Gilbert Gilkes & Gordon Ltd

Ross Priory Pumping Station

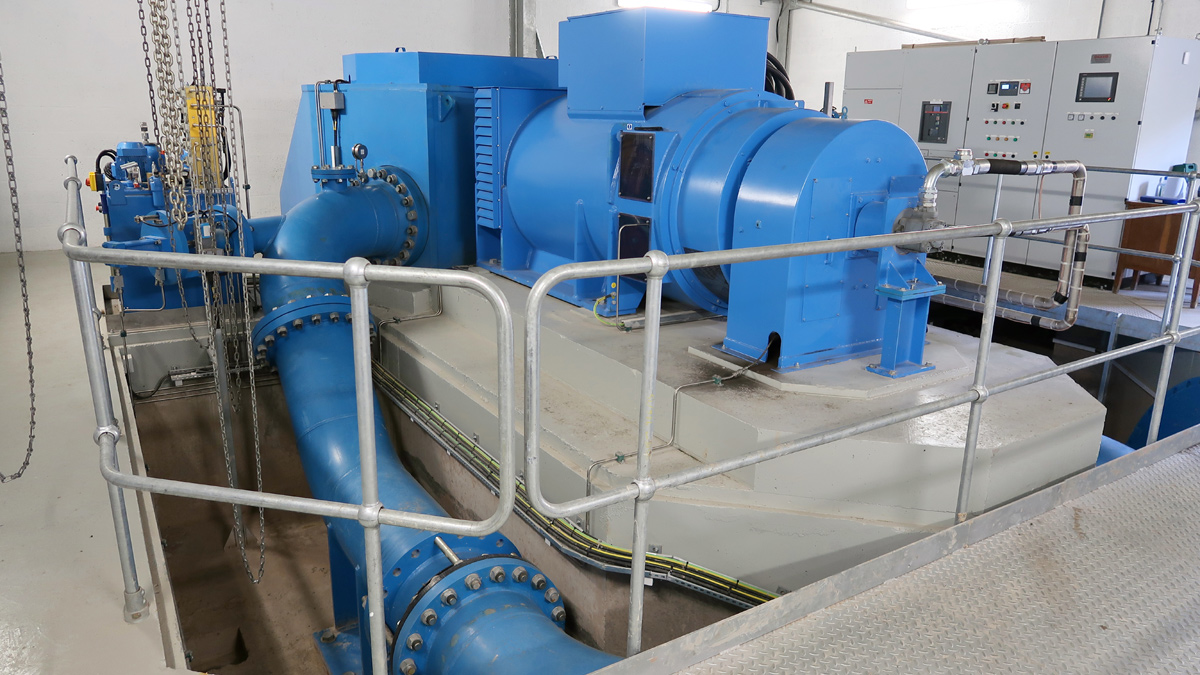

Ross Priory Pumping Station Turgo installation

Ross Priory Pumping station is a Scottish Water asset situated in West Dunbartonshire. The purpose of the station is to transfer water from Loch Lomond to the WTW at Balmore. The Balmore WTW has the capacity to contribute 360 Ml/d of potable water for the city off Glasgow.

The scheme is locally known as the Loch Lomond Water Supply scheme and is on a section of the Scottish Water network known as the cross connection between Strathblane and Balmore WTW.

Energy recovery

The Gilkes turbine provides two essential roles, primarily to reduce the pressure in the main and at the same time generate renewable energy for the benefit of Scottish Water.

The Gilkes Turgo was selected as it is capable of continuously delivering pre-determined flows even in the event of a loss of grid situation. The Gilkes Turgo provides a proven and robust solution for pressure reduction and power generation in one box. Simply put the turbine is able to operate as a pressure reducing valve (PRV) whether it is functioning as a turbine or not. In a conventional reaction turbine, there is the risk that a grid trip would either require the turbine to shut down or for a complex by-pass arrangement to be in place. This Turgo turbine also avoids the possibility of pressure surge travelling back up the main.

