AUMA Actuators Limited

The Cromford Waterpower Project

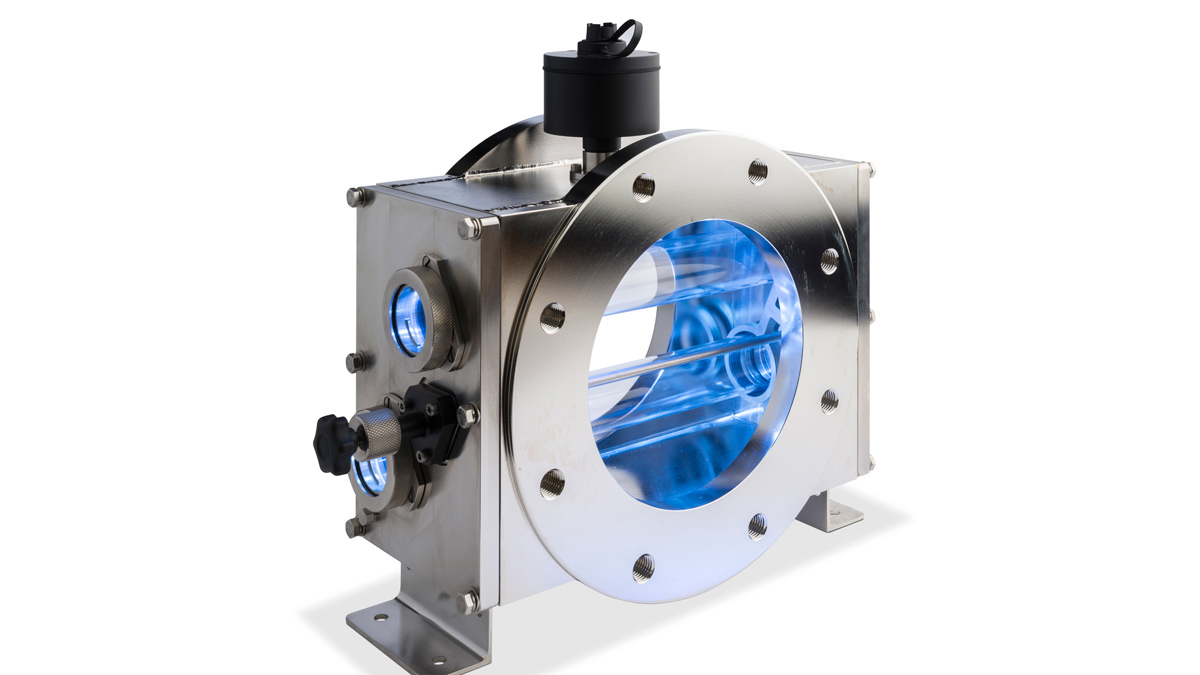

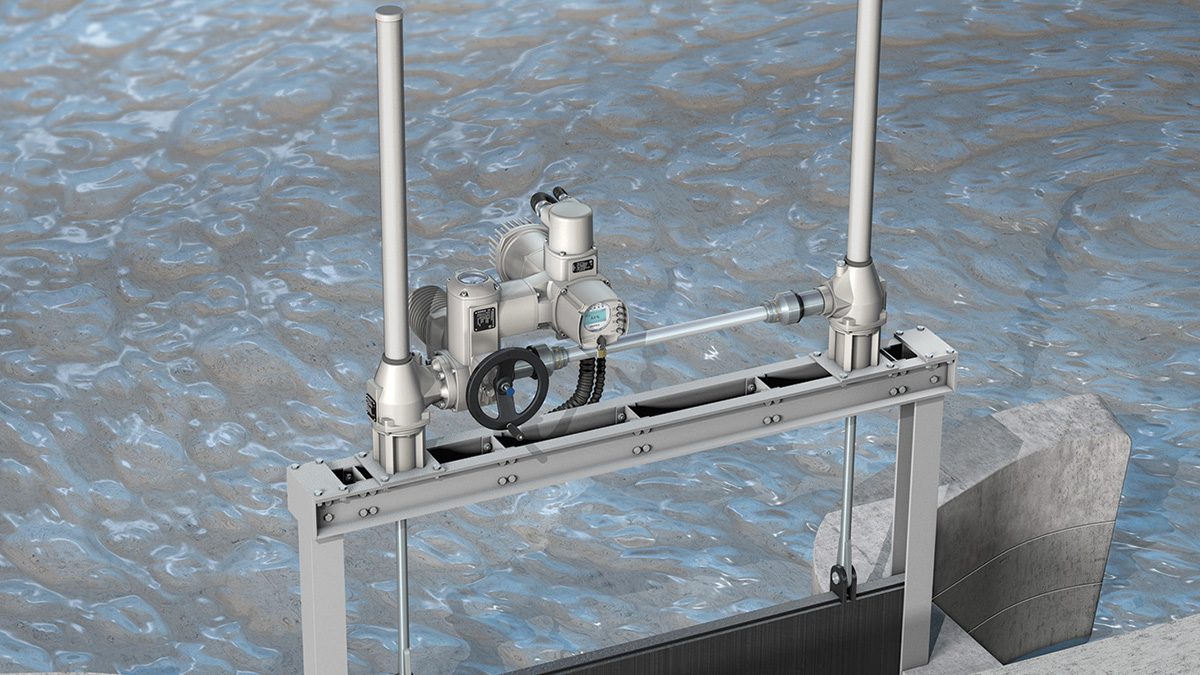

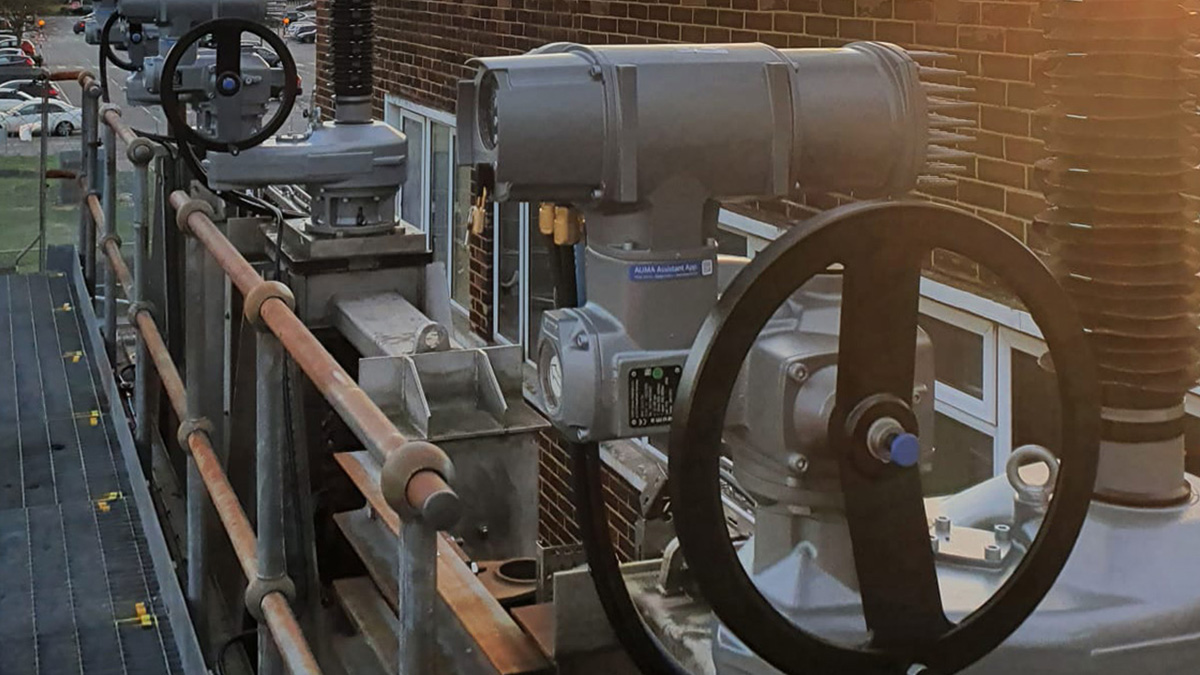

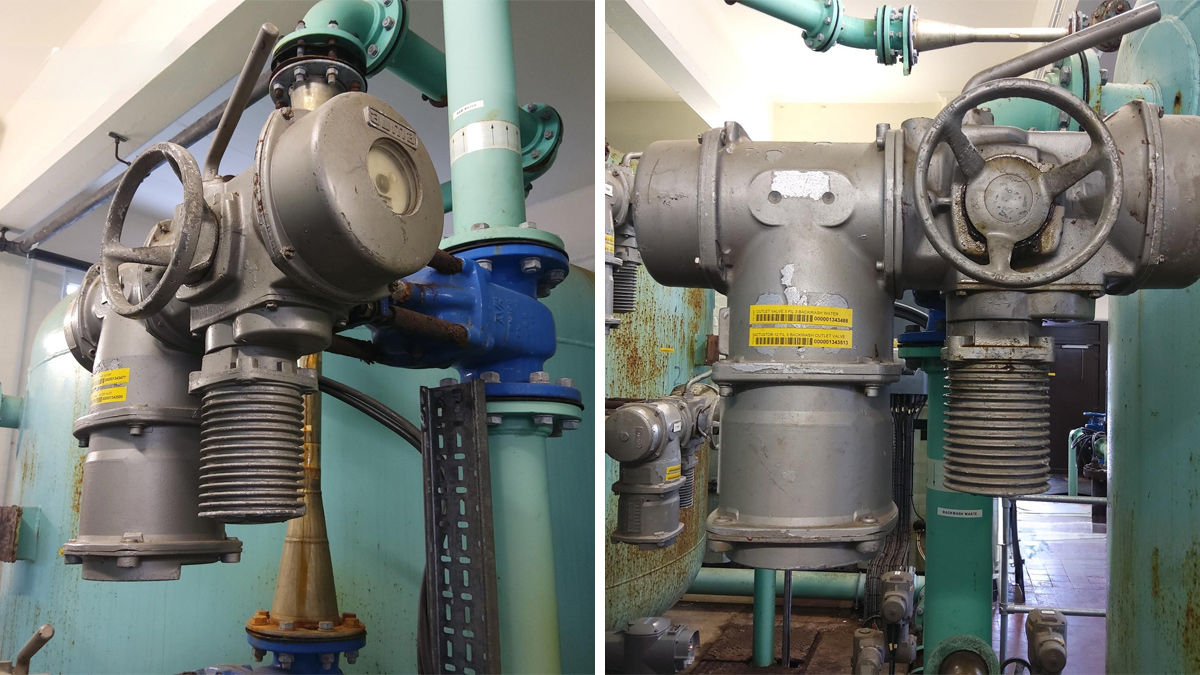

