SEEPEX UK Ltd

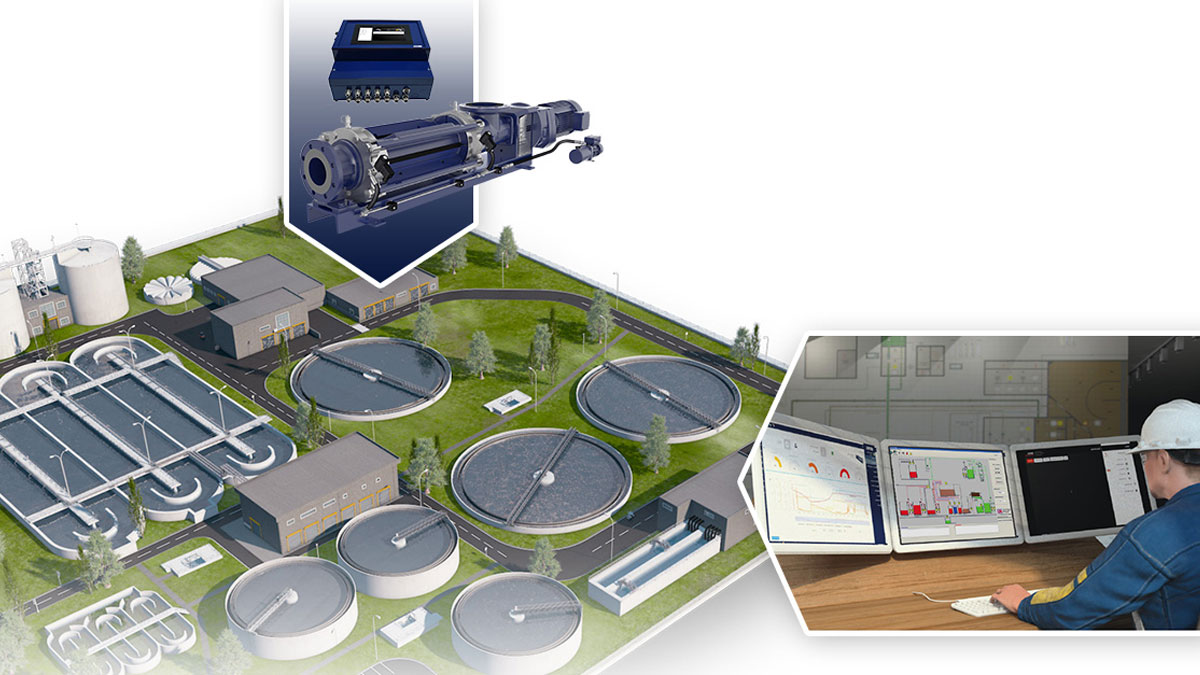

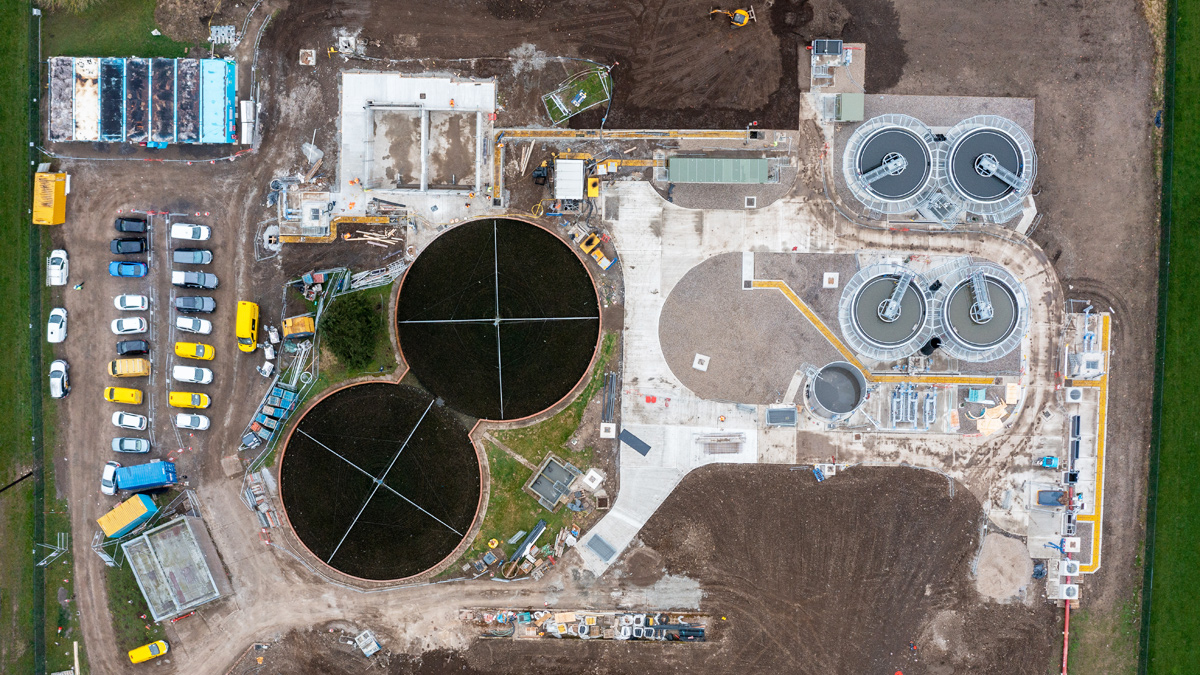

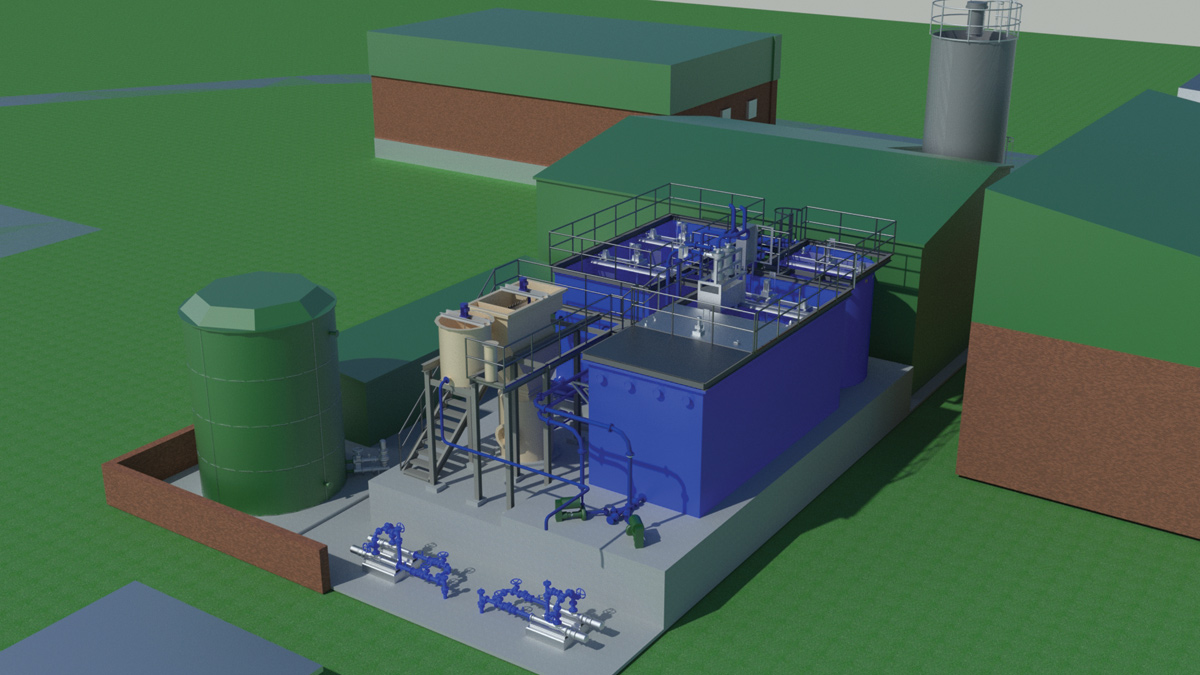

Our products and expertise are applied in most applications in the wastewater industry wherever thin to highly viscous and high % DS media is conveyed. Each solution is custom-configured to suit our customers’ requirements.

