Cross Hands WwTW (2025)

Side view of the DfMA anaerobic-anoxic lane and the two SMART™ units - Courtesy of Mott MacDonald Bentley

Cross Hands Wastewater Treatment Works (WwTW) is located approximately 14 miles north-west of Swansea. The municipal treatment plant serves a catchment of residential, commercial and industrial trade contributors with a population equivalent (PE) of 5813. To meet the growth initiative by Carmarthenshire County Council, the works must expand its treatment capabilities and is subject to Growth and Quality regulatory drivers stipulated by Natural Resources Wales; tightening biological oxygen demand (BOD), total suspended solids (TSS), ammoniacal nitrogen (AmN) and Total Phosphorus (TP) permit limits to low concentrations. Mott MacDonald Bentley was commissioned to carry out outline, detail design and build to implement the final solution.

Exiting works

Existing treatment begins with the preliminary treatment of crude sewage through inlet 2D, 6mm screens. Flows are pumped into a single primary settlement tank (PST) and subsequently into a conventional complete-mix activated sludge plant (ASP) with two radial final settlement tanks (FST). There are two continuously operated upflow sand filters (COUF) to provide tertiary solids treatment for a final polish. To comply with the existing Total Phosphorus permit, ferric sulphate is dosed from an IBC into the PST incoming flow. Surplus activated sludge is thickened and stored. There is a radial storm tank to store excess storm flows and flows returned to treatment after the storm event.

DfMA chemical dosing kiosk and tank by Colloide – Courtesy of MMB

The case for enhanced biological phosphorus removal (EBPR)

A conventional method to meet the Total Phosphorus permit would be to dose wastewater with a chemical coagulant, to precipitate particulate phosphorus. To meet the tight permit at Cross Hands WwTW, a permanent chemical dosing system with additional pre-tertiary dosing points would be required. This would increase chemical usage, sludge storage demands and sludge tankering, thus increasing operational expenditure (OPEX).

A conventional solution would also require two additional identical aeration lanes, additional FST and additional tertiary treatment to treat the extra flows and load.

Enhanced biological phosphorus removal (EBPR) is the conditioning of a selected group of micro-organisms in existing ASP mixed liquors suspended solids (MLSS) called phosphorus-accumulating organisms (PAOs) to biologically uptake phosphorous. This will reduce demands of chemical dosing.

During the development of the Basis of Design in the outline design stage, sample data analysis showed that there was an abundance of nutrients derived from industrial discharges into site. The data showed fairly consistent discharge rates with favourable volatile fatty acid concentrations and BOD : Total P ratios, which are important indicators for a viable operation of EBPR.

Unlocking innovative opportunities through collaboration

Following ecology surveys, it was not possible to expand the existing site boundary due to ancient woodlands surrounding the site. Subsequent outline design solutions focussed on maximising existing assets, minimising process downtime and avoiding requirements for temporary treatment.

Alongside EBPR, alternate innovative processes were considered, including the integration of fixed film into the existing ASP, hybrid activated sludge (HYBACS®) and sequencing batch reactors. Site visits were organised for design team and Welsh Water stakeholders to study the design, implementation and operation of these processes constructed by MMB previously in AMP6 for other water framework clients.

GFS sludge holding tanks by Balmoral Tanks Ltd – Courtesy of MMB

With information collated, MMB organised a four-day design sprint to collaborate with client stakeholders to gain buy-in of a viable process solution that would meet the agreed Measures of Success criteria. The sprint comprised of several workshops starting with a technology forum where sub-contractors were available to present and address questions of the associated technologies. Following optioneering discussions, three solutions were selected for further development.

The sprint progressed into engineering design workshops where general arrangement layouts, P&ID diagrams, associated calculations were developed, receiving input from client operations as needed. This enabled equipment schedules to be produced to inform costings, utilising the client Unit Cost Database model. On the final day, the options were scored based on sustainability, cost, operability and residual risk utilising the client Risk and Value template to compare outputs with key stakeholders to identify the lower whole life cost and best benefit/cost ratio.

The sprint has helped to accelerate outline design which typically takes several months for optioneering, removed the need for multiple meetings to assess and agree the final solution with client stakeholders. The identification of package plants and appointment of sub-contractors were also agreed in advance, ultimately reducing programme and cost.

