Trimpley to Hampton Loade Pipeline P...

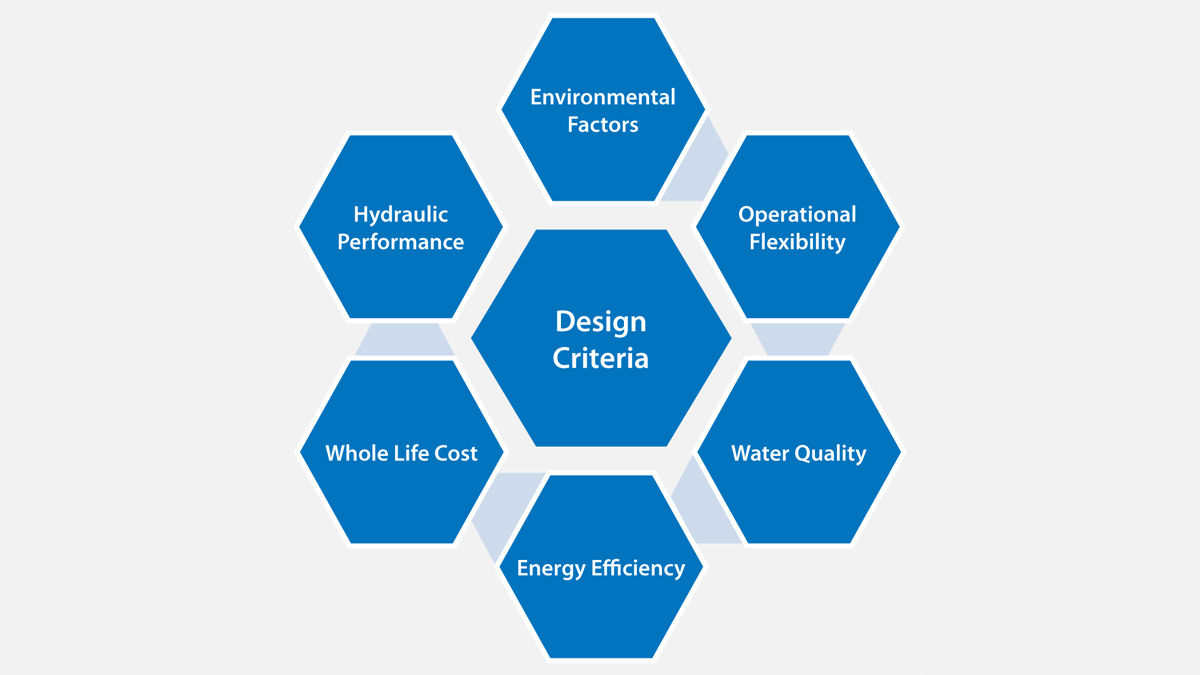

The Trimpley to Hampton Loade Pipeline Project is a strategic infrastructure initiative designed to enhance water supply resilience for 65,186 customers currently served by Trimpley Water Treatment Works (WTW). The project involves constructing an 11.5 km, 500mm internal diameter (ID) single-directional pipeline from South Staffordshire Water’s Hampton Loade WTW to Severn Trent’s Trimpley Top Service Reservoir (SR). This pipeline will enable the transfer of up to 20 Ml/d in the event of a failure at Trimpley WTW, ensuring continuity of service and supporting the company’s AMP7 Second Source Resilience commitment and delivering the project in a phased, efficient, and minimally disruptive manner.

Second Source Resilience

Trimpley WTW is a critical asset in the regional water supply network. However, its single-source dependency presents a significant risk in the event of operational failure, which would result in widespread service disruption, posing risks to public health, customer satisfaction, and regulatory compliance.

As part of the company’s AMP7 programme, which includes a 9% commitment to Second Source Resilience, this project has been identified as a key enabler of supply continuity.

[caption id="attachment_23925" align="alignnone" width="1200"] 52-ton and 70-ton HDPE pipe strings welded and awaiting winching into the bore on the larger HDD crossings - Courtesy of Coffey Construction UK[/caption]

Project scope

The project was divided into three main sections to facilitate phased delivery and allow for Coffey to begin construction of the critical infrastructure in August 2023.

