Veolia Water Technologies UK

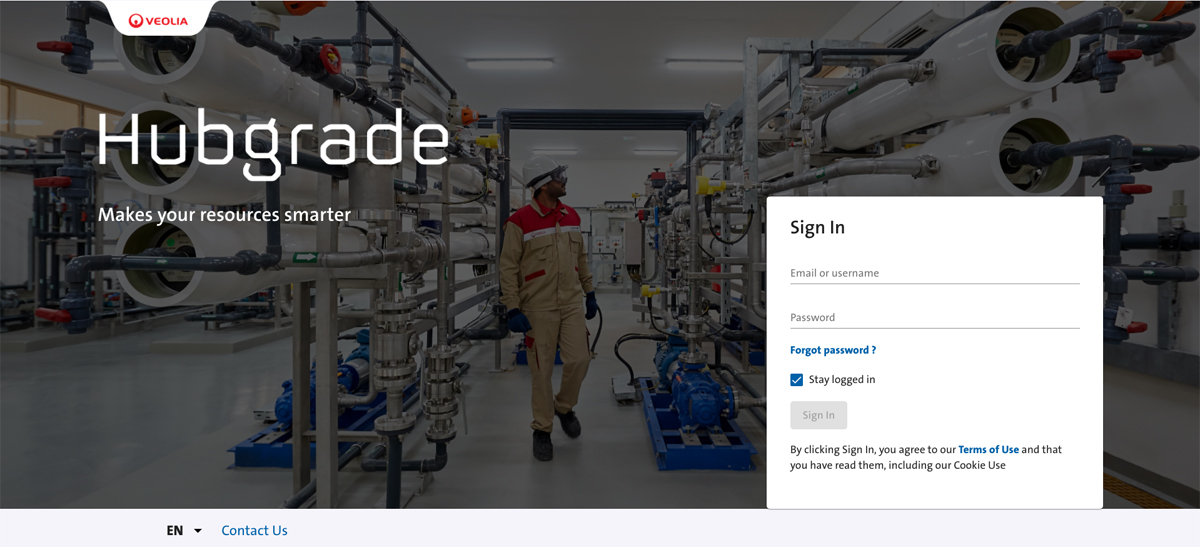

Hubgrade (2022)

Courtesy of Veolia Water Technologies

In its 2019 price review, Ofwat set municipal water companies a number of key objectives to meet by the end of the current Asset Management Period (AMP7). These objectives included lowering customer bills by 12% before inflation, decreasing interruption to a water supply by 64%, reducing water leakage by 17% and meeting more stringent water quality standards. Furthermore, £4.6 billion of investment has been granted to water companies to deliver the ambitious Water Industry National Environment Programme for England (WINEP) and the National Environment Programme for Wales. This is with the aim of improving 12,067 km of rivers for the benefit of people and wildlife. In order to effectively deliver on these requirements and meet the various challenges associated with the impact of the climate crisis, it is crucial that water companies utilise funding to invest in the right solutions. Digital monitoring and optimisation technology should be high on that agenda.

