Gilbert Gilkes & Gordon Ltd

Water Turbine & Pump Solution in Kenya

KEY STATISTICS

- Customer: SiBo Water & Sanitation Company

- Turbines: 5 (No.) Series C Francis Turbines

- Pumps: 7 (No.) Multi-stage pumps

- Total power output: 360 kW

- Runner diameter: 7.5”

- Net head: 27m

- Flow: 340 l/s

- Speed: 1250-1500 rpm

- Installed: 2016

The customer, the towns of Siaya & Bondo Water & Sanitation Company Limited (SiBo), required a water turbine and pump solution that would deliver clean water to their local population utilising the energy available within the existing local river. The project to upgrade and expand the existing SiBo WTW was financed by the African Development Bank and Government of Kenya to deliver a clean safe water supply to over 100,000 present population.

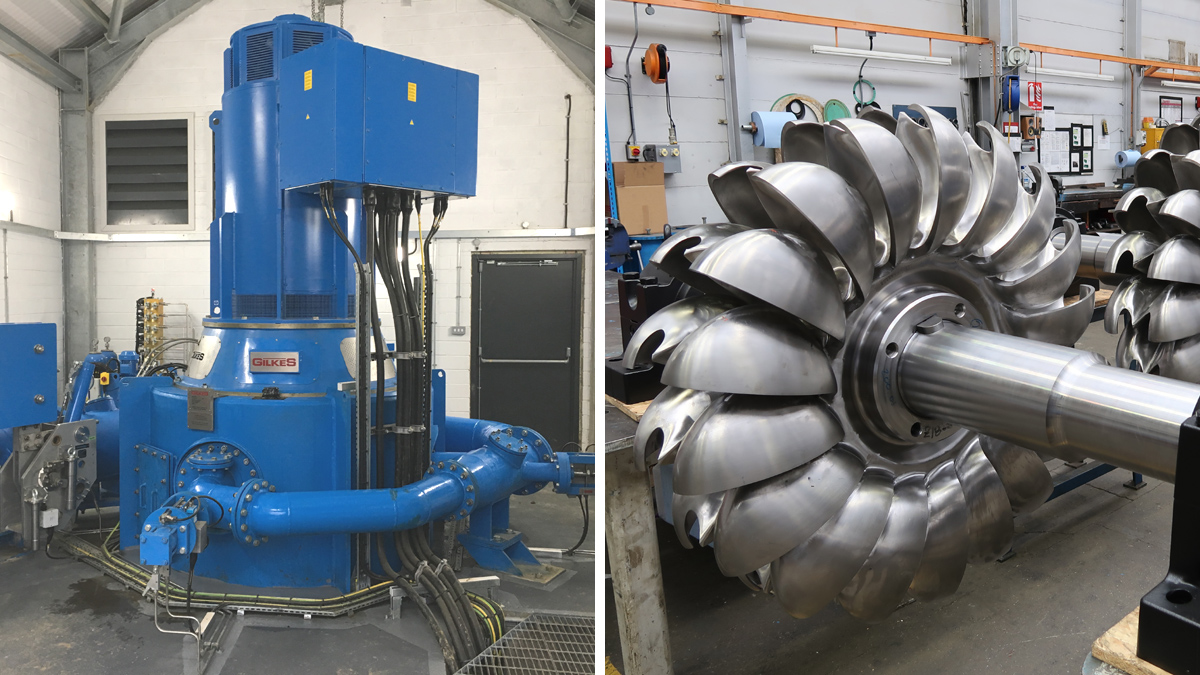

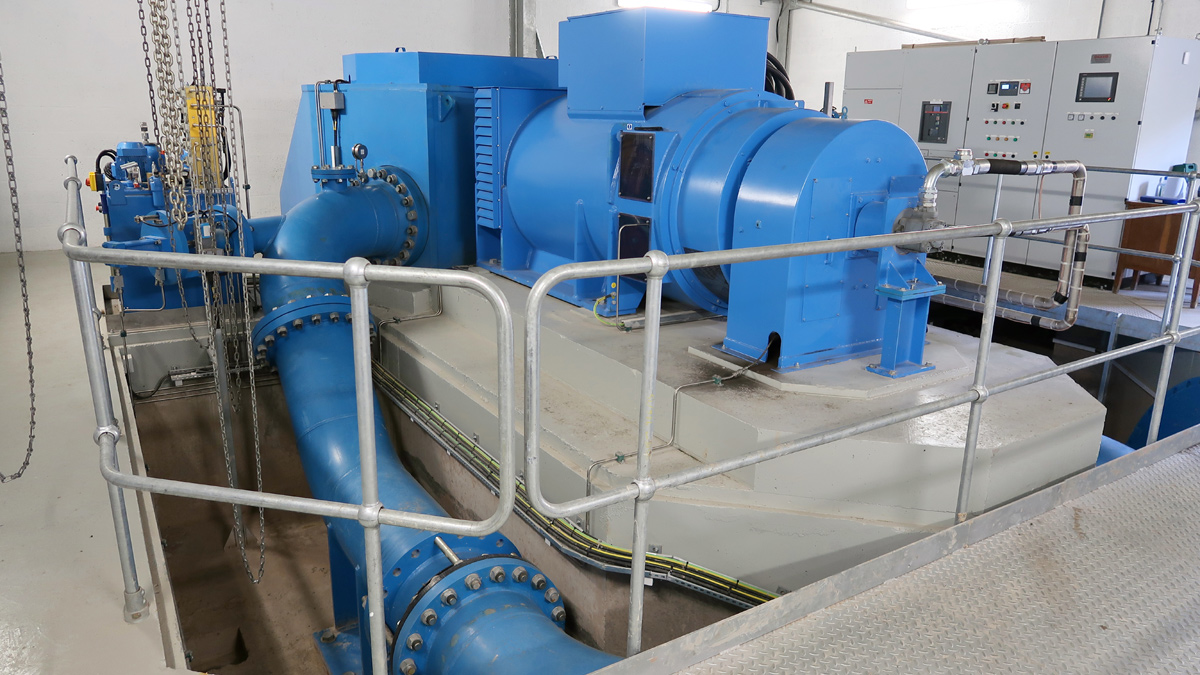

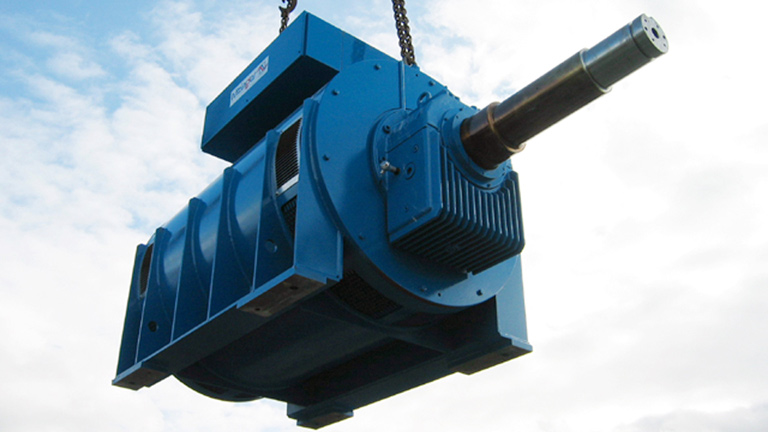

Gilkes solution proposed utilising 5 (No.) Series C Francis turbines directly driving 5 (No.) KSB Multitec multi-stage water pumps. The Series C Francis turbines were the chosen solution by Gilkes because of their robust design, ideally suited to the remote location. The turbines are also engineered to be simple to operate for semi-skilled operators.

The river off-take just above a waterfall provides both the raw water to power the turbines and the raw water supply to the water treatment works, which subsequently supply clean water to the pumps.

