Technocover Ltd

Physical Protection of Water Assets (2017)

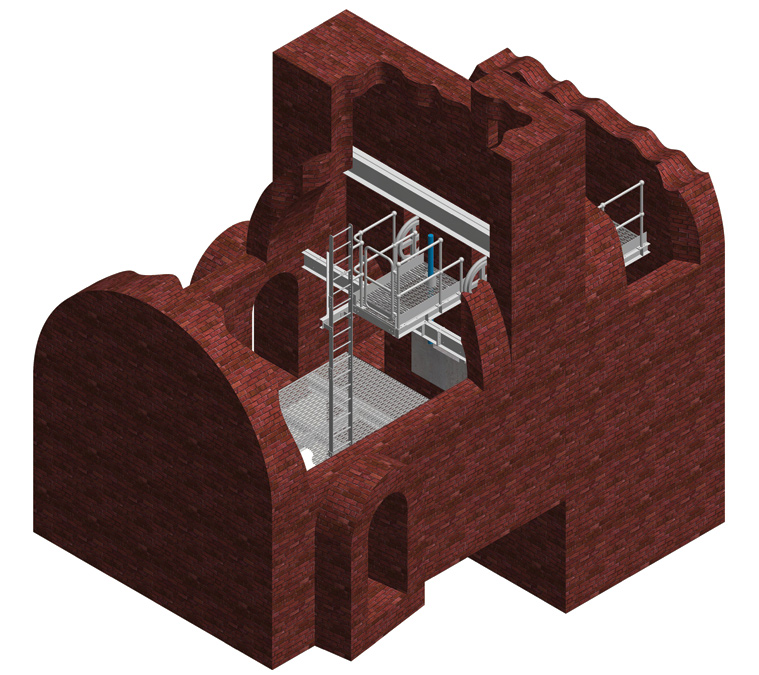

Complex access cover assembly proving cost effective solutions but maintaining the clients safety and operational needs

During two decades of working to legislated levels of security for physical access, the UK water industry has ushered a revolution in certified physical protection. While meeting this critical and immovable benchmark of resilience, solutions in AMP6 are pushing the envelope in design and functionality as never before. Security performance, of course, remains king, but criminal attack, extortion, infiltration, and terrorism in its many and increasingly unexpected forms are all a constant threat to lifestyle and the national infrastructure that underpins it. But applications are becoming more specialised as the drive for greater cost efficiency is being seen in upgrades and refurbishment of older assets to extend service life.