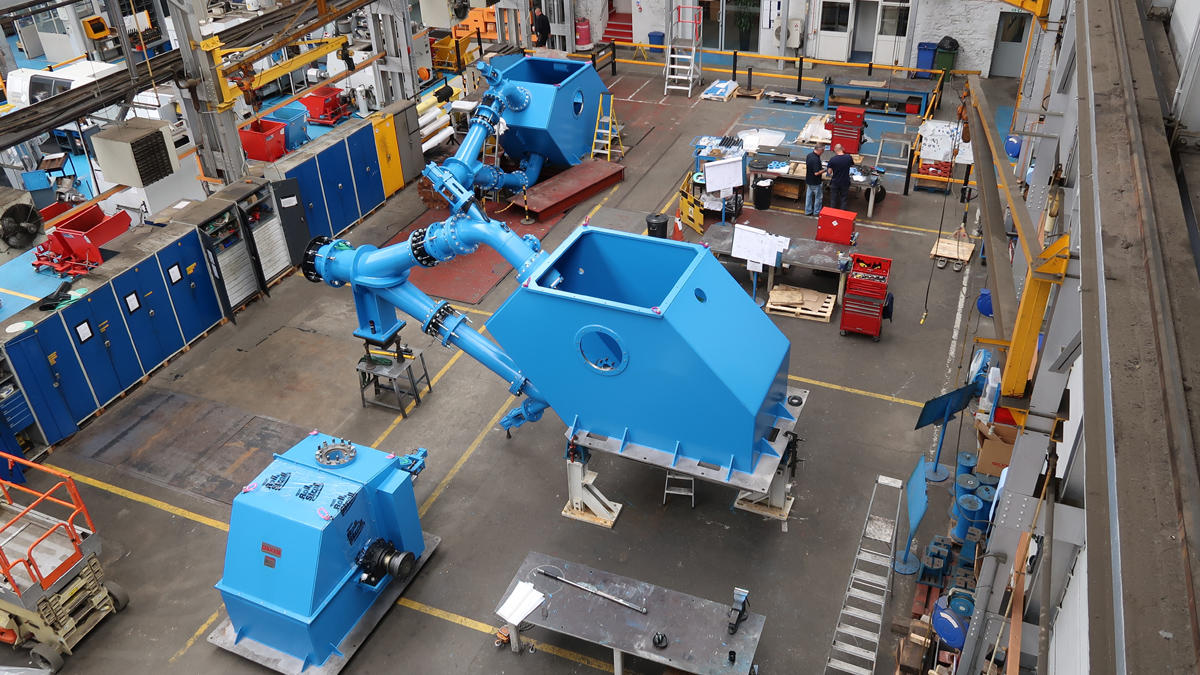

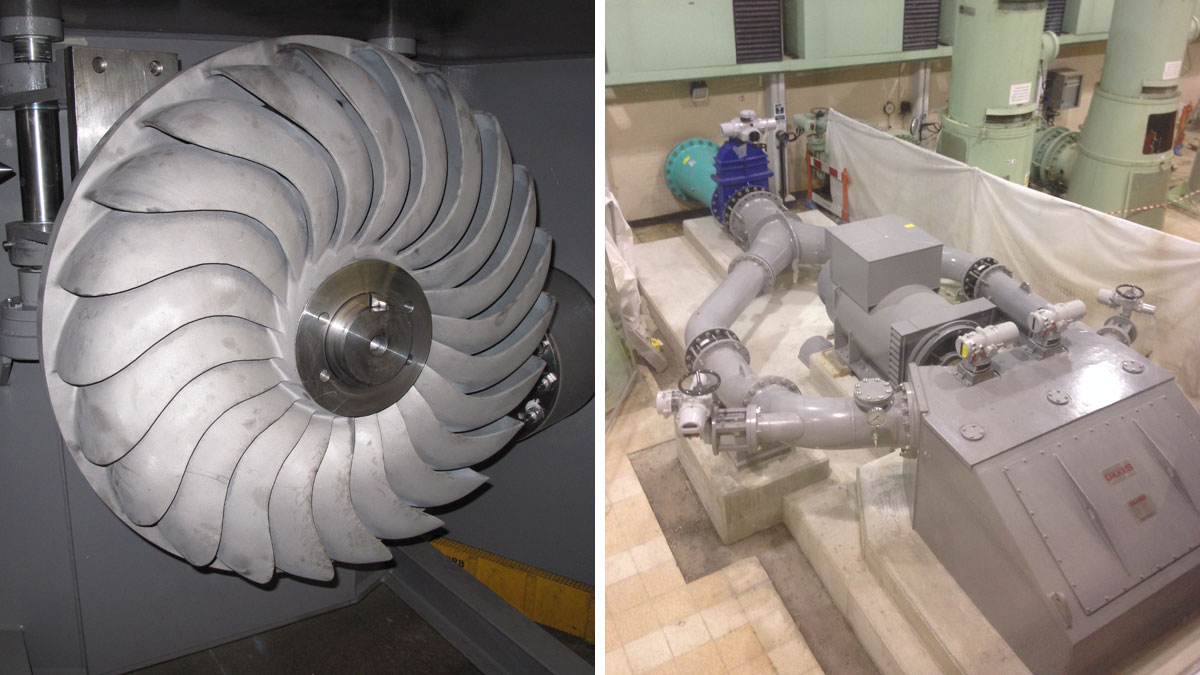

Due to the Turgo’s unique design, Gilkes engineers were able to achieve pressure reduction and power generation from a single machine without the use of hydraulics or additional valves.

The Turbine is fitted with deflectors that allow water to continue passing through the turbine while at the same time being deflected away from the runner. This allows the machine to achieve a rapid shutdown, regardless of the spear valve (flow regulation) setting. This means that the flow through the turbine is not effected should the unit be required to shut down. The top and bottom deflector plates are mounted on vertical shafts supported by flanged bushes inside the turbine case. The deflectors are independent of each other and each unit is operated by its own electrical actuator mounted on the turbine case. Each deflector actuator has an integrated position transducer which indicates the deflector’s position for the full range of travel to the control system.

