GoFlo

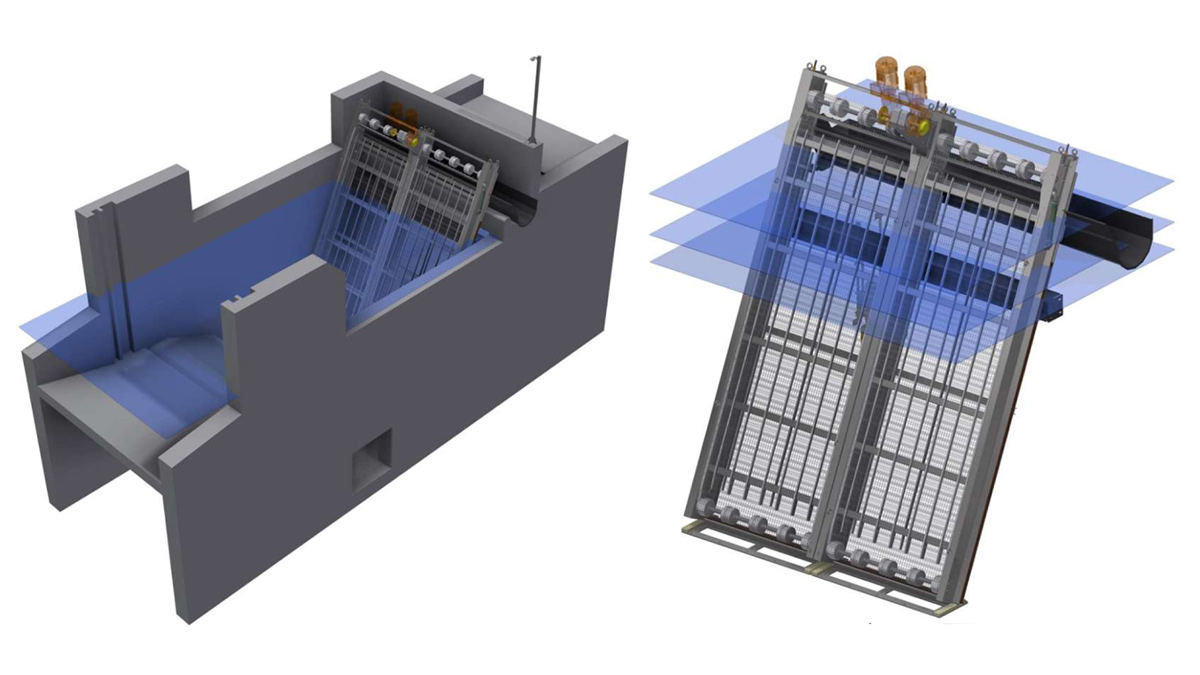

Our screens can be supplied with a bar-spacing down to 1.8 mm to ensure compliance with the Eel Regulations or strictest fisheries regulations. They are self-cleaning and incorporate debris flights to carry the debris up the screen, an inside-outwards high pressure debris spray boom and integrated debris trough and return channel. Ourscreens use an innovative mounting system, enabling them to be quickly lifted in and out, and on re-installation they are guided precisely into position without the need for divers, even into flooded intakes. We can supply just the screens, or a complete system including debris trough and return channel and walkways.

We design our systems in 3D and work closely with our clients to design an optimised overall solution to meet their requirements. Water Utility clients include Southern Water, Southwest Water, Wessex Water and Welsh Water, along with various hydropower operators who use our screens. We are always keen to help solve your problems; recent innovations include an ‘intake box’ system that allowed our screens to be installed by divers without having to de-water a 4.5 metre deep live intake that could not be taken offline for more than 8 hours, and a recent slide in/slide out mounting system that allowed our screens to be installed underneath live 11 kV powerlines – in both cases our innovations saved the client substantial amounts of money.

If you have a new intake project or have to upgrade an existing intake to be Eel Regs or fisheries compliant, we are keen to find out more. We are happy to provide a budget proposal and initial design/3D model at no cost, so please get in touch.