The purpose of Hubgrade

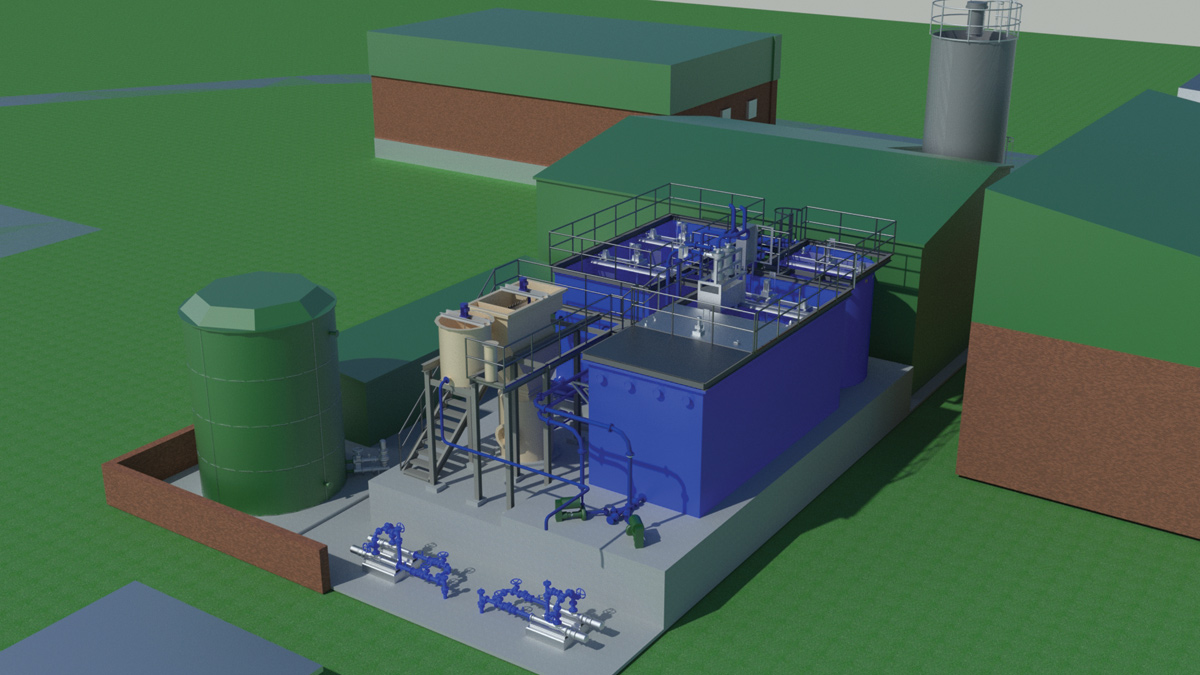

Digital technologies enable remote, real-time monitoring and optimisation of treatment systems. Veolia Water Technologies UK’s’ Hubgrade solution utilises data sources that are placed throughout a wastewater plant and network, allowing operators to monitor the system’s performance remotely by using real-time data.

