Supply Chain - Wastewater Treatment - Precast Concrete Structures

- AquaPyr (2024)

- Silicon Carbide Ceramic Membranes (2024)

- FilterClear® (2024)

FilterClear® (2024)

FilterClear® (2024)During AMP7 over 800 sites were required to meet tighter phosphorus permits under the National P Removal Programme. The majority of these sites adopted the solution of using tertiary solids removal (TSR) plant with ferric or aluminium dosing to meet the permit requirements. There are 6 major TSR plant suppliers in the UK, three of which use the same technology, each with its unique feature, competing in the P removal market. This has driven the TSR technologies to evolve and improve, addressing the needs to enhance reliability and to minimise the use of chemicals whilst meeting increasingly stringent standards.

FilterClear for phosphorus removal

FilterClear is a true depth filtration technology, with 900 mm of filtration bed depth. The influent is pumped to the top of the filter and flows through four layers of media: anthracite, silica, alumina and magnetite, which have decreasing particle size and increasing density. This configuration provides an equivalent of 4-stage filtration in a single vessel, allowing the filter to operate at a much higher filtration rate (up to 35m3/h) and achieve a better effluent quality than conventional sand filters; coupled with its much smaller footprint. FilterClear is a powerful tool in a designer’s armoury.

The key benefit of depth filtration is to enable the solids to be removed progressively through the entire depth of the 4-layer filter bed, extending the run-time and reducing backwash frequencies. The backwash can be controlled by timer or pressure. After backwash, the media will settle back to the original layers thanks to the carefully selected density and particle sizes of the four media types.

FilterClear has an average operating pressure of 0.4 bar, offering a low energy demand and a low operational carbon footprint.

Experience across the many FilterClear plants installed to date has highlighted the low cost of ownership, particularly with respect to operation and maintenance. The plants are fully automated and typically require just one annual service (less on sites with activated sludge upstream). There is no routine requirement for replacement parts or filtration cloths and the FilterClear plants require only a top-up of anthracite every few years.

Furthermore, all media layers are naturally-occurring minerals, thereby not introducing any microplastics or fibres into the treated effluent or dirty backwash water.

[caption id="attachment_13686" align="alignnone" width="1200"] FilterClear plant at Yeovil WRC - Courtesy of Bluewater Bio[/caption]

FilterClear plant at Yeovil WRC - Courtesy of Bluewater Bio[/caption]

For chemical P removal, good coagulation and flocculation are critical. Many TSR technologies need purpose-built coagulation and flocculation tanks with mechanical mixing, and some will also require polymer dosing.

By comparison, FilterClear only requires coagulant dosing for P removal; no polymer or ballast material is required. This is because large flocs are not essential for depth filtration. Chemical dosing can be added directly upstream of the FilterClear plant via an inline static mixer, and flocculation will occur in the headspace inside the filter vessel, above the media bed, removing the need for mechanical mixing or a flocculation tank, thereby simplifying the asset and reducing associated costs.

The absence of a separate flocculation tank further minimises the FilterClear footprint, makes the solution simpler to build and operate and eliminates the associated operational and maintenance tasks. It also eliminates the need for an overflow from the flocculation tank which, having been dosed with coagulant, represents a compliance risk.

Design for manufacture and assembly (DfMA)

Increasingly, clients and their tier one partners are looking to minimise site construction activities and durations. FilterClear plants are designed to allow off-site assembly and testing, then delivery to site as a package plant. Where possible, the complete filter gallery, including backwash pumps, blowers, actuated valves, instruments and controls are skid-mounted and transported fully assembled. Site activities are then limited to coupling the filter vessels, adding the media and commissioning. This DfMA approach ensures both quality and safety are well controlled and ultimately delivers a better solution in a shorter time at a lower overall cost.

Health and safety is an integral part of the design process, ensuring that all equipment is safe to install, operate and maintain. Filtration and backwash of the FilterClear plant is fully automated, with minimum operational input. The filters are enclosed, with no moving parts or serviceable components within the vessels and need minimal operator intervention. Due to the enclosed, fully automated design, risk of operator exposure to wastewater or chemicals is minimised. Furthermore, all machinery is at ground level for easy access.

Proven performance

Most TSR plant suppliers prefer to offer an effluent total suspended solids (TSS) guarantee as a surrogate to a TP guarantee. However, water companies have realised that, at low concentrations, there is a very poor correlation between the TSS and TP concentrations thereby introducing compliance risk.

As the developer and owner of the technology, Bluewater Bio Ltd has a deep understanding of both the process and phosphorus removal, and accordingly are able to provide a TP guarantee. This offers the client and their contractor the simplest and clearest assurance of meeting the final effluent permit as well as being contractually most straightforward. FilterClear performance has been tested and proven at over 50 sites across most UK water companies, all reliably achieving the respective permit requirements for both TP and iron. Knowing that more stringent TP permits will be imposed in AMP8, Wessex Water carried out long-term trials to push the performance limits at several sites with impressive results.

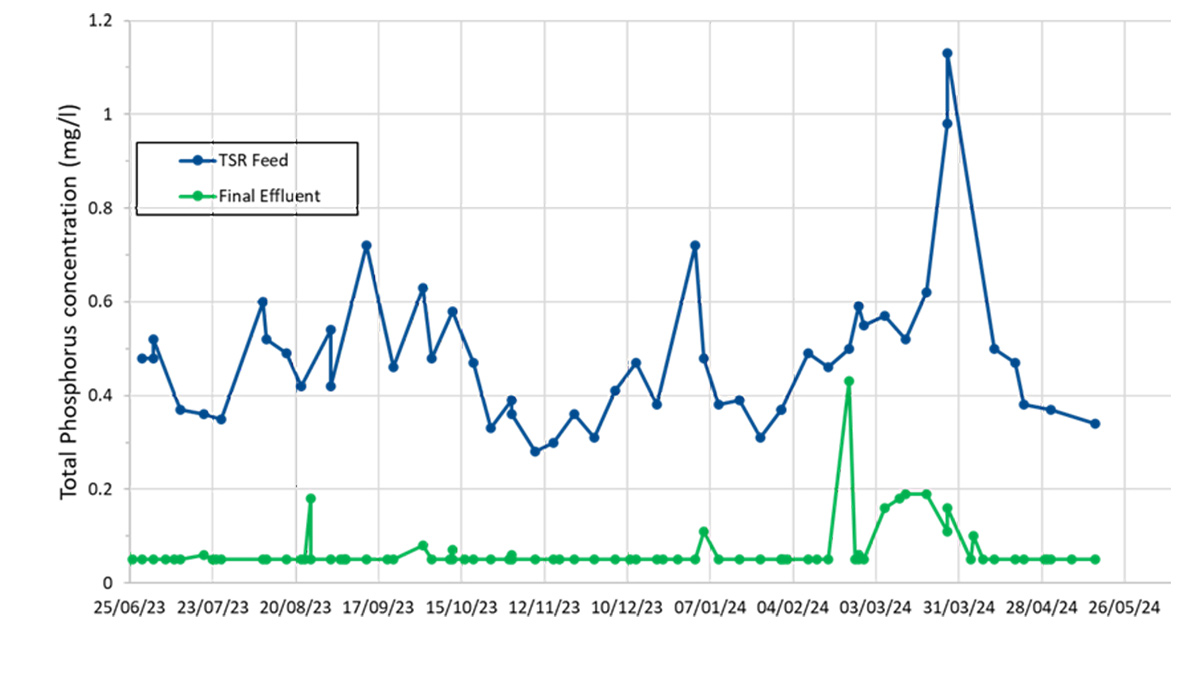

[caption id="attachment_13681" align="alignnone" width="1200"] ‘Site A’ performance graph: Blue line shows the Total P concentration of the TSR feed and the green line shows the Total P concentration of the final effluent after FilterClear treatment - Courtesy of Bluewater Bio[/caption]

‘Site A’ performance graph: Blue line shows the Total P concentration of the TSR feed and the green line shows the Total P concentration of the final effluent after FilterClear treatment - Courtesy of Bluewater Bio[/caption]

‘Site A’ is a typical small trickling filter site. In AMP7, a FilterClear plant was installed to meet a new 0.5 mg/l TP permit. The trial demonstrated that the plant achieved an average TP below 0.07 mg/l, with a 95%ile iron concentration of 0.27 mg/l. This performance has been achieved with an overall ferric dose of just 15 mg/l (including 1st point and 2nd point dosing) with simple flow-proportional dosing control, and despite some unrelated control issues during the trial. The long-term trials have demonstrated that FilterClear plants can reliably achieve a TP permit of 0.1 mg/l, making the solution future-proof. This offers the client a means of reducing WLC whilst adding future certainty.

FilterClear: Key advantages

Proprietary stratified FilterClear media of up to four layers, specially developed and applied over 10 years for exceptional performance.- High loading rate (25-50 m3/m2/h, i.e. 2-5x flow rate of competing technologies).

- High solids retention (low pressure drop and long backwash interval).

- High quality filtrate in a single step (SDI <3 : NTU <0.1 : BOD concentration <6mg/l).

- Low CAPEX (2-5x less media, fewer vessels).

- Low OPEX (no chemical use, low electricity consumption).

- Low backwash volume (<6% of filtrate, small backwash tanks, better yield, less waste).

- Small footprint (2-5x smaller filter area, smaller plant).

- Low O&M (simple, reliable, easy to maintain).

- Modular systems up to 1200m3/h per vessel.

Case study: Wessex Water: Yeovil Pen Mill WRC

During AMP7, Wessex Water installed 14 FilterClear plants across its region for phosphorus removal, ranging from small sites less than 4,000 population to large sites over 75,000 population. Yeovil Pen Mill Wastewater Recycling Centre (WRC) is the largest site among these.

Yeovil WRC in Somerset is a large treatment works owned by Wessex Water, serving a population equivalent (PE) over 75,000 (including trade discharge). The existing treatment processes comprised:

- Primary settlement tanks.

- High-rate plastic media filters.

- Intermediate humus tanks.

- Trickling filters (slag media).

- Humus tanks.

To meet tightened consent requirements, a major upgrade was required during AMP7; comprising tertiary MBBR plant and a tertiary solids removal (TSR) plant.

The TSR plant with chemical dosing is required to achieve the total phosphorus (TP) consent of 0.5 mg/l. On a whole life cost basis, taking into account process reliability, delivery programme, power demands, chemical consumption and maintenance requirements, FilterClear from Bluewater Bio Ltd was identified as the preferred solution, and the contract was awarded in May 2022.