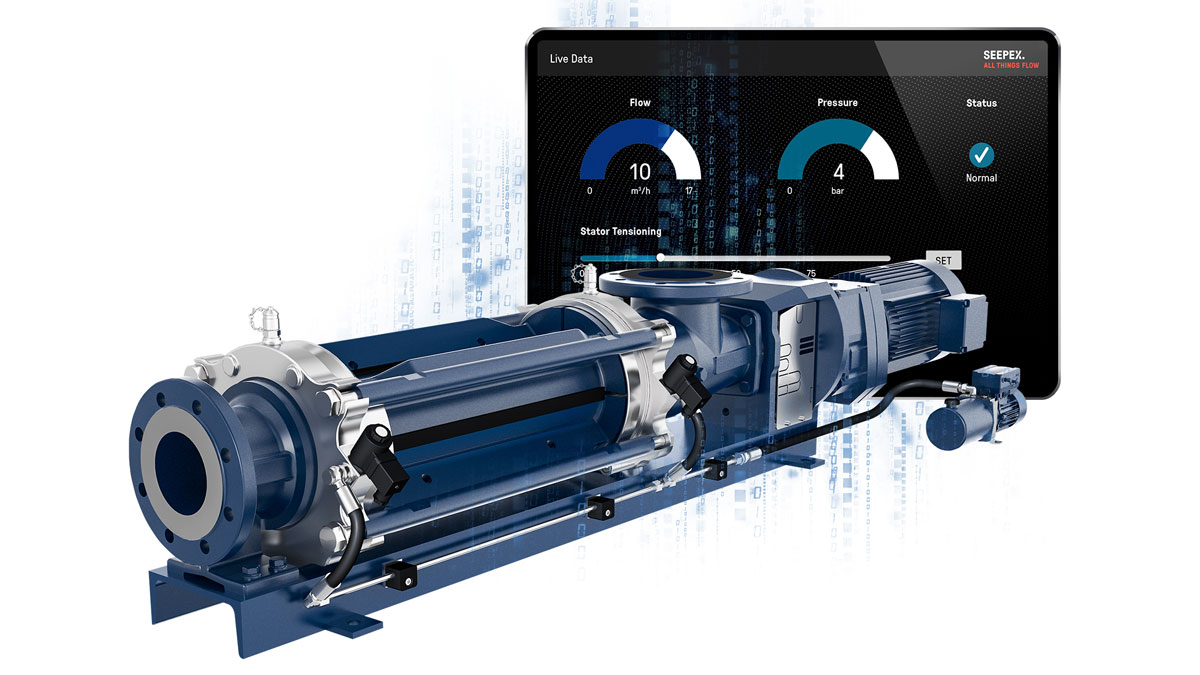

Pump Technology 4.0

SEEPEX Digital Solutions incorporating the Pump Monitor turn the progressive cavity pump into an intelligent field device, operating in a networked system of smart products, services and processes. SEEPEX cloud-based service provides online remote monitoring and management of the pumps and process. Data collection and advanced analytics enable process and pump optimisation and reduce inspection, downtime and operating costs, facilitating predictive maintenance and timely delivery of spare parts to improve overall equipment and plant efficiency.

Unlocking the Power of Digital

Our latest innovation, the most intelligent progressive cavity pump in the world, allows remote adjustment to maintain pump performance without onsite manual intervention. With SEEPEX unique SCT AutoAdjust technology, combined with our digital solutions, site visits for maintenance are eliminated and access to otherwise hard to reach pump installations can be carried out remotely.

