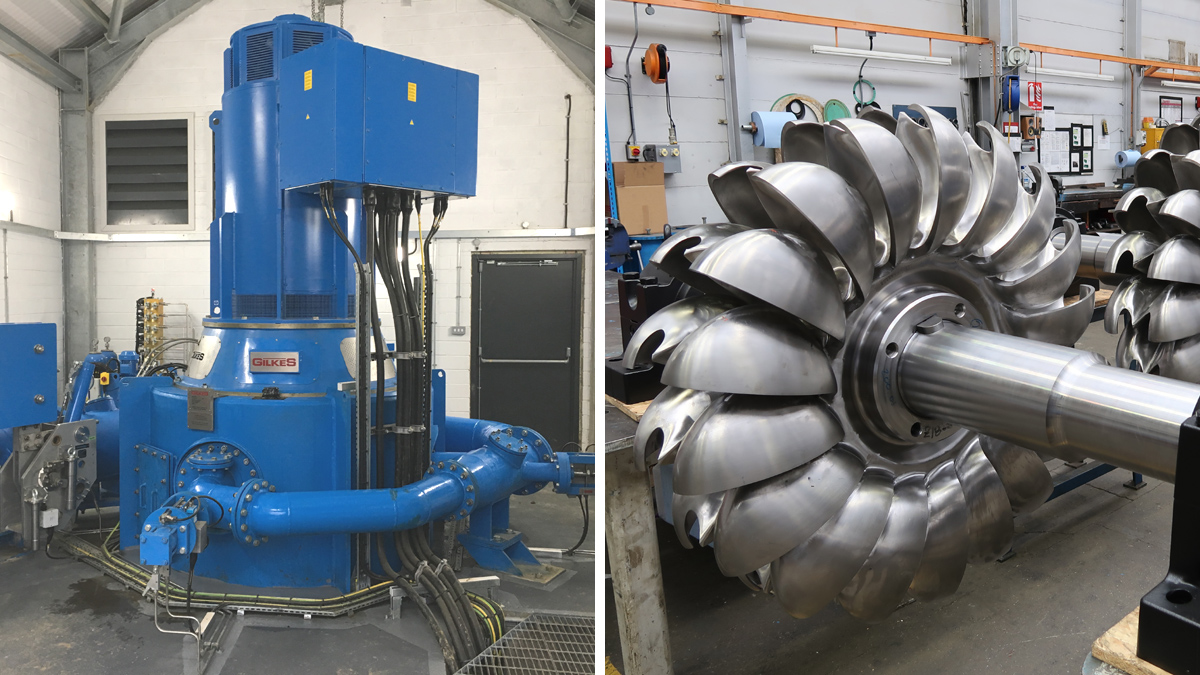

Gilbert Gilkes & Gordon Ltd

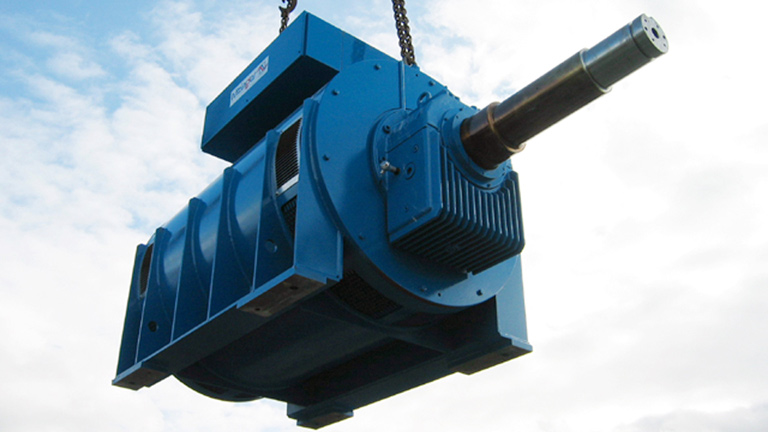

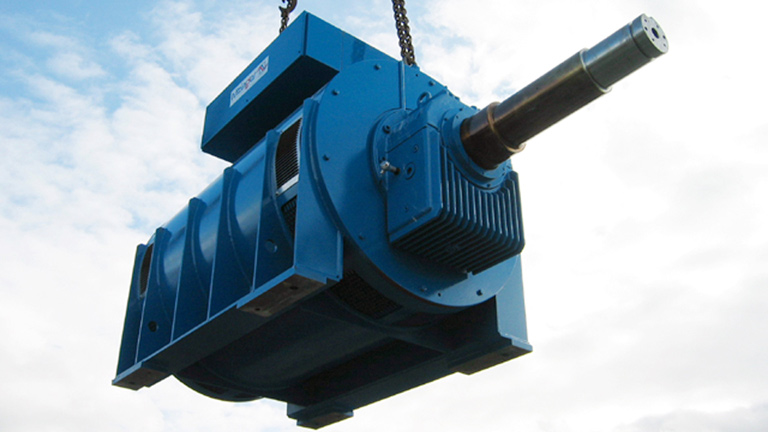

Franklaw Power Recovery Turbine

Courtesy of Gilbert Gilkes & Gordon Ltd

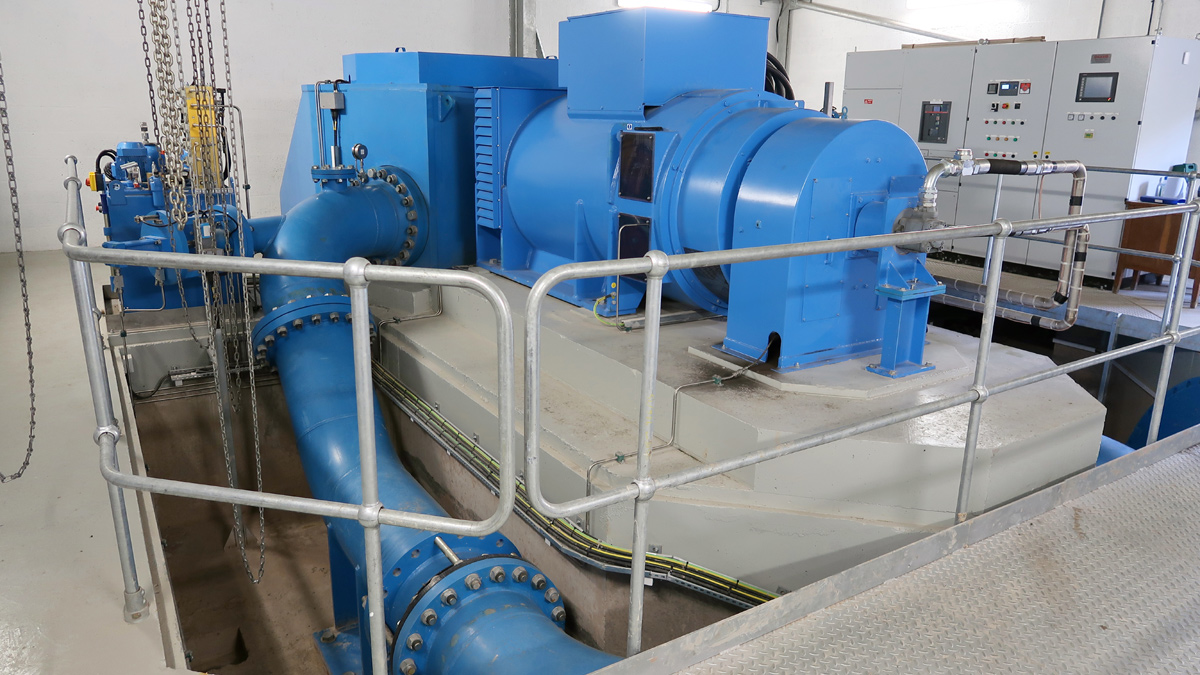

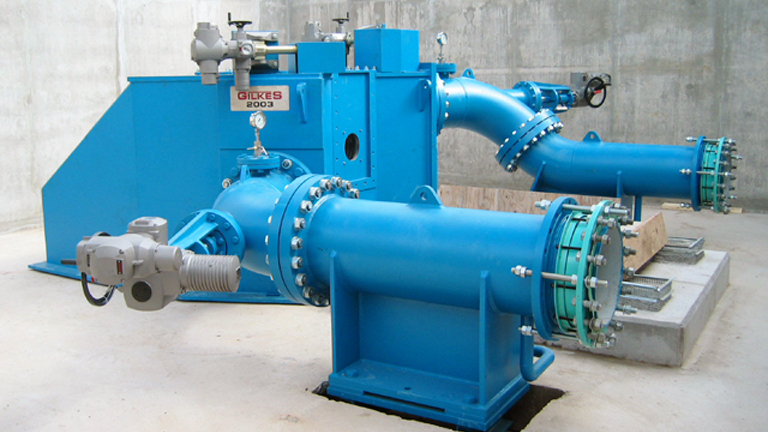

When United Utilities needed to increase the throughput of Franklaw Water Treatment Works in Lancashire they considered energy recovery as part of the overall design. Water is abstracted from the Thirlmere Aqueduct and conducted to the site through underground pipes. The water treatment process required that downstream of the energy recovery plant there should be a pressure of some 8m to drive the water through. Upstream however, there could be no possibility of pressure surge, due to the long pipeline.

