Sulzer Pumps Wastewater Ltd

Sulzer HL Feed Pumps at Hampton Loade WTW

Courtesy of Sulzer Pumps Wastewater Ltd

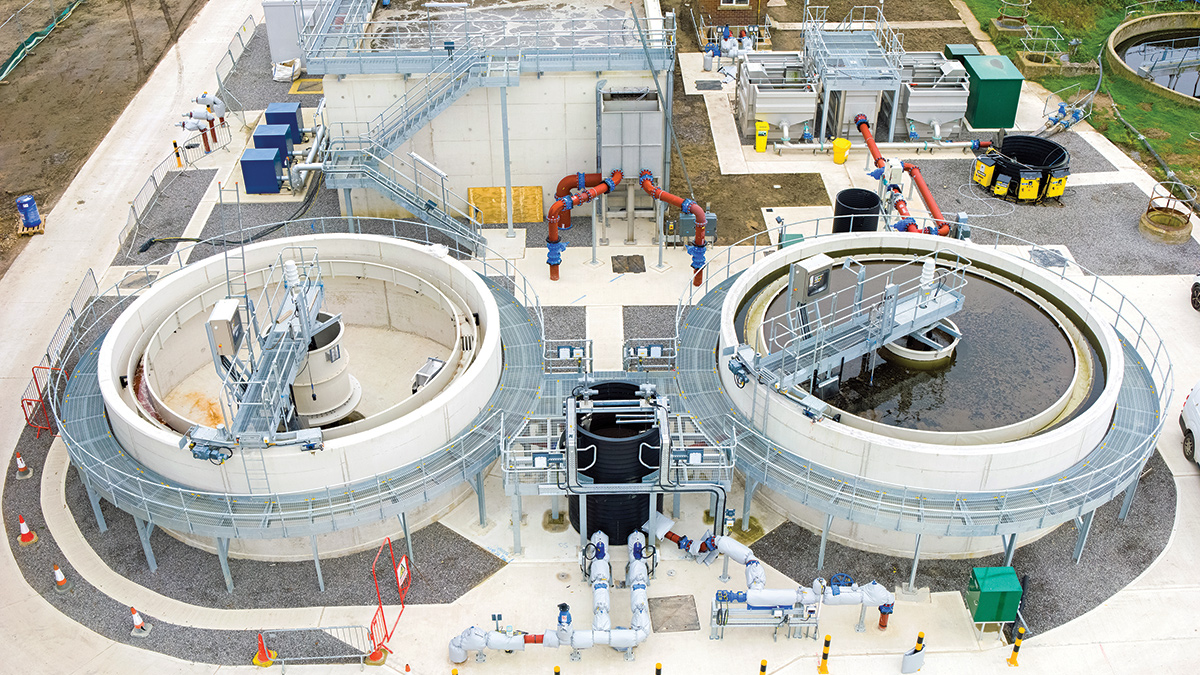

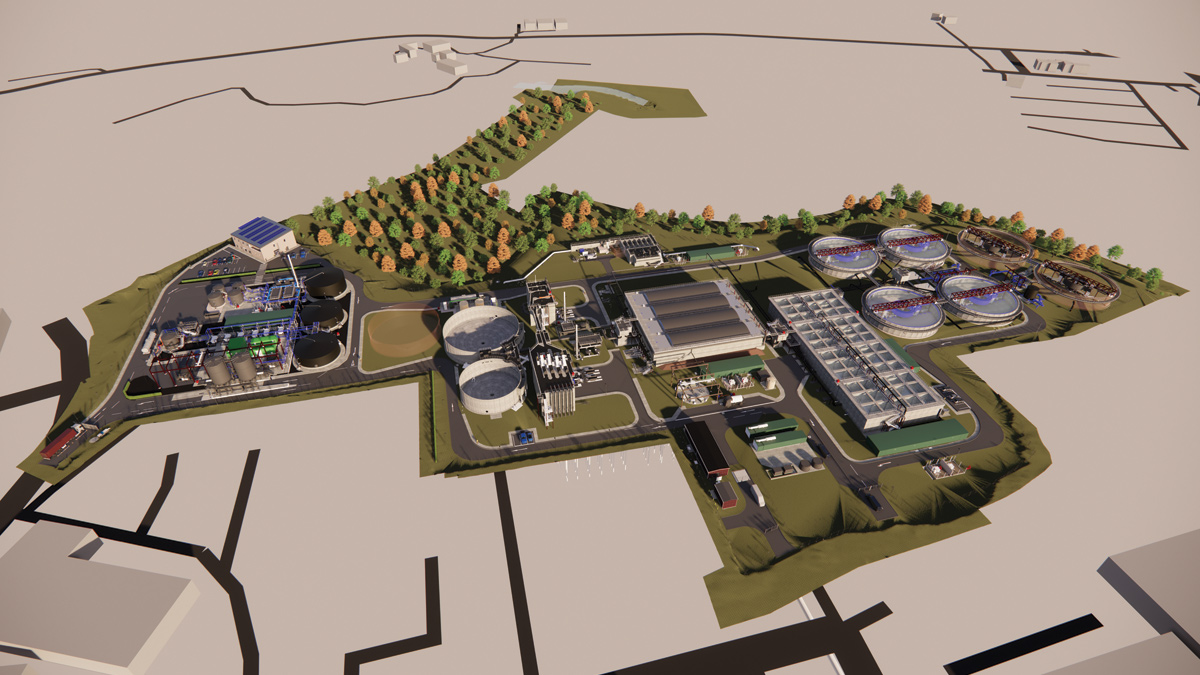

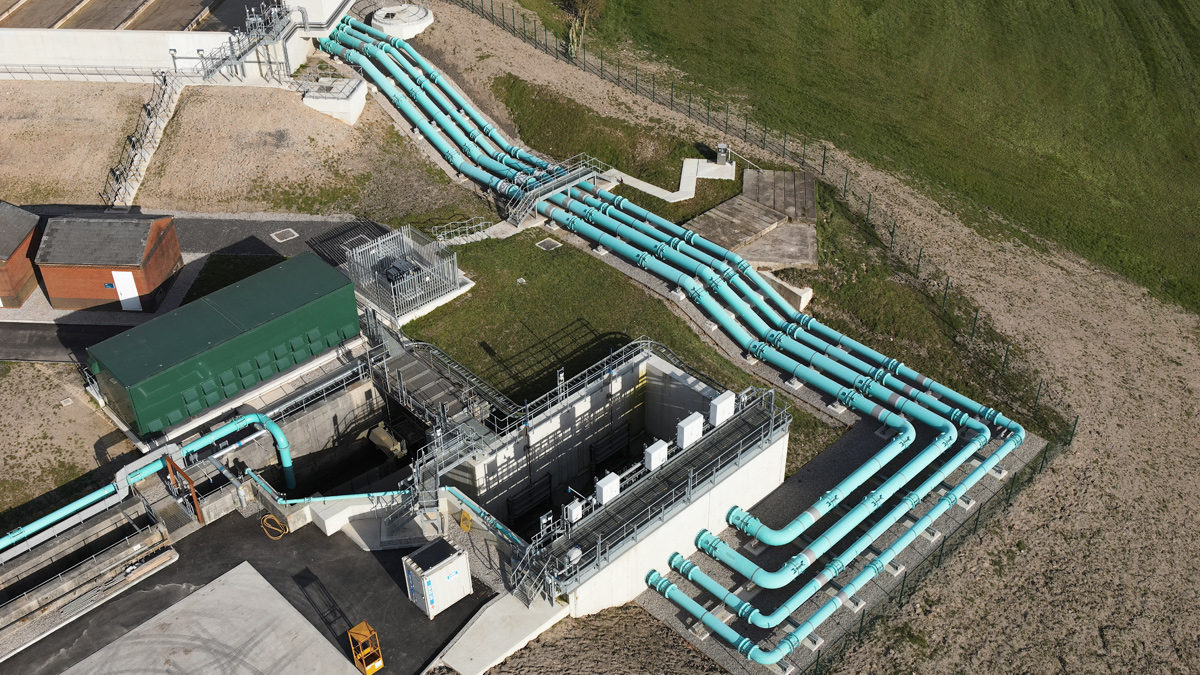

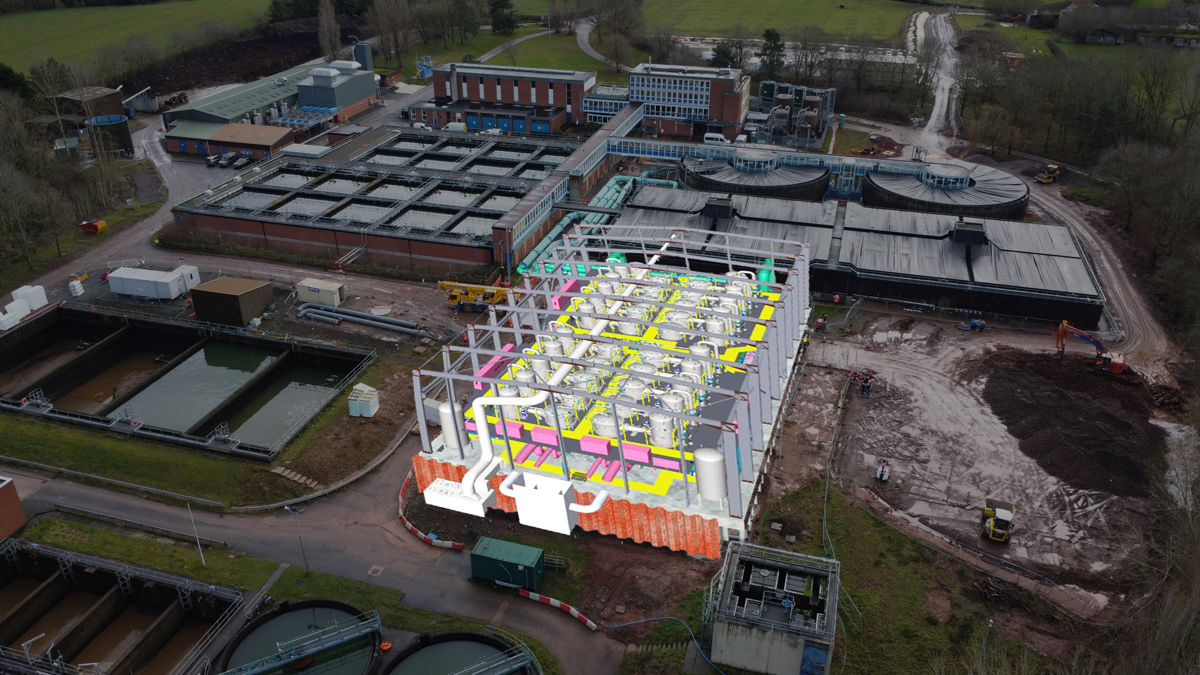

Hampton Loade WTW project is part of South Staffs Water’s current investment plan. It provides an interstage filtration system for the water treatment plant improving water quality for customers across the region. Ross-shire Engineering Ltd (RSE) – a UK’s leading company specialising in engineering services, was appointed to install one of the world’s largest CeraMac® filtration plants from PWNT.

Project background

Souths Staffs have carried out a project to introduce an additional stage of filtration level to enhance the water treatment. This was to be in place by the end of March 2024. After significant trials and piloting works, South Staffs chose to install a PWNT CeraMac® filtration system which brings significant benefits to the process. With this choice, the completion date was revised to end of March 2025.

