Technocover Ltd

Physical Security for Infrastructure (2016)

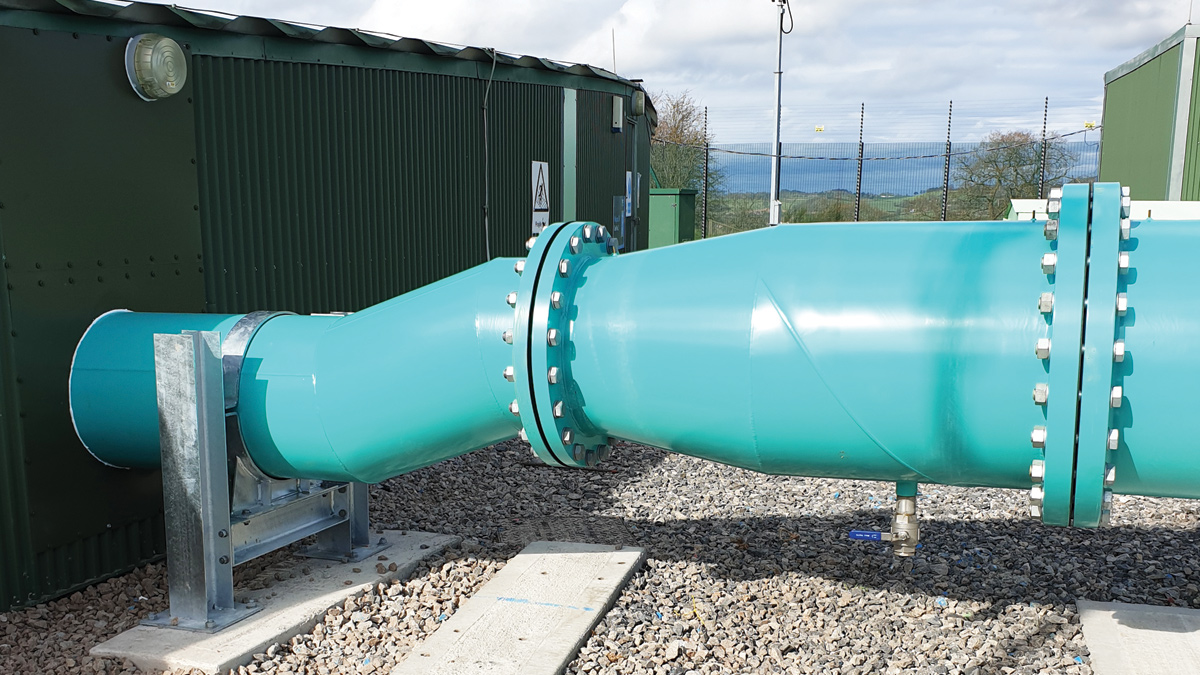

LPCB certificated SR3 UltraSecure mesh cage system

The physical security of assets on infrastructure sites is reaching new levels of sophistication and technical challenge. Utilities and other critical industries are systemically ‘hardening’ their operations, above and below ground, against identified risks of attack or infiltration by the criminal, saboteur or terrorist. Not only are the challenges growing in scale, clients are also demanding even greater functionality, adaptability and speed of installation from security enclosures, access covers and associated products for protecting vital process, storage and distribution assets.

‘Total service’ providing lowest cost solutions

Above or below ground, new build or retrofit, small or large: Technocover has unmatched design, production and installation capabilities to deliver right-first-time, lowest cost solutions answering every physical protection challenge.

How our ‘Total Service’ works to deliver the lowest cost solution:

- Early involvement and close collaboration with the project team ensures every opportunity to value-engineer and rigorously plan solutions. This ensures efficient, problem-free installation incurring minimum site impact and asset downtime.

- System design and manufacture is refined to address the full range of project considerations: identifying and resolving site access and installation constraints addressing health & safety and operational needs.

