Technocover Ltd

Our extensive in-house design and manufacturing facilities are home to well established research and development unit and comprehensive testing facility. Our commercial offices incorporate our design team who utilise the latest computer aided design technology and work alongside our dedicated planning section who oversee everything from surveying, scheduling and contract reviews, to the management of framework agreements.

We have been designing and manufacturing innovative steel products since 1993. In that time, through organic growth, planned expansion and acquisition, we have gained a reputation as the UK’s leading supplier of Physical Steel Security Access Products. We have a range of aperture security solutions for virtually every application, establishments in the UK and overseas have sought our expertise in providing security products for asset protection.

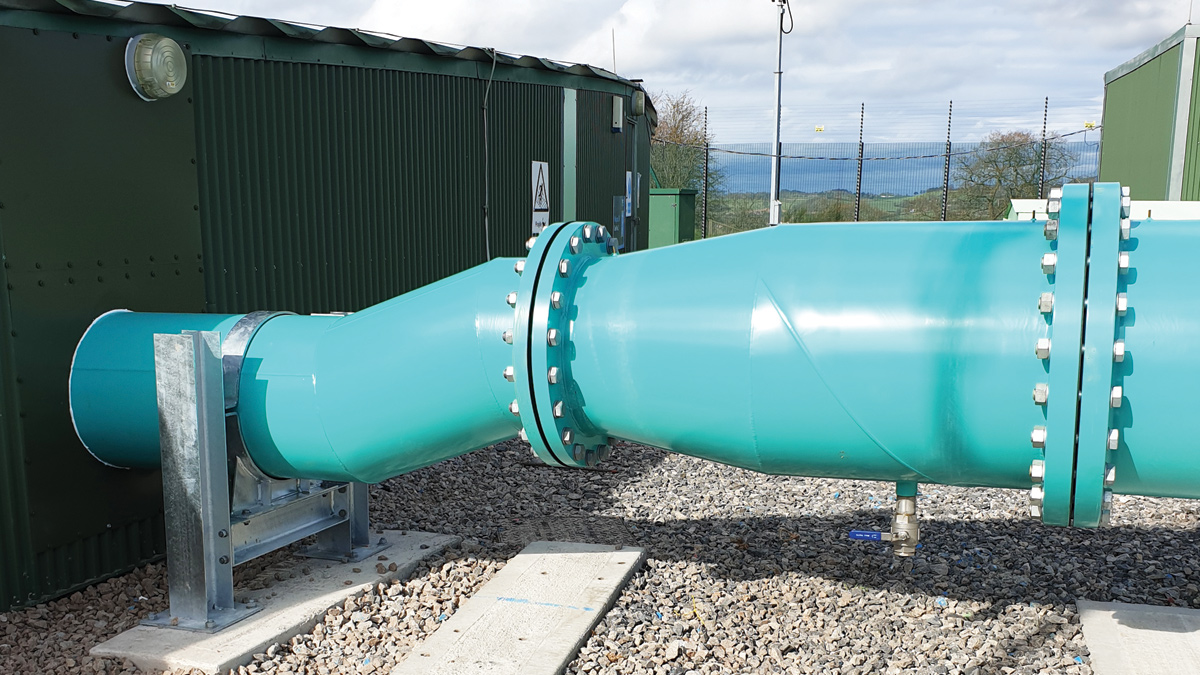

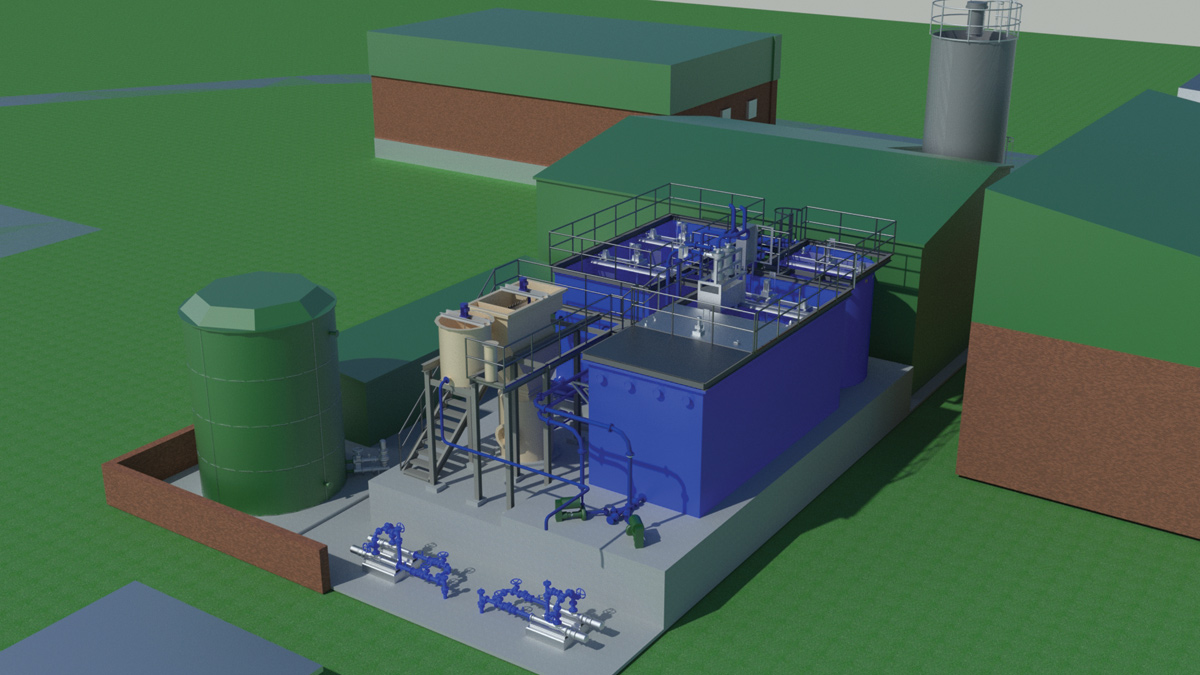

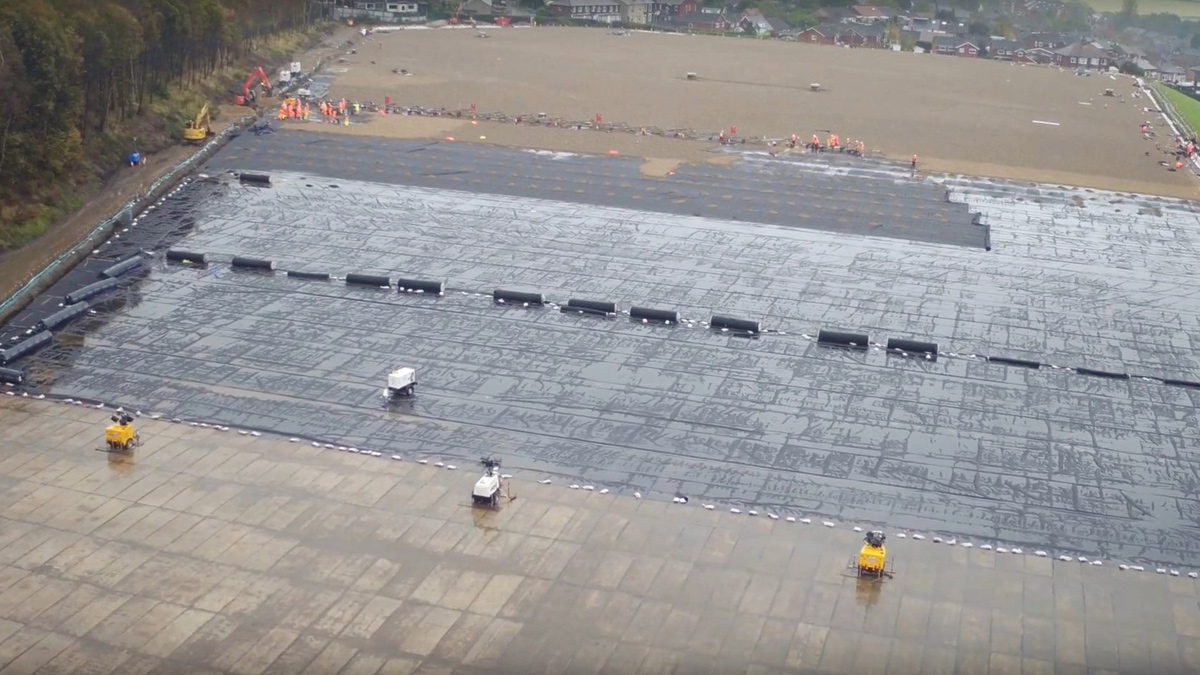

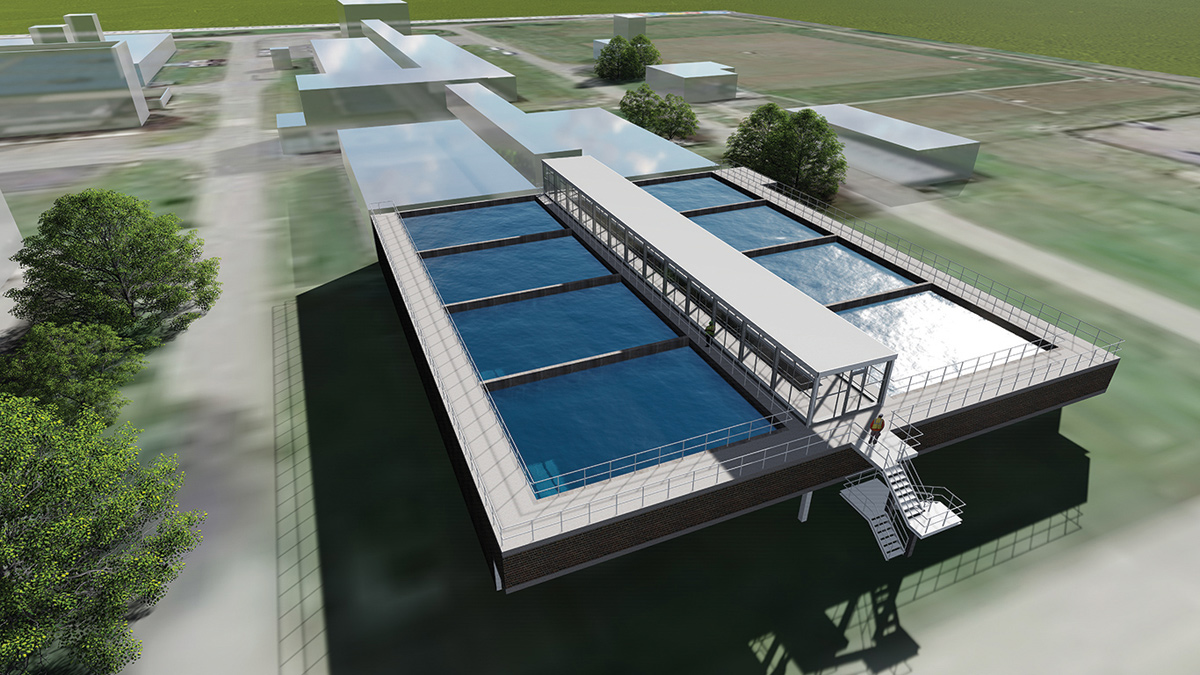

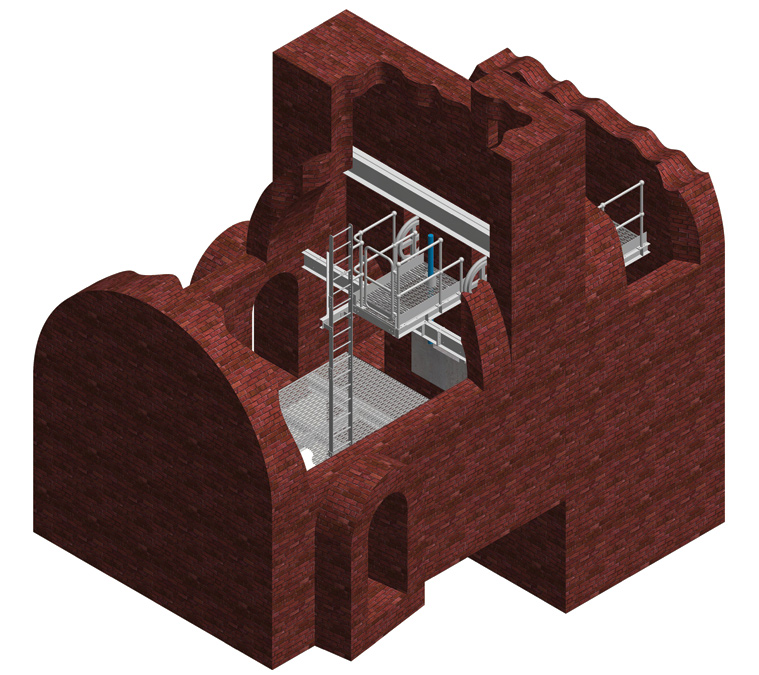

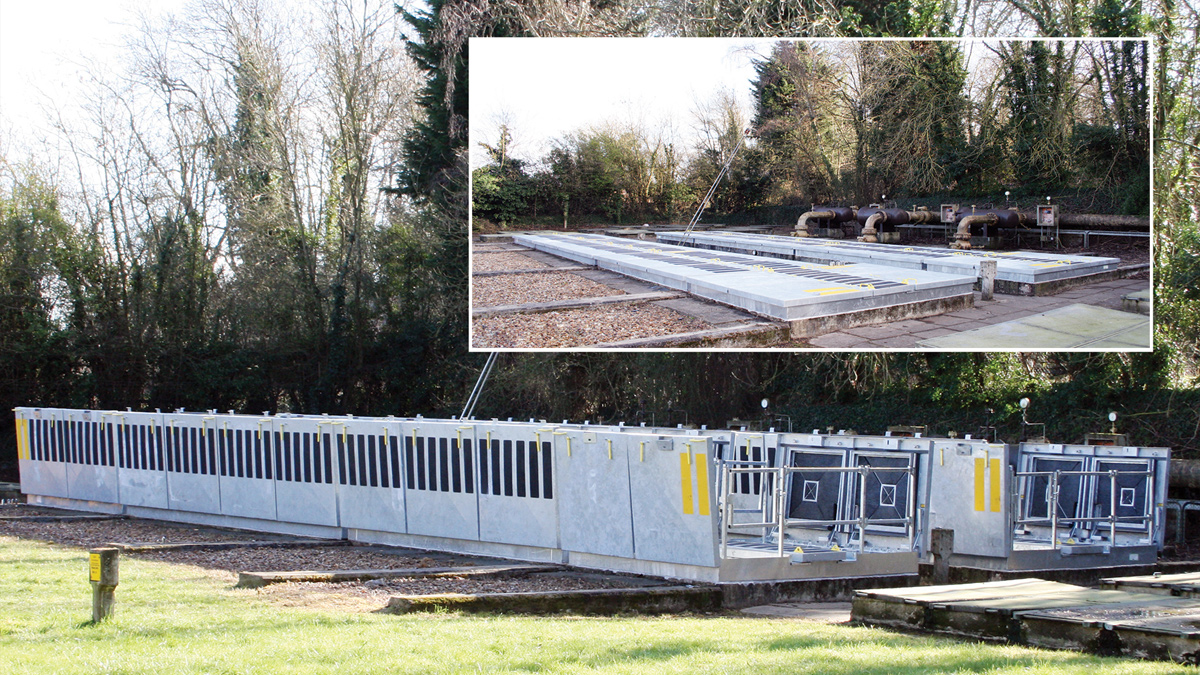

We operate a Total Service Philosophy and can handle complete projects from site survey to final installation, whether for new or refurbishing projects, the adaptability of our galvanised steel access products means the most complex design criteria can be met. Our range of high quality access products offer custom built operational and security solutions to prevent unauthorised persons gaining access, securing key assets against all levels of trespass, malicious vandalism, theft, extortion, contamination or terrorism.

Many of our access system products have been tested and approved by the Loss Prevention Certification Board (LPCB) to LPS 1175 issue 5 or above, Security Rating Levels 2, 3, 4 or 5.

Frameworks

We hold both exclusive and shared framework agreements with most of the major UK water companies. Framework Security items include:

- LPCB Level 2 Universal Gas Cylinder Clamps

- LPCB Level 3 Mesh Cage Systems

- LPCB Level 3 Flush Access Covers

- LPCB Level 4 Upstand Access Covers

- LPCB Level 4 Padlockable Access Doors

- LPCB Level 4 Key Entry Doors

- LPCB Level 4 Enclosures/Kiosks/Cabinets

- LPCB Level 4 Walk-In Modular Buildings

- LPCB Level 4 Window Bar Sets

- LPCB Level 5 Louvres