The key elements of the FilterClear plant at Yeovil WRC are:

- Number of filters (800mm diameter): 11

- Number of backwash pumps: 2 duty/2 standby

- Number of backwash blowers: 2 duty/2 standby

- Number of clean backwash tanks: 1

- Number of dirty backwash tanks: 1

(left) FilterClear plant at Yeovil Pen Mill WRC next to a trickling filter and tertiary MBBR plant at Yeovil WRC and (right) Skid design at Yeovil Pen Mill WRC for easy access and maintenance - Courtesy of Bluewater Bio[/caption]

(left) FilterClear plant at Yeovil Pen Mill WRC next to a trickling filter and tertiary MBBR plant at Yeovil WRC and (right) Skid design at Yeovil Pen Mill WRC for easy access and maintenance - Courtesy of Bluewater Bio[/caption]

The FilterClear plant design has taken into account the following:

- Treat the peak flow during filter backwashing.

- Ensure the solids holding capacity is adequate under the worst-case scenario.

- Manage the interfaces with tertiary pumping/ferric dosing.

- Minimise the whole life cost and footprint.

- Enable safe and easy access, lifting and maintenance (ALM).

Thanks to the high filtration rate, the FilterClear plant has a smaller footprint in comparison to conventional filters. The compact nature of the FilterClear plant makes it ideal for the very congested site at Yeovil. At the time of writing (July 2024), the FilterClear plant has been installed and is currently being commissioned.

Throughout the project, the design teams worked closely with Wessex Water on the ALM assessment to ensure that the plant is operator-friendly. Particular attention was paid to eliminating hazards during operation and maintenance.

Highest accolade - rising to the challenge in AMP8

Innovation plays a critical role in the water industry’s ability to adapt to climate change, population growth and new and emerging pollutants. Bluewater Bio Ltd continue to develop and enhance technologies so that they excel in performance, value, reliability and sustainability.

[caption id="attachment_13682" align="aligncenter" width="356"] FilterClear technology received a King’s Award for Enterprise (Innovation category) in 2024[/caption]

FilterClear technology received a King’s Award for Enterprise (Innovation category) in 2024[/caption]

In 2024 Bluewater Bio Ltd received a King’s Award for Enterprise in the Innovation category for its FilterClear technology. The award was granted on a recommendation by the Prime Minister and approved by His Majesty The King and is the most prestigious award for a UK business. This award is further recognition that FilterClear has become the preferred choice for clients.

With AMP8 on the way, over 900 sites will be on the national P removal programme and FilterClear will play a major part in delivering a successful outcome.

Winchester House, 259-269 Old Marylebone Road, London NW1 5RA

| 020 7908 9500 | bluewaterbio.com |

- The Beast at Pellows Waste Disposal Services

The Beast at Pellows Waste Disposal ...At Pellows Waste Disposal Services, near Truro, a typical 4.5m3 tanker (1,000 gallons) that used to take over 20 minutes to empty, can now get back out on the road to collect more liquid waste after less than three minutes discharge time. The turnaround is due to "The Beast" made by SAVECO Environmental, that with a fully integrated 5mm screen, conveyor and compactor, all in one unit, removes harmful debris and dewaters it prior to discharge. It can handle 200m3/h and up to 6-8% solids as a plug-and-play system. Payback is expected in just four months, as Pellows’ Director, James Martin, explains:

The Beast at Pellows Waste Disposal ...At Pellows Waste Disposal Services, near Truro, a typical 4.5m3 tanker (1,000 gallons) that used to take over 20 minutes to empty, can now get back out on the road to collect more liquid waste after less than three minutes discharge time. The turnaround is due to "The Beast" made by SAVECO Environmental, that with a fully integrated 5mm screen, conveyor and compactor, all in one unit, removes harmful debris and dewaters it prior to discharge. It can handle 200m3/h and up to 6-8% solids as a plug-and-play system. Payback is expected in just four months, as Pellows’ Director, James Martin, explains:“The Beast has far exceeded our expectations. It injects water to accelerate the process, and is so much more efficient and robust than our previous system. Investing in The Beast is part of a major upgrade that we’ve put into place to address the big changes that have happened in Cornwall’s collection and disposal of liquid waste.”

The upgrade at Pellows, which includes a centrifuge, aeration, and larger tanks, has enabled the company (established in 1964) to expand its customer-base by offering a complete in- house service. It will also provide a potential lifeline to other contractors who collect liquid waste from the holiday parks, factories, hotels and many thousands of homeowners in Cornwall that are not connected to the sewer network. The closure in April 2022 of what turned out to be two large disposal sites that were trading illegally, has forced contractors into sending their vehicles long distances away to discharge their collected waste. The headache has been partly alleviated by being able to take some liquids to be treated by South West Water, but during heavy rainfall and storm events, the water company has had to keep its gates closed because capacity has been reached. James Martin continued:“Storms and flooding from prolonged rainfall is all too common these days. We couldn’t just stop working for long periods due to the weather, letting our customers down, or keep sending our vehicles miles and miles away to unload. We had to act to protect and grow our business, so first contacted Centri Force, who make very good decanter centrifuges. They gave us plenty of good advice about how we could become independent by treating the collected waste ourselves, which included a strong recommendation of "The Beast" from SAVECO Environmental.”

The pneumatic press (with de-stoner) that had been in operation at Pellows not only took far longer to receive incoming waste, but, according to Richard Montanaro, Managing Director of Centri Force, was too small and far less sturdy, with too many areas where the process would require costly maintenance or be likely to slow or fail.“In comparison, "The Beast" is very well designed. It is a great product that integrates very well with other parts of a plant to provide an excellent front-end pre-screen. With a centrifuge as part of a process, it gives us exactly what we’re looking for, and has helped Pellows greatly increase productivity and take this important step to becoming a liquid waste contractor with its own treatment facility".

Environmental wet waste is a big issue, and Cornwall, with far less infrastructure and sewer connections than many counties, faces some big challenges, so it is good to see Pellows play a big part in reducing the environmental impact of septic tank liquids.” Rotating around its axis, The Beast’s cylindrical filter conveys screenings into a loading hopper placed in the centre, whilst a set of spray nozzles washes the filter during operation. A screw, placed inside the conveying pipe (with its top inside the discharge hopper), conveys the screenings towards the treatment stages, during which organic substances are washed out. Subsequently, solids are compacted and dewatered in the compacting and drainage area, before exiting through a discharge chute. Despite septic tank contents often containing solidified calcium, rocks, stones, and sanitary products, installation of The Beast now sees Pellows’ 27-tonne artics discharge waste in less than 13 minutes, compared preciously (depending on the thickness of the liquid) to 45-minutes, up to one hour. Craig Webb, SAVECO’s Municipal Sales Engineer, commented:“We have worked closely with Pellows and Centri Force to bring about a big improvement in treating liquid waste. Allowing effluent to be put directly through "The Beast", which avoids placing further stress on an existing plant, is also a huge benefit to water companies. Liquid waste contractors and the water industry can see that by screening, washing, conveying and dewatering - all in one unit - there is a reduction in risk, and the opportunity to make big savings by removing the need for multiple pieces of equipment.”

James Martin from Pellows, continued:“The whole system is so much better now. We get better biosolids too at the end of the process. Apart from South West Water, we’ve now become the first company in the County who have the capability to treat liquid waste for safe disposal into the foul sewer main.”

For more information contact SAVECO Environmental Ltd | +44 (0)1684 299104 | https://saveco-water.co.uk

- Greenham Common STW

Greenham Common STWThames Water’s Greenham Common Sewage Treatment Works (STW) is situated in the shadow of a former US Air Force base in Bishops Green, Newbury, and alongside the River Enborne. The untreated wastewater that Greenham Common receives has a high rag content and repeated screening carry over was affecting the full treatment process, the overall performance of the site and risked that the site would go out of environmental compliance. Thames Water approached Hydro International’s UK Wastewater Services team, M&N, to evaluate the site and propose a robust solution. The team installed the MNSS Combined Screen, to capture larger influent materials at the front end of the wastewater treatment process, protecting and improving the efficiency of the downstream treatment system. Due to the site hydraulics/flows, there was no reliable wash water system for the MNSS Combined Screen, so the team found an innovative way to solve this. They created a bespoke system, including pumps, to use the effluent from the site’s primary settlement tank. The spray nozzles on the MNSS Combined Screen were also altered to accommodate the change. [caption id="" align="alignnone" width="1200"]

Greenham Common STWThames Water’s Greenham Common Sewage Treatment Works (STW) is situated in the shadow of a former US Air Force base in Bishops Green, Newbury, and alongside the River Enborne. The untreated wastewater that Greenham Common receives has a high rag content and repeated screening carry over was affecting the full treatment process, the overall performance of the site and risked that the site would go out of environmental compliance. Thames Water approached Hydro International’s UK Wastewater Services team, M&N, to evaluate the site and propose a robust solution. The team installed the MNSS Combined Screen, to capture larger influent materials at the front end of the wastewater treatment process, protecting and improving the efficiency of the downstream treatment system. Due to the site hydraulics/flows, there was no reliable wash water system for the MNSS Combined Screen, so the team found an innovative way to solve this. They created a bespoke system, including pumps, to use the effluent from the site’s primary settlement tank. The spray nozzles on the MNSS Combined Screen were also altered to accommodate the change. [caption id="" align="alignnone" width="1200"] Greenham Common STW MNSS Combined Screen[/caption]

Simon Brum, Project Manager, Hydro International’s UK Wastewater Services Team, said:

Greenham Common STW MNSS Combined Screen[/caption]

Simon Brum, Project Manager, Hydro International’s UK Wastewater Services Team, said:

"We needed to find a quick and effective solution for the Greenham Common STW to prevent any overflows, and designed and installed a robust, reliable inlet works system that combines screening, washing, transport, compaction and dewatering in a single cost-effective standalone solution.”

Henry Crompton, Lead Project Engineer at Thames Water Utilities Ltd, commented:“We needed a suitable solution that was effective and within budget, and the team delivered that. We are very happy with the work undertaken on this site and will be using it as an example to our other Thames Water teams who may encounter the same issues.”

Handling flows of up to 150 l/s, the MNSS Combined Screen is designed for smaller plants and those facilities that require a more cost-effective screening solution - helping engineers, operators, and site owners to maintain treatment effectiveness even at remote and budget - constrained sites. [caption id="" align="alignnone" width="1200"] Greenham Common STW MNSS Combined Screen[/caption]

Optimised for reduced maintenance and extended component lifetimes by the UK Wastewater Services team, only the MNSS Combined Screen achieves a screenings capture ratio of 53%, the highest of any independently tested 6mm combined screen.

Greenham Common STW MNSS Combined Screen[/caption]

Optimised for reduced maintenance and extended component lifetimes by the UK Wastewater Services team, only the MNSS Combined Screen achieves a screenings capture ratio of 53%, the highest of any independently tested 6mm combined screen.

