Veolia Water Technologies UK

AQUAVISTA Plant – Meeting Modern Wastewater Challenges (2019)

Veolia Water Technologies UK

The next Asset Management Period (AMP7) will introduce a new focus on lowering expenditure, reducing costs to the customer, developing long term solutions and meeting more stringent quality standards. A significant part of meeting these objectives will be ensuring facilities are operating in the most efficient way.

Continual advances in technology, including the ongoing growth of the industrial Internet of Things, are helping to drive efficiency improvements in a wide range of sectors. Digital monitoring and optimisation technology has the potential to allow significant steps forward in the way wastewater is managed.

These systems use sensors installed across the wastewater facility or even the whole network to collect real-time data about the system’s performance as well as tracking the external factors that will affect the wastewater network. This information is aggregated, analysed and displayed in real time. This data is then used, through the use of specially designed software, to identify and meet the optimum operational parameters. Often these cloud-based systems provide the option to access the information from any location, including mobile devices. This provides an enhanced level of flexibility in managing the wastewater and treatment processes.

By optimising the process, water companies can significantly increase both the biological and hydraulic capacity of their facilities while reducing operating costs and minimising the need for further capital investment. For example, a system such as Veolia Water Technologies’ AQUAVISTA Plant that uses a sophisticated algorithm-based optimisation can deliver as much as a 40% increase in biological load with the same effluent concentrations and facilitate between a 20% and 100% higher flow rate through the wastewater treatment process. These improvements in performance have a number of benefits for water companies in terms of meeting stricter standards and tighter financial targets.

The first and most immediate advantage of optimising the treatment process is a reduction in operational costs. Without continual monitoring of the incoming effluent quality levels it is often the case that the water will frequently be overaerated and overdosed with chemicals. For example, the blowers on the biological treatment line are often set when the plant is commissioned and remain at that level regardless of variations in the volume or quality of the wastewater. By monitoring the parameters and adjusting the plant accordingly, an optimisation platform can significantly reduce energy consumption. Typically, aeration costs can be lowered by up to 30% and mixing costs by between 25 and 75%. It can also optimise the use of chemicals required to extract phosphorus and also be used to promote biological p-removal.

A further benefit of optimisation is reducing the level of capital expenditure required. By maximising the potential hydraulic and biological capacity of the plant it allows water companies to meet the demands of a growing local population or stricter regulatory standards without investing unnecessarily in new plant or facilities. However, where investment is required, having a full overview of the performance of the plant and its potential capacity allows a more informed decision to be made about how best to spend the capital in order to achieve the best results.

Furthermore, an increasingly intensive use of land means that in certain areas of the UK there is a lack of space for expansion of sites. In these situations, improving the capacity and efficiency of existing plant to cope with increased local demand is particularly valuable. Digital plant optimisation platforms also help solve a further issue that has arisen.

Real Time Control plays an important part of enabling and up skilling Plant Engineers and Operators to manage multiple plants more efficiently and effectively. Digital monitoring technology helps engineers to troubleshoot more effectively as it provides a real time overview of how the plant is operating and allows them to quickly isolate the cause of the issue. This reduces the need for time consuming investigations that are based on a process of eliminating the likely causes one by one. Cloud-based systems further improve this efficiency by allowing remote monitoring of the plant, removing the need visit the site unnecessarily.

In addition, being able to access and interrogate information on each piece of plant, including both current and historical performance data allows managers to develop an optimum maintenance schedule. This ensures that resources are allocated in the most efficient way as well as preventing issues from occurring – increasing the overall up-time of the plant.

Moving beyond monitoring only the treatment plant, digital technology can be used to support a whole system approach to water management. This allows water companies to predict and plan for big events. As an example, weather data can be analysed alongside plant data to build a picture of what might happen to the facilities and network in the event of a storm. This enables the system to identify where high-flow events are likely to occur in the network and allows a strategy to be formulated. It can also help managers to understand the system’s ability to cope with infrequent and exceptional stormwater events – again allowing the correct level of capital investment to be made.

