FLI Precast Solutions

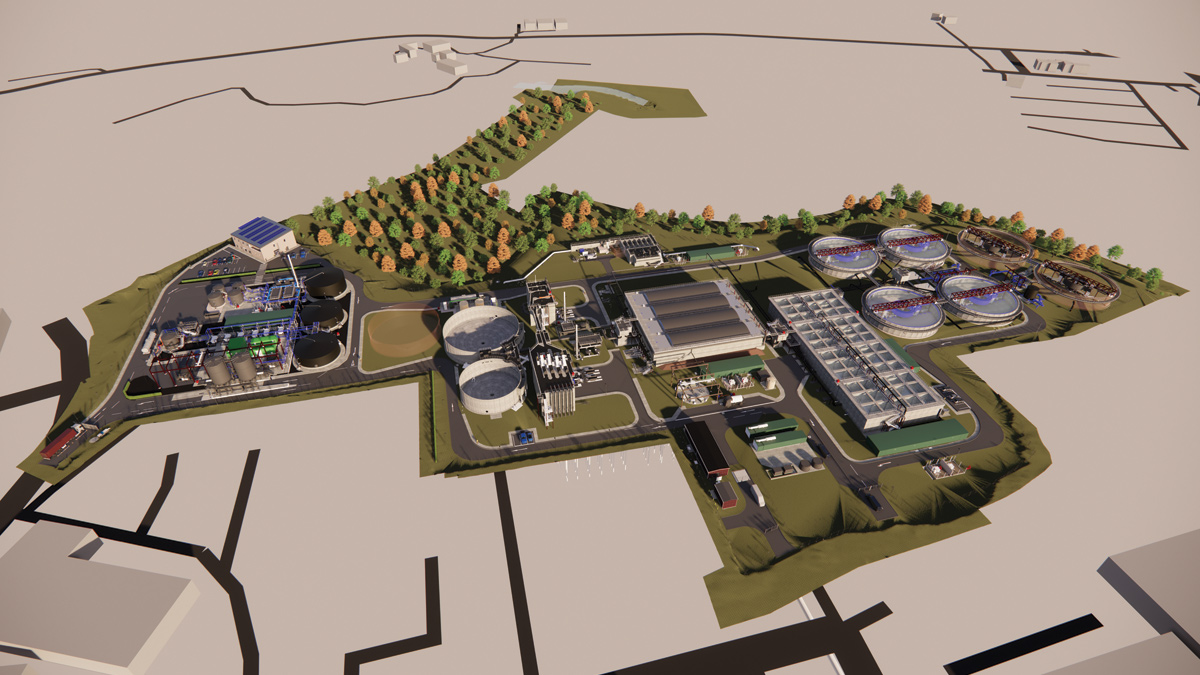

Gowerton WwTW

Precast concrete structures under construction - Courtesy of FLI Precast Solutions

Project Information

- Location: Swansea

- End client: Welsh Water

- Main contractor: Morgan Sindall

- Scope of works: Design, manufacture, delivery and installation of the PFET and Blending Chamber structures for Gowerton WwTW

Background

The reasoning behind the works at Gowerton was a requirement to meet permit conditions in South Wales by 2020. It is a cost-effective approach to challenging flow management at Water Treatment works which enables DCWW to meet their spill permit regulations as laid down by the Welsh Government and Natural Resources Wales.

The client was working to an extremely tight programme to achieve consent dates, which meant that the FLI Precast Solutions precast construction methods delivered key advantages over the traditional build process.