To learn more about how our inlet works specialists can help you with your wastewater needs

M&N Electrical & Mechanical Services Ltd | +44 (0)1305 821142 | www.hydro-int.com/ukwws

- Walsall Wood STW: Mecana Installation

- Gowerton WwTW

Gowerton WwTW

Gowerton WwTWProject Information

- Location: Swansea

- End client: Welsh Water

- Main contractor: Morgan Sindall

- Scope of works: Design, manufacture, delivery and installation of the PFET and Blending Chamber structures for Gowerton WwTW

Background

The reasoning behind the works at Gowerton was a requirement to meet permit conditions in South Wales by 2020. It is a cost-effective approach to challenging flow management at Water Treatment works which enables DCWW to meet their spill permit regulations as laid down by the Welsh Government and Natural Resources Wales. The client was working to an extremely tight programme to achieve consent dates, which meant that the FLI Precast Solutions precast construction methods delivered key advantages over the traditional build process. On completion of the design the precast panels were produced off site at the same time as the 500,000m3 excavation was undertaken to receive the panels. The area was suitably prepared for the delivery of the panels which was coordinated with the site team and the client’s operators to facilitate the existing treatment process. Key drivers for the scheme included the requirement for complex M&E integration which also lends itself to the FLI Precast Solutions design and production philosophy for off-site manufacture. [caption id="" align="alignnone" width="768"] Precast concrete structures under construction - Courtesy of FLI Precast Solutions[/caption]

The Gowerton scheme is the first project in the UK to utilise American company WesTech’s Flexfilter technology.

Precast concrete structures under construction - Courtesy of FLI Precast Solutions[/caption]

The Gowerton scheme is the first project in the UK to utilise American company WesTech’s Flexfilter technology.

Solution

- Controlled production of elements to a very high standard.

- Integration of complex M&E systems.

- Reduced H&S risk on site.

- Programme savings in the works through a shorter construction programme.

- Reduced workforce on site resulting in reduced main contractor preliminaries.

- Reduced construction traffic for the local area, meaning less disruption for residents.

- Lower carbon footprint as a result of the FLI Precast Solutions construction methodology, which is typically half that of traditional in situ build.

- Flexibility for programme phasing on site, if necessaryAll units manufactured off-site and called in as dictated by the programme.

- FLI Precast Solutions provide a secondary sealing system which traditional methods do not offer.

- Clear works development through Building Information Modelling (BIM) and cutting-edge design capability.

Precast concrete structures under construction - Courtesy of FLI Precast Solutions[/caption]

A word from our client: Kevin James, Project Manager - Wastewater Infrastructure, Welsh Water Capital Delivery Alliance:

Precast concrete structures under construction - Courtesy of FLI Precast Solutions[/caption]

A word from our client: Kevin James, Project Manager - Wastewater Infrastructure, Welsh Water Capital Delivery Alliance:

“The scheme involved installing various complex precast structures to house a new flexseal treatment system that will deal with foul water storm flows before discharging to the consented outfall, the first of its kind in Europe. The PFET structure alone was 27m x 26m x 8m deep (at the deepest part), consisting of 3 different levels and various interconnecting chambers.

Due to the high priority of the scheme and the tight deadlines to meet NRW consents, a precast option was progressed. This enabled the design of the structure to be passed to FLI Precast which released our design team to concentrate on other areas of the scheme, showing significant programme savings on the design.

Due to the competency and efficiency of the FLI Precast team the precast installation was completed on time with zero accidents/incidents and to the end client’s satisfaction.”

For more information: FLI Precast Solutions: +44 (0)1279 423303 | www.fliprecast.com

- P Removal

P Removal

P RemovalProject Challenge

Although phosphorus is a necessary nutrient for plants and animals, excessive phosphorus in waterways can lead to the extreme growth of plants and algae. High levels of plants and algae in the water can have a detrimental impact on aquatic life and the quality of water, including low dissolved oxygen concentrations.Solution

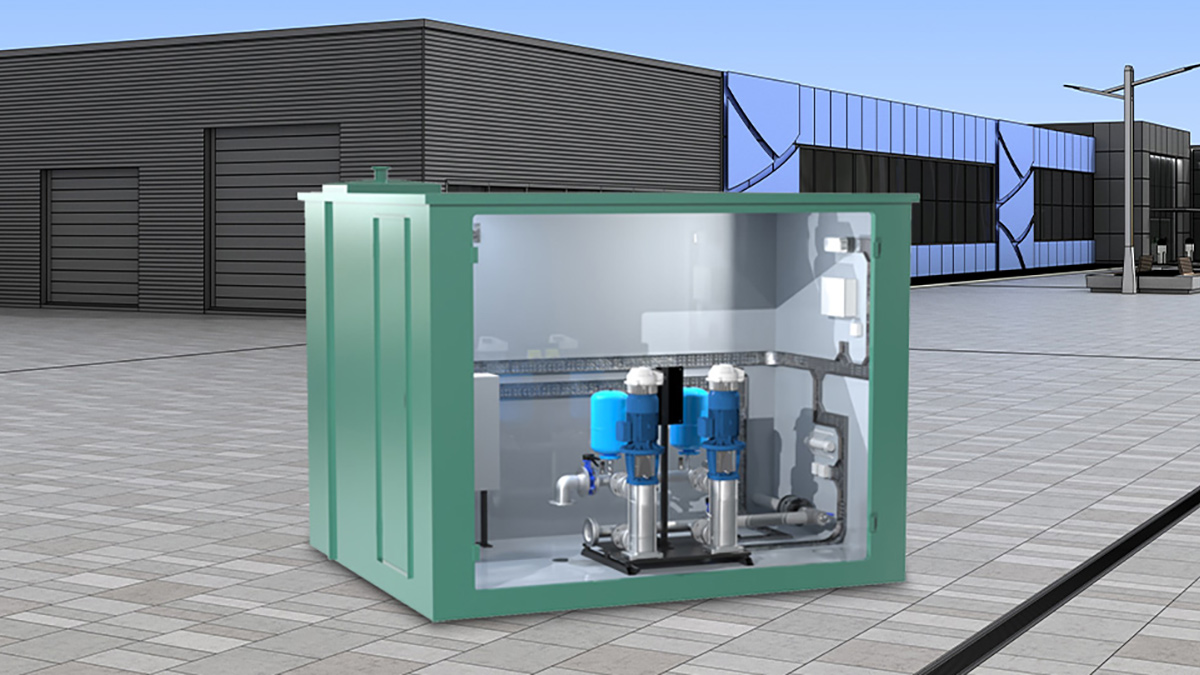

Dutypoint successfully supplied, delivered and installed its weatherproof GRP kiosk, the QuadraTANK™, incorporated with a standardised wash-down package, ensuring it was efficiently operational and ready for use. The product was manufactured to the client’s project specifications and houses a water storage tank, controls, twin booster pump system for a network of wash-down points. To meet the client’s needs of removing phosphorus, the wash-down capabilities of the QuadraTANK™, combined with an additional hose reel component, provided a solution to significantly improve water quality by aiding in the removal of phosphorus, resulting in a very happy client. The wash-down additions are a valuable feature in hitting water regulations, including its CAT 5 protection capabilities. Our hose reel was a built-in check valve (one-way valve), which prevents the backflow of hazardous contaminated water into the water systems. [caption id="attachment_12307" align="alignnone" width="1200"] QuadraTANK™ with Additional wash-down/Irrigation hose reel[/caption]

QuadraTANK™ with Additional wash-down/Irrigation hose reel[/caption]

For more information about Dutypoint Ltd | 01452 300110 | www.dutypoint.com

For more information about QuadraTANK | 01452 300110 | QuadraTANK™

About Dutypoint Ltd

Since 1976, Dutypoint has become one of the leading players in fluid technology, trusted by clients in the UK and overseas. Integrity, transparency, accountability and clear communication are crucial to how we do business. We stand by what we say - today and every day. The Dutypoint range includes a variety of industry-leading products, including cold water booster sets and QuadraTANK™.

- Civil Engineer - Water (6331)

Civil Engineer - Water (6331)

Civil Engineer - Water (6331)The opportunity

Do you have a passion for Civil Engineering ? Are you driven to create solutions for the unprecedented climate, environmental, and efficiency challenges facing our clients and the wider community? Then make a real difference and join us at Stantec! We are excited to continue our growth journey in Ireland and Northern Ireland and we have exciting plans for expansion in 2025 and beyond. We look forward to continuing our work with Uisce Eireann on the Engineering Design Services Framework and in Northern Ireland, we are proud to have been appointed to Northern Ireland Water’s IF182 Professional Services Framework. Taoiseach Simon Harris recently opened our new Dublin office, and we have now also moved to a new city center office in Belfast. This exciting pipeline of work, coupled with the scale of opportunity across the AMP8 cycle in the UK means that we seeking Civil Engineers at all levels with experience in the water/wastewater industry to join us. We are flexible with location so the position can be based in Dublin, Belfast or elsewhere. You will have the opportunity to join a dynamic team spread across the UK and Ireland, supporting the delivery of a variety of projects as part of a major capital investment programme.You will play an important role in the team, developing technical solutions & providing advice to our clients. You will provide technical expertise to ensure projects are delivered to cost, schedule & quality standards and work collaboratively amongst multi-disciplinary teams to ensure first class delivery of our projects. You will work closely with external stakeholders & clients to develop long term relationships.About You

You will be Degree qualified (or equivalent) in Civil Engineering or other relevant subject and have some experience of working within the regulated water industry.You will have knowledge of water and wastewater infrastructure/networks and treatment. Due to the nature of upcoming projects, ideally, you will also have experience in areas such as Clean Water and Wastewater Treatment, Trunk Mains and Large Diameter Pipeline Design.Ideally, you’ll have previous consultancy experience in a design role.Most importantly, you’ll embody our values and ethos of client focus and service excellence and have a passion for making a difference in the Water sector.Why Join us?

- Our People Culture: We're a close knit team and very proud of our friendly and collaborative environment

- Growth: We're on an exciting growth journey in Ireland and Northern Ireland - we want you to be part of it!

- Awards: Stantec were awarded the International Consulting Firm of the Year and Best place to work - Large Consulting Firms at the 2024 NCE awards as well as being consistently recognised in the top 10 Corporate Knights most sustainable companies in the world.

- Great Benefits: Competitive salary, pension plan, holidays, free private medical insurance, discounted gym membership and lots more.