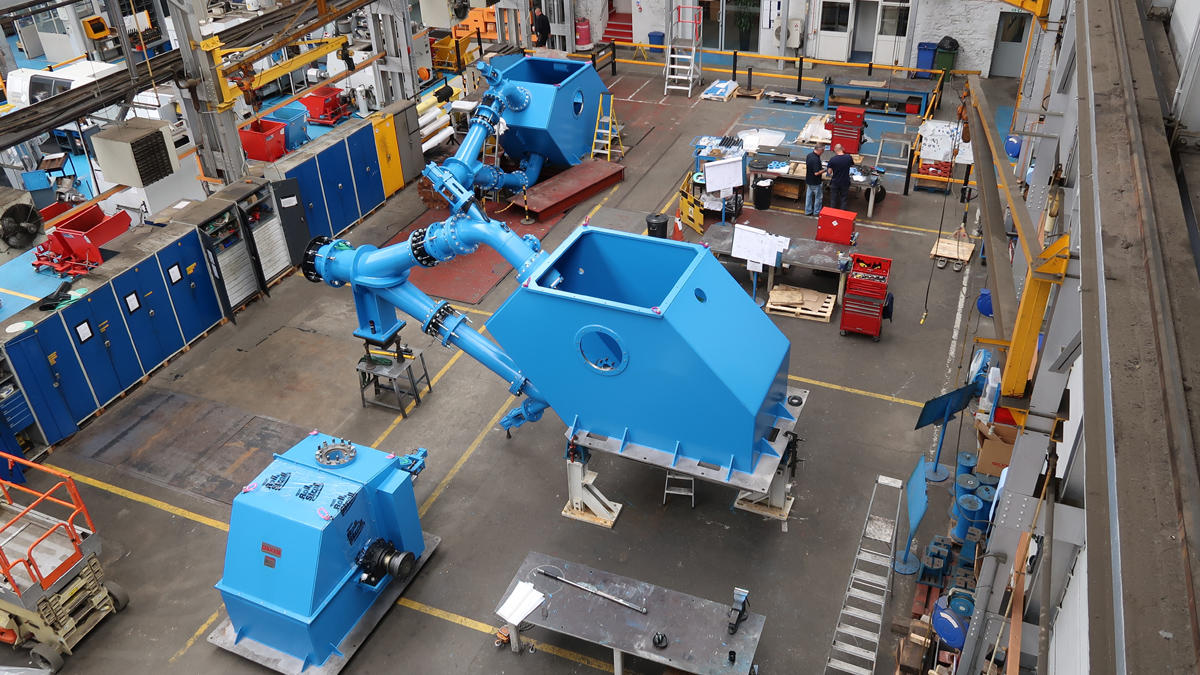

It was also imperative that water should flow at all times. Lightening strikes could potentially cause the set to trip and with some machine types this would result in either complete or partial shut down of the main. Gilkes were consulted and together with United Utilities engineers arrived at the solution seen in these images. An inlet chamber was always going to be required, this was built above ground and the mains conducted to it.

Courtesy of Gilbert Gilkes & Gordon Ltd

A Gilkes Impulse Turbine could then be installed as the power recovery turbine as the plant now facilitated a free discharge machine. The turbine acts as both pressure and flow regulator for the intake works. In the event there is a loss of grid, the flow regulating needle valves, integral in the machines design, remain fixed until such time as mains power is recovered. Pressure continues to be broken by means of directing the needle jets at deflector plates inside the turbine case and the water falls to the intake chamber from where it continues in the normal way to the process plant.

Courtesy of Gilbert Gilkes & Gordon Ltd

Key statistics

- Head: 93 m

- Flow: 1.39 m3/s

- Power: 1000 kW

Operated in this way there is no pressure surge seen in the conduit on loss of grid. A controlled shut-down of the turbine inlet valves can then be initiated and an alternate water supply used on the works.

By designing in energy recovery, the engineers were able to justify the use of larger than normal conduit systems to maintain head at the point of delivery, rather than increase velocity and minimise head at the works, where any remaining head has to be destroyed.

For more information: Gilbert Gilkes & Gordon | +44 (0)1539 720028 | www.gilkes.com