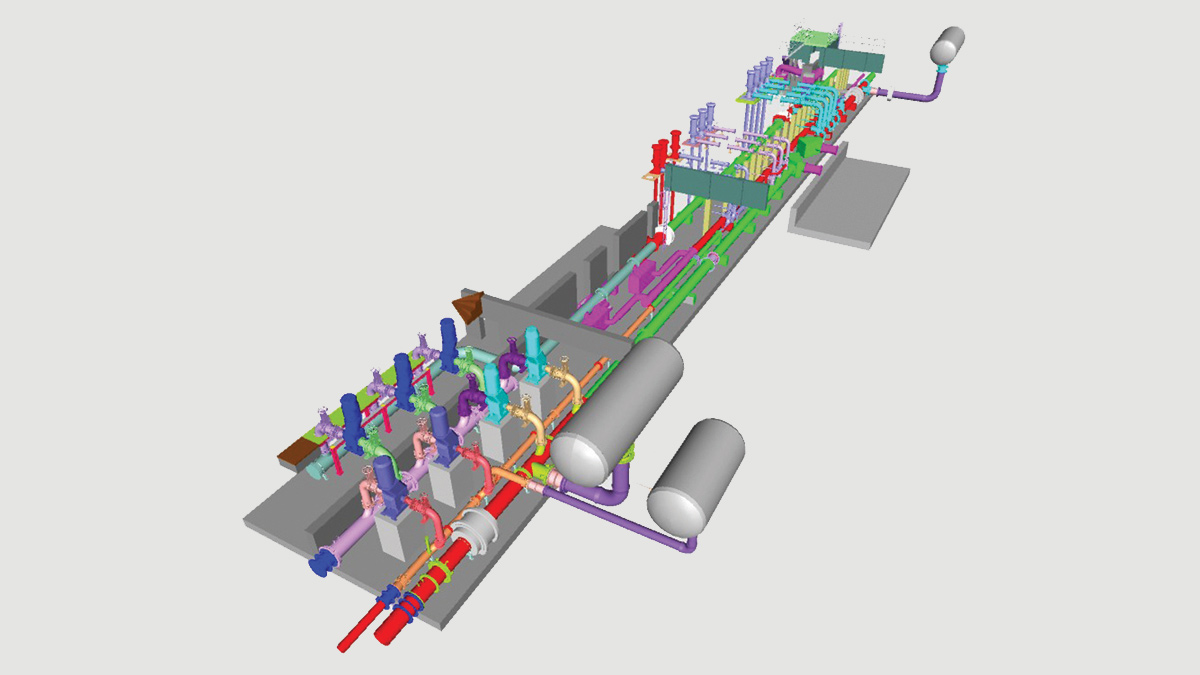

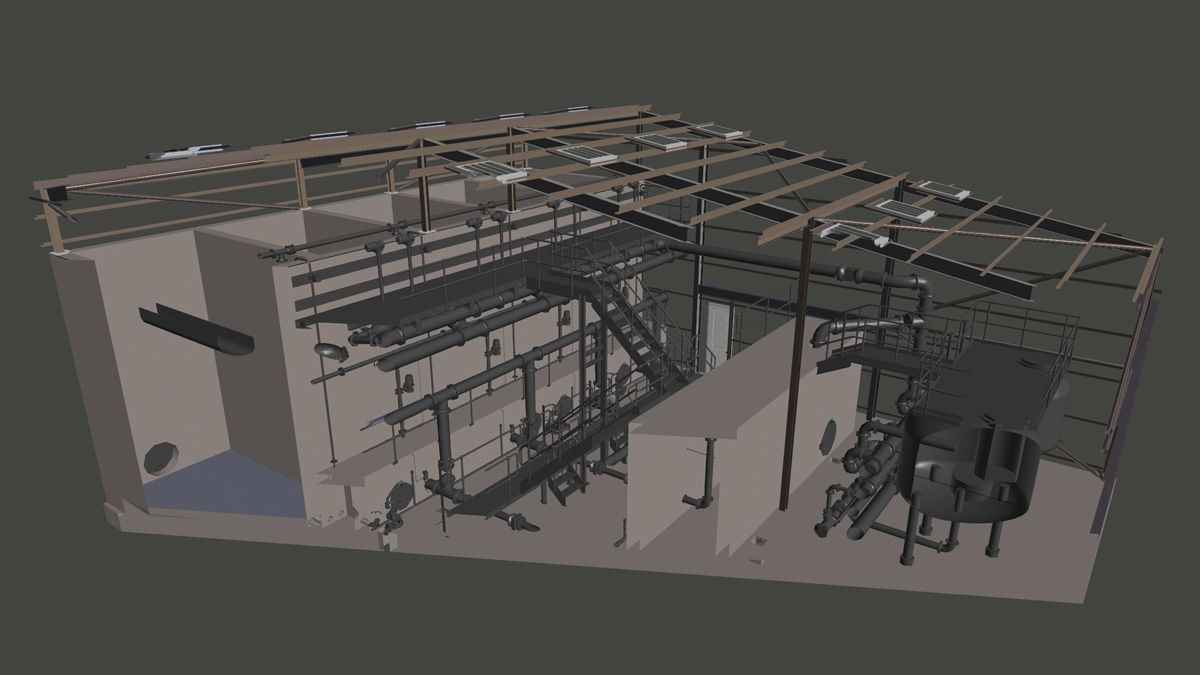

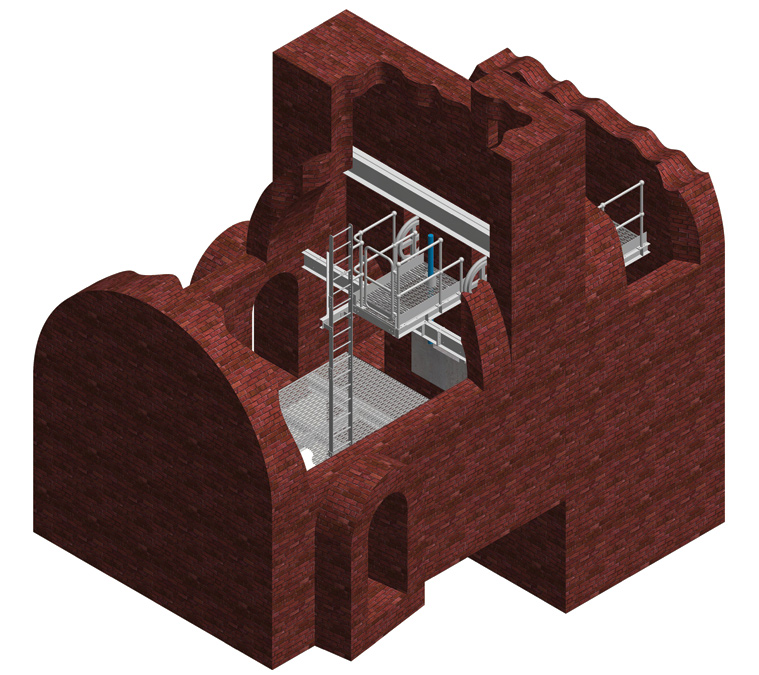

- 3D modelling allows design verification of standard and complex assemblies and coordination with the client design teams if required.

- Flexible build and installation options ensure most efficient solution to suit site logistics – from full factory build complete with M&E services, to part-built systems finished on site for ‘dropping’ over existing assets, or flat pack delivery for traditional installation.

- With advanced steel fabrication facilities and delivery fleet, we can take on complex and large off-site builds under quality management factory-controlled conditions. This reduces client/subcontractor costs while alleviating site safety and project management risks.