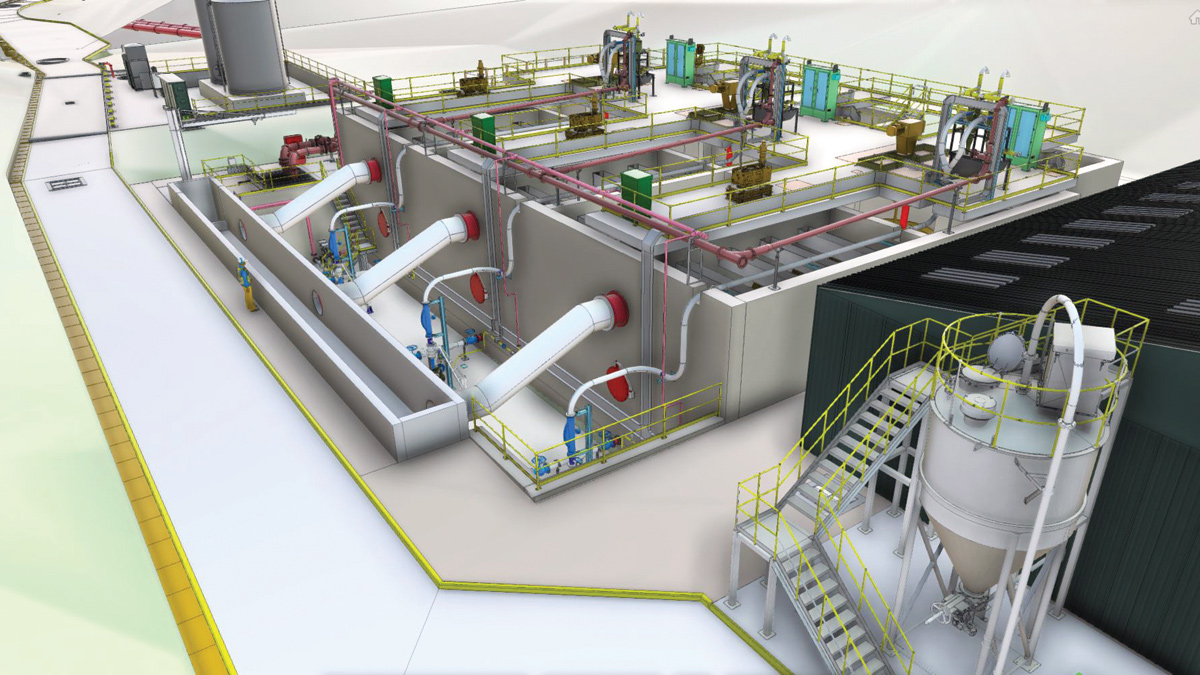

Hubgrade aggregates real-time data and applies analytics and algorithms to optimise a plant’s performance. The Plant Module of Hubgrade is an online digital twin of the wastewater treatment plant and network. It creates a digital representation of a customer’s assets and uses predictive analysis in real-time to provide setpoints to the PLC, delivering insight to the operators, process engineers and management.

An operator can connect to Hubgrade’s Plant Module service in the cloud and forward their choice of data for optimised setpoint calculations. There are also 60 standard features available to choose from for real-time optimisation, overview and forecasting.

So far, the Plant Module has been installed at over 100 wastewater treatment plants and installations worldwide. Data from these plants have shown that up to 30% of energy for aeration has been reduced, 100% of chemicals have been cut, biological capacity has increased by 40% and hydraulic capacity has doubled.

A further benefit of optimisation is reducing the level of capital expenditure required. By maximising the hydraulic and biological capacity of the plant it allows municipal water companies to meet the demands of population growth or tighter regulations without having to invest in new plants or facilities.

Courtesy of Veolia Water Technologies

Hubgrade Assist

Veolia can further support customers through Hubgrade Assist. This allows operators to be supported with remote expert assistance and site support that includes troubleshooting and regular review and recommendations. It is ideally bundled with other Hubgrade packages to boost their benefits.

Operators who choose Hubgrade Assist will benefit from a number of unique features, including relevant and customisable indicators, expert review reports, interactive technical support and remote live assistance from VWT UK experts. Bespoke e-learning courses are also available directly from the Hubgrade portal.

Overall, Hubgrade Assist is an expert companion that offers peace of mind for safe, reliable and effective operations at any time.

Courtesy of Veolia Water Technologies

Case Study – Nosedo WwTP

VWT’s Hubgrade has been implemented on a range of different projects. One such project took place at the Nosedo Wastewater Treatment Plant (WwTP) in Milan, Italy. Here, a large volume of treated water is reused for agriculture and the challenge was to guarantee that the water was always in the best condition for water reuse, over and above environmental directives.

To provide a solution to this challenge, Hubgrade Performance was specified, with the system promising to obtain significant total average operational savings from reduced energy consumption, chemical consumption and sludge production. It would also offer more efficient handling of the large biological load variations together with fewer manual adjustments and an increase in the hydraulic capacity.

After the installation, the results were very positive, with the WWTP saving approximately €630,000 per year from a reduction in energy, chemical and sludge production. Specifically, energy usage went from 0.431 to 0.323 kWh/kg – a significant drop of 25%. Hydraulic capacity also increased by 20-30% during wet weather. Overall, operation was more stable and less manual adjustment was required.