Section 1: The first section of works involved the installation of 2.75km 500mm internal diameter (ID) ductile iron pipework whilst also undertaking the site investigation (SI) and ground investigation (GI) for the subsequent sections which were under design.

Section 2: The second section of works comprised the installation of 5.54km of ductile iron pipework including four horizontal directional drilling (HDD) 630mm (OD) SDR9 drill shots 1960m in total under carriageway works (A442) and river crossings.

Section 3: The final section of the pipeline encompassed the remaining 3.21km of ductile iron pipework, including two 660m and 400m HDD drill shots located in Coal Authority land and drilling under ancient natural woodland. This phase also includes the connection to Trimpley Top Service Reservoir and installation of 250mm (ID) washout pipework, actuated valves, bypasses, and monitoring equipment as well as the final pressure testing and commissioning of the entire pipeline.

The complex project included myriad of activities to enable seamless construction throughout the phased delivery of the works. Through early contractor engagement, Coffey was able to advise and assist the client in elements such as ecological assessments, design constraints, aerial photogrammetry and third-party utility liaison.

With a strong supply chain of valuable and efficient suppliers, all aspects of the project were constructed with minimal disruption to stakeholders resulting in a long-term valued pipeline and a critical investment in water supply resilience.

The key elements of the project delivery are detailed below.

[caption id="attachment_23922" align="alignnone" width="1200"] Easement fenced and topsoil stripping underway with geo-referenced UAV position in foreground - Courtesy of Coffey Construction UK[/caption]

Ecology

As part of the project, a series of ecological assessments and reports were conducted to ensure compliance with environmental regulations and to support biodiversity. These included:

Ecological desktop & constraints mapping: A comprehensive review and mapping of ecological data to identify environmental constraints and inform route planning and construction methodology to be used.

Protected species surveys:

Water vole and otter surveys: Field assessments of watercourses to confirm the presence of protected species and ensure legal compliance.

Dormouse surveys: Habitat suitability evaluations and targeted surveys for dormice were undertaken along the full length of the pipeline alignment.

Tree constraints schedule: Identification and classification of mature and protected trees and critical habitat within the project corridor to assess ecological value and potential construction impacts. Managing laying pipeline either through or drilling under Ancient Natural Woodland.

Hedgerow classification: Assessment of hedgerows along the route to determine their ecological significance under the Regulations.

Habitat suitability & mitigation reporting: Detailed evaluations of habitat conditions for protected species, with recommendations for mitigation where necessary.

Ecological enhancement reporting: Proposals for biodiversity improvements, including habitat creation and restoration measures along the pipeline corridor.

Surveying & geospatial data

As part of the Trimpley to Hampton Loade Pipeline Project, an unmanned aerial vehicle (UAV) photogrammetry survey was conducted along the full pipeline route within a 50m corridor. The aerial data was processed into Autodesk Civil 3D-compatible formats to support precise terrain modelling and route planning.

[caption id="attachment_23934" align="alignnone" width="1200"] (left) UAV support played a pivotal role during the pipeline project, (top right) implementation of remote-guided advanced navigation systems during the pilot bore phase of the complex HDD crossings and (bottom right) Combining GPR survey data within the machine control files to achieve a zero-service strike rate across the full pipeline - Courtesy of Coffey Construction UK[/caption]

The terrain modelling, apart from supporting construction planning and method of pipelaying, provided a baseline for the machine control element of the installation and reinstatement process.

In addition, a utility and ground penetrating radar (GPR) survey was carried out within a 30m corridor to identify existing underground infrastructure and third-party assets and support safe excavation.

Desktop utility mapping complemented the GPR data, reducing the risk of service strikes. Up to date desktop utility searches (DURS) reports were undertaken and, with the data being incorporated with the GPR survey and incorporated into the machine control element of the excavation works.

Value engineering

To facilitate the successful delivery of the pipelaying element of the project, a series of coordinated construction and reinstatement activities were utilised to ensure the efficient delivery of the pipeline using specialist earthworks contractor Collins Earthworks to provide the plant, equipment and expertise suitable for constructing a pipeline of this magnitude.

Through carefully coordinated and planned activities and with the added value of machine control systems, the efficiency and accuracy of the installation process was greatly improved.

