Gilbert Gilkes & Gordon Ltd

Gilbert Gilkes & Gordon Ltd is a privately owned, internationally established manufacturing business based in the UK. Hydro & Pump Specialists since 1856, Gilkes now export to over 85 Countries around the world.

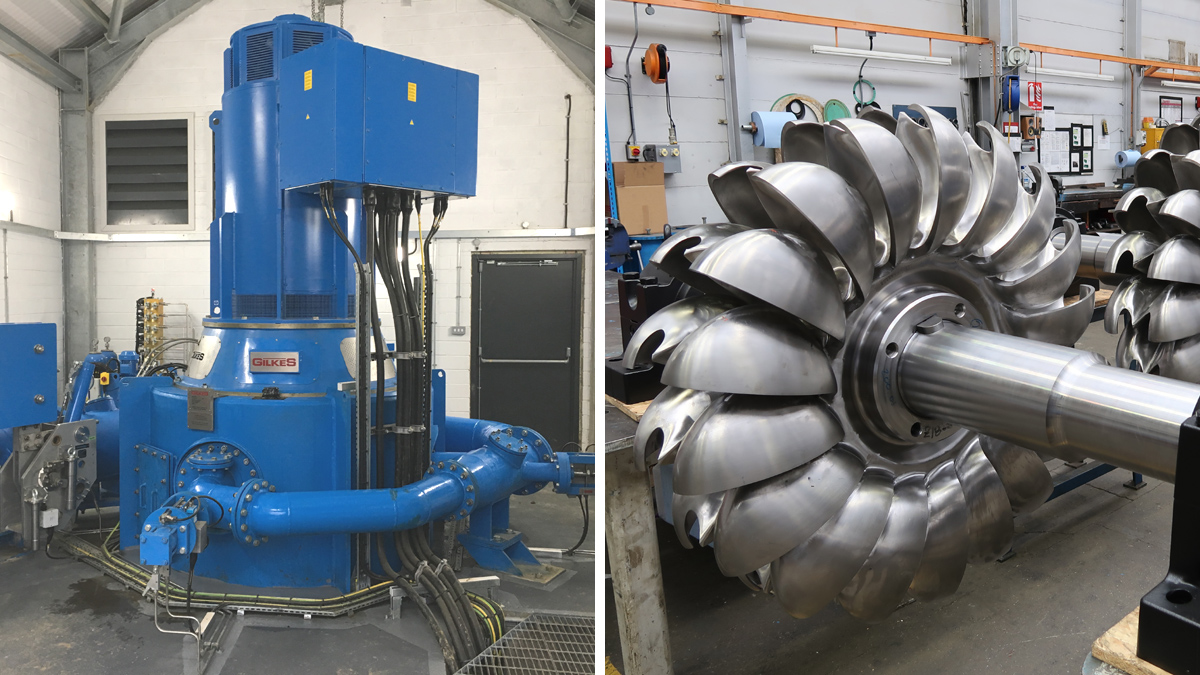

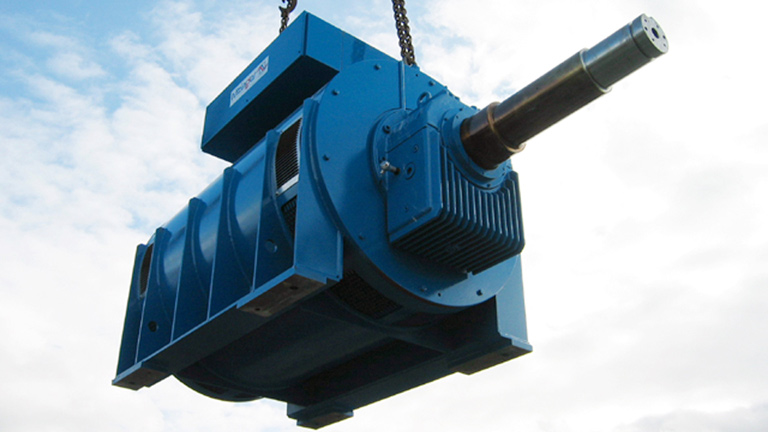

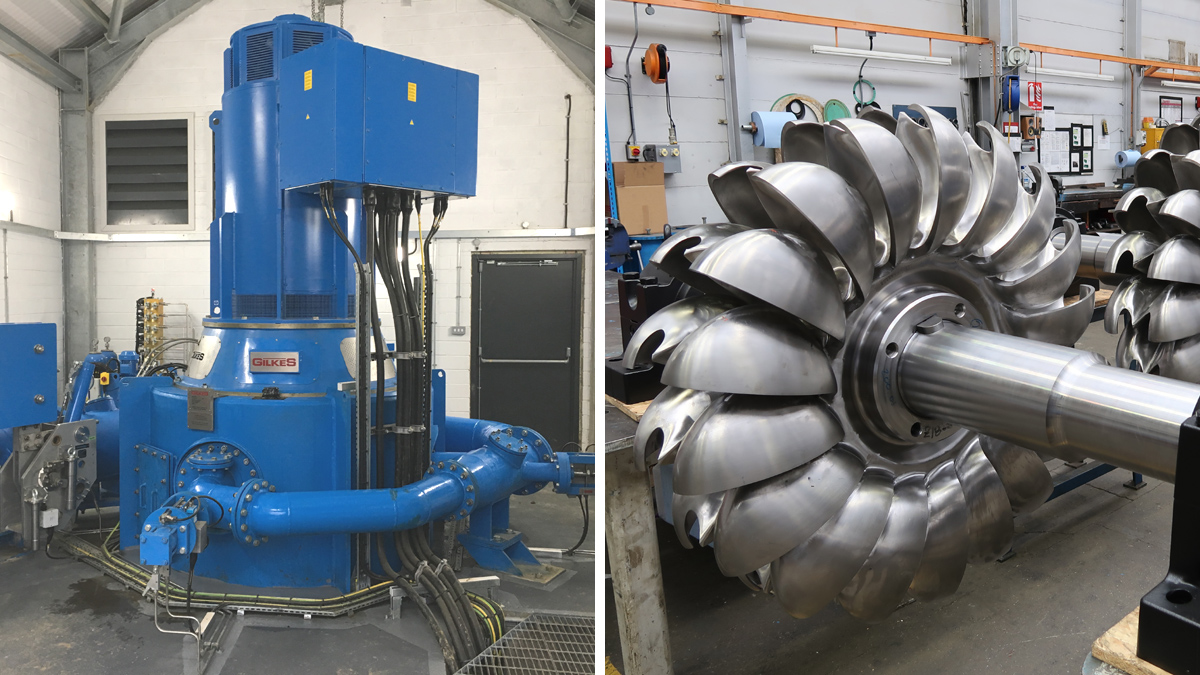

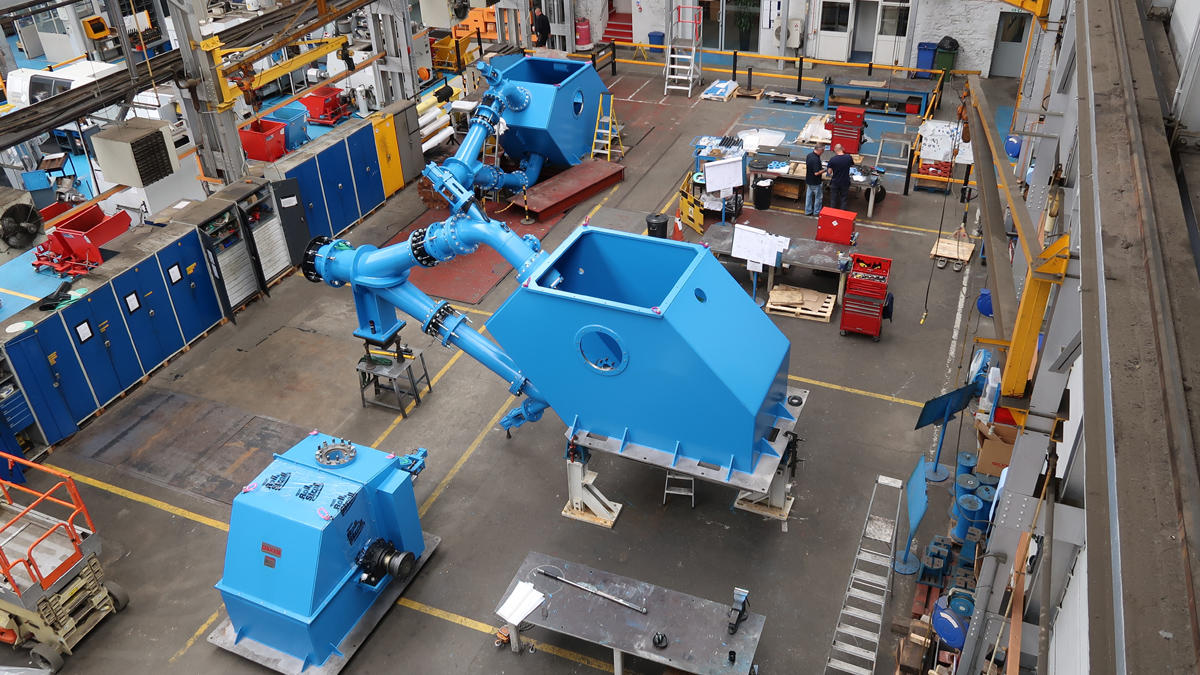

Gilkes Hydro offer a reputable single source solution for a range of hydropower