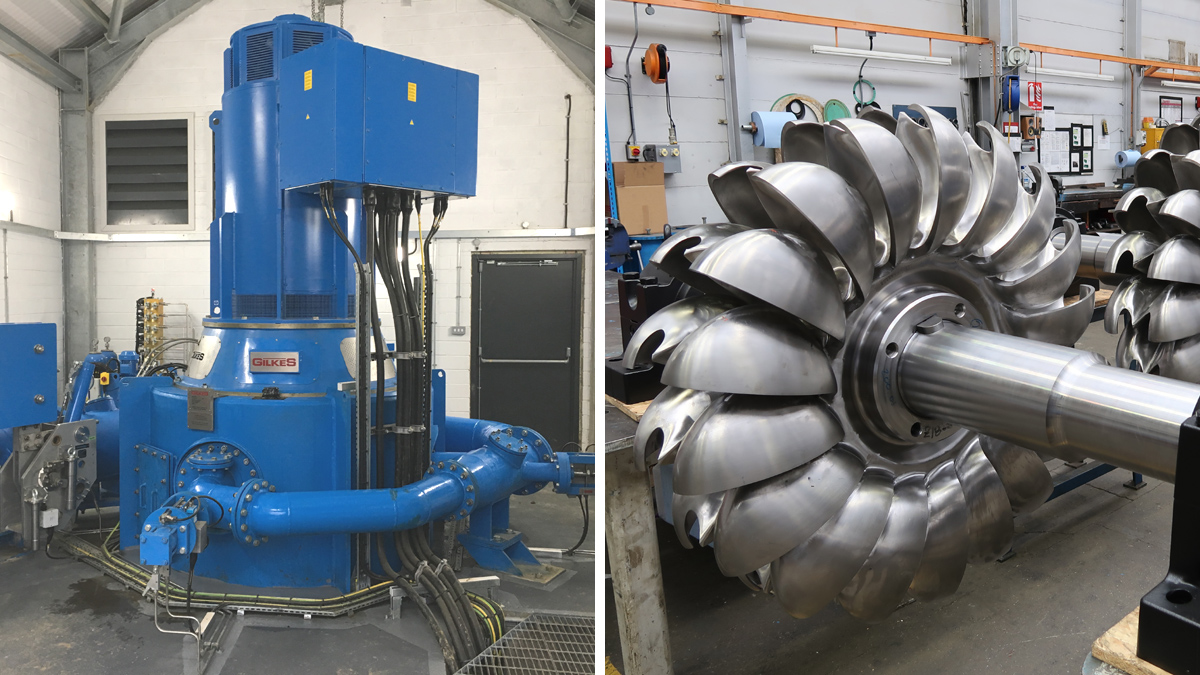

Gilbert Gilkes & Gordon Ltd

Turbine Technology Upgrade, Oregon USA

Courtesy of Gilbert Gilkes & Gordon Ltd

KEY STATISTICS

- Customer: Farmers Irrigation District

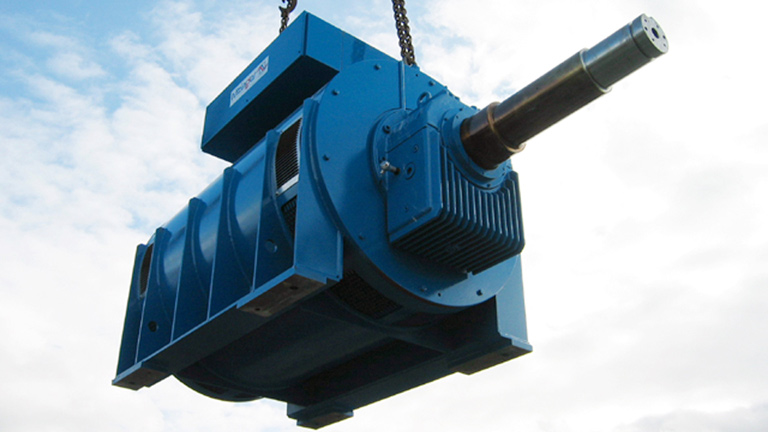

- Turbine type: Gilkes HCTI Twin Jet Turgo

- Number of turbines: 1

- Power (kW): 2.6MW

- Net head: 352ft

- Flow: 108cfs

- Diameter: 31”

- Speed: 600 rpm

Gilkes were extremely honoured when the Farmers Irrigation District (FID) sourced them to completely upgrade their existing plant, and to change the turbine technology being employed. The plant’s original configuration consisted of two dissimilar sized Francis turbines of a mid-1980s vintage. The configuration made sense when looking at one aspect of the project, which was the peak energy production based on the head and flow conditions. With the Francis technology however, they were limited to certain flow ranges and were unable to recover some of the lower flows they experience during the irrigation months of April to October. There was one other key area that plagued the project for many years which was the sediment-laden water due to the minerals from their watershed which is delivered from the north east slope of Mount Hood.