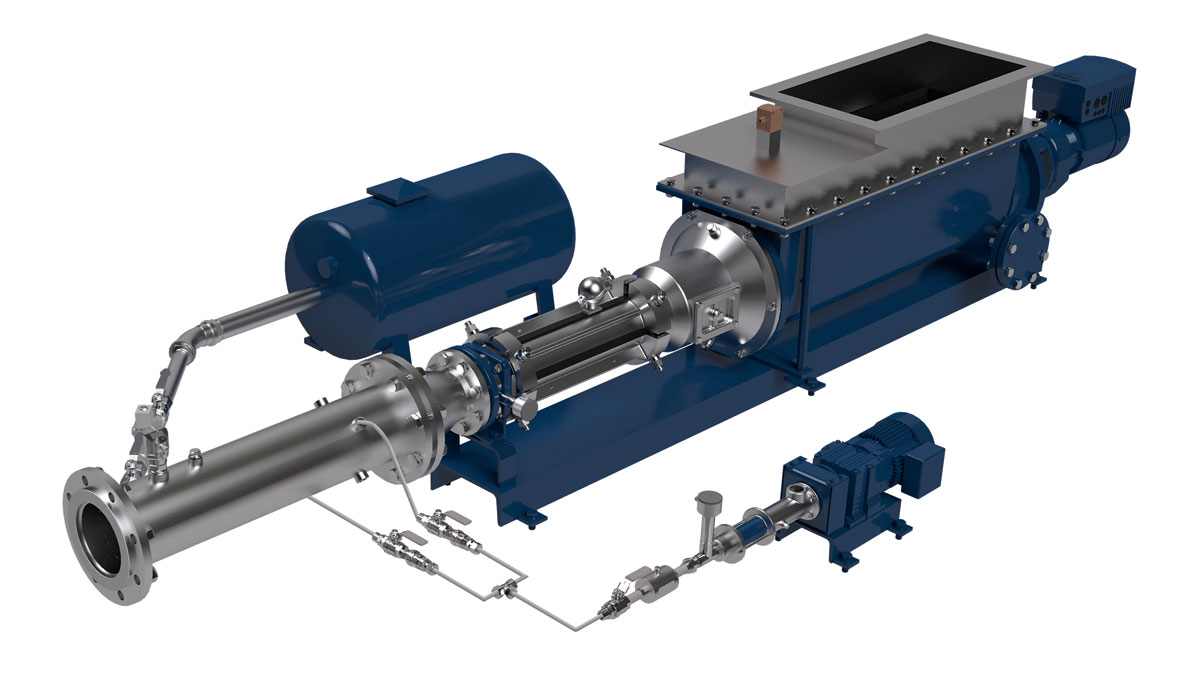

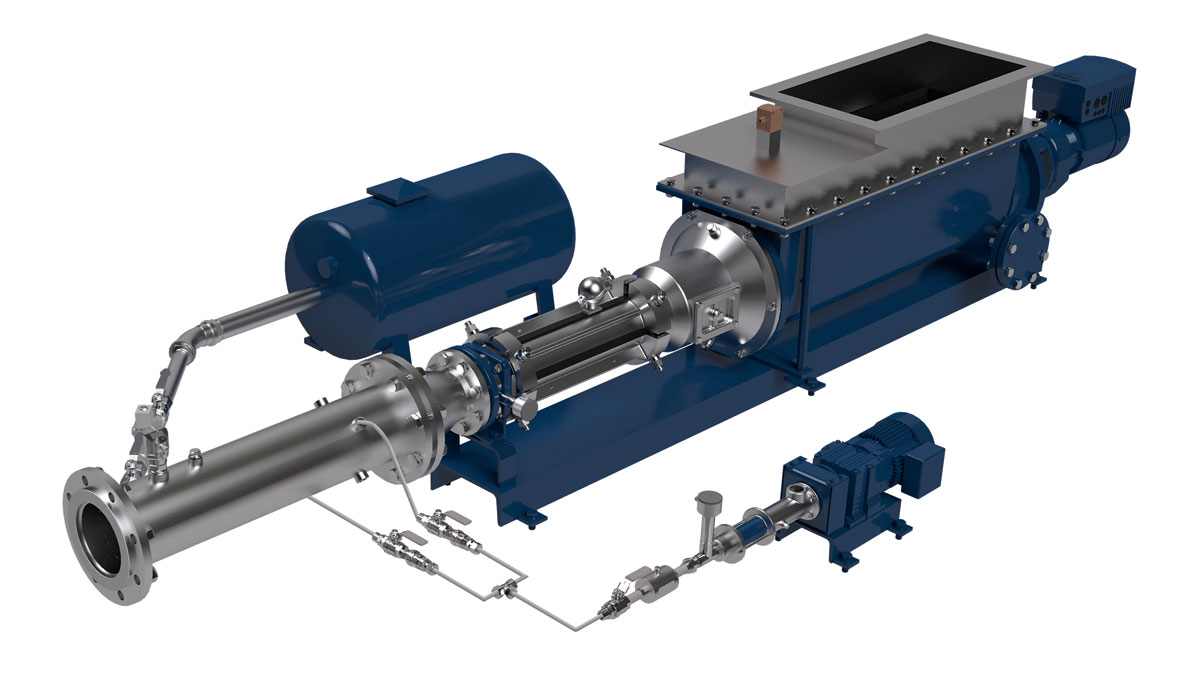

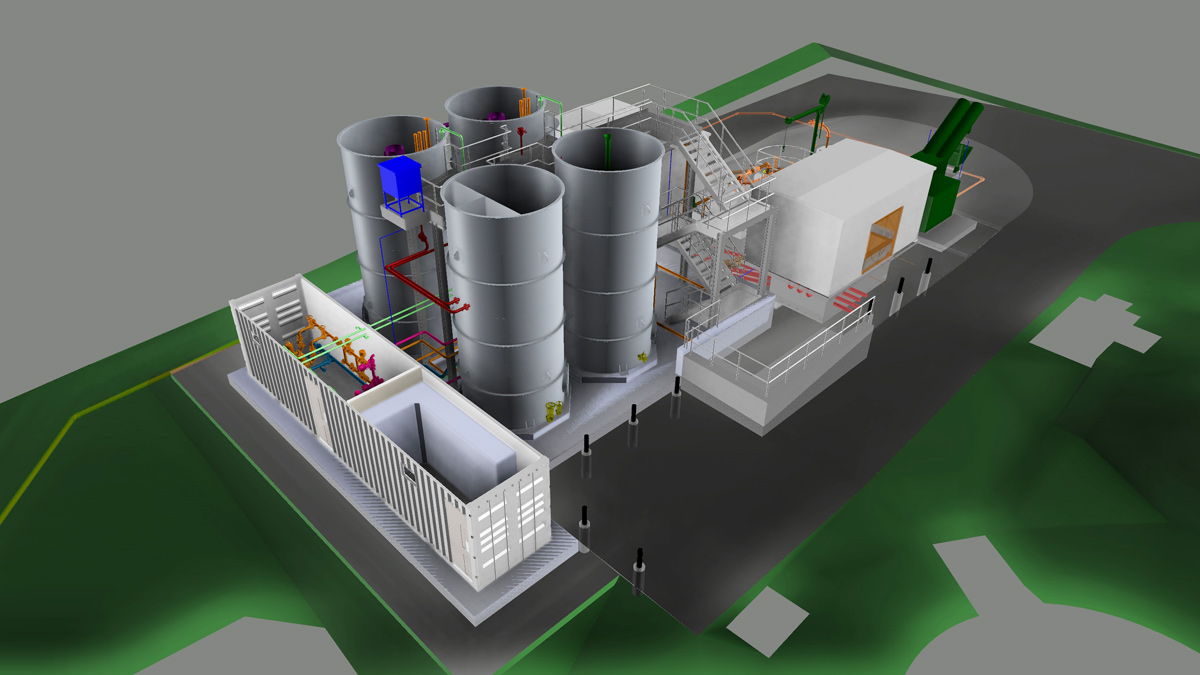

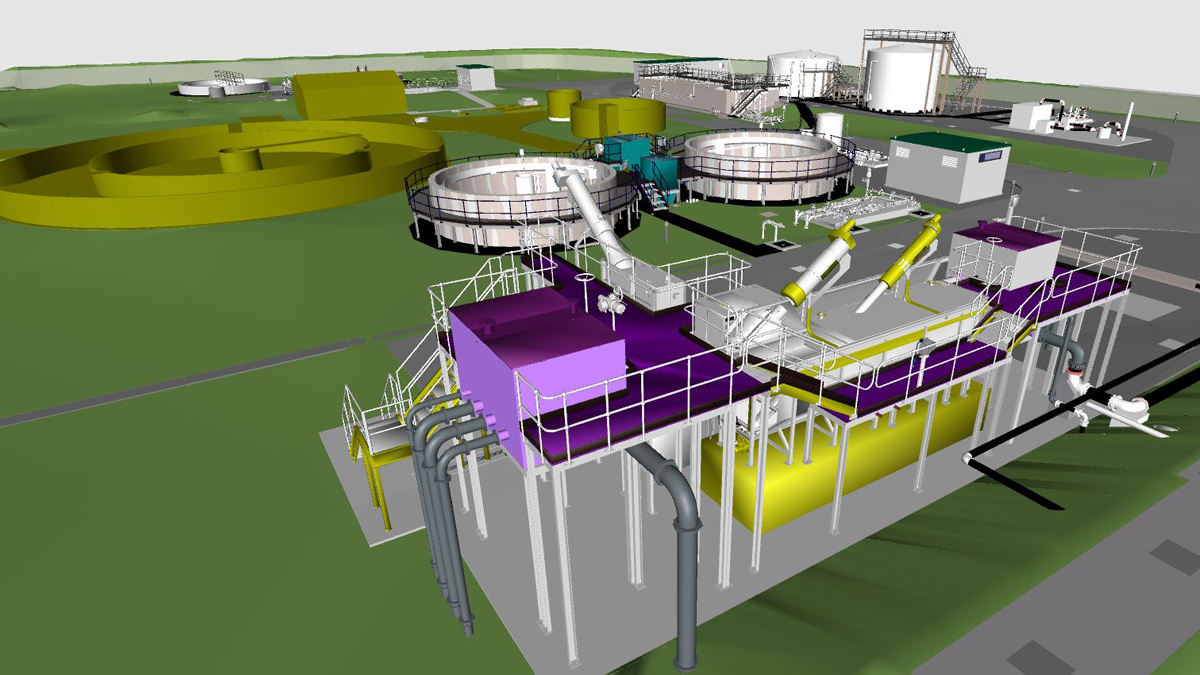

Energy Efficient Long Distance Pumping of Dewatered Sludge

Our dewatered sludge handling solutions include Smart Air Injection (SAI) technology, an energy efficient system delivering energy savings of approximately 40% by combining a progressive cavity pump with pneumatic dense phase conveying to transport 14-40% DS sludge over long distances up to 1,000 meters. This alternative to conventional technologies has proven to significantly reduce operational (energy, spare parts and downtime) and total investment costs.