Background

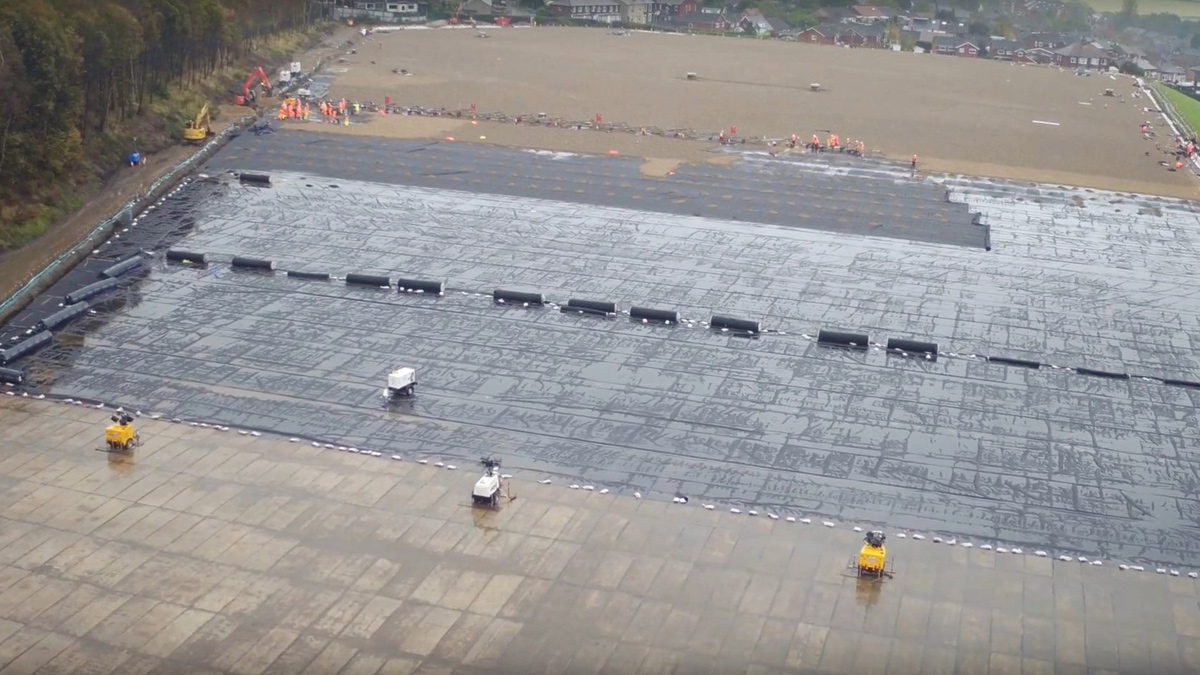

With the introduction of reservoir security legislation in 1997, water companies were initially immersed in the widescale upgrading of service reservoirs with a new staple – the double-skin upstand access cover approved to LPCB (Loss Prevention Certification Board) criteria.

In successive AMPs, security programmes have been rolled out to all areas of the industry, prompting the development of a raft of high security access systems, doors, cabinets, and other physical protection. Alongside a tranche of equipment evolved to CPNI criteria, a vast range of needs have been met by significant growth in LPCB certified products. These have taken the form of largely standardised designs with little differentiation, giving rise to a crowded market for these water security staples over the last decade.

AMP 6, however, has heralded different, more complex challenges which can be met less and less by off-the-shelf commodities.