[caption id="attachment_23928" align="alignnone" width="1200"] (left) Advanced excavators using the latest in machine control technology for precision pipelaying activities and (right) Utilisation of halo keel cold cutter to provide a safer means of cutting pipework - Courtesy of Coffey Construction UK[/caption]

Coupled with the GPR survey data, this ensured a zero-service strike rate was achieved across the entire length of the pipeline.

By using the latest technology in machine control systems, this not only accelerated construction timelines but also minimized material wastage and environmental impact.

Additionally, real-time data feedback improved quality control, reduced the risk of human error, while enhancing operator productivity and site safety supporting a cost-effective delivery in adherence to the pipeline design.

Coal Authority land and historic shallow mine workings

The final section of the pipeline encompassed certain areas designated under the jurisdiction of the Coal Authority, which oversees land affected by historical and active coal mining operations. Traversing these areas necessitated specific engineering and monitoring strategies.

Undertaking the horizontal directional drilling within this zone dictated meticulous planning, strict regulatory compliance, and robust risk mitigation strategies to safeguard both public safety and environmental integrity.

Prior to any works commencing, a formal permit was acquired from the Coal Authority, supported by comprehensive documentation including site-specific risk assessments, method statements, and ground investigation reports. These assessments were critical for identifying the potential hazards the land may contain such as subsidence, mine gas emissions, and the presence of abandoned mine workings.

[caption id="attachment_23930" align="alignnone" width="1200"] (left) Pre-construction drainage installed along easement, and (right) 500mm (ID) ductile pipe laying in progress - Courtesy of Coffey[/caption]

Construction methodologies were adapted to account for ground instability and contingency measures for unexpected ground movement through subsidence.

Continuous engagement with the Coal Authority and the client’s geotechnical representative ensured that all activities aligned with statutory requirements and best practice guidance.

Horizontal directional drilling: Gun Hill Crossing

The Gun Hill crossing, comprising a technically complex and challenging 660m section of 630mm SDR9 water main, was delivered using horizontal directional drilling to minimise surface disruption within an environmentally sensitive and geologically challenging area within the Coal Authority Land and in proximity to Ancient Natural Woodland.

Located in the South Staffordshire Coalfield, Gun Hill features challenging geology consisting of a mixture of part of the Pennine Coal Measures Group; prone to instability and mine gas emissions and, Early Devonian Clee Sandstone Formation which varies from hard, abrasive layers to softer, friable sections impacting borehole stability.

Coffey collaborated with specialist HDD contractor Johnston Trenchless Solutions (JTS) to execute the HDD crossing using advanced technology and a state-of-the-art 220 tonne capacity drill rig (the only one in the UK) to navigate the geological challenges and install the 70 tonne HDPE pipe within the permitted land. An advanced de-sander was used to recycle and clean the drilling mud thereby reducing water demand and reduction in disposal costs.

[caption id="attachment_23926" align="alignnone" width="1200"] (left) 630mm (OD) SDR9 pipe welding progressing on the HDD crossings and (right) 70-ton HDPE pipe string being winched into the bore on Gun Hill - Courtesy of Coffey Construction UK[/caption]

The pilot bore was drilled along the predetermined path using advanced navigation systems for accuracy through coal seams and sandstone. Reaming of the bore to 900mm was conducted in multiple stages to ensure stability. The 70 tonne 630mm SDR9 pipe was then winched into the bore during a 12-hour shift.

The Gun Hill crossing, part of a 1800m trenchless installation across six ground conditions, was a critical milestone.

Drilling fluid management & environmental mitigation at Gun Hill

During the horizontal directional drilling operations at the Gun Hill crossing, the team encountered heavily fractured substrata formations. These geological conditions, combined with the high-pressure fluid injection required for pilot bore advancement, led to instances of drilling fluid loss particularly evident at river crossing points along the alignment.

To address this, Coffey implemented a proactive and robust environmental management strategy. A dedicated frac-out containment team was deployed to monitor the drilling corridor in real time, utilising unmanned aerial vehicles for aerial surveillance and rapid detection of surface fluid emergence. Pre-positioned frac-out mitigation materials were strategically placed along the route, enabling the team to respond swiftly to any fluid escape events. These measures ensured that any drilling fluid that reached the surface was immediately contained and managed, significantly reducing the risk of environmental harm. Through continuous monitoring, rapid response protocols, and effective containment practices, Coffey successfully mitigated the environmental impact of fluid loss incidents, maintaining compliance with environmental standards and safeguarding sensitive habitats throughout the drilling operation.