turbines. Our range of Pelton, Francis and Turgo Turbines cover low, medium and high head projects capable of generating up to 30MW per unit and includes compact solutions for the 50kW to 100kW market as well as a new Streamline range designed for the sub 1MW market. Having manufactured over 6800 turbines, Gilkes offers complete water to wire solutions for small hydroelectric developments. Activities include design, manufacture, installation, commissioning, testing, routine service and plant upgrade.

Gilkes expertise and experience allow a full range of products and services to be offered for the following applications:

- Run of River

- Dam & Reservoir Storage

- Energy Recovery

- Rural Electrification

- Plant Modernisation & Optimisation

- Long Term Service Contracts

Pattack Hydro Scheme

Ardverikie Estate, Loch Laggan, Scotland

mini-case-study

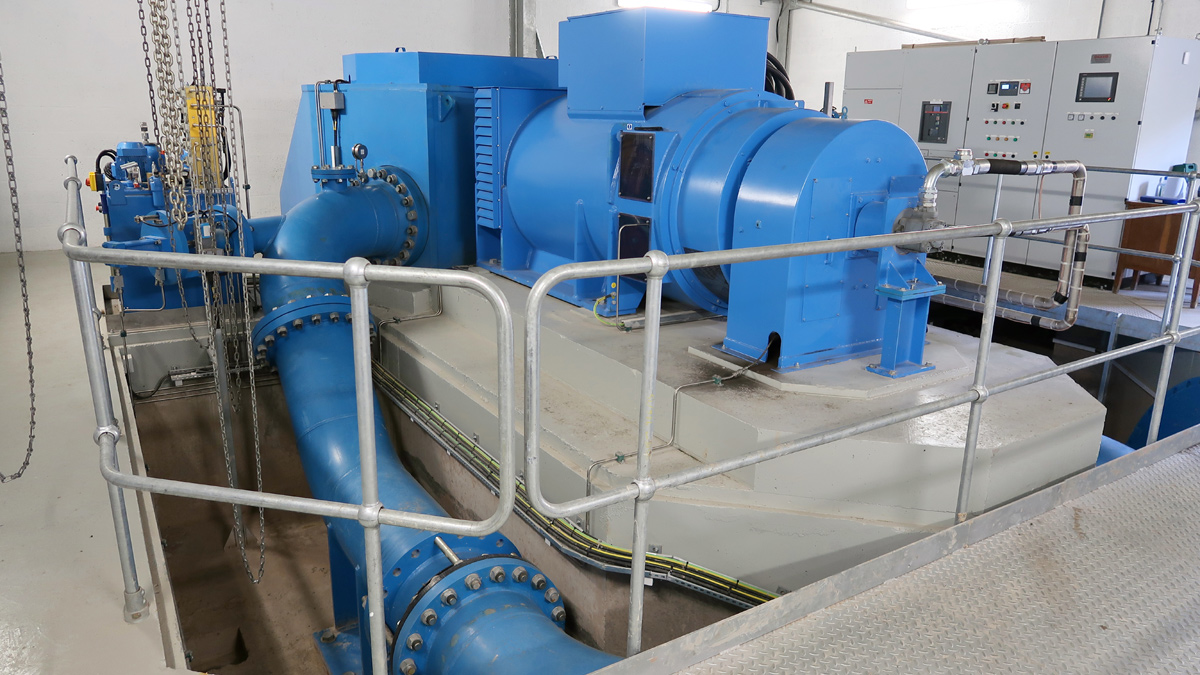

Bryn Cowlyd WTW

Single jet Pelton renewable energy generation

mini-case-study