Courtesy of Sulzer Pumps Wastewater Ltd

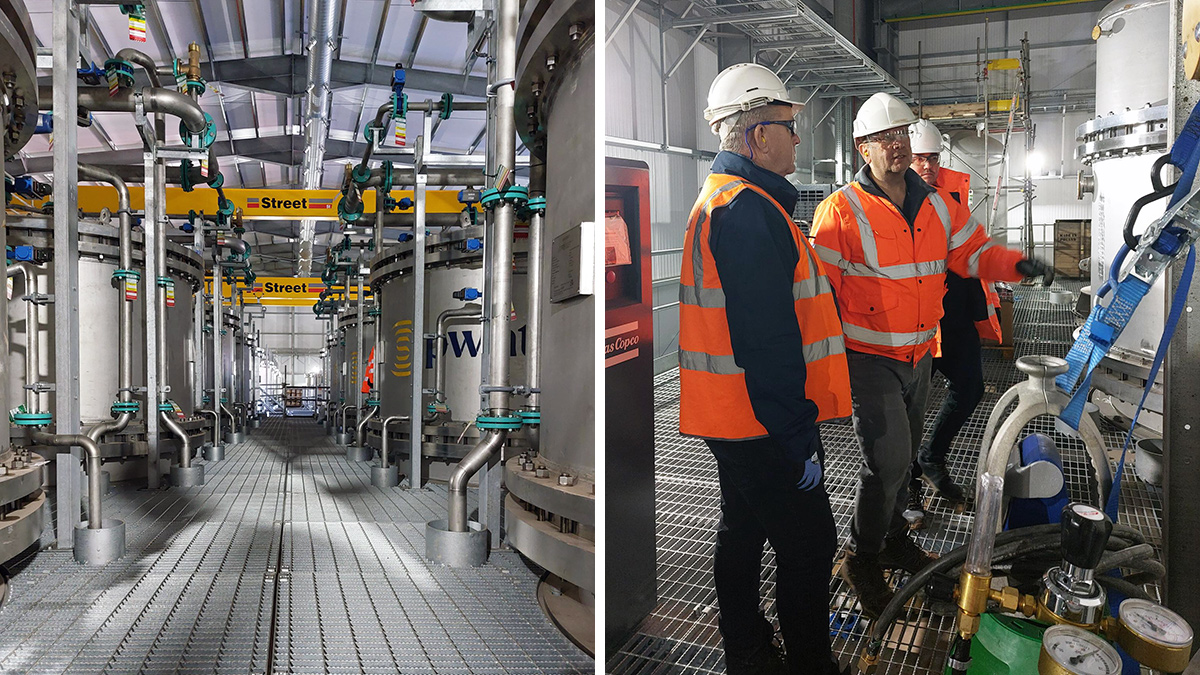

Adding the CeraMac® filtration

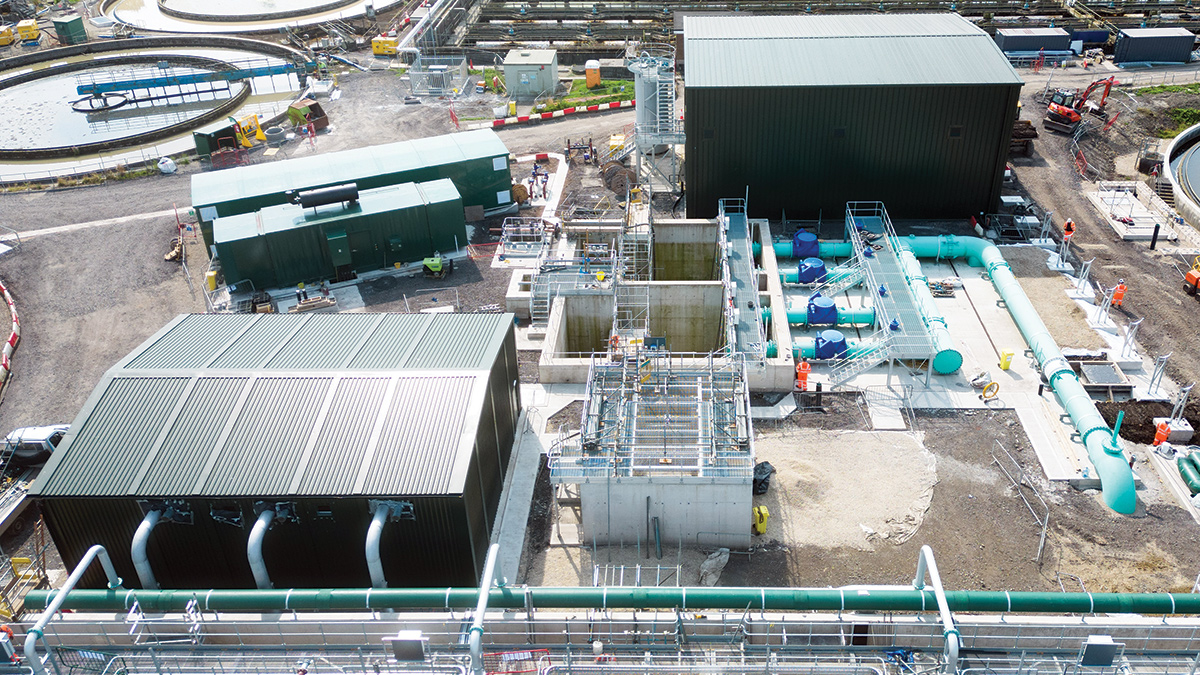

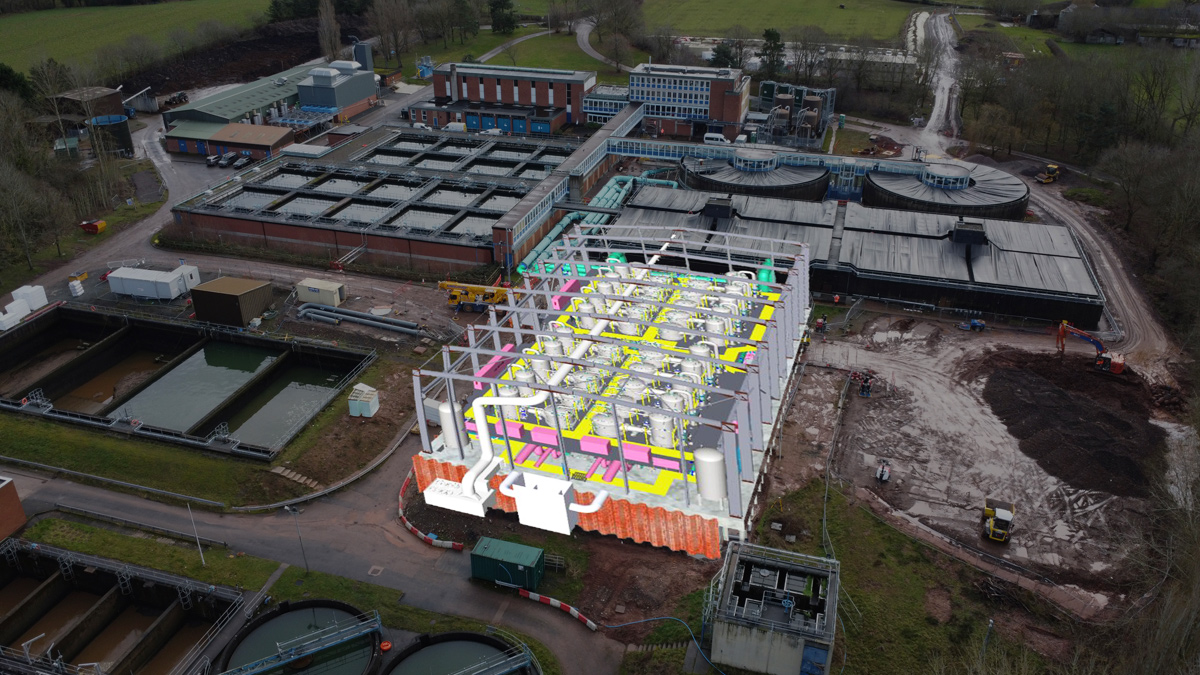

The project will deliver 20 CeraMac® C90 vessels. Each of the C90 units will be complete with a dedicated feed pump and backwash vessel. The 20 units are divided into two streams of 10 each with supporting membrane cleaning systems.

Paul Foden RSE Project Manager said:

‘’The CeraMac® solution was chosen as it provides the robust and ultimate physical barrier against particulates within the raw water. It also presents cost benefits, as in future the UV process can be removed.’’

