Sheet Piling (UK) Ltd

Swift Cofferdam Installation Works Waste No Time at STW

Swift Cofferdam Installation Works Waste No Time at STW

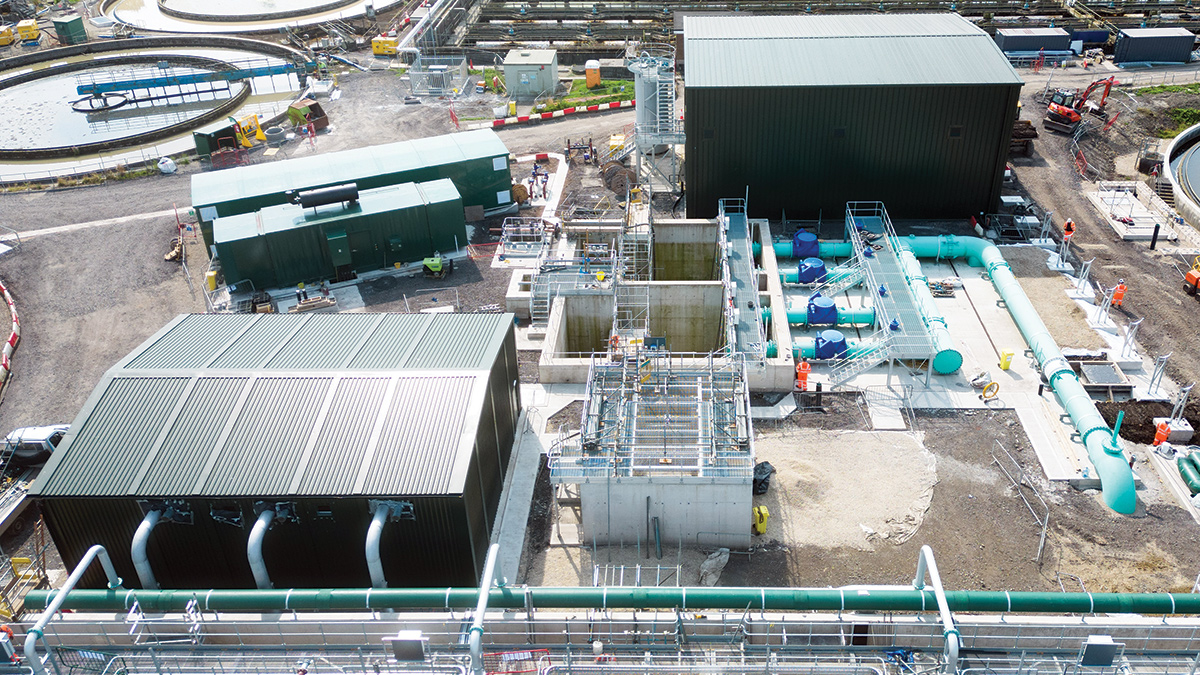

Following appointment by MWH Treatment, Sheet Piling UK was furnished with a set of designs for which it provided both the physical sheet piles required and the necessary installation expertise.

Sheet pile cofferdam installation works

These elements were focused on equipping the project with two temporary sheet pile cofferdams, with diameters of approximately 10 metres and a retained height of 5.6 metres. Given the large retained height, both cofferdams required temporary support, in the form of 1no. ring beam composed of curved a 254x254x101UC waler. The temporary support was also supplied and install by Sheet Piling (UK).

The design also required several fully interlocking ‘omega’ corner profiles to be installed around the perimeter of the cofferdams, so as to achieve the small diameter.

What are omega corner profiles used for in sheet piling?

Omega corner profiles are specialist steel section that usually help create corners and junctions in sheet pile walls. They allow for the connecting of two straight sheet pile sections at an angle between what is typically 90° and 135°. They can be useful when a more complex design is required for a project and also for helping overcome the impacts of different types of on-site geology.

Sheet pile installation methods

The 10-metre GU16N sheet piles required for the cofferdams were installed using Sheet Piling UK’s unique long-reach ABI TM20 rig. This was fitted with a variable moment vibratory hammer, to help drive the piles into the prevailing ground conditions. To facilitate acceptance of the piles into dense soils, pre-augering of the sheet pile line took place prior to the cofferdams’ installation.

