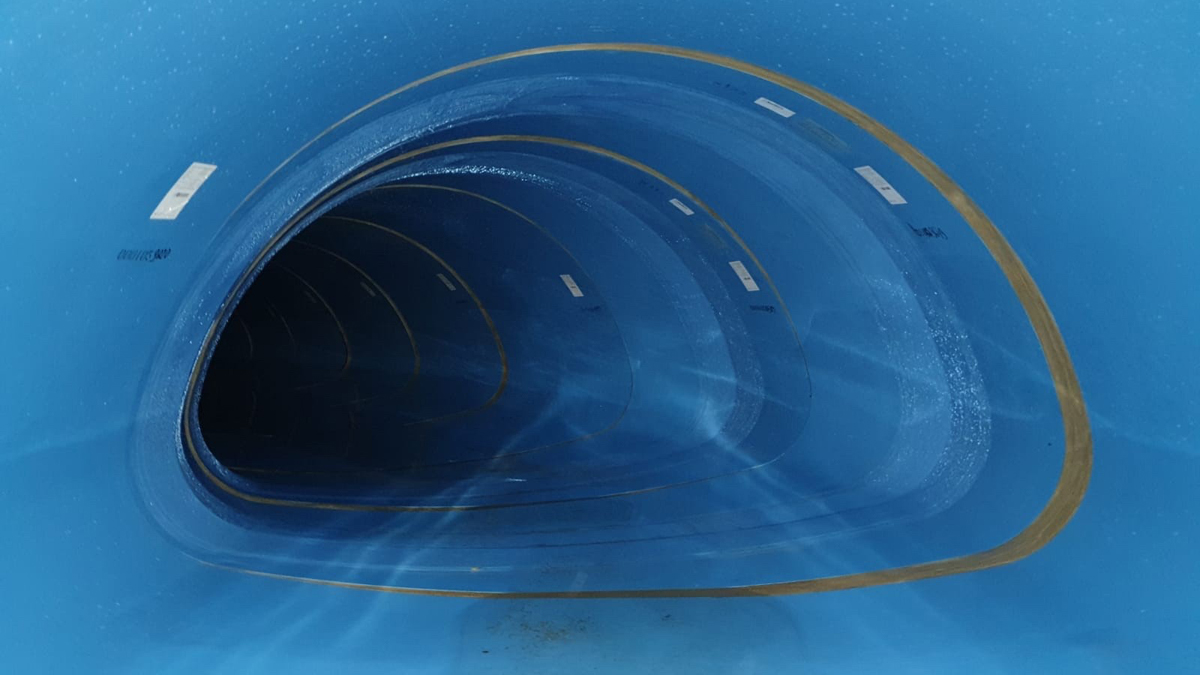

Flowtite Biaxial pipe c/w lock joint - Courtesy of MMB

During AMP 6 United Utilities invested £20m into Preston WwTW to improve performance and resilience. Flowtite GRP Biaxial and Pressure Pipes have been installed to assist with achieving project objectives.

Preston WwTW serves a population in excess of 250,000 within the Borough of Preston and the South Ribble Districts. The Preston Storm Tank Project was awarded to specialist design and build contractor Mott MacDonald Bentley (MMB) with objectives to reduce stormwater spills and improve both the underperforming inlet works and the primary settlement stage.

All of the inflows to the WwTW were pumped and the catchment generated high concentrations of screenings, particular during storms after long dry periods, resulting in the existing inlet works struggling to deal with the peak screenings load, exacerbated by many recent UID (Unsatisfactory Intermittent Discharge of Storm Water ) projects undertaken locally.

The solution was to construct a new storm storage tank with a capacity of 51,000m³ comprising two compartments utilising the same fill/empty pipework for the majority of the pipeline.

Cross-site pipework

A 530m long pipeline was required to transfer screened and degritted storm water from the inlet works to the new storm tanks during storm events. When the new storm tanks reach capacity, this pipeline provides 800m3 of additional storage, before the existing storm tanks begin to fill.