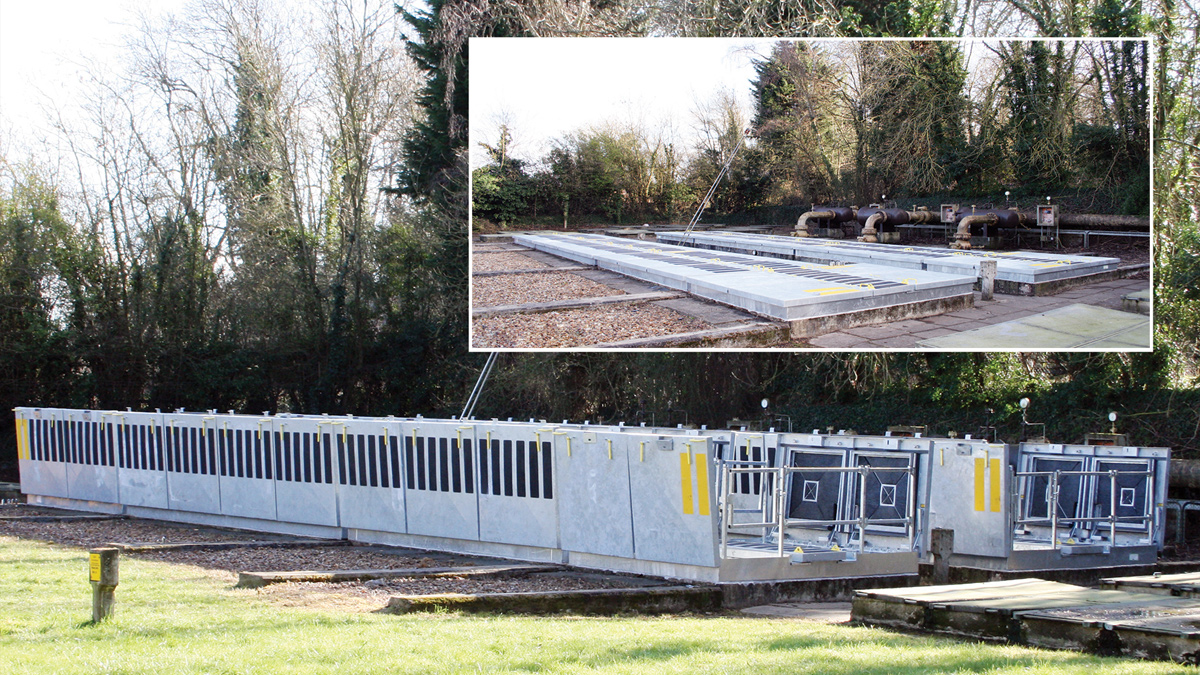

Large UltraSecure drop-on multiple upstand cover

Lowest cost in practice No 1: Value engineered UltraSecure cover installation

The client’s initial layout for this multiple-leaf access cover was overly complicated, with 14 inspection points and 8 personnel access points. Through early consultation with us, we were able to CAD model a much leaner solution, reconfiguring and value engineering the design to provide all required personnel, inspection and plant access without conflicts. This saw a reduction from 32 to 15 covers, resulting in a cost saving to the client in excess of 20%.

Our UltraSecure LPCB approved new generation of modular covers allow unprecedented scope in the size, number of leaves, and provision of inset lids for inspection, personnel entry, spindle valves – all as a standard solution.