Courtesy of Gilbert Gilkes & Gordon Ltd

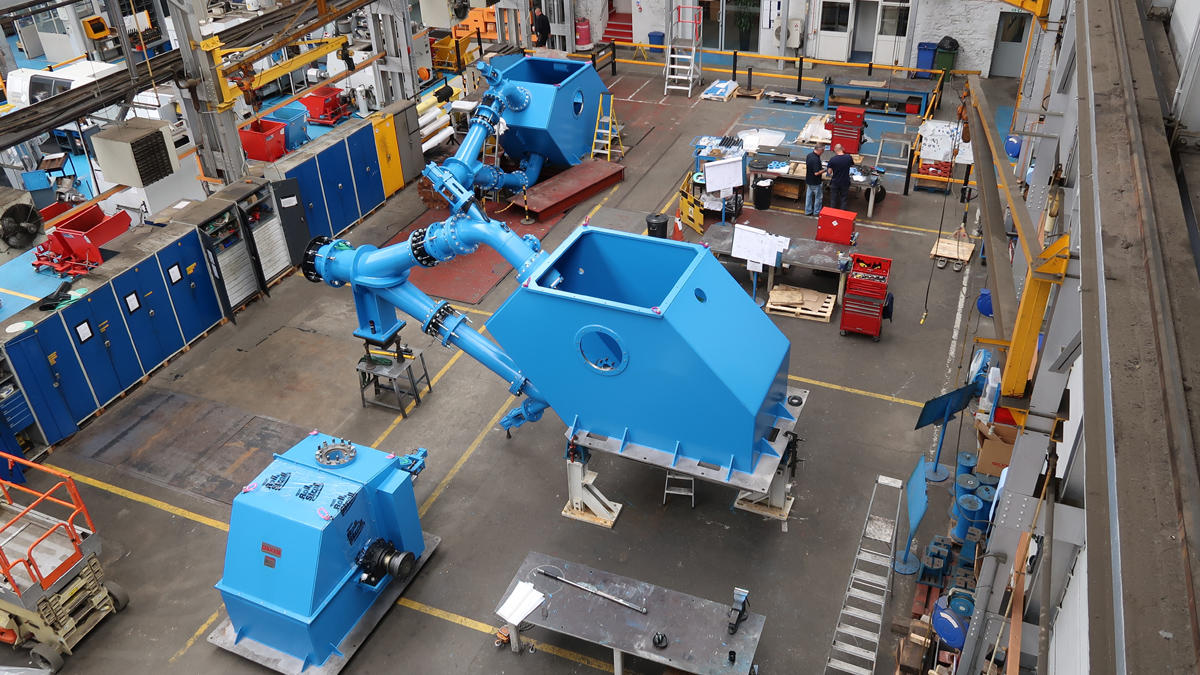

Gilkes engineers quickly got to work to thoroughly evaluate every aspect of the project, and to openly discuss all of the available technologies with FID. Through our analysis, we determined that a Gilkes Turgo turbine would be the best-suited machine for the site conditions, as well as for the overall annual energy production.

