Sheet Piling (UK) Ltd

Sheet Piles Drive River Water Quality Improvements

Sheet Piles Drive River Water Quality Improvements

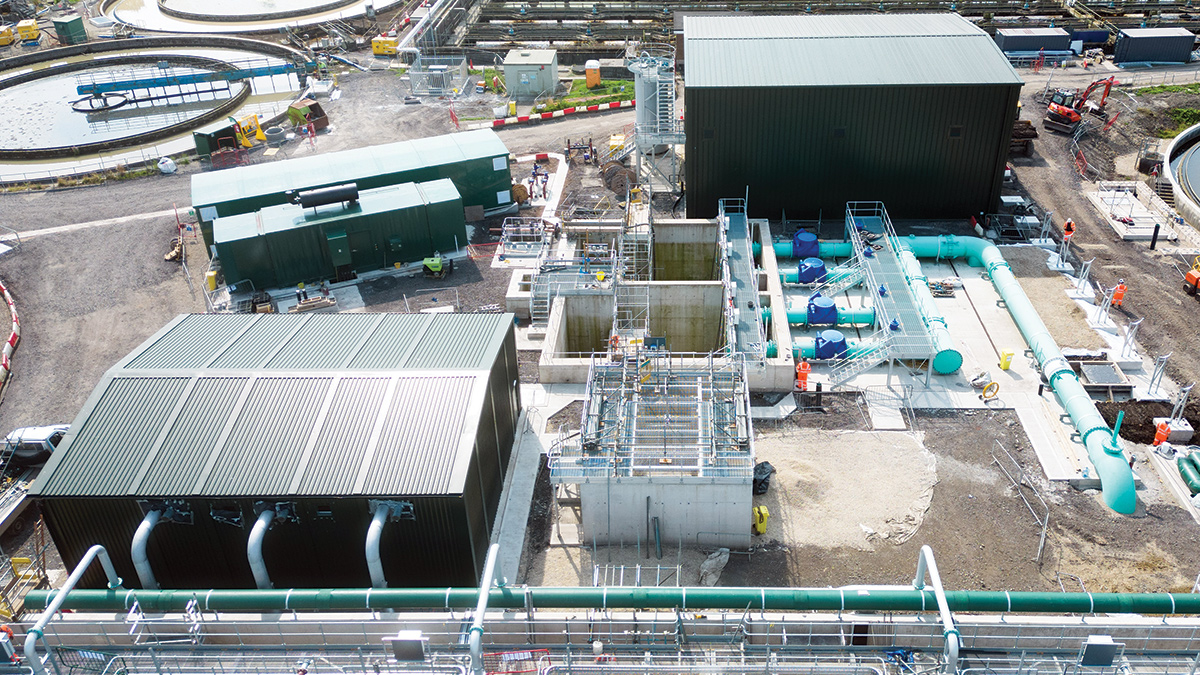

Owing to the nature of the ground conditions, very stiff clay with sand lenses, it was determined that the pile line would need to be pre-augured before installation could commence. Pre-augering helps to reduce the density of the ground, enabling the sheet piles to be driven into ground conditions that might otherwise be deemed unsuitable.

The nine metre long sheet piles were installed using one of our ABI Telescopic Leader Rigs, complete with a Vibratory Hammer, drawn from our own extensive in-house fleet of specialist piling equipment.

With the site being so close to the Sheet Piling (UK) Head Office, just seven miles away, several team members took time out to visit the site as part of their professional development. Apprentice Quantity Surveyors Scott Burrow and Leighton Carney, were joined by Design Engineers Abasi Shabani and Callum Pinder. They were accompanied by Associate Director for Construction, Andy Ball who commented:

“Helping our team develop their professional skills and knowledge is vitally important. Seeing first hand, the difficult ground conditions on this project, helps give them a better understanding of the challenges faced on site.”

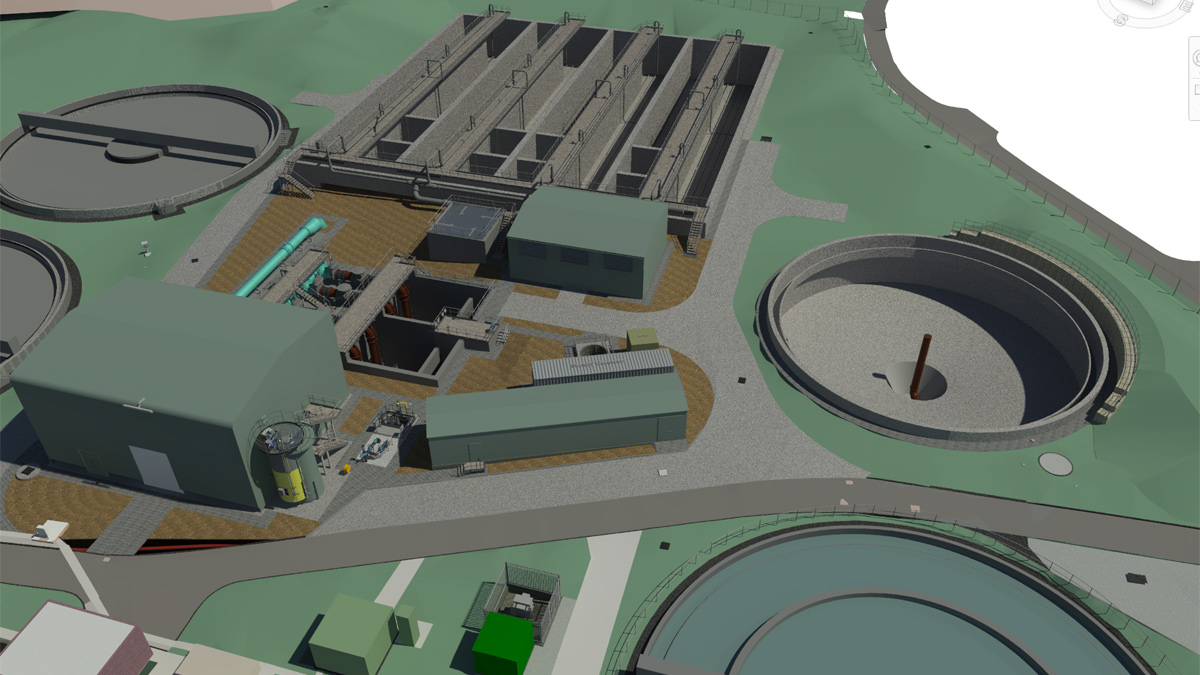

Once complete, the two stormwater tanks will have a combined capacity of over 3.6 million litres, which is almost as much as one and a half Olympic sized swimming pools. The tanks store and manage excess waste and storm water, before releasing it slowly, in a controlled manner. This helps prevent localised flooding and reduces the strain on local drainage systems and the nearby Chorley Wastewater Treatment Works facility.

These detention tanks are part of on-going £12 million investment to improve river water quality in the River Yarrow, and in turn the River Ribble in Lancashire, meeting ever more stringent environmental standards.

For More Information, contact us at https://www.sheetpilinguk.com