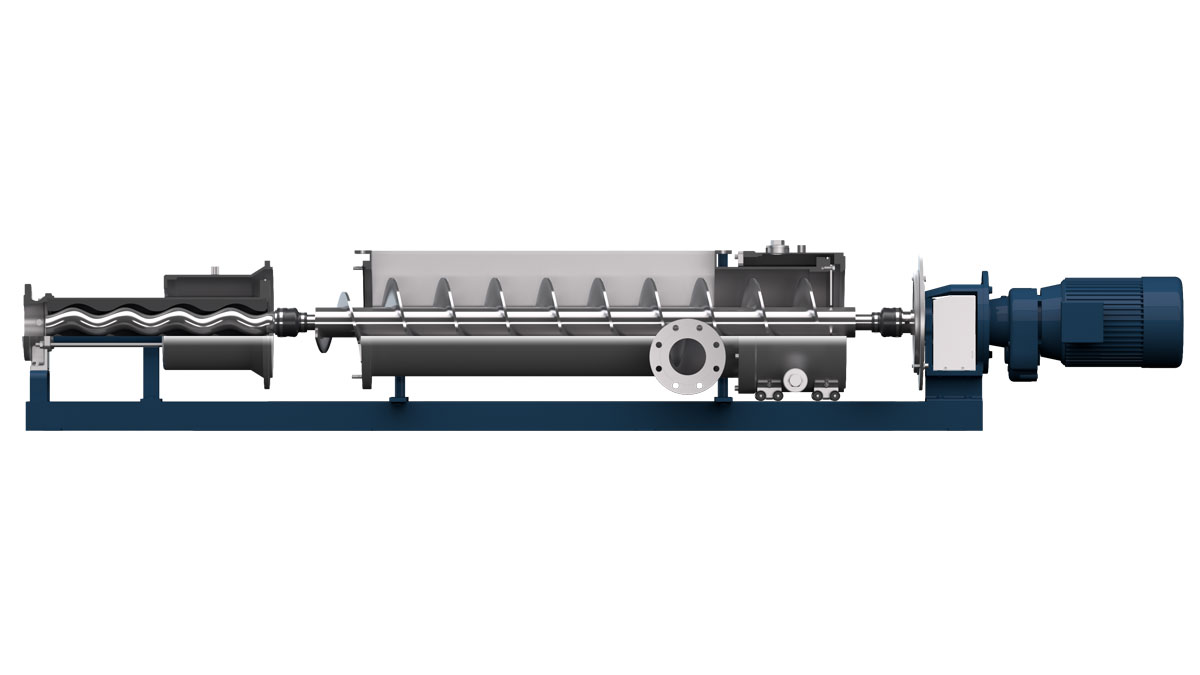

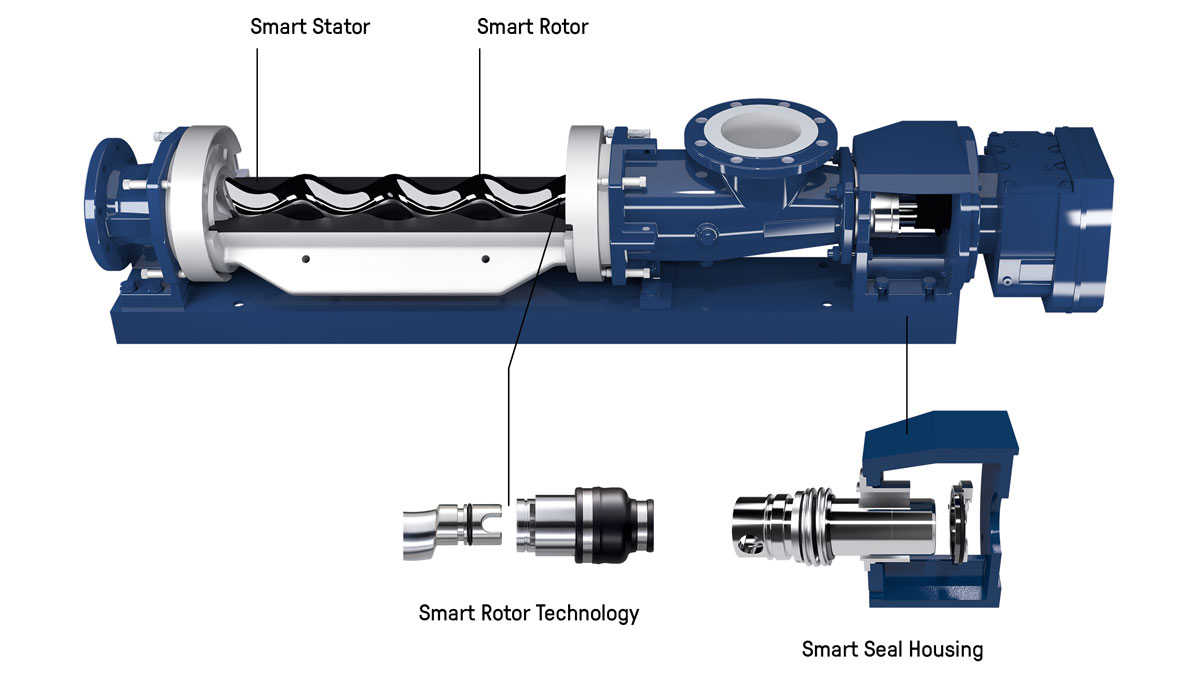

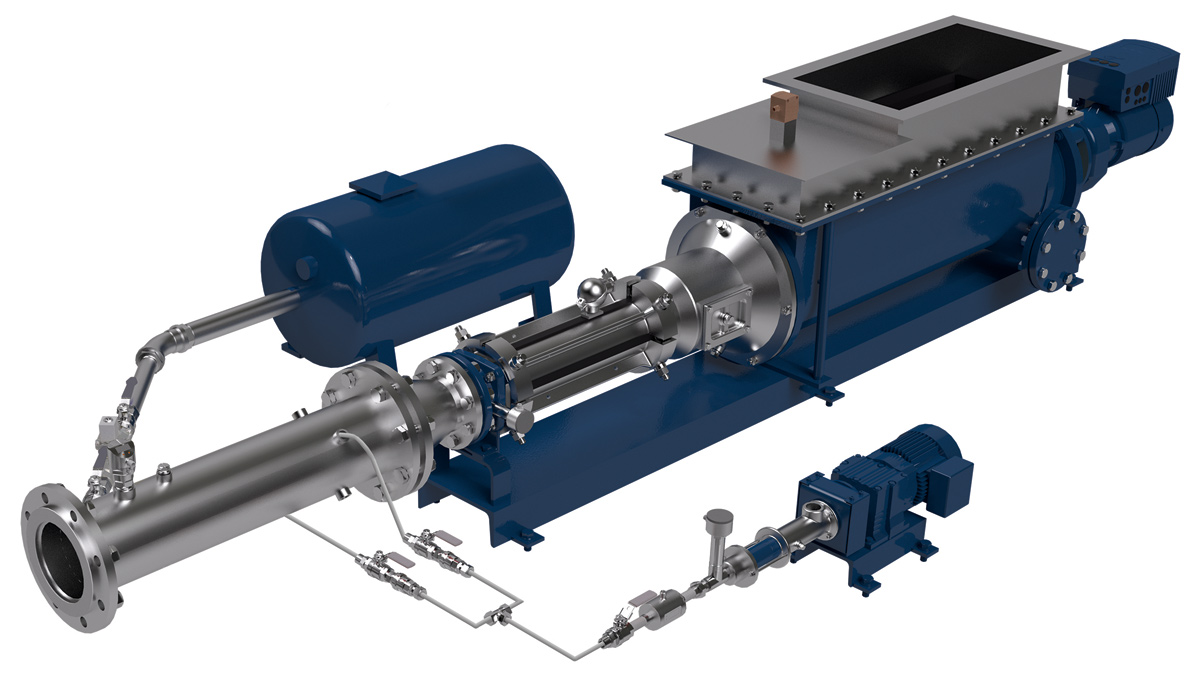

Patented Solutions for Smart Maintenance. Fast and Simple.

SEEPEX continues to extend its world class portfolio of maintain-in-place technologies for pumps with capacities up to 300m3/hr and 48 bar, able to handle flowable to highly viscous products with a high % DS content. The new patented BNM range has been designed to simplify customers’ maintenance and can reduce maintenance time by up to 80% with a significant reduction in related costs.

SEEPEX latest ease of maintenance solution for big pumps complements our Smart Conveying Technology (SCT), launched in 2008 and still setting standards in the maintenance of smaller standard progressive cavity pumps, and Drive Joint Access (DJA) technology for open hopper pumps. All of these patented solutions increase uptime and plant availability.