Courtesy of Gilbert Gilkes & Gordon Ltd

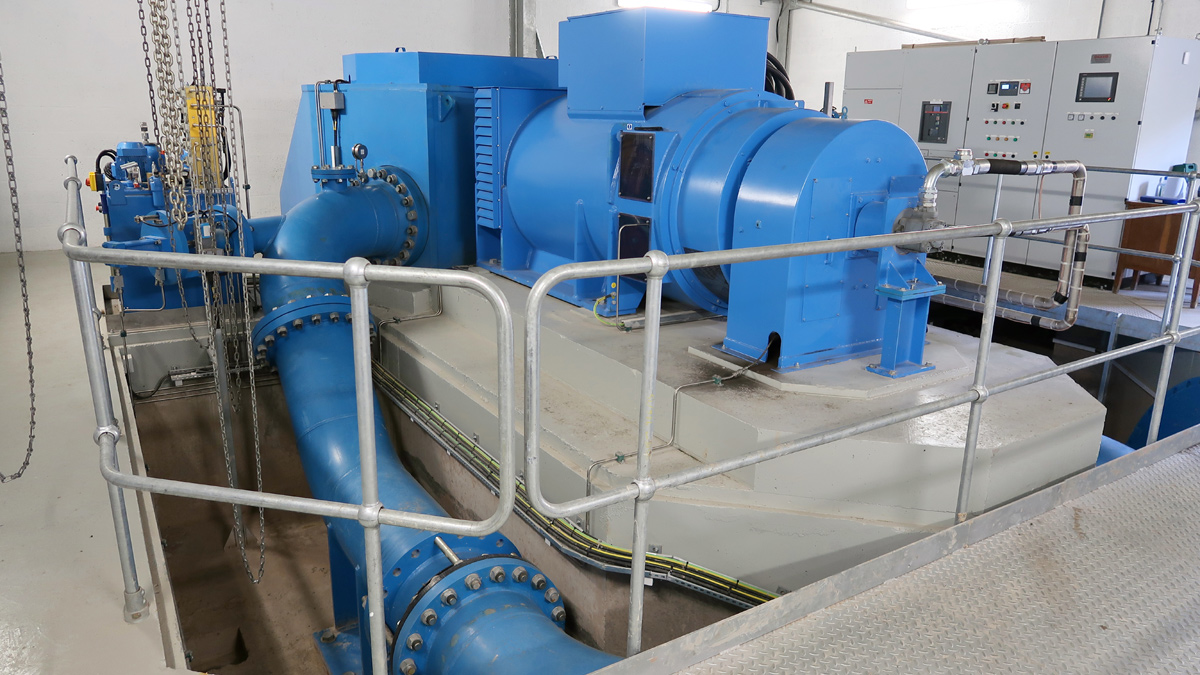

SCOPE OF SUPPLY

- Gilkes 31” high capacity Twin Jet Turgo Impulse Turbine valve: 36” Ball Valve, PN16

- Generator: 3,310 KVA, 60hz, 3 Phase, 4160V, 600rpm, with hydrodynamic, babitted sleeve bearings.

- Generator controls & switchgear: PLC based fully automated controls, turbine governor, electrical protection system, station services, DCY, MCC and generator switchgear.

- Hydraulic control module: Installation and commissioning

The Gilkes Turgo, which was designed and patented in 1919 by our current Chairman’s grandfather, was the perfect match as it was able to capture the flows that FID were currently unable to use. More importantly the Turgo’s ability to efficiently and effectively handle ‘aggressive’ water would significantly reduce the owner’s annual operation and maintenance expenditures.

All of these factors combined made the decision for the turbine technology to be a Turgo turbine as opposed to Francis turbine technology. Each have their place for various site conditions, and in this case the Turgo was by far the logical choice.

The project deliverables consisted of a full water-to-wire package including a 36” ball valve to isolate the plant when needed, a Gilkes 31” twin-jet Turgo turbine, a hydraulic control module to operate the inlet valve, spear valves, and deflectors, a synchronous generator with sleeve-lined pedestal

bearings, and a fully automated turbine controls and switchgear package. Additionally, the existing trifurcation inlet pipework was removed and Gilkes engineers delivered a single inlet pipe section to match the existing penstock and new turbine.

The project was delivered on-time, on-budget, and ahead of schedule which allowed FID to begin generating earlier than planned and assisted them with their annual generation targets and project pay-back.

Jerry Bryan, FID’s former District Manager and Project Manager for this project comments:

“After our long struggle with an ancient, low-bid turbine-generator scheme that many times over the past thirty years threatened to drag the Farmers Irrigation District into bankruptcy, our new Gilkes Turgo turbine is music to our ears.

“Gilkes is the exact company it rightfully claims to be — a collective group of highly professional, relationship-based, sophisticated, genuine, and friendly people dedicated to a common goal of excellence. Best of all, even though we set the bar very high, every single last one of you working at the Gilkes exceeded our expectations.”

“Our new Gilkes Turgo unit is producing green, renewable electrons in excess of the Gilkes’ guaranteed efficiencies, and we know that our new system will operate reliably and efficiently for decades to come.”

For more information: Gilbert Gilkes & Gordon | +44 (0)1539 720028 | www.gilkes.com