Retrofit challenges

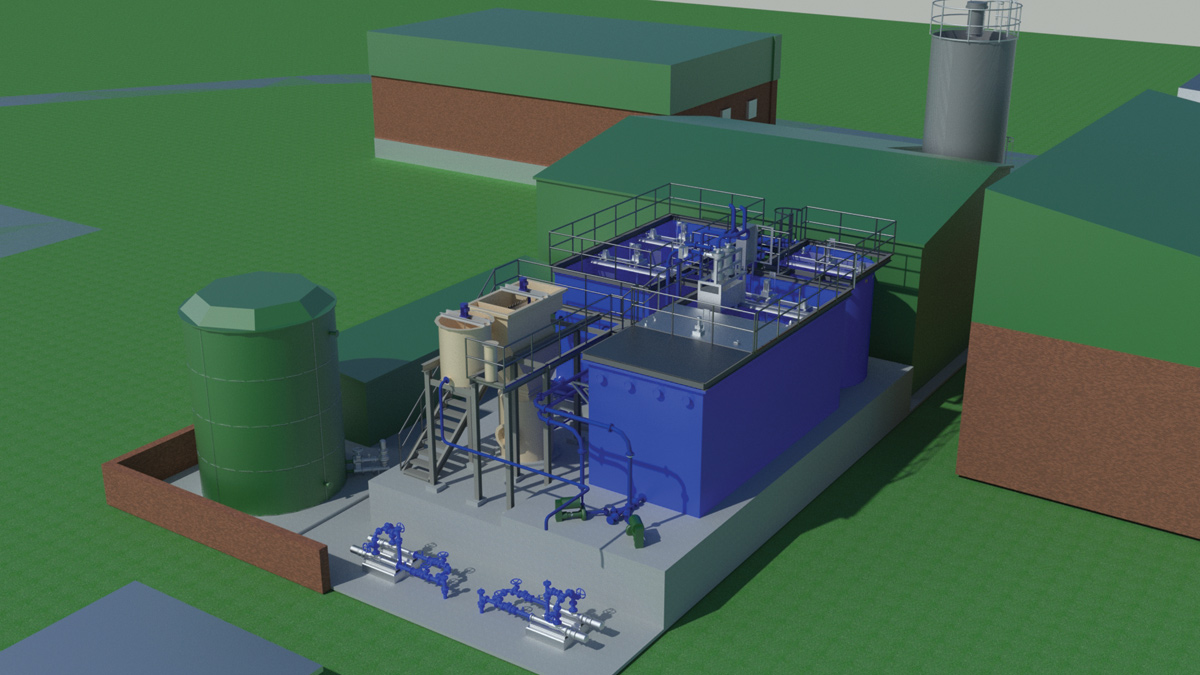

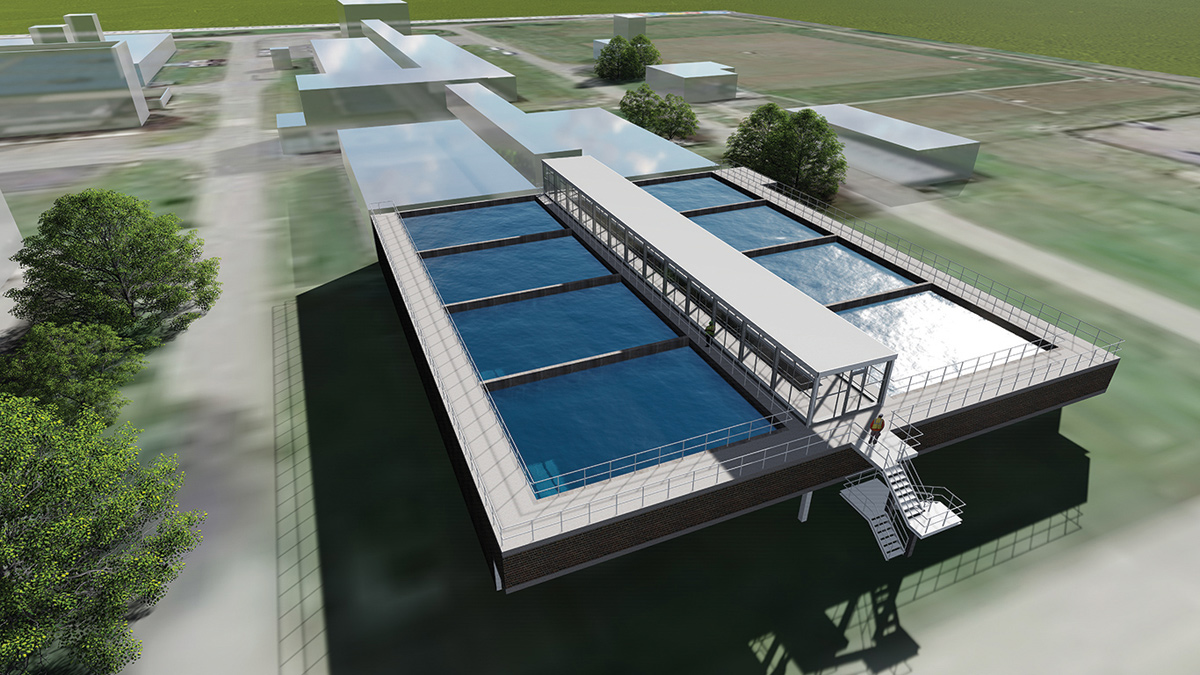

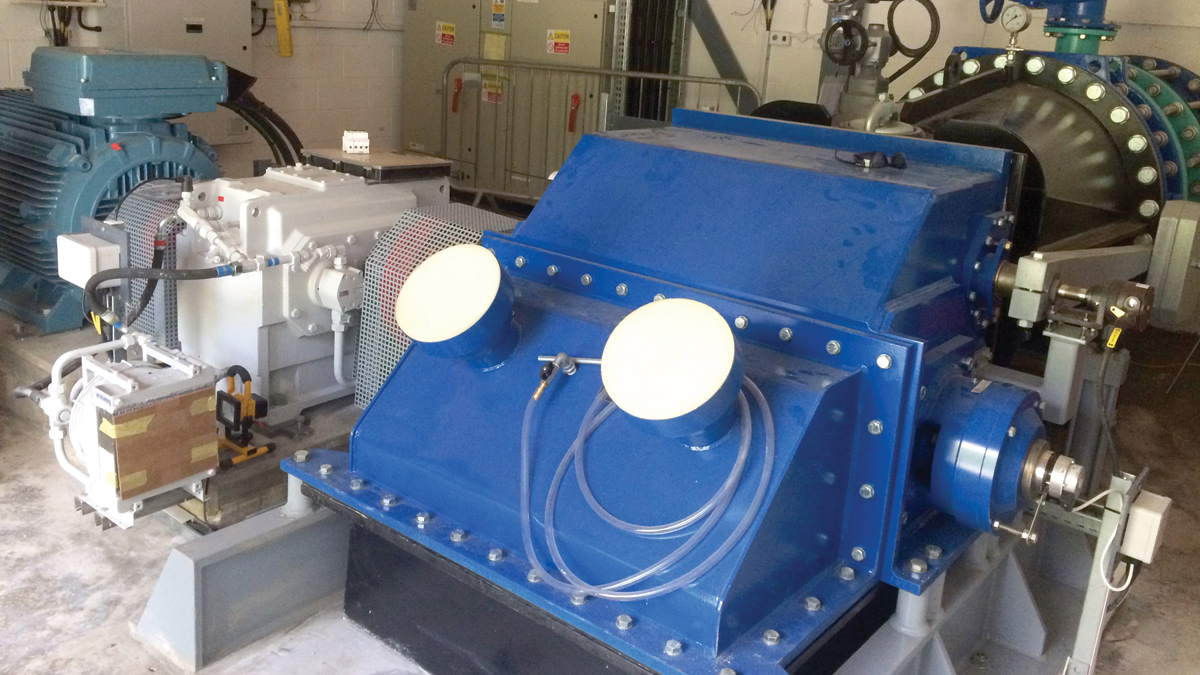

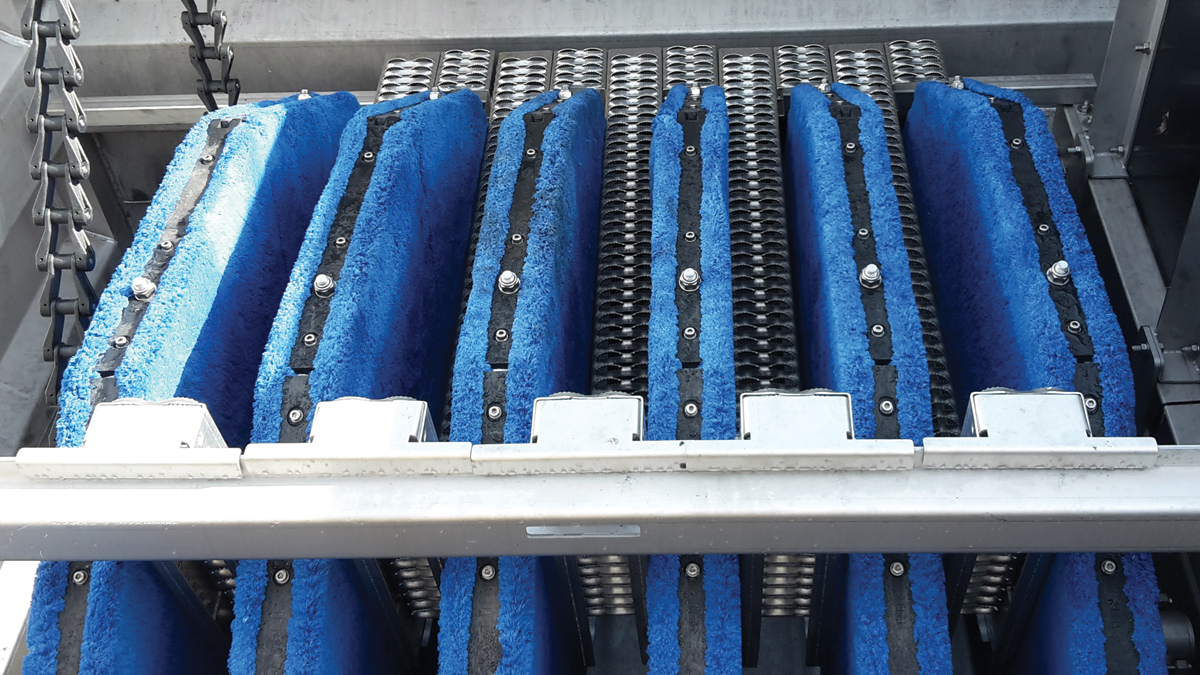

Predominantly, projects are focused on the hardening of existing infrastructure and its adaptation for new process technologies. These retrofit challenges run the full gamut of the UK’s water heritage, from Victorian waterworks and towers to the post-war development of the 1950s and 60s.