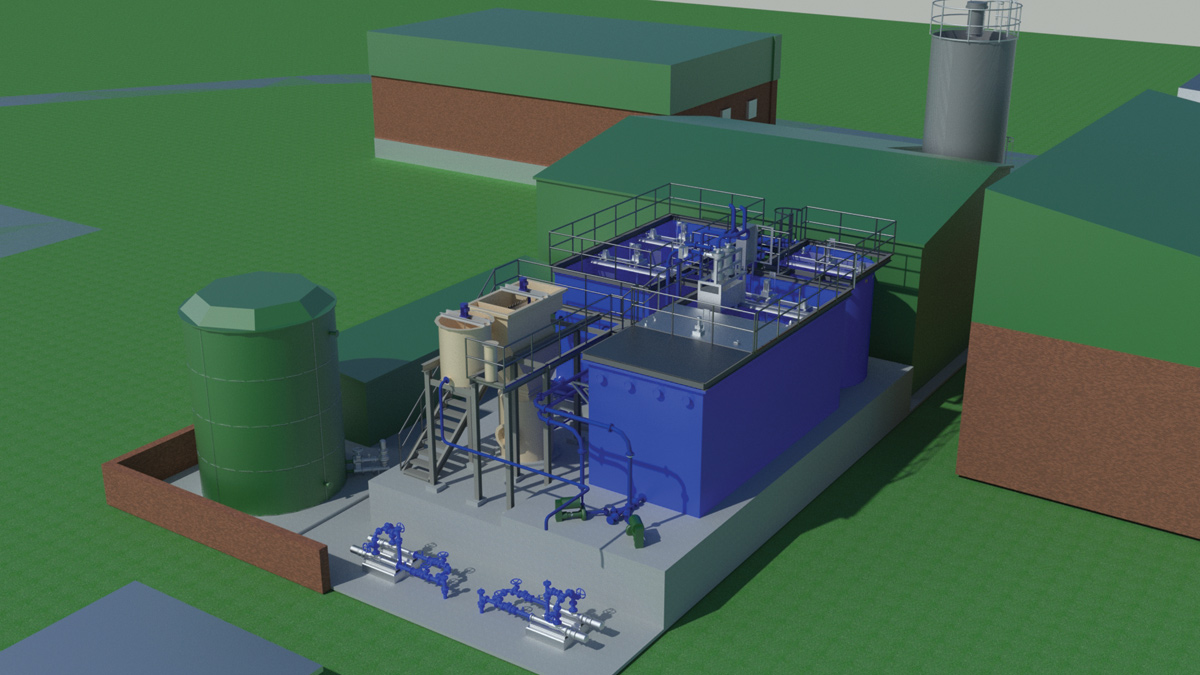

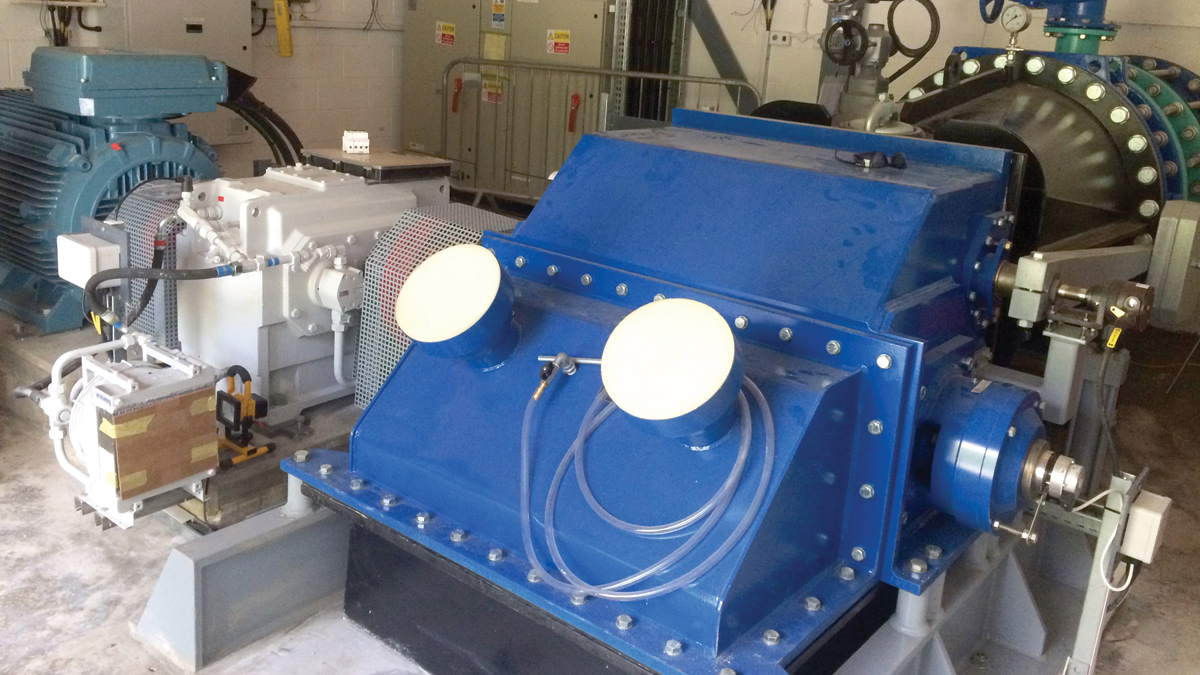

Lowest cost in practice No 2: Factory-built, fully fitted UltraSecure enclosures

For this utilities project, four kiosks were pre-built and pre-fitted with electrical and Heating & Ventilation services, tested and certificated under factory-controlled conditions. Through early consultation and careful planning of equipment delivery, lifting and installation was completed in just three days, saving up to five days programme time.