The Turgo turbine is able to operate continuously as a pressure reducing valve (PRV). This is true whether the machine is operating as a PRV or as a PRV and turbine combined.

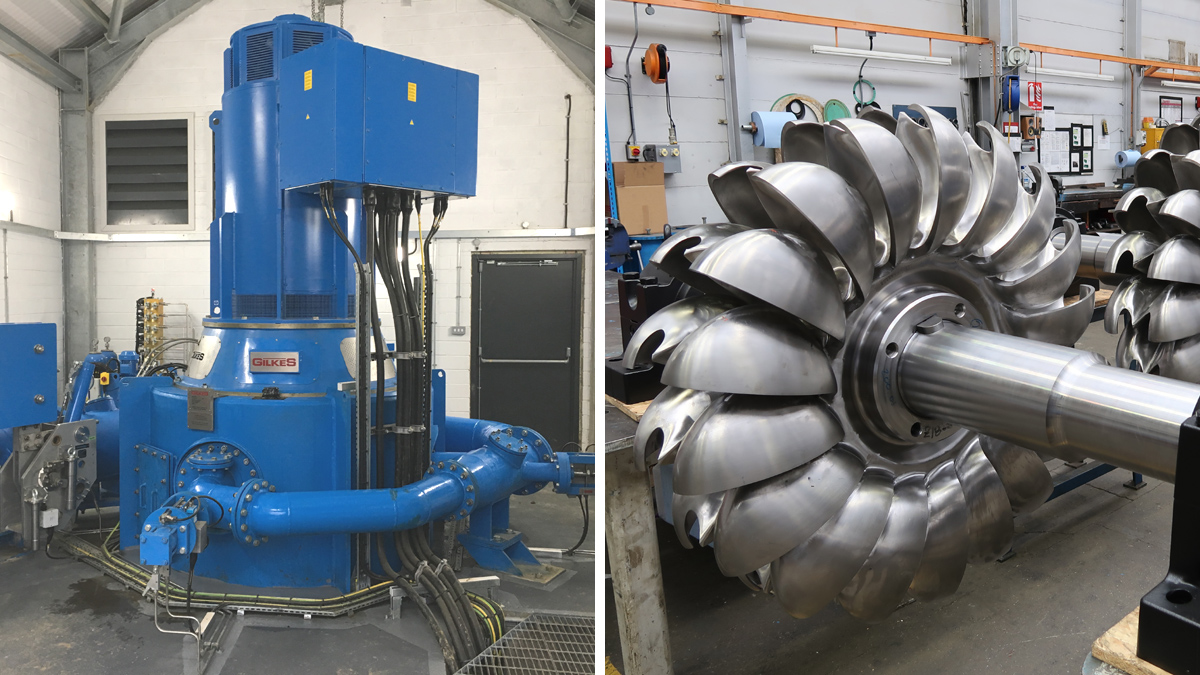

(left) 20″ runner and (right) Turgo installation

Gilkes Turgo

Gilkes has considerable, worldwide experience of replacing the break pressure valve with a Turgo Impulse Turbine. The use of a Turgo Impulse turbine does not result in the plant using losing any flow control. The turbine may be set so that is primary purpose is to provide the correct value of water at the correct pressure. One of the great advantages of a Turgo Impulse turbine is that it generates within a wide variety of flows.

Key statistics

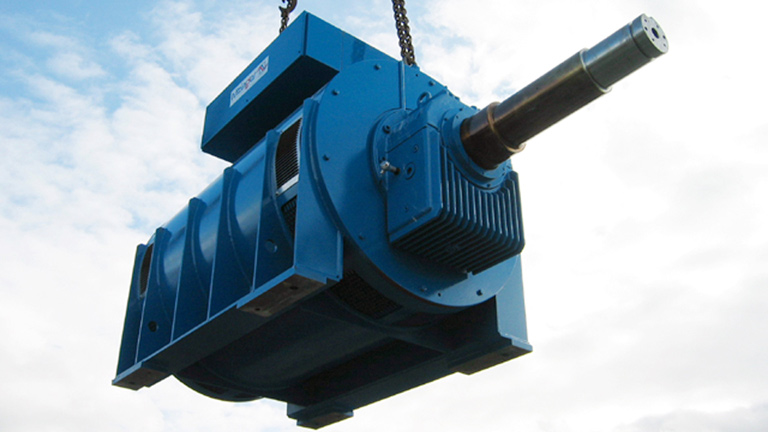

Gilkes’ scope of supply was for the supply, installation and commissioning of a Twin Jet Turgo hydro-turbine

- Power: 735 kW

- Net Head: 80m

- Flow: 1000 l/s

- Runner Dia: 20”

- Speed: 750 rpm

For more information: Gilbert Gilkes & Gordon | +44 (0)1539 720028 | www.gilkes.com