Single solution that provides headroom and resilience

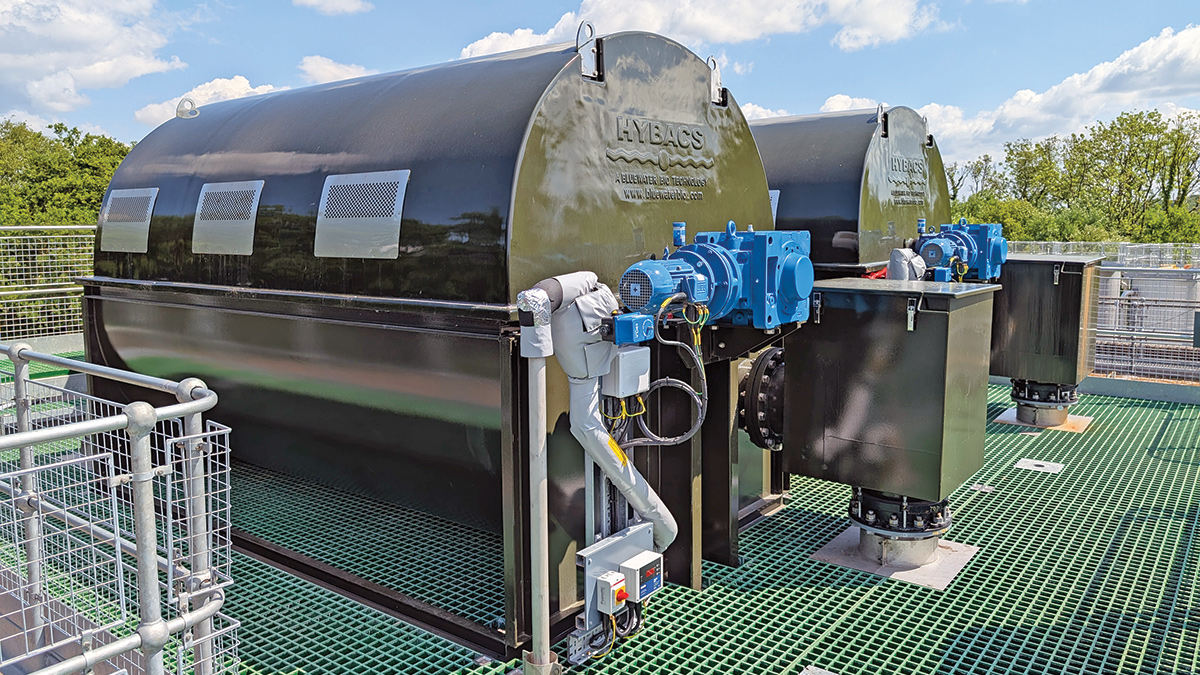

The agreed solution at Cross Hands WwTW was to modify the conventional ASP into an EBPR plant, using the anaerobic-anoxic-oxic (A2O) configuration. The modification required the incorporation of hybrid activated sludge (HYBACS®) supplied by Bluewater Bio Ltd and provision of a new anaerobic-anoxic (AA) lane prior to the aeration (oxic) lanes.

To provide additional resilience to the process, MMB scope included the install a drum sludge thickener, primary sludge tank, SAS storage tank, permanent chemical dosing package plant, two additional continuous upflow sand filters sand filters and additional final effluent instruments for improved water quality monitoring.

Two additional COUFs were incorporated to accommodate increase in flows to be treated – Courtesy of MMB