The kiosk build was completed under ISO9000 quality management at our Mid-Wales factory, including service fit-out. With a 27m2+ footprint & weighing 4.6 tonnes, the largest was engineered and constructed in two halves for simple bolt down and connection to site power.

Our factory-assembled, ‘plug and go’ security kiosks are fully fitted-out prior to delivery with all required M&E. On site, they simply need bolting to their foundations and connection to mains power, saving labour and programme time.

UltraSecure drop-over modular building installation

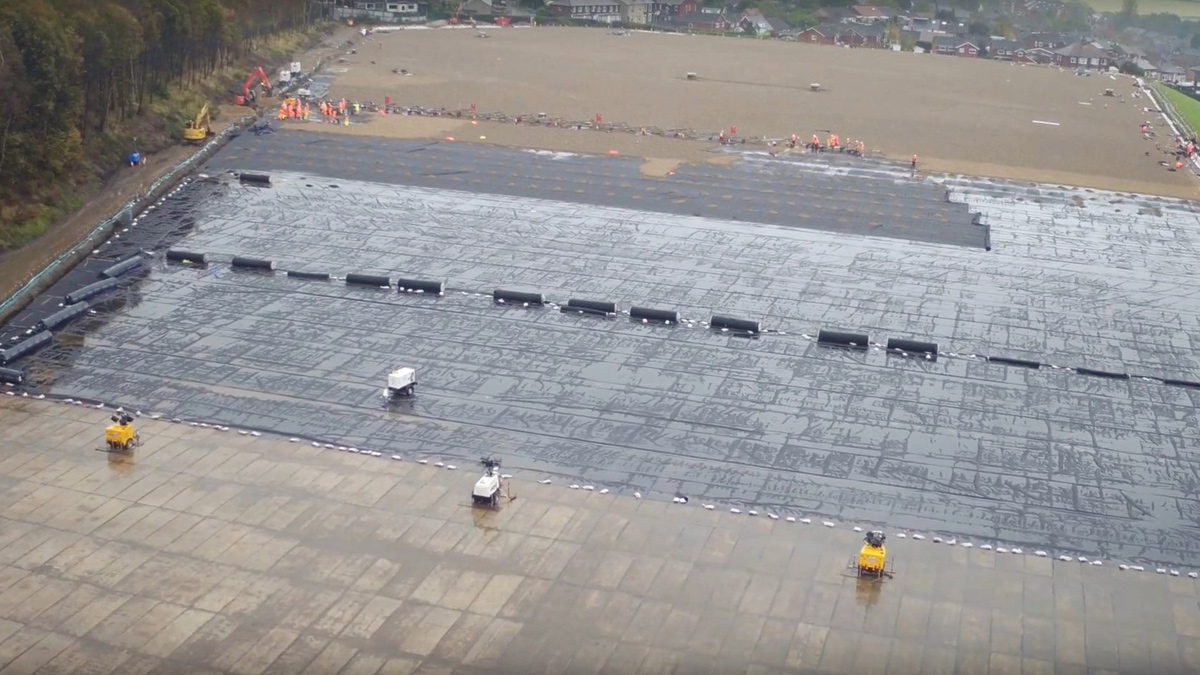

Lowest cost in practice No 3: ‘Drop-on’ UltraSecure enclosures

These UltraSecure enclosures reduced off-line time on security upgrades at this utilities site from around four weeks to just one day. The larger kiosk was designed to fit with minimal tolerance over the existing asset and with minimal extension of footprint, being assembled on site and craned over.

Reducing installation time and operational downtime provides significant programme benefits – it removes the associated cost, health and safety, and security impacts when extended time is spent on the asset upgrade.

Our large LPCB enclosures have removable roofs, while all enclosures have the option of our new louvre system, which provides excellent yet secure free airflow.