- Flexible working arrangements

- Great Projects: We have secured positions on both the Uisce Eireann and NI Water Frameworks and are delivering a wide variety of projects that will make a real difference to our communities

- Industry leading training and development as well as paid for professional subscriptions

About Stantec

The Stantec community unites more than 31,000 employees working in over 450 locations across 6 continents. We have been working with our clients and communities in the UK for over 150 years. We plan, design, deliver and manage the development and infrastructure needed to support the creation of sustainable, healthy and prosperous communities. Our teams provide effective and relevant solutions, translating our clients’ vision into valued consents, deliverable plans for projects and programmes, and efficient designs for delivery, based on technical excellence and deep market insights. We deal with today’s challenges, but also keep a fairer, better tomorrow in sight, looking at how we deliver clean growth, support radical changes in our economy and meet the needs of future communities. Stantec provides equal employment opportunities to all qualified employees and applicants for future and current employment and prohibit discrimination on the grounds of race, colour, religion, sex, national origin, age, marital status, genetic information, disability, sexual orientation, gender identity or gender expression. We prohibit discrimination in decisions concerning recruitment, hiring, referral, promotion, compensation, fringe benefits, job training, terminations or any other condition of employment. Stantec is in compliance with laws and regulations and ensures equitable opportunities in all aspects of employment. Building an inspired, inclusive work environment that attracts, supports, and develops world-class talent is a crucial key to our success. If you are excited by this role but worry that your experience doesn’t exactly align, we encourage you to apply. - Senior Civil Engineer - Water (6286)

Senior Civil Engineer - Water (6286)

Senior Civil Engineer - Water (6286)The opportunity

Across the entire business, Stantec are building on top of what’s already been a highly successful period of growth. Our strategy within the Water division for 2023 and beyond is creating a number of new exciting opportunities across the business. We partner with the top water clients across the UK, work on some of the largest, most iconic water projects in the industry and we promise to design with community in mind by reducing environmental impacts and improving social impacts. We enable the delivery of sustainable development and infrastructure projects that adapt to and mitigate the effects of climate change. Our Civil Engineers work across the project lifecycle in asset planning / strategy, concept design, outline design and detailed design. We work in a variety of project areas within the water sector, including clean water treatment and networks, wastewater treatment, wastewater networks, flooding, and urban drainage. You can find out more about our work in the water sector here: Stantec H2O+U - UK. You’ll be responsible for the project’s civil engineering design, the leadership of civil engineering teams and will work alongside our overall project design leads to ensure successful project delivery and outcomes for our clients. You will also have access to Stantec’s world-class expertise to help you deliver cutting edge design.About You

You’ll have experience working as a Civil Engineer on projects within sectors such as the water, environment or other related infrastructure sectors. Ideally you will hold Chartered or Incorporated member status with a relevant professional body such as ICE or CIWEM. You’ll have a passion for the water and environment sector and supporting our developing civil engineers. You’ll also be experienced in successful project delivery and working collaboratively with project teams to develop innovative solutions. Finally, you will have experience of working in a client facing role, leading client engagement and collaboration on a regular basis.

About Stantec

The Stantec community unites more than 31,000 employees working in over 450 locations across 6 continents. We have been working with our clients and communities in the UK for over 150 years. We plan, design, deliver and manage the development and infrastructure needed to support the creation of sustainable, healthy and prosperous communities. Our teams provide effective and relevant solutions, translating our clients’ vision into valued consents, deliverable plans for projects and programmes, and efficient designs for delivery, based on technical excellence and deep market insights. We deal with today’s challenges, but also keep a fairer, better tomorrow in sight, looking at how we deliver clean growth, support radical changes in our economy and meet the needs of future communities. Stantec provides equal employment opportunities to all qualified employees and applicants for future and current employment and prohibit discrimination on the grounds of race, colour, religion, sex, national origin, age, marital status, genetic information, disability, sexual orientation, gender identity or gender expression. We prohibit discrimination in decisions concerning recruitment, hiring, referral, promotion, compensation, fringe benefits, job training, terminations or any other condition of employment. Stantec is in compliance with laws and regulations and ensures equitable opportunities in all aspects of employment. Building an inspired, inclusive work environment that attracts, supports, and develops world-class talent is a crucial key to our success. If you are excited by this role but worry that your experience doesn’t exactly align, we encourage you to apply. - Senior Civil Engineer (6463)

Senior Civil Engineer (6463)

Senior Civil Engineer (6463)The Opportunity

Following a number of successful frameworks bids across the water industry, and in preparation for the most challenging AMP ever, we are expanding our high-performing engineering teams across the country. In Newcastle, we are excited to have been appointed as a Strategic Technical Partner by Northumbrian Water for the AMP8 period. Stantec provide a range of technical enabling, solution delivery and design services to support Northumbrian Water in achieving its vision to be the leading provider of sustainable water and wastewater services. As part of our long-standing relationship with Northumbrian Water, including the ongoing ESH-Stantec joint venture, we will continue to develop innovative solutions to support their delivery of capital investment across both infrastructure & non-infrastructure projects. In order to continue providing our clients with our expert service, we are looking to recruit a Senior Civil Engineer into our team Newcastle on the picturesque Quayside. You will become part of an international team, redefining our landscape with sustainability, the environment and the communities we serve at the heart of everything we do. As a Senior Civil Engineer, you will work across the entire project lifecycle in asset planning, strategy, concept design, outline design & detailed design. You’ll be responsible for delivering civil engineering solutions, guided by our Principal Engineers & Design Leads, whilst also supporting & mentoring our more junior engineers.You can find out more about our work in the water sector here: Stantec H2O+U - UK.

About You

We are interested in speaking with passionate engineers with design experience within the UK water industry. You’ll hold a degree in Civil Engineering and ideally have achieved Chartered status with a relevant professional body such as ICE or CIWEM. You will have gained experienced delivering community focused projects, whilst working collaboratively with multi-disciplinary teams to delivery innovative solutions. We will support your growth & development through training & project exposure, though prior experience within storm overflows, SUDS, surface water management & sewage treatment would be beneficial.

About Stantec

The Stantec community unites more than 31,000 employees working in over 450 locations across 6 continents. We have been working with our clients and communities in the UK for over 150 years. We plan, design, deliver and manage the development and infrastructure needed to support the creation of sustainable, healthy and prosperous communities. Our teams provide effective and relevant solutions, translating our clients’ vision into valued consents, deliverable plans for projects and programmes, and efficient designs for delivery, based on technical excellence and deep market insights. We deal with today’s challenges, but also keep a fairer, better tomorrow in sight, looking at how we deliver clean growth, support radical changes in our economy and meet the needs of future communities. Stantec provides equal employment opportunities to all qualified employees and applicants for future and current employment and prohibit discrimination on the grounds of race, colour, religion, sex, national origin, age, marital status, genetic information, disability, sexual orientation, gender identity or gender expression. We prohibit discrimination in decisions concerning recruitment, hiring, referral, promotion, compensation, fringe benefits, job training, terminations or any other condition of employment. Stantec is in compliance with laws and regulations and ensures equitable opportunities in all aspects of employment. Building an inspired, inclusive work environment that attracts, supports, and develops world-class talent is a crucial key to our success. If you are excited by this role but worry that your experience doesn’t exactly align, we encourage you to apply.

(left) New trickling filter pumping station pipework and (right) chemical dosing facilities - Courtesy of CMDP[/caption]

(left) New trickling filter pumping station pipework and (right) chemical dosing facilities - Courtesy of CMDP[/caption]

Trickling filter tank precast panel installation - Courtesy of CMDP[/caption]

Trickling filter tank precast panel installation - Courtesy of CMDP[/caption]

Trickling filter pipework - Courtesy of CMDP[/caption]

Trickling filter pipework - Courtesy of CMDP[/caption]

New Humus tank construction and temporary works access - Courtesy of CMDP[/caption]

New Humus tank construction and temporary works access - Courtesy of CMDP[/caption]

Clean and dirty backwash tanks and the FilterClear tertiary package plant - Courtesy of CMDP[/caption]

Clean and dirty backwash tanks and the FilterClear tertiary package plant - Courtesy of CMDP[/caption]

Lingfield WwTW - Courtesy of CMDP[/caption]

Lingfield WwTW - Courtesy of CMDP[/caption]

Project Engineer Xenia Magdaleno-Tseng in front of the new trickling filter bed - Courtesy of CMDP[/caption]

Project Engineer Xenia Magdaleno-Tseng in front of the new trickling filter bed - Courtesy of CMDP[/caption]

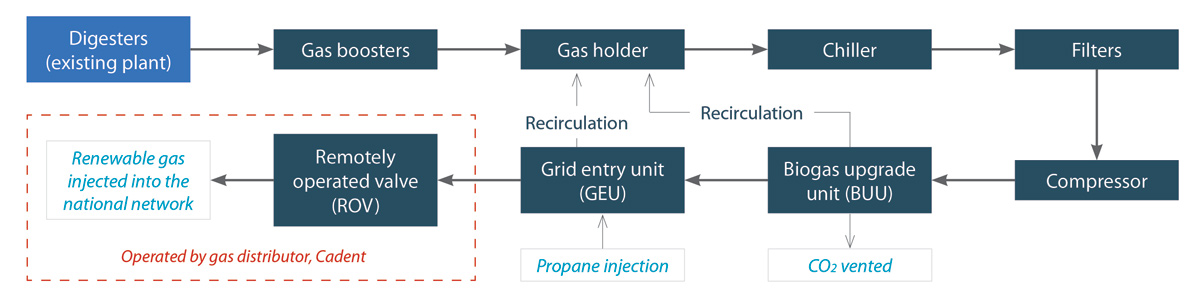

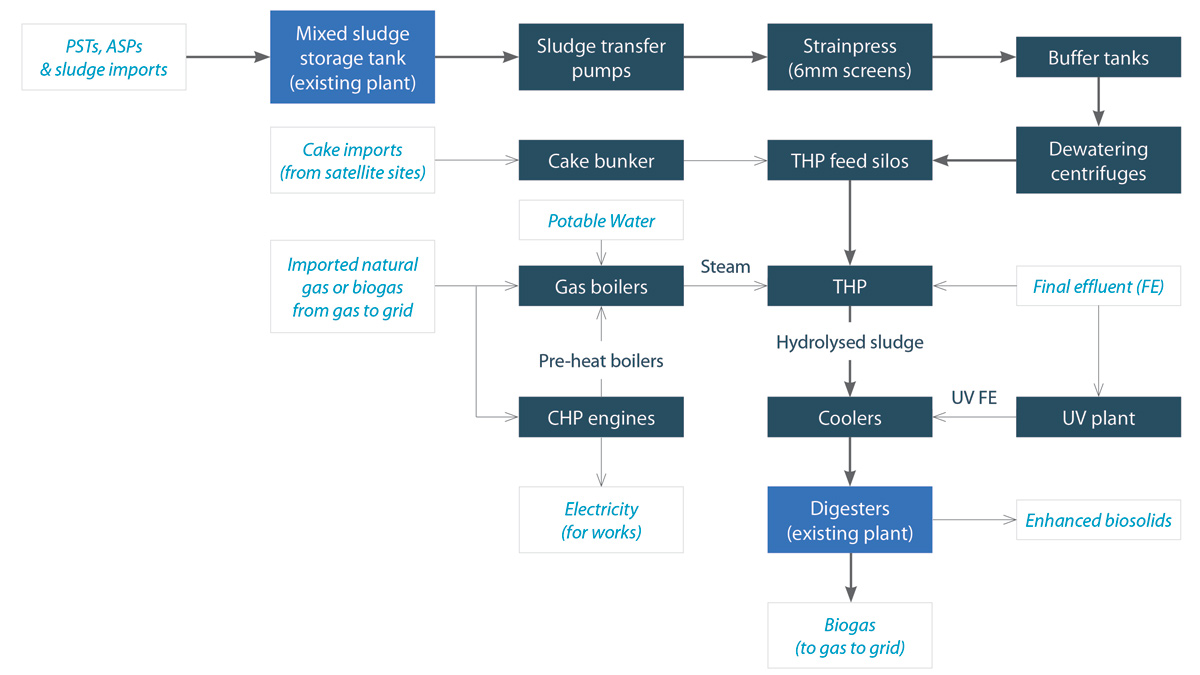

Gas to grid process diagram - Courtesy of Costain[/caption]