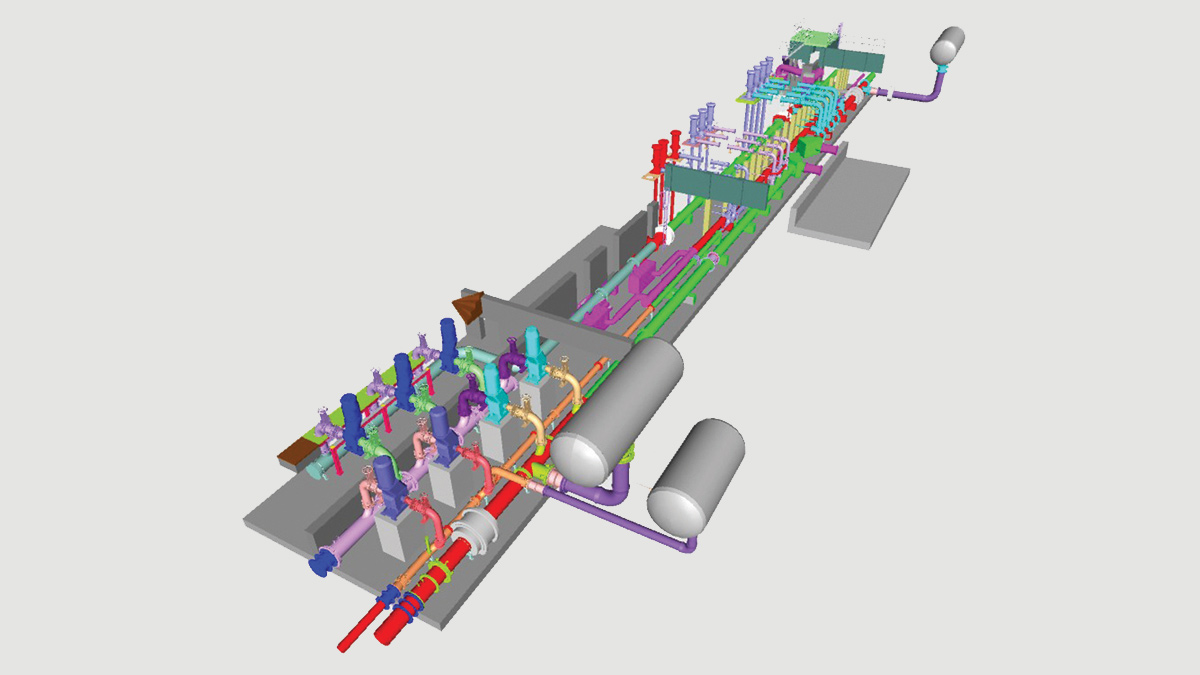

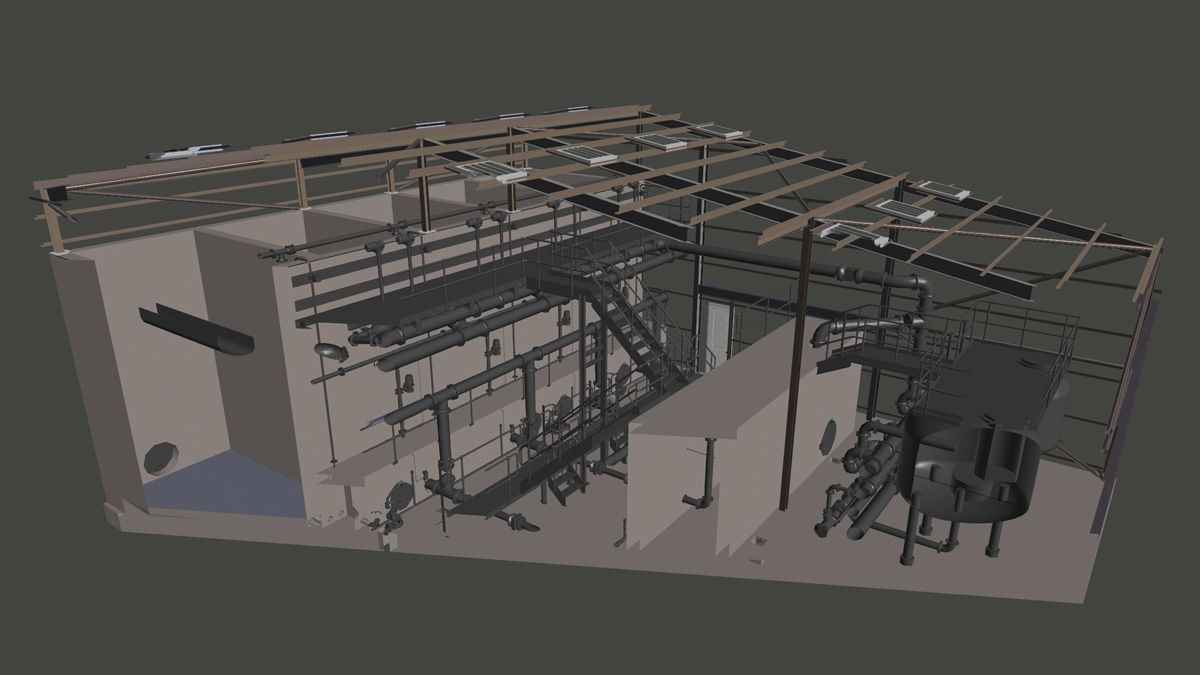

The procurement of high security access covers, buildings and enclosures to both protect and support the operational efficiency of the complex refurbishment project is rarely met by standard product solutions. While new build assets offer scope to accommodate standard products, each refurbishment site poses unique challenges – spatial, logistical, operational, and health and safety.