[caption id="attachment_23923" align="alignnone" width="1200"] Identification and proving of third-party assets using vacuum excavation pre-pipelaying activities - Courtesy of Coffey Construction UK[/caption]

Trimpley to Hampton Loade Pipeline Project: Supply chain - key participants

Principal contractor: Coffey Construction UK Ltd

Topographical surveys & mapping: Murphy Geospatial

Civils & site support: Three Shires Ltd

Pipe laying: Draper Civil Engineering Ltd

Horizontal directional drilling: Johnston Trenchless Solutions (JTS) | Joseph Gallagher Ltd

HDD equipment: Vermeer UK

Earthworks & pipe laying: Collins Earthworks Ltd

Civil & site support: CGL

Paving & surface reinstatement: Brad-Pave Ltd

Excavation plant & machinery supply: P Flannery Plant Hire (Oval) Ltd

Pipe supplier: Electrosteel Castings (UK) Ltd

Flow controls: AFFCO Flow Control (UK) Ltd

Valve supplier: AVK UK Ltd

Innovations

To support accurate and high-quality land reinstatement following pipeline installation and testing, a UAV-based terrain capture survey was conducted prior to construction commencement. This pre-works aerial mapping provided a precise digital record of existing ground conditions, enabling the reinstatement process to closely match original landform profiles and ensuring compliance with environmental and landowner expectations.

Ground penetrating radar scanning was used across the full working easement and the existing service results were integrating into state-of-the-art computer systems installed into all excavators (machine control technology). This system disabled any excavator working within close proximity to existing services and achieved a groundbreaking milestone: a zero-service strike rate throughout the entire pipeline project. This innovative approach not only enhanced safety and efficiency but also set a new benchmark for precision in underground infrastructure delivery.

Advanced excavators equipped with tilt-rotating attachments were introduced, enabling precise and flexible material handling from outside the trench. This innovation significantly reduced the need for pipelayers to enter the excavation zone, thereby minimizing the people–plant interface. This resulted in a substantial improvement in on-site safety and operational efficiency, setting a new standard for safe excavation practices. During the pilot bore drilling phase, remote-guided advanced navigation systems were implemented to maintain absolute precision in both line and level. This cutting-edge technology ensured that the pipe installation adhered exactly to design specifications. By leveraging real-time data and remote-control capabilities, we enhanced accuracy, minimized manual intervention, and delivered a more efficient and reliable installation process.

The integration of the TONGHAND® XS system into horizontal directional drilling operations marked a significant advancement in safety and automation. This innovative tool enables a single operator to remotely make and break pipe joints directly from within the excavator cab, eliminating the need for manual wrench handling. By reducing physical strain and removing personnel from high-risk zones, both safety and productivity were enhanced, setting a new standard for safety in tough conditions.

[caption id="attachment_23927" align="alignnone" width="1200"] (left) Integration of Tonghand XS to eliminate manual wrench handling during HDD crossing works and (right) Installation of a permanent cross connection setup within the existing pump house to facilitate the new resilience flows - Courtesy of Coffey Construction UK[/caption]

The continued deployment of unmanned aerial vehicle technology played a pivotal role in supporting both the design and construction teams throughout the pipeline project. By providing high-resolution aerial imagery, real-time site monitoring, and accurate topographical data, UAVs have enabled faster decision-making, improved planning accuracy, and enhanced progress tracking.

This innovative approach has not only streamlined workflows but also fostered greater collaboration between teams, ensuring a more agile and informed construction process.

Conclusion

The project is recognised as a strategically important investment in strengthening the resilience of the regional water supply network for Severn Trent. It addresses a critical operational vulnerability by establishing a reliable secondary source, thereby enhancing service continuity and reducing the risk of supply interruptions.

Through meticulous planning and a collaborative approach, Coffey successfully delivered the project in alignment with the client’s expectations. By proactively identifying and managing risks, the team ensured that all works were executed safely, efficiently, and to the highest quality standards. This disciplined execution not only met the technical and regulatory requirements but also reinforced Coffey’s commitment to excellence and client satisfaction.