Gas to grid process diagram - Courtesy of Costain[/caption]

Thermal hydrolysis plant process diagram - Courtesy of Costain[/caption]

Thermal hydrolysis plant process diagram - Courtesy of Costain[/caption]

(left) Inflated gas holder and (right) biogas upgrade unit and carbon storage silos - Courtesy of Costain[/caption]

(left) Inflated gas holder and (right) biogas upgrade unit and carbon storage silos - Courtesy of Costain[/caption]

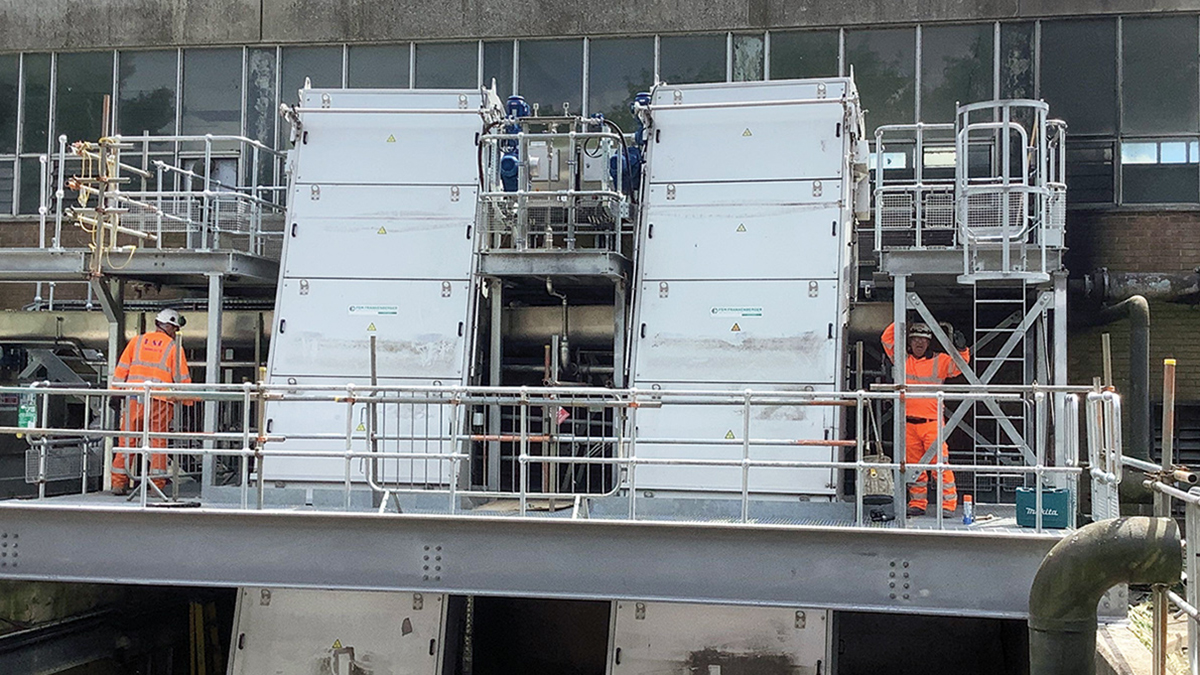

(left) Sludge transfer pumps and (right) elevated strain press in front of the buffer tanks - Courtesy of Costain[/caption]

Dewatering

The screened sludge is dewatered from approximately 3% to 20% dry solids for transfer to the THP feed silos. 3 (No.) centrifuges work in a duty/duty/standby arrangement and backwash with final effluent (FE) as required.

THP & boilers

The cake is diluted with FE to 16% dry solids and fed into one of the 2 (No.) THP streams which process up to a maximum of 60 tonnes of dry solids per day (tds/day) per stream.

The sludge is heated to around 95°C in pulper to become ‘homogenised’. This sludge is then pumped sequentially through each of the streams 4 (No.) reactors for batch treatment. Steam from the boilers is used to heat the sludge between 50-180°C where it is held at 6-bar pressure to undergo pasteurising hydrolysis for around 30-45 minutes. After hydrolysis, sludge is passed into the flash tank, where the pressure and temperature of the hydrolysed sludge are decreased by flashing steam back to the pulper. The flashtank provides the necessary thermal buffer capacity to release the excess energy contained in the sludge before entering the downstream pumps.

The process kills all pathogens and, in turn, increases the potential gas yield of the sludge.

2 (No.) boilers, procured from Italy, produce 192°C steam from potable water, operate at 12bar and can run on either natural gas imported from the grid or biogas produced from the gas to grid plant. 2 (No.) CHP engines are situated locally to the boilers and the exhaust gas heat is recovered by boilers to optimise performance, these CHP engines can also run on either natural or biogas. The boilers are operated by BOAS accredited operators who were transitioned across from Costain to Severn Trent upon handover.

The warm hydrolysed sludge is then blended with UV FE to reduce the temperature to around 42°C where it is fed back into the digesters via a bank of 8 (No.) sludge return pipes traversing 500m across the site footprint.

[caption id="" align="alignnone" width="1200"]

(left) Sludge transfer pumps and (right) elevated strain press in front of the buffer tanks - Courtesy of Costain[/caption]

Dewatering

The screened sludge is dewatered from approximately 3% to 20% dry solids for transfer to the THP feed silos. 3 (No.) centrifuges work in a duty/duty/standby arrangement and backwash with final effluent (FE) as required.

THP & boilers

The cake is diluted with FE to 16% dry solids and fed into one of the 2 (No.) THP streams which process up to a maximum of 60 tonnes of dry solids per day (tds/day) per stream.

The sludge is heated to around 95°C in pulper to become ‘homogenised’. This sludge is then pumped sequentially through each of the streams 4 (No.) reactors for batch treatment. Steam from the boilers is used to heat the sludge between 50-180°C where it is held at 6-bar pressure to undergo pasteurising hydrolysis for around 30-45 minutes. After hydrolysis, sludge is passed into the flash tank, where the pressure and temperature of the hydrolysed sludge are decreased by flashing steam back to the pulper. The flashtank provides the necessary thermal buffer capacity to release the excess energy contained in the sludge before entering the downstream pumps.

The process kills all pathogens and, in turn, increases the potential gas yield of the sludge.

2 (No.) boilers, procured from Italy, produce 192°C steam from potable water, operate at 12bar and can run on either natural gas imported from the grid or biogas produced from the gas to grid plant. 2 (No.) CHP engines are situated locally to the boilers and the exhaust gas heat is recovered by boilers to optimise performance, these CHP engines can also run on either natural or biogas. The boilers are operated by BOAS accredited operators who were transitioned across from Costain to Severn Trent upon handover.

The warm hydrolysed sludge is then blended with UV FE to reduce the temperature to around 42°C where it is fed back into the digesters via a bank of 8 (No.) sludge return pipes traversing 500m across the site footprint.

[caption id="" align="alignnone" width="1200"] (top left) Centrifuges, (top right) THP silos, (bottom left) the boiler and (bottom right) the boiler house - Courtesy of Costain[/caption]

UV treatment and sludge cake

A UV plant was constructed to ensure no pathogens were introduced to the sludge post-THP which would normally be present in non-UV treated FE. This ensures that the biosolids product produced by the works is ‘enhanced’ quality and can be sold to farmers to fertilise fields growing a wider range of crops than those which can have ‘standard’ biosolids. A pair of Bollfilters with 25µm strainers from Bollfilter UK Ltd screen the FE prior to UV treatment to ensure that stringent disinfection standards are achieved and to prevent particulates damage to the plant.

Other THP highlights

The THP installation also included a polymer dosing plant, FE and potable break tanks, odour control unit, deep drainage and centrate pump stations with 700m of buried return pipework to head of works, a new FE pump station and a 1200m3 cake bunker.

[caption id="" align="alignnone" width="1200"]

(top left) Centrifuges, (top right) THP silos, (bottom left) the boiler and (bottom right) the boiler house - Courtesy of Costain[/caption]

UV treatment and sludge cake

A UV plant was constructed to ensure no pathogens were introduced to the sludge post-THP which would normally be present in non-UV treated FE. This ensures that the biosolids product produced by the works is ‘enhanced’ quality and can be sold to farmers to fertilise fields growing a wider range of crops than those which can have ‘standard’ biosolids. A pair of Bollfilters with 25µm strainers from Bollfilter UK Ltd screen the FE prior to UV treatment to ensure that stringent disinfection standards are achieved and to prevent particulates damage to the plant.

Other THP highlights

The THP installation also included a polymer dosing plant, FE and potable break tanks, odour control unit, deep drainage and centrate pump stations with 700m of buried return pipework to head of works, a new FE pump station and a 1200m3 cake bunker.

[caption id="" align="alignnone" width="1200"] THP reactors - Courtesy of Costain[/caption]

THP reactors - Courtesy of Costain[/caption]

(left) Cake bunker cofferdam and (right) cake bunker - Courtesy of Costain[/caption]

(left) Cake bunker cofferdam and (right) cake bunker - Courtesy of Costain[/caption]

CHP engines- Courtesy of Costain[/caption]

CHP engines- Courtesy of Costain[/caption]

Muck shift in progress - Courtesy of Costain[/caption]

Costain worked collaboratively with Severn Trent to draft plans for the reuse of the muck in the proposed BIA and began the process of sampling and testing the muck. A comprehensive Materials Management Plan approved under the CL:AIRE regulations was produced detailing the proposal. Upon approval from all parties, the muck shift operation began. Costain operated three 30 tonne articulated dumpers (ADTs) to transport the muck across the site. Each dumper averaged 25 trips per day and the full operation was completed in just a little under two weeks.