Invariably, needs will not be met by a hotchpotch of standalone products. With the ‘whole life’ cost efficiencies of TOTEX in mind, the best value solutions being delivered by Technocover are typically in the form of fully integrated access and housing systems.

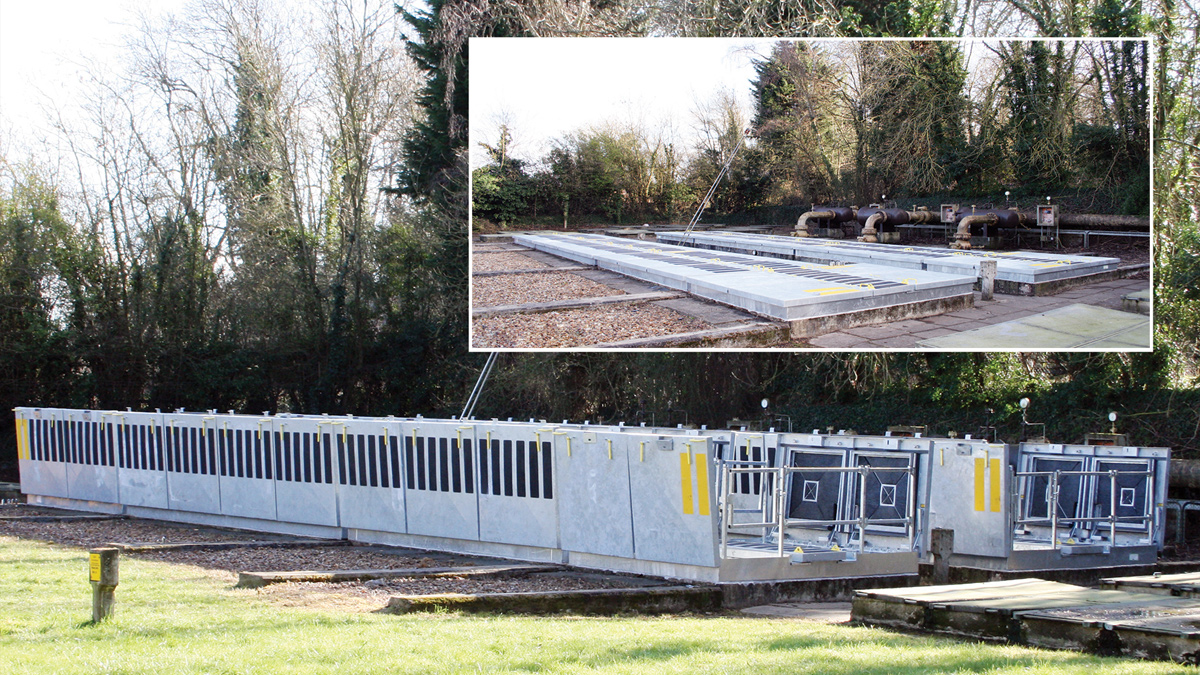

LPCB certificated SR4 UltraSecure mesh cage system being installed by Technocover