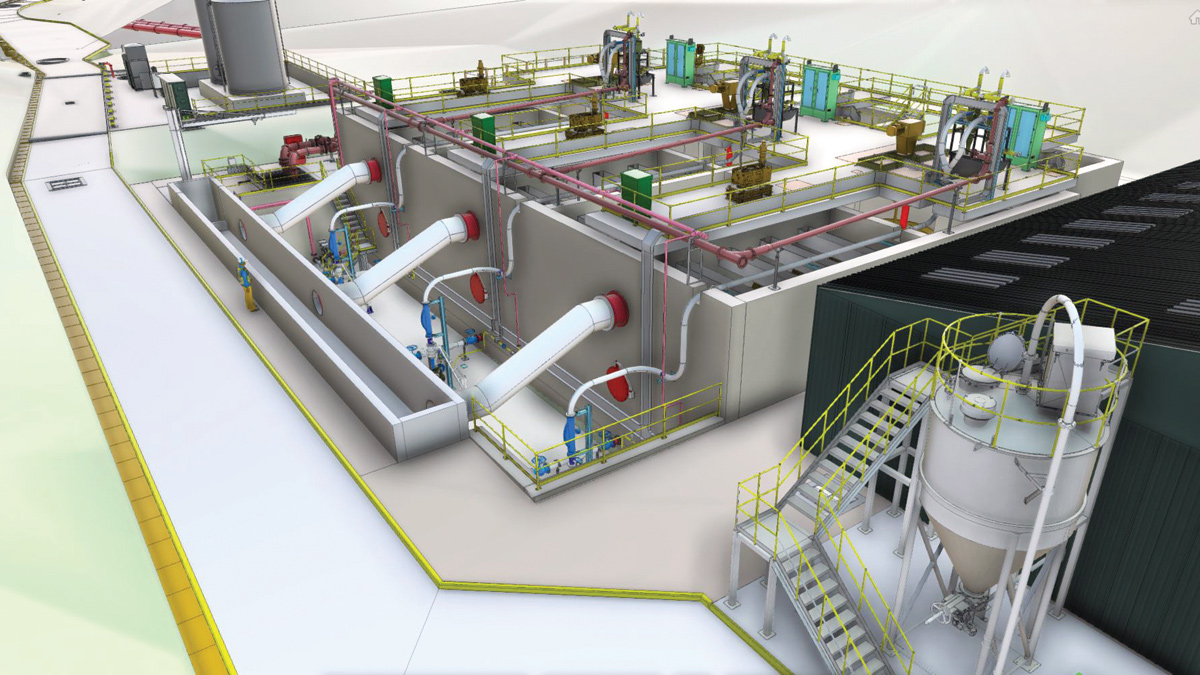

Courtesy of Veolia Water Technologies

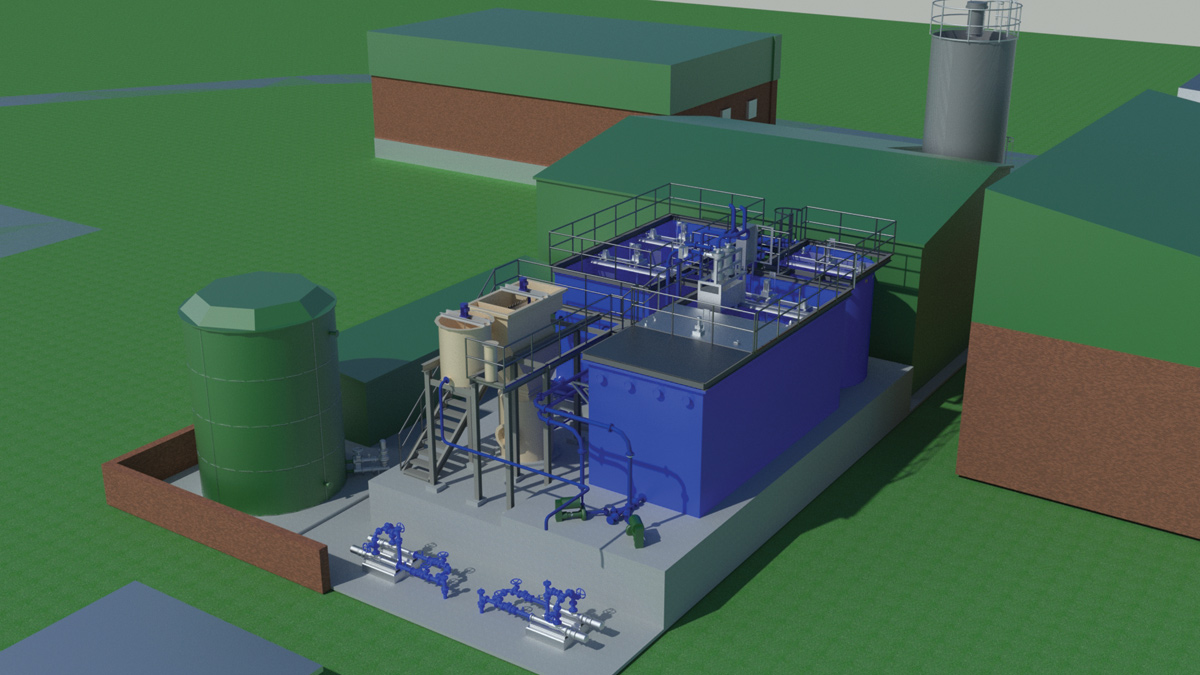

An example of how the optimisation of water treatment processes work in practice is the Danish utility company BlueKolding’s use of Veolia’s AQUAVISTA plant technology. BlueKolding provides the drinking water and manages the wastewater for the 100,000 citizens in the city and suburbs of Kolding in Southern Denmark. The company has embraced the concept of water as a resource and is continually looking for new ways to improve the way it handles waste including improving the efficiency of its facilities.

BlueKolding now has AQUAVISTA plant installed at all four of its wastewater treatment plants and across its sewer network. BlueKolding’s use of AQUAVISTA has grown and evolved over the last 10 years, beginning with the wastewater plants, then integrating the sewer systems and it is now also using it to manage energy production and use.

AQUAVISTA Plant enables BlueKolding to have an overview of the entire system, including the sewers so it can manage the wastewater in the most effective way. The customisable user interface allows the team to see exactly the information they need and access it from the computers in the office as well as mobile devices when they are on site. The data security of the cloud-based AQUAVISTA Plant system was also a key advantage for BlueKolding. The AQUAVISTA Plant platform installed in Kolding features an early warning system so that the managers get a notification if there is an issue with the plant.

AQUAVISTA Plant has provided BlueKolding with a 25% improvement in effluent quality and a 40% reduction in operating costs. By optimising the plant, electricity costs have been reduced by 23% and a 25% reduction in the use of chemicals has also been achieved. In addition, AQUAVISTA has produced an 80% increase in hydraulic capacity and as a result combined sewer overflows (CSOs) have been reduced by more than 67% as the basins have the capacity to store the water rather than release it.

This has not only allowed a 22% reduction in capital investment but has also contributed to the electricity cost savings. The BlueKolding facilities can now use the basins to store the wastewater when the electricity is expensive, then pump it out for treatment when the electricity is cheaper. By preventing overflows, it has also helped to ensure that the water in the Kolding Fjord is protected from sewer overflow.

Water companies now face increased challenges in terms of meeting targets and lowering costs both in the short and long term. The adoption of connected technology that would allow better management and control of the resources they have, is an important step in achieving the required objectives.

For more information: Veolia Water Technologies | +44 (0)203 567 7400 | www.veoliawatertechnologies.co.uk