An AUMA SA07.6-F10 actuator in action at Cromford Mills Derbyshire

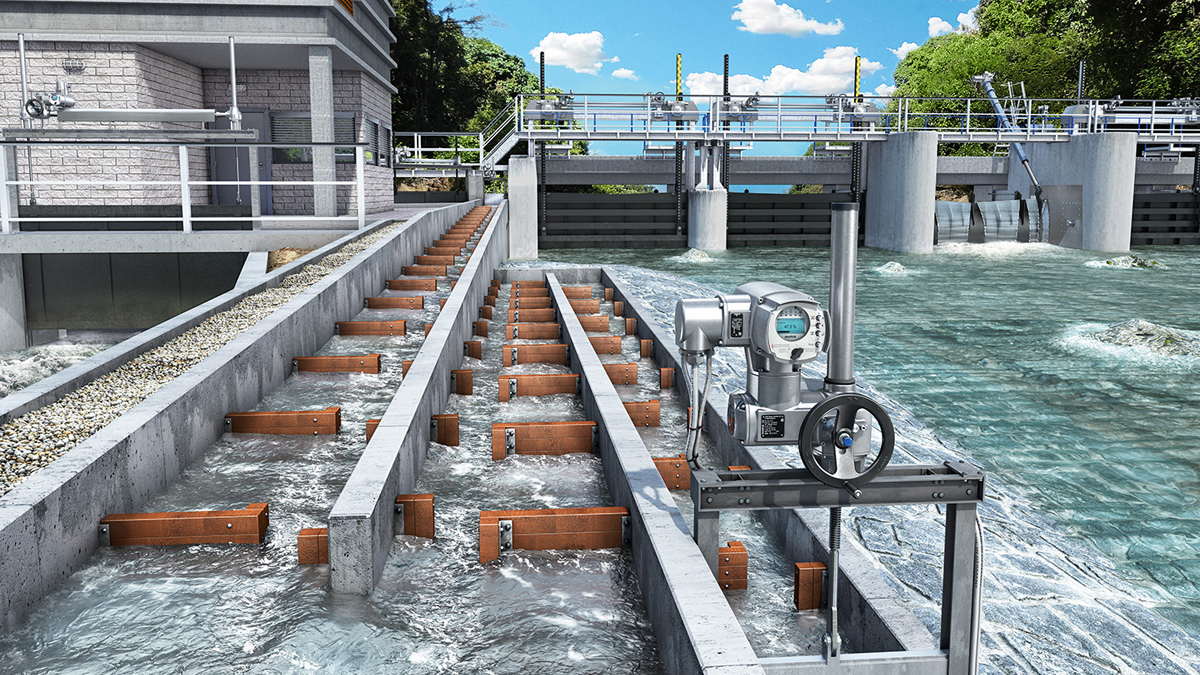

Cromford Mills in Derbyshire, built in 1771 by Sir Richard Arkwright, is returning water power to the popular tourist attraction located in the Derwent Valley Mills UNESCO World Heritage site thanks to an innovative hydropower project that uses AUMA actuators to control water flow to a newly installed hydro turbine.