Many are built off-site and devised with exhaustive functionality which clients are often unaware they should or can demand, though is crucial to providing lowest whole life cost. This functionality embraces a range of considerations, some obvious and others more subtle, which can have significant impacts on site safety and operational efficiency.

For example, do covers within a multi-cover assembly meet manual handling criteria where required? Does the frame provide sufficient shielded space for the installation of alarm equipment? Will you need to purchase and retrofit additional items to heighten a cover frame to allow access to the padlock?

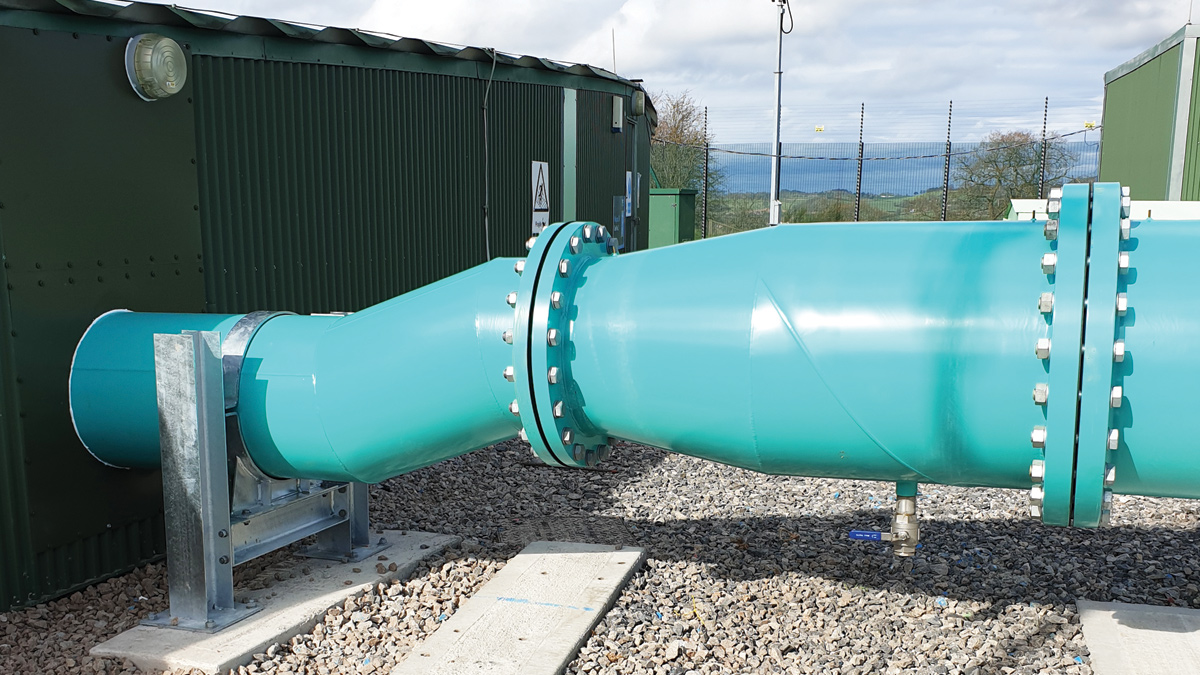

The refurbishment project calls for unusual shapes, such as hexagonal access systems, in hard-to-reach places – the top of reservoir towers or hemmed in between existing structures. With the emphasis on keeping assets live, clients and contractors want ‘plug and play’ solutions; built and kitted off-site with full M&E, then craned in and hooked up to services the same day, if possible.

LPCB performance

The challenge is delivering these more complex and increasingly super-size solutions within the scope of LPCB performance parameters. Water UK’s vision for AMP6 has pointed to the role of innovation in realising cost-efficiencies.