In total, circa 80Te of sheet piles were supplied for the cofferdams, with these being swiftly drawn down from Sheet Piling UK’s extensive UK stockholding of temporary steel sheet piles. This was also the source for the securing of the required Omega corner profiles.

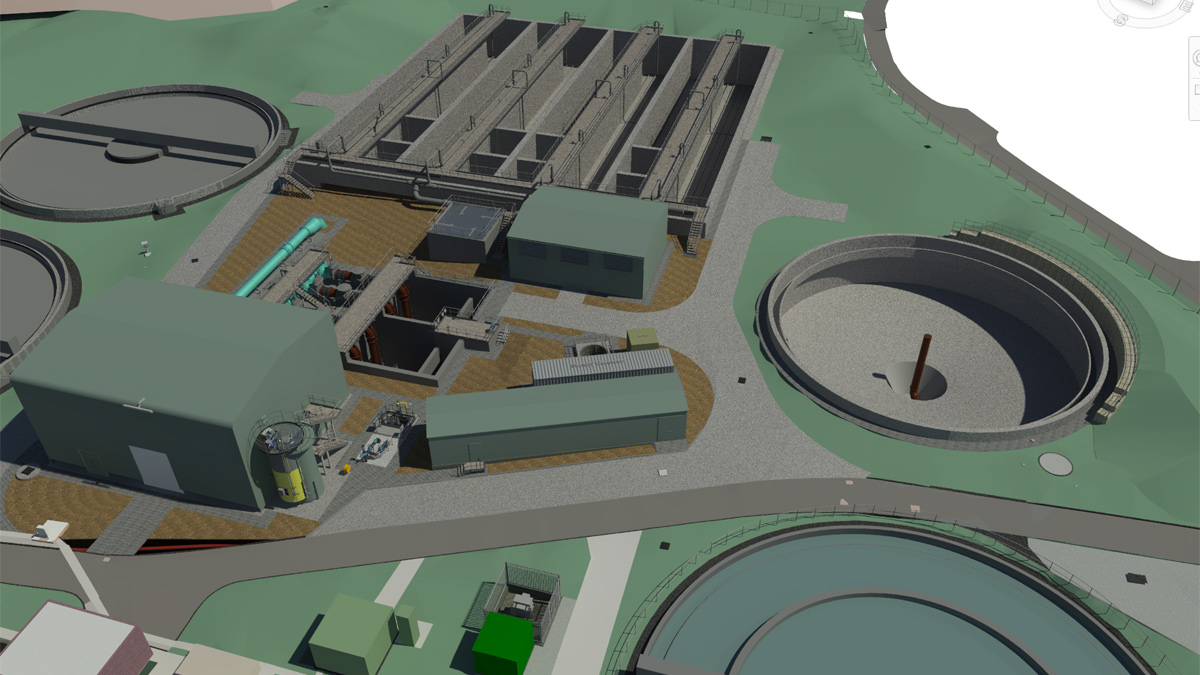

Facilitating the arrival of a new settlement tank

The installation of the temporary cofferdams and support structure was intended to allow MWH Treatment to excavate to formation level and cast a new, permanent reinforced concrete settlement tank. During this process, the sheet piles act as shuttering for the concrete. Once the concrete is cured, the reinforced concrete slab at the base of the settlement tank effectively becomes a buttress, allowing for the removal of the 10-metre-diameter ring. At that stage, the tank’s construction can be completed.

Settlement tanks, sometimes called sedimentation tanks or clarifiers, perform a vital function at sewage treatment works like Wanlip. They allow solid particles within waste to be separated from wastewater, using gravitational forces. Settled solid material, often called sludge, can be effectively separated from cleaner water.

Sewage treatment works enhancements

The current works at Wanlip, to which Sheet Piling UK has contributed through its cofferdam installation, will allow for an expansion in capacity and be a factor in driving improvements in water quality in the River Soar.

Thanks to swiftly supplying the sheet piles required, and marshalling cofferdam installation teams and equipment from its own fleet, Sheet Piling UK wasted no time in helping the client and Wanlip STW get well on track for the achievement of its objectives.

For More Information, contact us at https://www.sheetpilinguk.com