UltraSecure modular building in position over existing structure

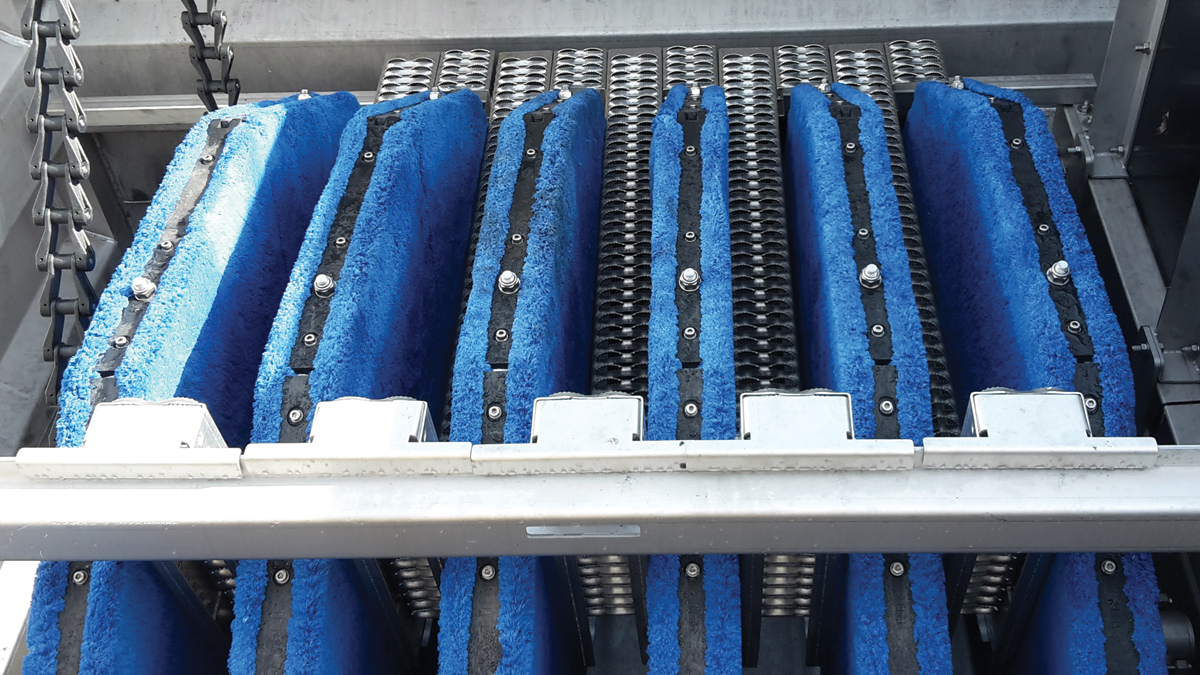

Loss Prevention Certification Board (LPCB) approved mesh cages

Technocover’s LPCB approved mesh cages provide naturally vented security of plant and visibility of the asset at all times. With extensive size and accessory options, including operational compliant sliding doors, they are a cost and time-efficient way to harden existing assets without dismantling structures and disrupting site operations.

The photograph (below) shows a full five-sided (with security gates and roof) UltraSecure LPCB mesh enclosure hardening the security of chemical storage, with a sliding door to accommodate delivery vehicle access due to site constraints.

UltraSecure mesh cage system with sliding gate

Our UltraSecure LPCB mesh enclosures provide unlimited sizes within their certification scope: from a simple two-sided structure against an existing building, to a full, stand-alone, multi-sided structure with roof providing secure encapsulation of existing buildings or processes, inside and out.

The photograph shows UltraSecure LPCB vertical partitions with single leaf hinged mesh panel padlocking outward opening doors providing protection of transformer installation.

UltraSecure LPCB certificated vertical mesh partitioning with entry gates

Improved features, extensive size options

Technocover is scaling up to the growing security challenges of today’s infrastructure site; and so is the scope of the company’s LPCB certification to the latest LPS1175 test update (Issue 7).

Technocover’s leading range of UltraSecure doors, modular enclosures, cabinets, kiosks, cages systems and access covers offer versatile sizing and configuration options, plus wide choice of locking, operational, and health & safety features for customisation to client needs – all within the scope of their LPCB certification.