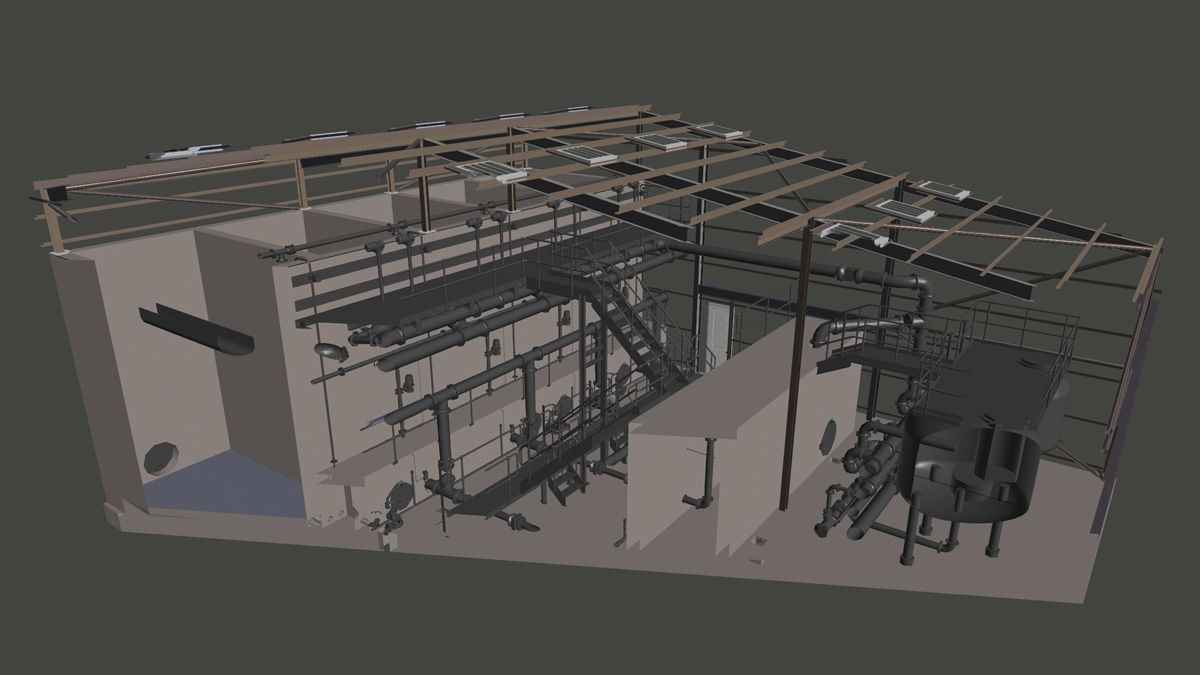

On completion of the design the precast panels were produced off site at the same time as the 500,000m3 excavation was undertaken to receive the panels. The area was suitably prepared for the delivery of the panels which was coordinated with the site team and the client’s operators to facilitate the existing treatment process.

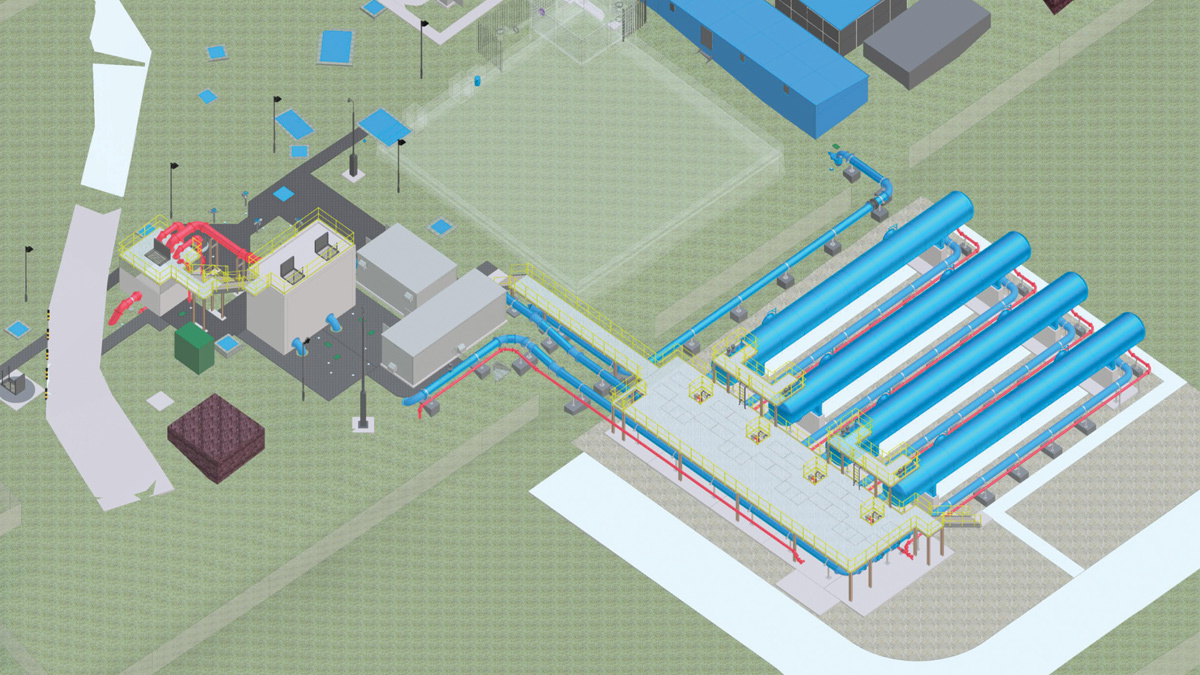

Key drivers for the scheme included the requirement for complex M&E integration which also lends itself to the FLI Precast Solutions design and production philosophy for off-site manufacture.

Precast concrete structures under construction – Courtesy of FLI Precast Solutions

The Gowerton scheme is the first project in the UK to utilise American company WesTech’s Flexfilter technology.

Solution

- Controlled production of elements to a very high standard.

- Integration of complex M&E systems.

- Reduced H&S risk on site.

- Programme savings in the works through a shorter construction programme.

- Reduced workforce on site resulting in reduced main contractor preliminaries.

- Reduced construction traffic for the local area, meaning less disruption for residents.

- Lower carbon footprint as a result of the FLI Precast Solutions construction methodology, which is typically half that of traditional in situ build.

- Flexibility for programme phasing on site, if necessaryAll units manufactured off-site and called in as dictated by the programme.

- FLI Precast Solutions provide a secondary sealing system which traditional methods do not offer.

- Clear works development through Building Information Modelling (BIM) and cutting-edge design capability.

Precast concrete structures under construction – Courtesy of FLI Precast Solutions

A word from our client: Kevin James, Project Manager – Wastewater Infrastructure, Welsh Water Capital Delivery Alliance:

“The scheme involved installing various complex precast structures to house a new flexseal treatment system that will deal with foul water storm flows before discharging to the consented outfall, the first of its kind in Europe. The PFET structure alone was 27m x 26m x 8m deep (at the deepest part), consisting of 3 different levels and various interconnecting chambers.

Due to the high priority of the scheme and the tight deadlines to meet NRW consents, a precast option was progressed. This enabled the design of the structure to be passed to FLI Precast which released our design team to concentrate on other areas of the scheme, showing significant programme savings on the design.

Due to the competency and efficiency of the FLI Precast team the precast installation was completed on time with zero accidents/incidents and to the end client’s satisfaction.”

For more information: FLI Precast Solutions: +44 (0)1279 423303 | www.fliprecast.com