The overall benefits were:

Muck shift in progress - Courtesy of Costain[/caption]

Costain worked collaboratively with Severn Trent to draft plans for the reuse of the muck in the proposed BIA and began the process of sampling and testing the muck. A comprehensive Materials Management Plan approved under the CL:AIRE regulations was produced detailing the proposal. Upon approval from all parties, the muck shift operation began. Costain operated three 30 tonne articulated dumpers (ADTs) to transport the muck across the site. Each dumper averaged 25 trips per day and the full operation was completed in just a little under two weeks.

The overall benefits were:

Finham THP & G2G - Courtesy of Costain[/caption]

Finham THP & G2G - Courtesy of Costain[/caption]

(top left) Construction of tertiary treatment system December 2022, (top right) construction of tertiary treatment system May 2023, (bottom left) Construction of tertiary treatment system July 2023, and (bottom right) Construction of tertiary treatment system November 2023 - Courtesy of Morgan Sindall Infrastructure[/caption]

(top left) Construction of tertiary treatment system December 2022, (top right) construction of tertiary treatment system May 2023, (bottom left) Construction of tertiary treatment system July 2023, and (bottom right) Construction of tertiary treatment system November 2023 - Courtesy of Morgan Sindall Infrastructure[/caption]

Construction of tertiary treatment system February 2024 - Courtesy of Morgan Sindall Infrastructure[/caption]

Construction of tertiary treatment system February 2024 - Courtesy of Morgan Sindall Infrastructure[/caption]

Fully constructed tertiary treatment system integrated into existing treatment works - Courtesy of Morgan Sindall Infrastructure[/caption]

Fully constructed tertiary treatment system integrated into existing treatment works - Courtesy of Morgan Sindall Infrastructure[/caption]

Example of a Cubis Systems modular chamber and (inset) chamber being assembled at Leominster- Courtesy of Cubis Systems & Morgan Sindall[/caption]

For the smaller alkalinity MCC kiosk (not DfMA), it was decided that the kiosk would sit at ground level but as it still required access under the panel for installation, a below ground trench was required. To make the construction process more efficient, the trench comprised of innovative and sustainable HDPE recycled plastic modular units from Cubis Systems, that were put together on site and built around with minimal concrete surround and base slab and backfill to support the kiosk. As well as the material of the modular solution being more sustainable, it also led to a reduced carbon footprint in delivery due to it being very light weight. This also made it a safer and quicker installation as the manual handling involved was minimal.

Example of a Cubis Systems modular chamber and (inset) chamber being assembled at Leominster- Courtesy of Cubis Systems & Morgan Sindall[/caption]

For the smaller alkalinity MCC kiosk (not DfMA), it was decided that the kiosk would sit at ground level but as it still required access under the panel for installation, a below ground trench was required. To make the construction process more efficient, the trench comprised of innovative and sustainable HDPE recycled plastic modular units from Cubis Systems, that were put together on site and built around with minimal concrete surround and base slab and backfill to support the kiosk. As well as the material of the modular solution being more sustainable, it also led to a reduced carbon footprint in delivery due to it being very light weight. This also made it a safer and quicker installation as the manual handling involved was minimal.

Installation of DfMA low voltage distribution board MCC kiosk - Courtesy of Morgan Sindall Infrastructure[/caption]

Installation of DfMA low voltage distribution board MCC kiosk - Courtesy of Morgan Sindall Infrastructure[/caption]

New Fineguard inlet screens from SPIRAC Ltd with improved safe access for operators – Courtesy of Morgan Sindall Infrastructure[/caption]

New Fineguard inlet screens from SPIRAC Ltd with improved safe access for operators – Courtesy of Morgan Sindall Infrastructure[/caption]

(top left) Federated 3D model capture of sampling kiosk with tertiary filters - Courtesy of Arcadis, (bottom left) as built sampling kiosk with tertiary filters - Courtesy of Morgan Sindall Infrastructure, (top right) Federated 3D model capture of lift pumping station with tertiary filters - Courtesy of Arcadis, and (bottom right) As built tertiary filter lift pumping station pipework with duplex filter and tertiary filters - Courtesy of Morgan Sindall Infrastructure[/caption]

(top left) Federated 3D model capture of sampling kiosk with tertiary filters - Courtesy of Arcadis, (bottom left) as built sampling kiosk with tertiary filters - Courtesy of Morgan Sindall Infrastructure, (top right) Federated 3D model capture of lift pumping station with tertiary filters - Courtesy of Arcadis, and (bottom right) As built tertiary filter lift pumping station pipework with duplex filter and tertiary filters - Courtesy of Morgan Sindall Infrastructure[/caption]

Lift pumping station - Courtesy of Morgan Sindall Infrastructure[/caption]

Lift pumping station - Courtesy of Morgan Sindall Infrastructure[/caption]

Installation of tertiary sand filters adjacent to railway line under agreed BAPA procedures - Courtesy of Morgan Sindall Infrastructure[/caption]

Installation of tertiary sand filters adjacent to railway line under agreed BAPA procedures - Courtesy of Morgan Sindall Infrastructure[/caption]

Leominster WwTW: Tertiary sand filters - Courtesy of Morgan Sindall Infrastructure[/caption]

Leominster WwTW: Tertiary sand filters - Courtesy of Morgan Sindall Infrastructure[/caption]

Fully constructed tertiary treatment system integrated into existing treatment works - Courtesy of Morgan Sindall Infrastructure[/caption]

Fully constructed tertiary treatment system integrated into existing treatment works - Courtesy of Morgan Sindall Infrastructure[/caption]

New inlet screens supplied by Hydro International UK Wastewater Services division - Courtesy of CMDP JV[/caption]

New inlet screens supplied by Hydro International UK Wastewater Services division - Courtesy of CMDP JV[/caption]

The existing deep bed sand filter is being extended with three additional cells to enhance the tertiary treatment process - Courtesy of CMDP JV[/caption]

The existing deep bed sand filter is being extended with three additional cells to enhance the tertiary treatment process - Courtesy of CMDP JV[/caption]

The two new Moving Bed Biofilm Reactors (MBBR) to remove ammonia from the final effluent returning to the River Arun - Courtesy of CMDP JV[/caption]

The two new Moving Bed Biofilm Reactors (MBBR) to remove ammonia from the final effluent returning to the River Arun - Courtesy of CMDP JV[/caption]

DN900 outlet pipework installed on one of the newly constructed MBBRs - Courtesy of CMDP JV[/caption]

DN900 outlet pipework installed on one of the newly constructed MBBRs - Courtesy of CMDP JV[/caption]

(left) One of the two existing inlet screens being removed, (middle) one of the new 12.8m long Alpha Beta Escalator Screens being lifted carefully into place, and (right) the new inlet screens installed - Courtesy of CMDP JV[/caption]

(left) One of the two existing inlet screens being removed, (middle) one of the new 12.8m long Alpha Beta Escalator Screens being lifted carefully into place, and (right) the new inlet screens installed - Courtesy of CMDP JV[/caption]

Inside one of the new MBBRs as its installation approached completion - Courtesy of CMDP JV[/caption]

Inside one of the new MBBRs as its installation approached completion - Courtesy of CMDP JV[/caption]

Setting out for piling works in alkalinity dosing area with sheet piling in place for bank stability - Courtesy of CMDP JV[/caption]

Setting out for piling works in alkalinity dosing area with sheet piling in place for bank stability - Courtesy of CMDP JV[/caption]

The new MBBR blowers are fitted with acoustic barriers to minimise any possible impact on nearby residential properties - Courtesy of CMDP JV[/caption]

The new MBBR blowers are fitted with acoustic barriers to minimise any possible impact on nearby residential properties - Courtesy of CMDP JV[/caption]

(left) Garry Burgess, CMDP Construction Manager, receiving the award for the efforts of the Horsham New WwTW team and (right) CMDP JV and Southern Water staff pictured volunteering to support local charity, Ten Little Toes - Courtesy of CMDP JV[/caption]

(left) Garry Burgess, CMDP Construction Manager, receiving the award for the efforts of the Horsham New WwTW team and (right) CMDP JV and Southern Water staff pictured volunteering to support local charity, Ten Little Toes - Courtesy of CMDP JV[/caption]

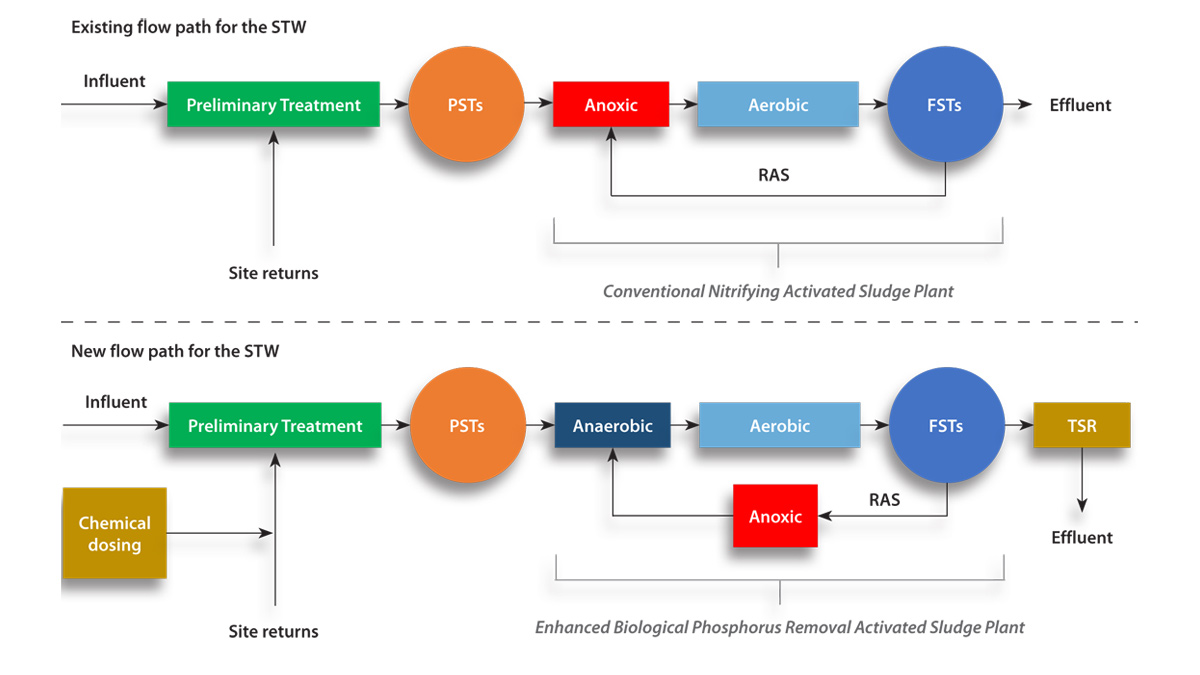

An overview of the changes to the process flow path[/caption]