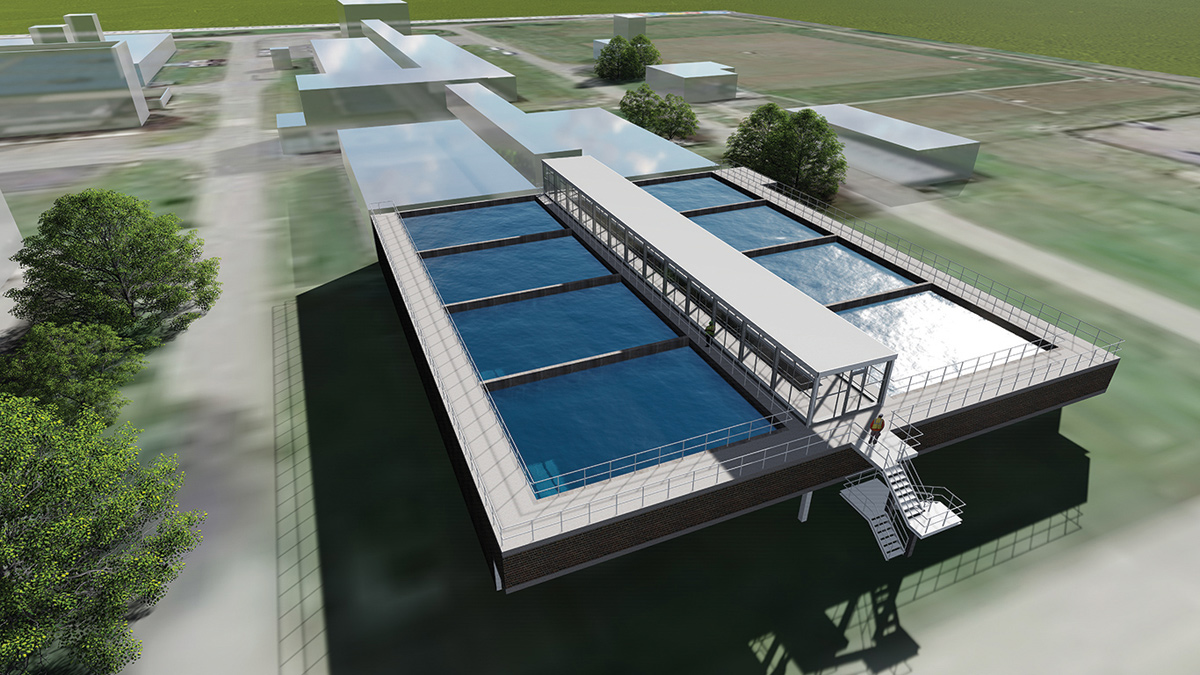

UltraSecure covers: Bigger & more versatile

Exclusive to Technocover, the new, wider single span design of our multiple leaf drop-on covers features simplified support structures, meaning less material and installation time. This significant development enhances our lowest cost proposition on large access covers all within the scope of their LPCB certification to issue 7. We also offer greater scoping in the sizes of valve spindle covers and hatches available for multiple cover assemblies.

The photograph (below) shows a large UltraSecure upstand cover assembly, single span multiple ‘drop-on’ access covers with in-line hinged twin leaf personnel inspection access hatch lids.

UltraSecure LPCB certificated SR4 upstand assembly with hinged access covers

Sentinel LPCB doors: Larger sizes, more accessories

LPCB issue 7 certified single and twin leaf doorsets with optional accessories including head blanking plates and louvre vents – now offering bigger sizing scope. Certified entry and exit locking control systems as well as louvre vents and vision panels.

UltraSecure cabinets: New features, more accessories

Improved functionality is offered by our UltraSecure cabinets under the scope of their LPCB certification to issue 7. These include sloped cabinet roofs, shedding water away from the access doors to the rear, for the comfort of personnel carrying out maintenance and inspection. There are new louvres, lockable cat flaps, cable entry cowls plus padlocking and key entry options.

(left) UltraSecure plug and go walk-in modular security kiosk and (right) UltraSecure drop-over twin door cabinet/enclosures

UltraSecure Sentinel security doors with SR3 & SR4 vision panels

Technocover: Your total service partner for lowest cost physical security for critical infrastructure

For over 25 years, Technocover Ltd have refined a total service experience bar none, closely partnering the client’s project team from site survey, early planning and design, through to delivery, installation and in-service maintenance.