Aerzen Machines

Air Blower Retrofit at Wastewater Treatment Works

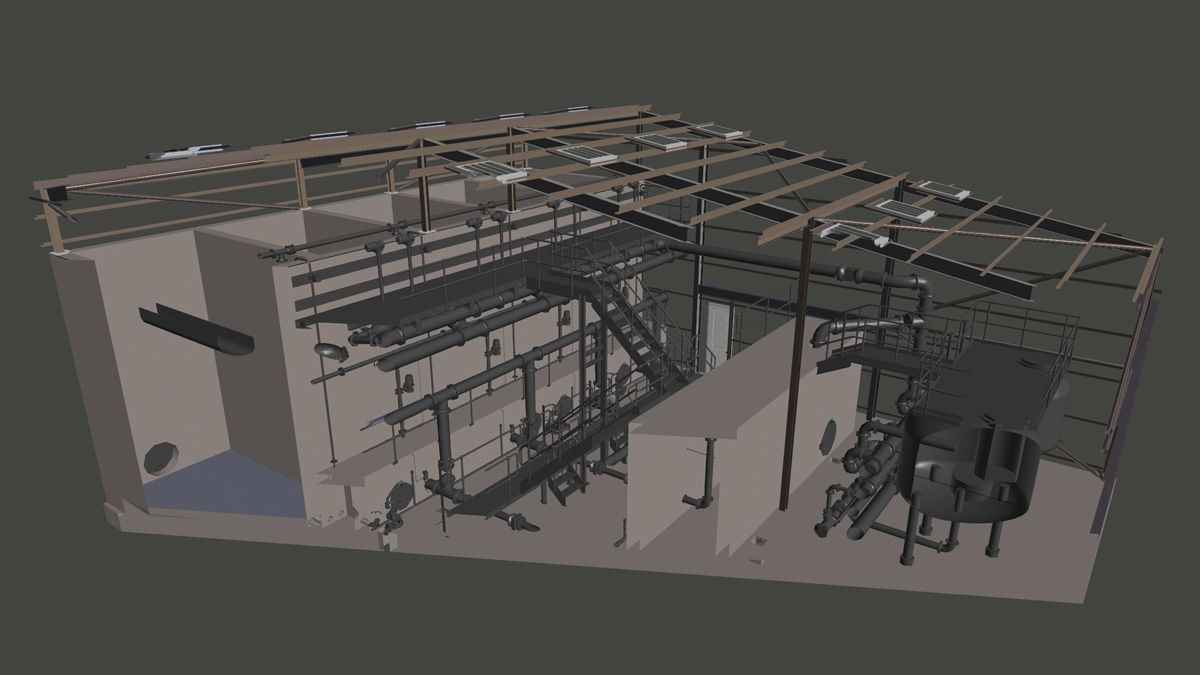

Courtesy of AERZEN Machines

The issue: Energy efficiency has not been the focus so far

Operational efficiency and reliability should be priorities in wastewater treatment plants. Consequently, there has been a prominent focus on being more efficient and reducing carbon footprint. This WwTP treats wastewater for over eight million people. The company was working with three energy-intensive competitor blowers that no longer met today‘s standards, this is where AERZEN was consulted.