An overview of the changes to the process flow path[/caption]

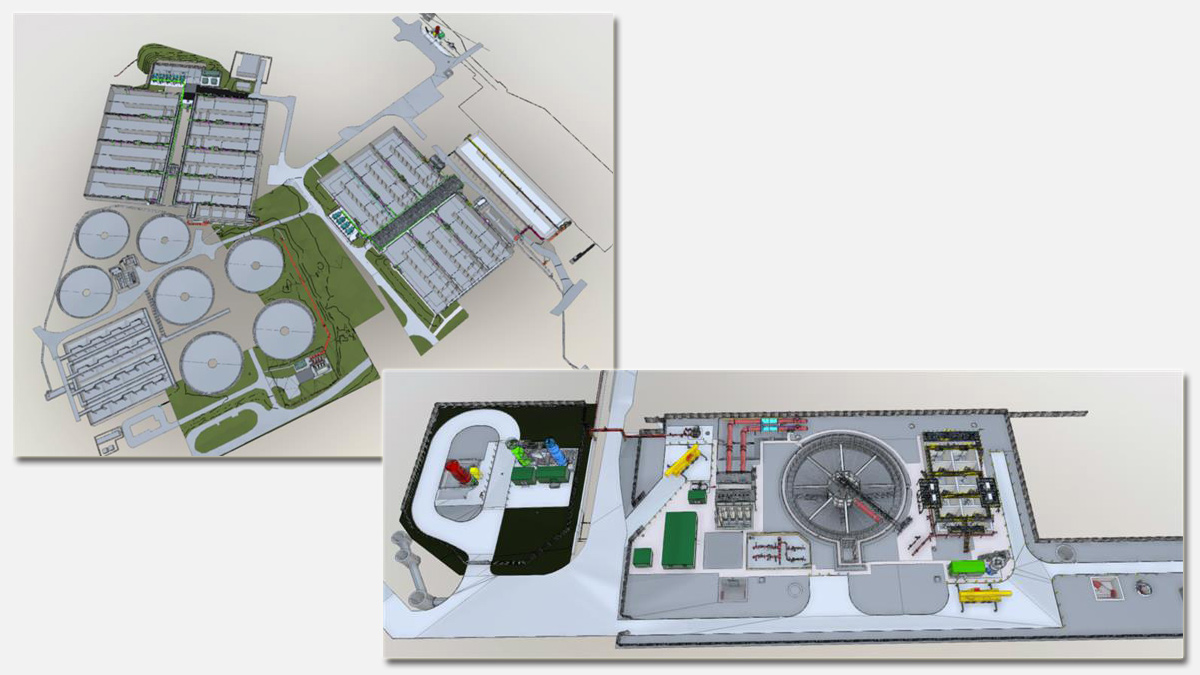

(left) 3D model image of the EBPR 1 & 2 site layout and (right) 3D model image of the future TSR site layout[/caption]

To put this into context, fifteen 40m FSTs are existing to act as the final settlement for the sites full flow to treatment, however 75% of this flow will be able to pass through one 32m high-rate clarifier designed for the CoMag® technology. The required surface area to treat 75% of the flow in a traditional FST is therefore 14,136m2 versus the 804m2 required for the high-rate ballasted clarifier (ie. 17.5 times more efficient). The treated water will then weir over and discharge to the river, while the sludge is recovered and passed through a magnetic drum recovery unit, and the magnetite is recycled.

An additional ferric sulphate dosing system will also be installed and dosed upon the filtrate returns from the AD plant. This is prior to the returns discharging into the high-level PSTs.

Using this design, EBPR has the potential to reduce the Total Phosphorus down in the wastewater to 0.4 mg/l. The TSR will then remove the Total Phosphorus down to <0.4 mg/l. Introducing EBPR prior to a TSR for phosphorus removal greatly reduces the chemical cost used in the TSR.

(left) 3D model image of the EBPR 1 & 2 site layout and (right) 3D model image of the future TSR site layout[/caption]

To put this into context, fifteen 40m FSTs are existing to act as the final settlement for the sites full flow to treatment, however 75% of this flow will be able to pass through one 32m high-rate clarifier designed for the CoMag® technology. The required surface area to treat 75% of the flow in a traditional FST is therefore 14,136m2 versus the 804m2 required for the high-rate ballasted clarifier (ie. 17.5 times more efficient). The treated water will then weir over and discharge to the river, while the sludge is recovered and passed through a magnetic drum recovery unit, and the magnetite is recycled.

An additional ferric sulphate dosing system will also be installed and dosed upon the filtrate returns from the AD plant. This is prior to the returns discharging into the high-level PSTs.

Using this design, EBPR has the potential to reduce the Total Phosphorus down in the wastewater to 0.4 mg/l. The TSR will then remove the Total Phosphorus down to <0.4 mg/l. Introducing EBPR prior to a TSR for phosphorus removal greatly reduces the chemical cost used in the TSR.

(left) Progress of the new ASP2 blower slab, MCC and transformer area and (right) installation of the diffusers in the new activated sludge lane - Courtesy of Yorkshire Water and Ward & Burke[/caption]

(left) Progress of the new ASP2 blower slab, MCC and transformer area and (right) installation of the diffusers in the new activated sludge lane - Courtesy of Yorkshire Water and Ward & Burke[/caption]

Base pour of the new RAS anoxic tank for EBPR2 - Courtesy of Yorkshire Water and Ward & Burke[/caption]

Similar to ASP2, ASP3 will require a new RAS anoxic tank. This 14,000m3 tank is built on the foundations of old decommissioned sludge beds and both grouting and CFA piling were required in this area due to the presence of coal seams.

The flow from the existing RAS pumping station will be diverted to this new anoxic tank, where the tank will then discharge back into the anaerobic zone of ASP3. Again, an under-pressure hot tap will be used for the RAS tie-in, and a limpet dam used to discharge into the anaerobic zone.

With the addition of these new anoxic tanks, the biological stage of Knostrop STW will be changed to two EBPR ASPs. Commissioning of this system is forecast for November 2023 (ASP3) and February 2024 (ASP2), and a predicted 6-month seeding/climatisation period is assumed before the POAs have established.

The new Total Phosphorus consent is 0.4mg/l which will require a further solid associated phosphorus removal after the exiting FSTs. The final effluent will be diverted into a tertiary solids removal (TSR) plant, where a new pumping station will lift 75% of the sites FFT into a new reception chamber.

The wastewater then flows down duty/duty pipelines through in-line mixers, where the ferric sulphate is dosed prior to a reaction tank. The reaction tank is split into two streams, each with four tanks connected by under and overflow baffle walls. Submersible mixers enable the coagulation of the phosphate with the ferric sulphate, while further dosing of magnetite and then polymer occur in tanks 3 and 4 of the reaction tank to create the ballasted particles.

[caption id="" align="alignnone" width="1200"]

Base pour of the new RAS anoxic tank for EBPR2 - Courtesy of Yorkshire Water and Ward & Burke[/caption]

Similar to ASP2, ASP3 will require a new RAS anoxic tank. This 14,000m3 tank is built on the foundations of old decommissioned sludge beds and both grouting and CFA piling were required in this area due to the presence of coal seams.

The flow from the existing RAS pumping station will be diverted to this new anoxic tank, where the tank will then discharge back into the anaerobic zone of ASP3. Again, an under-pressure hot tap will be used for the RAS tie-in, and a limpet dam used to discharge into the anaerobic zone.

With the addition of these new anoxic tanks, the biological stage of Knostrop STW will be changed to two EBPR ASPs. Commissioning of this system is forecast for November 2023 (ASP3) and February 2024 (ASP2), and a predicted 6-month seeding/climatisation period is assumed before the POAs have established.

The new Total Phosphorus consent is 0.4mg/l which will require a further solid associated phosphorus removal after the exiting FSTs. The final effluent will be diverted into a tertiary solids removal (TSR) plant, where a new pumping station will lift 75% of the sites FFT into a new reception chamber.

The wastewater then flows down duty/duty pipelines through in-line mixers, where the ferric sulphate is dosed prior to a reaction tank. The reaction tank is split into two streams, each with four tanks connected by under and overflow baffle walls. Submersible mixers enable the coagulation of the phosphate with the ferric sulphate, while further dosing of magnetite and then polymer occur in tanks 3 and 4 of the reaction tank to create the ballasted particles.

[caption id="" align="alignnone" width="1200"] Construction of the new RAS anoxic tank for EBPR2 - Courtesy of Yorkshire Water and Ward & Burke[/caption]

The flow then passes through a 32m diameter clarifier, complete with a fixed bridge and sludge scraper system. The clarifier is built of precast concrete panels to improve construction time.

A return chamber brings the wastewater back into the original final effluent line, and a new final effluent sampling chamber will be built downstream of this. Within the TSR, a sludge recycle system will be installed, along with a sludge return pumping station which will send the waste sludge back to the high-level PSTs.

Ferric sulphate, polymer and magnetite dosing systems will be designed and built off-site and then installed and commissioned, and a new control system will be installed for the entire TSR. The completion of this TSR is predicted for October 2024.

Construction of the new RAS anoxic tank for EBPR2 - Courtesy of Yorkshire Water and Ward & Burke[/caption]

The flow then passes through a 32m diameter clarifier, complete with a fixed bridge and sludge scraper system. The clarifier is built of precast concrete panels to improve construction time.

A return chamber brings the wastewater back into the original final effluent line, and a new final effluent sampling chamber will be built downstream of this. Within the TSR, a sludge recycle system will be installed, along with a sludge return pumping station which will send the waste sludge back to the high-level PSTs.

Ferric sulphate, polymer and magnetite dosing systems will be designed and built off-site and then installed and commissioned, and a new control system will be installed for the entire TSR. The completion of this TSR is predicted for October 2024.

Progress of the new tertiary solids removal area (April 2023) - Courtesy of Yorkshire Water and Ward & Burke[/caption]

The TSR is still under civil construction, with the reaction tank and clarifier concrete works completed, and the new lift pumping station and reception chamber under construction. Pipework, electrical ducting, and surface drainage is also ongoing in this area. The ferric sulphate, polymer and magnetite storage and transfer silos are currently under fabrication off-site.

The scheme has a targeted beneficial completion date of October 2024. This is when the site will be meeting the Total Phosphorus and Total Iron consent levels via use of the TSR, with both ASPs changed over to the EBPR configuration.

Progress of the new tertiary solids removal area (April 2023) - Courtesy of Yorkshire Water and Ward & Burke[/caption]

The TSR is still under civil construction, with the reaction tank and clarifier concrete works completed, and the new lift pumping station and reception chamber under construction. Pipework, electrical ducting, and surface drainage is also ongoing in this area. The ferric sulphate, polymer and magnetite storage and transfer silos are currently under fabrication off-site.