Courtesy of Gilbert Gilkes & Gordon Ltd

![]() Scope of supply

Scope of supply

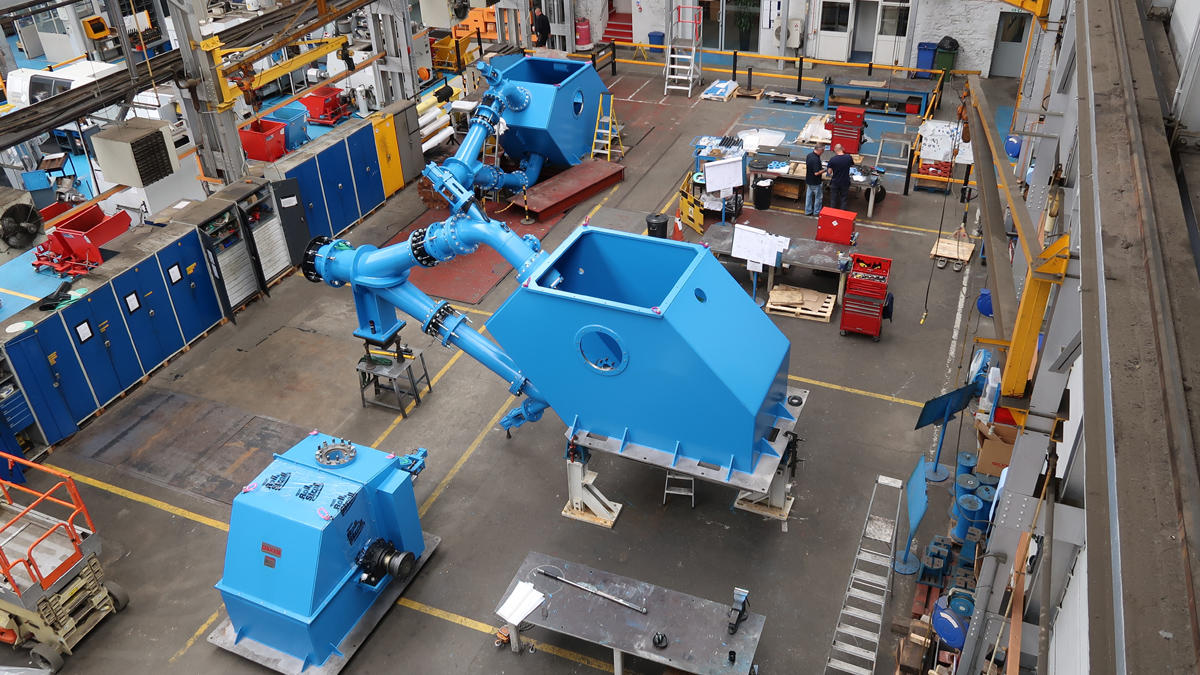

- 5 ‘skid plate’ mounted turbine pump systems consisting of:

- 5 (No.) 7.5” Series C Francis Turbines.

- 5 (No.) multi stage pumps.

- Manual control and instrumentation system.

- 2 (No.) further electric motor driven pumps.

- Control and soft start motor panel.

- 5 (No.) turbine inlet valves, inlet pipes and draft tubes.

- 7 (No.) pump inlet valves and inlet pipes.

- 7 (No.) pump discharge pipe, non-return valve, gate valve.

- Full installation and commissioning.

Each turbine has an inlet pressure of approximately 27m net head, at a flow rate of 340 litres/second. The turbines drive through a flexible coupling to each pump which nominally develops 115m of head, at a flow rate of 145m3/hour.

The water pumps are gravity fed from the water treatment works, pumping the clean water over 4 kilometres to two reservoir tanks.

The design had to consider a number of scenarios and variables of having multiple turbines and pumps operating, sharing common pipework, and still operate effectively to meet the customers pumped clean water requirements and raw water head and flow available. Gilkes specifically matched the turbine and pump characteristics, to achieve a solution with the best efficiency.

Each turbine and pump unit was assembled at Gilkes manufacturing facility in the UK and transported to site fully assembled, just requiring anchoring and plumbing in once on site. The units were skid mounted, meaning the pump and turbine could be aligned in-house before being transported to site, resulting in less on site installation & commissioning time and providing a solution to the lack of on-site tooling.

Courtesy of Gilbert Gilkes & Gordon Ltd

Gilkes are very proud to have been involved in such a unique project. With a Chinese lead contractor, an Indian civil engineering consultant, a local Kenyan workforce and the customers own engineers, this was a truly multi-national contract. Working in close collaboration with all parties ensured the success of the SiBo project.

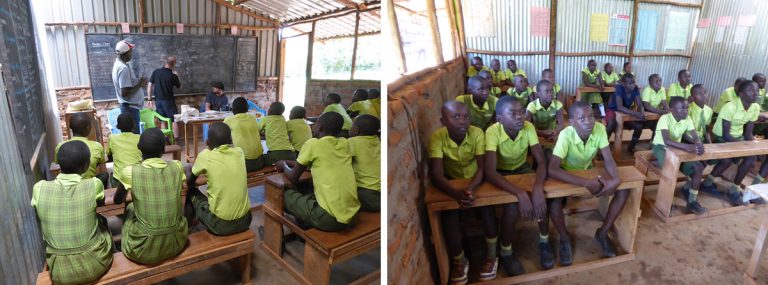

During their time on site, our engineers also took time out to teach children at the local school about hydropower.

Courtesy of Gilbert Gilkes & Gordon Ltd

For more information: Gilbert Gilkes & Gordon | +44 (0)1539 720028 | www.gilkes.com