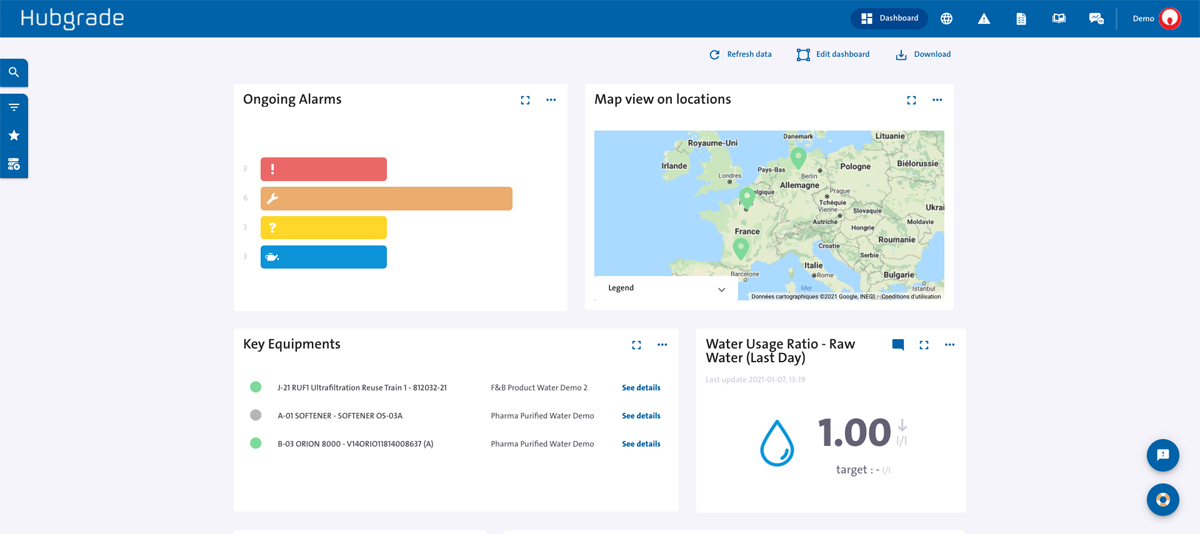

Case Study – BlueKolding

For many years, BlueKolding A/S has prioritised and applied software solutions for capacity extension and operations optimisation for the entire sewerage system, from the sewer network to the wastewater treatment plants. The aim was to maximise the use of the existing facilities and at the same time ensure optimum and compliant operation under both dry and wet weather conditions.

Hubgrade Performance was first installed in 2007 at the BlueKolding’s Agtrup WwTP. After the company completed a larger extension of its plant facilities in 2011, Hubgrade Performance was then installed at three further satellite WwTPs in Vamdrum, Christiansfeld and Lunderskov. Finally, in 2017, BlueKolding expanded its Hubgrade Performance to integrate the control of Agtrup WwTP together with the sewer network for the city of Kolding as well as the three satellite wastewater treatment plants.

Courtesy of Veolia Water Technologies

The results were impressive. In 2007, the aim for Agtrup was to improve its effluent quality and ensure operational savings. In total, there was a 25% reduction in effluent total nitrogen and a 45% reduction of the chemical precipitant. Then the introduction and integrated control of the Agtrup WwTP and sewer system in 2011 secured an 80% higher hydraulic load. This meant that costs related to a planned extension for the catchment area were reduced by 22% compared to the original budget.

For the satellite wastewater treatment plants, the purpose was to ensure a stable operation and maximise the operational savings by providing its team with relevant software for optimisation of the plant. Over the years, BlueKolding has experienced compliant operation under all conditions by active online control and with less manpower than previously required.

Sewerflex for BlueKolding

BlueKolding was also able to streamline its response to storm water events, thanks to the Sewerflex software that is now part of Hubgrade Performance. The Sewerflex software is a real-time control software, which can reduce the amount and effect of overflow incidents and ensure the intelligent use of storage volumes during rain events.

VWT’s solution was to develop an inflow forecast for the catchment of the BlueKolding WWTP, based on real time flow measurements from the inlet, radar data and a conceptual model. With this inflow forecast, plant operators could look to increase hydraulic capacity when needed and also predict and utilise future periods of dry weather for the emptying of storage basins in the sewer systems. A predicted dry weather period could also be used to schedule any required maintenance of sewer installations.

With Sewerflex, Hubgrade Performance was able to optimise the hydraulic capacity of the WwTP during storm water conditions by up to 80% and reduce the use of sewer overflows by as much as 83%. Coupled with a 23% reduction in energy consumption during these periods, this contributed to savings of €2 million for the BlueKolding WwTP.

Courtesy of Veolia Water Technologies

Conclusion

Overall, Hubgrade is a high-quality technology that has proven it can help municipal waste water companies to increase plant efficiency and ensure a consistently high quality output with a reduction in OPEX costs. As the impact of the climate crisis continues, Ofwat is likely to continue to pressure companies to improve the efficiency of their processes and tighten final effluent requirements.

Digital monitoring technology such as Hubgrade can be an increasingly important asset in this drive. WwTPs looking to modernise, future-proof and protect their facilities long-term, would be advised to start making steps towards implementation.

For more information: Veolia Water Technologies | +44 (0)203 567 7400 | www.veoliawatertechnologies.co.uk