Cross Hands WwTW: Supply chain – key participants

- Design & construct: Mott MacDonald Bentley

- Ground investigation: Quantum Geotechnical Ltd

- BIOWIN modelling: MPAMOT Africa (Pty) Ltd

- Electrical survey: General Panel Systems Ltd

- HYBACS®: Bluewater Bio Ltd

- Reinforced concrete tank: Tank Consult Ltd

- Electrical installation: Protocol Control Systems Ltd

- MCC kiosk: Morgan Marine Ltd

- Systems integration: GPS Links Ltd

- Mechanical installation: Whitland Engineering Ltd

- Continuous upflow sand filters: Jacopa Ltd

- Coagulant dosing: Colloide Ltd

- Safety showers: Hughes Safety Showers

- Sludge thickener: Alfa Laval Ltd

- Anaerobic-anoxic tank mixers: Grundfos Pumps Ltd

- Flow controls: AFFCO Flow Control (UK) Ltd

- Valves: AVK UK Ltd

- Internal recycling pumps & sludge tanks mixers: Xylem Water Solutions UK Ltd

- Sludge storage tanks: Balmoral Tanks Ltd

- Final effluent instrumentation: Partech (Electronics) Ltd

- Generator: A&M Generators Limited

HYBACS® & BIOWIN modelling

HYBACS® is a patented process that comprises of two biological stages followed by clarification. In the first stage, settled sewage and return activated sludge is combined then fed into two shaft mounted advanced reactor technology (SMART™) units.

The reactors help accelerate the biodegradation of wastewater by stimulating biomass to produce enzymes that will promote hydrolysis. Hydrolysed organic material provides readily-biodegradable carbon to accelerate fermentation in the anaerobic lane and phosphorus re-release by the PAO microbes. Nitrate rich MLSS is returned from the aeration lane back to the anoxic tank for denitrification and alkalinity recovery.

Hybrid activated sludge (HYBACS®) plant – Courtesy of Mott MacDonald Bentley

The SMART™ reactors in the first stage enables a higher food to microbe (F/M) ratio to be operated in the second biological stage. The benefit of a higher F/M ratio in the existing aeration lanes has removed the need to build additional aeration lanes, maximising existing asset and reducing carbon footprint.

The HYBACS® process has a second benefit by encouraging the formation of granular activated sludge floc, producing excellent settlement. Having improved settleability would enable higher loading rates to be applied onto the existing FSTs and has removed the requirement to build an additional FST.

MMB further commissioned MPAMOT Africa (Pty) Ltd to carry out modelling of the EBPR configuration, drawing on their extensive expertise in biological nutrient removal and BIOWIN modelling. MPAMOT Africa is a South African engineering and development consultancy established in 1997, with a proven track record of delivering projects globally; including in the UK, where they have previously partnered with Mott MacDonald. The modelling team assessed a range of scenarios, configurations, and operating conditions to ensure the robustness of the proposed solution in meeting the tightened permit requirements.

Procurement lead approach

Recognising the tight timescale to design, build and commission multiple processes, MMB utilised a procurement lead design approach. Early Contractor Involvement with key sub-contractors including Protocol Control Systems Ltd, General Panel Systems Ltd, and Whitland Engineering Ltd was initiated early in the programme.

There was significant migration of existing electrical equipment onto new motor control centres (MCCs) that required in-depth surveys and electrical design support from the electrical sub-contractors. Collaboration with Whitland Engineering Ltd realised several opportunities to build assets and associated infrastructure offline. For example, the internal recycle pump access platform was fabricated off-site and installed without the need to shut down existing biological treatment; ultimately avoiding the hire of temporary treatment.

Access steps were also fabricated to bridge access between existing lanes and to the new SMART™ units and anaerobic-anoxic lanes.

Elevated MCC kiosk from Morgan Marine Ltd – Courtesy of MMB

MMB also utilised Welsh Water’s standard design product for sludge tanks, MCCs and ferric dosing package plant to reduce design time. A 3D BIM model was developed for Cross Hands WwTW which helped with the visualisation of the new assets being built and has assisted discussions with client Operations stakeholders on ALM (access, lifting and maintenance).

Several business continuity plans were developed by MMB MEP team to navigate planned short duration shutdowns to implement electrical and mechanical scope of works without impacting and causing a detriment to existing final effluent (FE) compliance.

Conclusions

Despite construction challenges working alongside live assets and navigating existing buried services, construction was completed on-time and met the NEP regulation date of 31 March 2025. This achievement was made possible through great collaboration with Welsh Water stakeholders, MMB design, Construction & MEP team, and working closely with the sub-contractors and suppliers.

Data is still being collected on the EBPR plant, but initial results are showing that the HYBACS® has showed rapid settlement in the FST. The investment and completed scope of works delivered at Cross Hands WwTW has contributed towards improved final effluent quality in Afon Gwili, providing resilience to site and headroom to its new FE permit.