The scheme has a targeted beneficial completion date of October 2024. This is when the site will be meeting the Total Phosphorus and Total Iron consent levels via use of the TSR, with both ASPs changed over to the EBPR configuration.

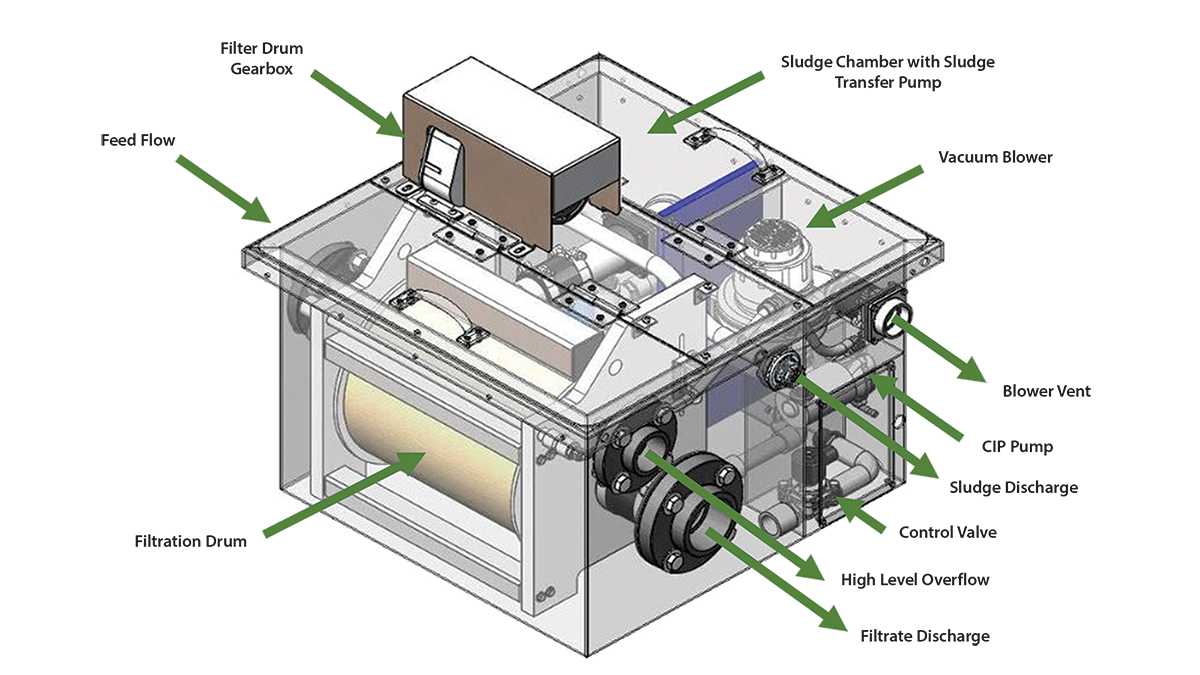

AquaPyr Model 440 - Courtesy of ACWA Services[/caption]

AquaPyr Model 440 - Courtesy of ACWA Services[/caption]

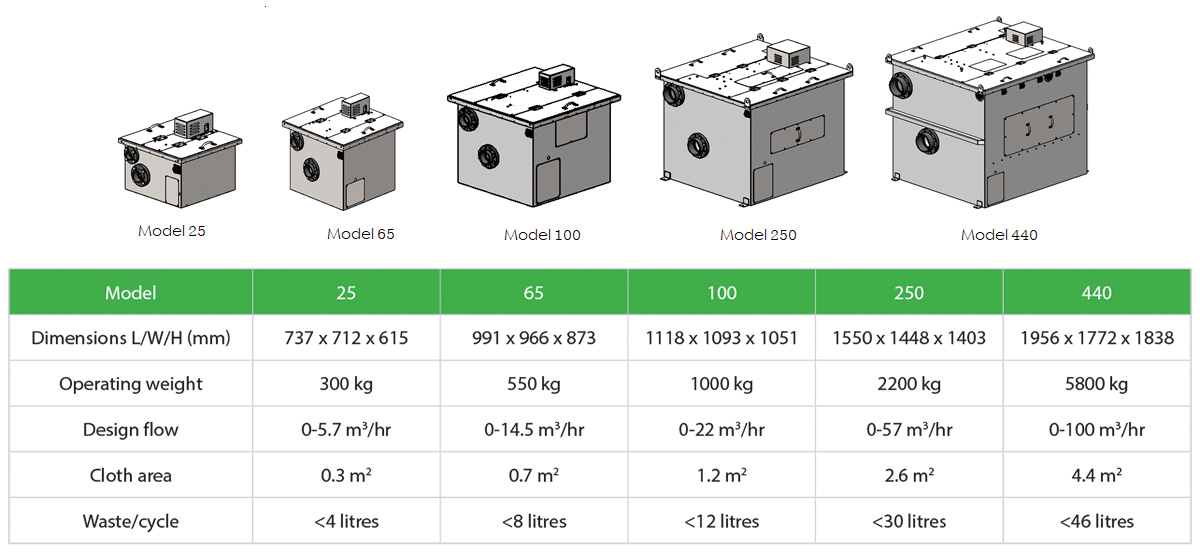

The AquaPyr Ultra Low Waste Filter product range - Courtesy of ACWA Services[/caption]

The AquaPyr Ultra Low Waste Filter product range - Courtesy of ACWA Services[/caption]

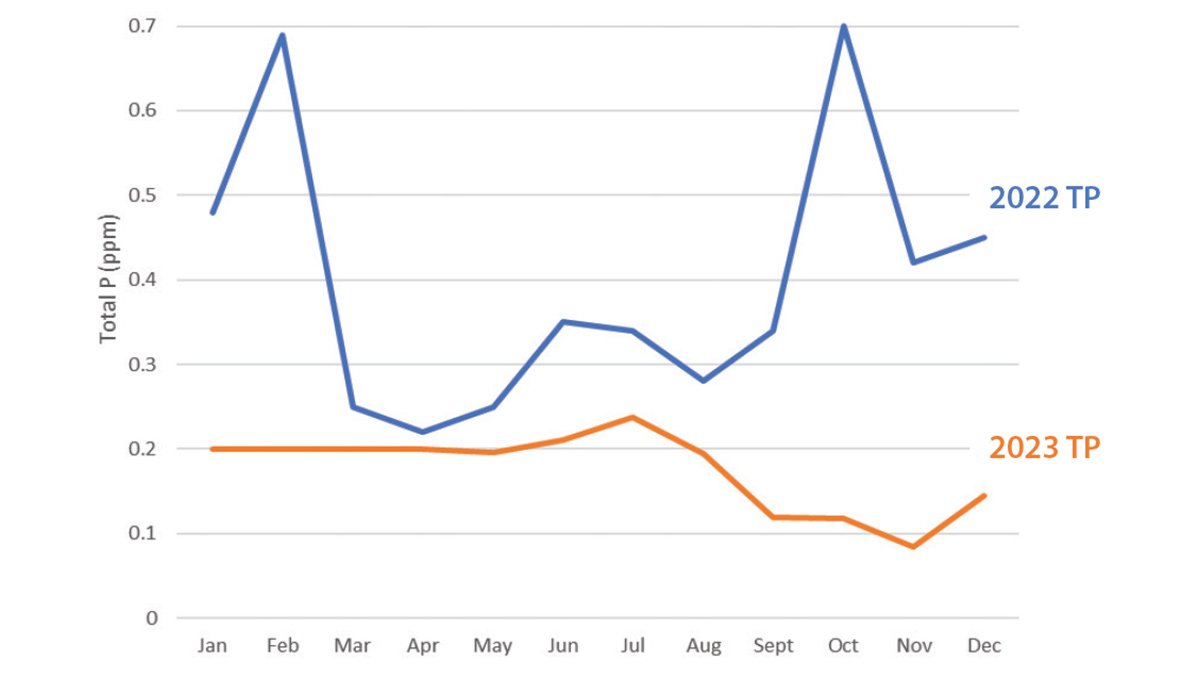

Silver Lake WwTP: Effluent TP before/after the installation of the ACWA AquaPyr Ultra Low Waste Filter - Courtesy of ACWA Services[/caption]

Silver Lake WwTP: Effluent TP before/after the installation of the ACWA AquaPyr Ultra Low Waste Filter - Courtesy of ACWA Services[/caption]

Cembrane SiC membranes, modules, stacks & towers - Courtesy of Enpure Ltd[/caption]

Cembrane SiC membranes, modules, stacks & towers - Courtesy of Enpure Ltd[/caption]

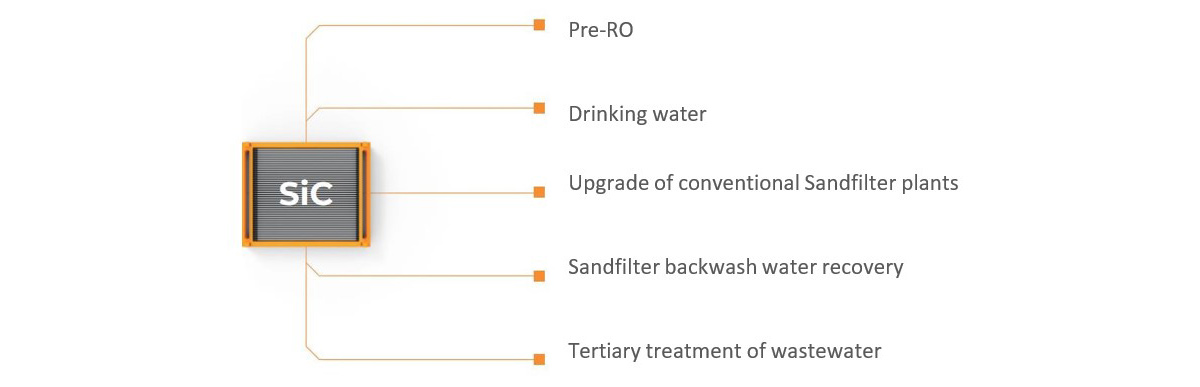

Applications of Cembrane SiC membranes - Courtesy of Enpure Ltd[/caption]

Applications of Cembrane SiC membranes - Courtesy of Enpure Ltd[/caption]

(left) Installation of Cembrane SiC stack, (top right) Cembrane SiC stack from above, and (bottom right) SiC membranes have sprinkler cleaning option - Courtesy of Enpure Ltd[/caption]

(left) Installation of Cembrane SiC stack, (top right) Cembrane SiC stack from above, and (bottom right) SiC membranes have sprinkler cleaning option - Courtesy of Enpure Ltd[/caption]