The solution: Turbo technology for efficient aeration

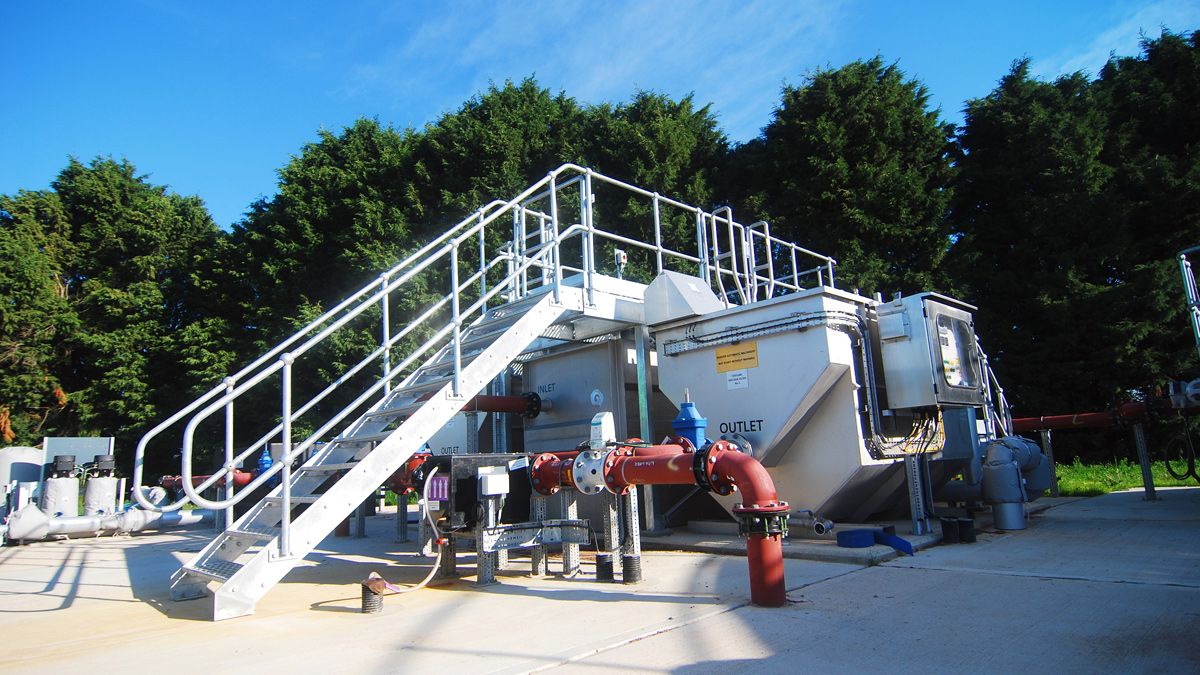

For this replacement a detailed calculation of profitability showed a potential energy saving. All three blower units were showing significant signs of wear. Therefore, instead of an extensive and costly refurbishment, it was decided that these old units should be replaced with three new efficient AERZEN Turbo Blowers.

- AERZEN consulted with the company Air Technology to determine the current load requirement. A detailed profitability calculation indicated energy savings of over 20%.

- AERZEN supplied 3 Turbo G5plus blowers (3 x AT150 0.8S DN250), which modernised the plant as they replaced the competitor’s aging blowers that were consuming a lot of energy.

- While these works were going on, the client involved AERZEN Rental to avoid downtime, who supplied the end user with 2 BVO 55000 skid mounted assemblies.

| Type of technology | Turbo blower | Overpressure | 1,000 mbar |

| Version | Positive pressure | Conveying media | Air, neutral gases |

| Volumenstrom | 360 to 8,400 m3h | Conveying | oil-free |

Courtesy of AERZEN Machines

The result: Modern technology used to reduce CO2 emissions

The space-saving installation of the new turbo technology from the G5plus series enables an efficiency gain of approx. 21% for the aeration of wastewater tanks which ultimately leads to savings in operating costs.

Additionally, in comparison to the earlier ventilation systems, the noise emissions were significantly decreased.

Summary

This wastewater treatment facility can save over £21.000 by utilising state-of-the-art technology, the AERZEN Turbo G5plus blower. AERZEN had a 4-week lead time. The calculation assumes an amortisation period of about three years. The cost and energy savings coincide with the customer‘s desire to reduce their carbon footprint.

Ian Moore, Technical Director, Air Technology, commented:

“It’s looking like a really good installation, and it is much quieter and more efficient than the old system.”

For more information: AERZEN Machines | +44 (0)208 502 8100 | www.aerzen.com