Courtesy of Sulzer Pumps Wastewater Ltd

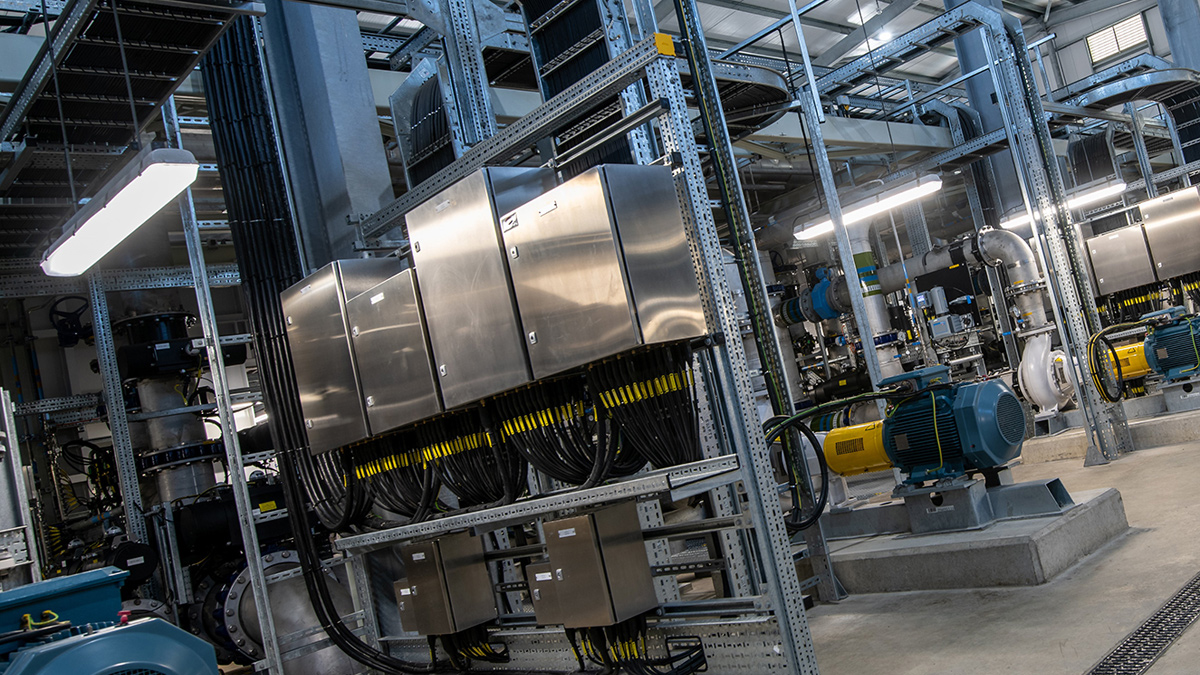

Enhancing filtration process with Sulzer feed pumps

Sulzer supported this stage of filtration by providing 40 HL feed pumps. These will pump water forward from the existing clarifier units onto the CeraMac® membranes.

Steve Wilburn, Sulzer UK Business Development Manager, commented:

“This is a very significant project. We are glad to be part of it and to support the customer both in the construction of this state-of-the art filtration plant, as well as in the upgrade of the treatment process.”

Extending the filter run time with Sulzer pumps

In addition to the second stage filtration, there will be various cleaning systems installed to ensure that the membranes are maintained at their optimum operating conditions.

There are two filtrate water storage tanks in the plant, each fitted with a clean backwash pump running between 3,5-4 bar. To this process, Sulzer delivered 4 backwash pumps. Their application in the process is to refill pressurised backwash vessels by pumping water into the system, allowing the air spring to remove accumulated particles and debris. Backwashing will help to maintain the efficiency of the filter and will prevent it from becoming clogged with debris.

For the enhanced cleaning, Sulzer supplied 4 neutralisation pumps and 4 CIP pumps.

Paul Foden concluded:

“We are very happy with the pumps provided and Sulzer’s support in delivering the best value and quality of products in the time of economic challenges.”

For more information contact: Sulzer Pumps Wastewater Ltd | +44 (0)1293 558140 | www.sulzer.com

|

Hampton Loade WTW |

|

| Hampton Loade WTW treats raw water from Chelmarsh Reservoir, located approximately two miles north-west of the site. The reservoir is supplied by the river intake pumps located within the intake building immediately adjacent to the River Severn. The maximum flow that can gravitate to the works from the reservoir is 130-135 megalitres/day (MLD). To increase the flow from the works up to the design value, there are four low-lift pumps which are also situated within the intake building … MORE |