However, innovation in the physical protection of water is not always possible through thinking ‘outside the box’. More often than not, it relies on the manufacturer’s ingenuity to problem-solve within the constraints of certification. The move from off-the-shelf products to complex, tailored systems that meet certification is like charting new territory, where design credentials and track record truly come to the fore.

LPCB certificated SR3 UltraSecure Sentinel twin security doors

Now more than ever, the industry is turning to the engineering know-how of time-served LPCB specialists like Technocover to execute intelligent and complex solutions that fully exploit, but do not breach, the envelope of their security certification. As a trail-blazer in LPCB solutions for water, we are ahead of the game. Our designers and installers are already well versed in the discipline and finer detail of configuring successful bespoke systems within the performance scope of LPCB.

It is no coincidence that Technocover’s Total Service approach has been evolved for over 20 years around the whole life cost-efficiencies embodied in TOTEX. Based on the premise of providing the lowest cost solution, it addresses every possible aspect of the product’s life cycle to ensure the best return on investment.

This goes from maximising the buildability and operational advantages of the design, to ensuring a high quality system finish for long, low maintenance service.

Technocover’s TOTEX/Total Service response comes down to the rigorous application of value engineering principles through early consultation and close collaboration.

Will the system be easy to install, operate and maintain? How can it be constructed to overcome access constraints on site, or reduce construction time? Is the design configured in every aspect for site compatibility and functions such as water-shedding, installation of site alarms and client locking suites? Can components be hoisted to give access for inspection and replacement equipment where it is needed? Can bespoke interfaces between security enclosures and impinging cover frames be resolved within the certification parameters, or does the assembly need modifying?

LPCB certificated SR4 UltraSecure walk-in modular security kiosk

Be wary

The industry must be wary of pursuing short-term savings through low product price. Specifiers and procurers must get to grips with the whole life implications of equipment choices. While LPCB certificated products conform to a defined series of security ratings, there can be wide differences in their operational sophistication and system finish. Meeting a security rating alone is not enough.

Product designs, especially the bespoke systems highlighted in this article, will result in significant outcomes in terms of cost-efficiency across service life.

A study of the operational costs, health and safety risks, and labour input of running and maintaining a complex access system would be revealing. If poorly designed, you would undoubtedly see cost impacts accrue from retrofit work, unexpected maintenance and longer cycle times for personnel using the systems. These could dramatically affect the bottom line for site operations over the life of the product, especially if it required premature replacement.

When it comes to equipment designed to safeguard lives and critical resources, the longevity and integrity of materials is paramount. Specifiers must ask: What’s protecting the protection?

LPCB certificated SR4 UltraSecure multiple leaf flush covers

A defensive and potentially life-critical piece of engineering warrants a high quality finish, which means a galvanised zinc coating to properly corrosion-proof steel. Clients must also scrutinise this aspect of a product as it may not meet service life expectations, or could possibly be compromised to lower price. The outcome can be a product that may meet the security specification but needs replacing after, say, as little as three or five years.

Despite technical advancements in the performance of modern paint systems, few if any will give much more than 10 years complete protection. Technocover uses high quality steel, galvanising and paint processes to provide 25 years minimum service life of products. While we also offer the option of a paint finish for aesthetic purposes, galvanised steel is the crucial element to assuring long service life.

When adding functionality, every component and accessory should be included within the LPCB certification for the product to be security compliant. Photo shows a Technocover LPCB certified twinleaf door, with a primary door leaf, entry and exit ironmongery, and an arched head blanking plate.

Originators of the LPCB approved service reservoir cover certified to LPS : 1175 Issue 7, Security Rating 4

Operational resilience

With its early adoption of LPCB certificated equipment, the water industry has led the way in operational resilience and set a bar for other utilities to follow. As the originator of the LPCB approved service reservoir cover and numerous innovations since, Technocover remains committed to leading the way in meeting the industry’s security and operational needs.

Our success in delivering solutions that achieve the full continuum of functional needs within the LPCB performance envelope provides the only truly robust foundation for total cost accountability in this TOTEX era. We firmly believe it can help water companies and their design/construction partners to better control ‘whole life’ cost in the pursuit of lower prices for customers.