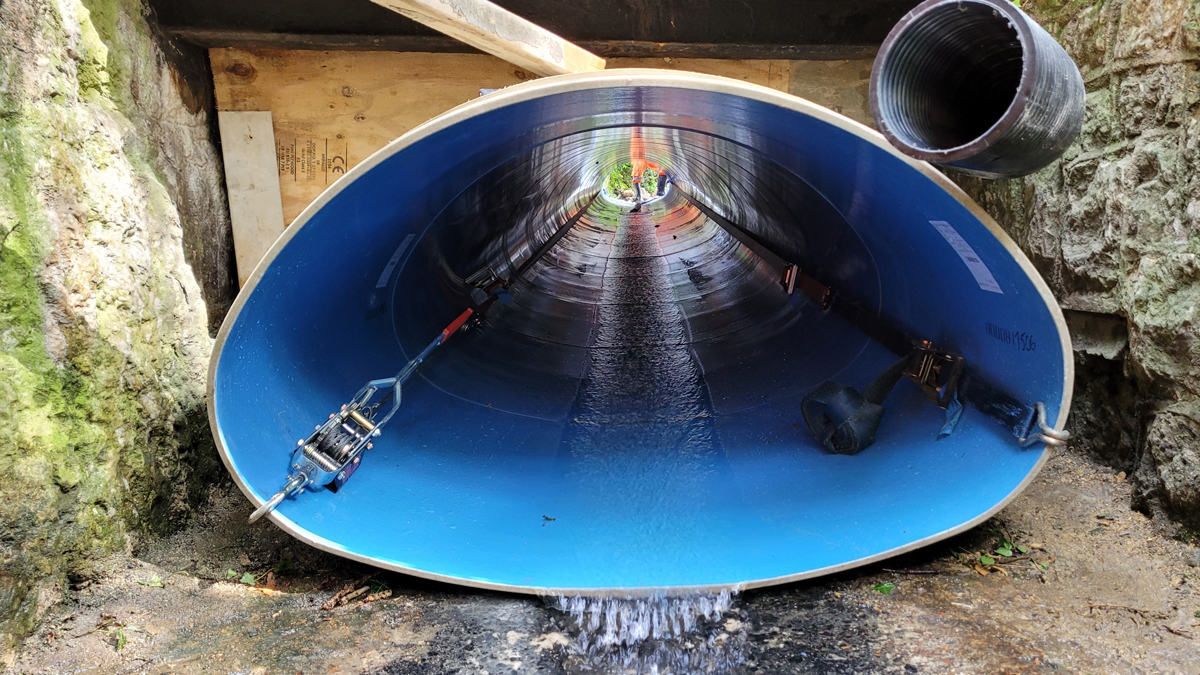

Flowtite GRP PN6 pressure rated pipes were used for the installed pipeline route which comprises 445m of 1400mm diameter pipe (fill and empty) and 90m length 1200mm diameter (empty only). Then a further 80m of 1200mm diameter pipe connects into the existing storm water return pump sump. Once the storm flows cease, the pipeline transfers this storm water to the storm return pumping station.

Project details

- Country/city: UK, Preston

- Year of Construction: 2018

- Application: Sewer

- Installation: Open Cut

- Technology: Flowtite

- Total length of pipe: 530m

- Nominal diameter DN (mm): 1400 & 1200mm

- Nominal pressure PN (bar): PN6

- Nominal stiffness SN (N/mm2): 5000

Supply chain

- Client: United Utilities

- Contractor: MMB

- Consulting engineer: MMB

- Flowtite GRP PN6 pressure rated pipes: Amiblu

Laying new GRP pipeline – Courtesy of MMB

Amiblu’s Flowtite filament wound pipes provide capacity to resist high internal pressures and maintain excellent long-term stiffness, corrosion and abrasion resistance and are engineered for 150 year’s service.

Where changes of direction in the pipeline were required, Flowtite biaxial pipe and lock joints were installed. This removed the need for expensive concrete thrust blocks and ultimately saved time on programme.

The Flowtite biaxial pipe and lock joint system is reinforced in the hoop and axial directions to resist pressure, end thrust and bending loads and is suitable for applications where transfer of load between pipes is required.

Measures to improve operability and resilience at the inlet works have been accomplished. Route cause and analysis techniques were adopted to ensure the best outcome and was delivered to a full PAS 1192-2 information delivery cycle. With Preston being a collaborative 3D BIM project, a federated model was compiled by amalgamating several different models from MMB, GHD and Longwood into one which proved advantageous.

Jonathan Edwards, Contracts Manager with MMB, commented:

“Choosing a GRP pipe solution provided a significant materials cost saving, when compared to the alternative ductile iron option.”

For more information: Amiblu UK | +44 (0)7786 013574 | www.amiblu.com