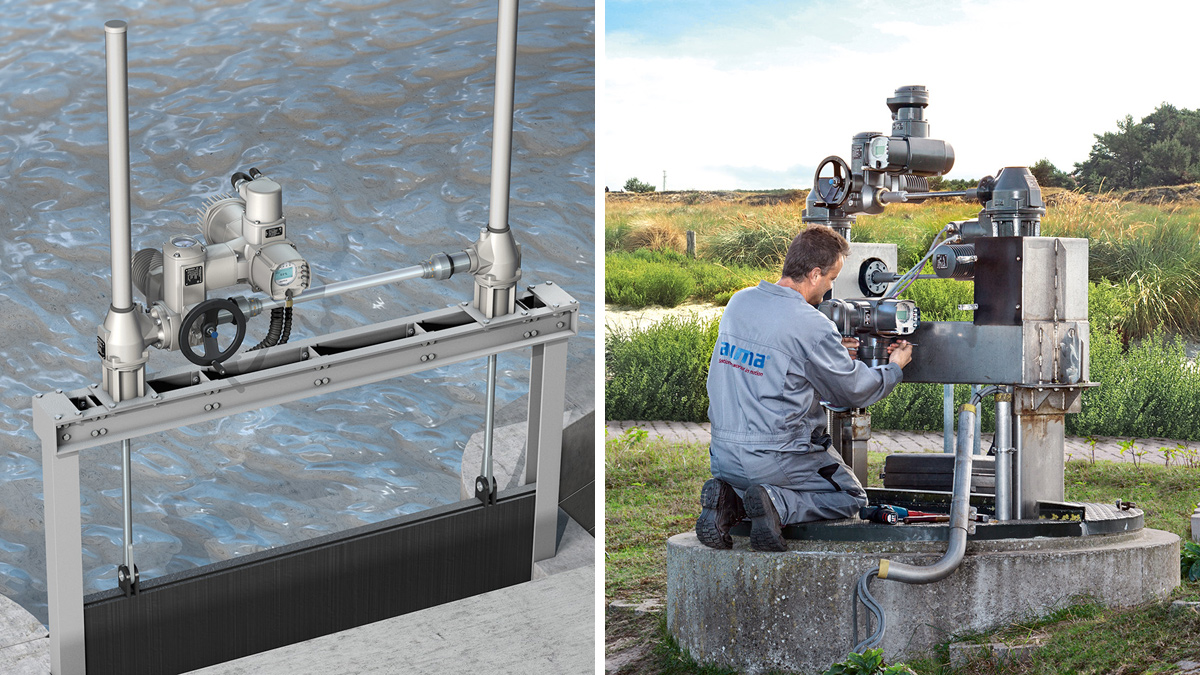

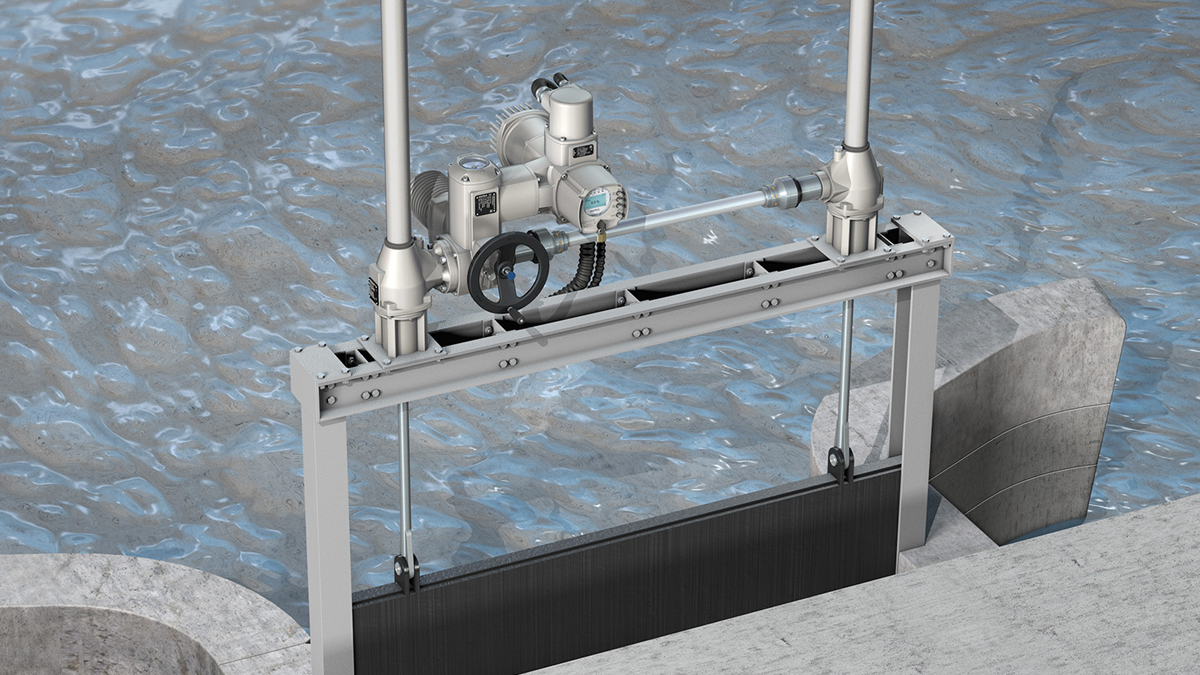

AUMA Actuators Limited, part of global actuator manufacturer AUMA Group, supplied site contractor Derwent Hydroelectric Power Ltd (DHPL) with a SA07.6-F10 actuator that is used to raise and lower the sluice gate controlling flow to the project’s 15kw Gilkes Francis turbine, originally manufactured and installed in 1957 and refurbished by DHPL. The water powering the turbine is drawn from the local Bonsall Brook, via the mill pond, which then feeds into Cromford Mill via a mill watercourse that has been desilted as part of the site’s overall restoration project.

Paul Hopkins is managing director of AUMA Actuators Limited in Clevedon near Bristol. He says:

“It’s extraordinary to think that this site is where the industrial revolution all started over 250 years ago. And it used water as its source of power. So it’s only fitting that hydro electric power will be providing energy security to the site for the next 250 years.

“Whilst AUMA’s actuator is only playing a small part in this, it’s an important role as controlling the rise and fall of the gate regulates the flow to the refurbished Gilkes Francis hydro turbine, which is key to its safe operation and the generation of energy for the heritage site.”

The Cromford Waterpower project has reinstated a large six metre waterwheel and installed a 15kW hydro-turbine to power the mill buildings. The scheme also includes water source heat pumps to provide heating to the site.

Paul Jardine, Hydroelectric Development Engineer, DHPL, adds:

“We are in the process of putting the finishing touches to this incredible project, which will see water power return to this unique World Heritage Site. The AUMA actuator fulfils a key role in controlling the water flow from the mill watercourse to the hydro turbine. It can be controlled remotely, using AUMA’s smart app, which means we are able to respond quickly to changes in water levels by raising or lowering the sluice gate accordingly. That saves time and resources all round.”

Éilis Scott, Chief Executive, Sir Richard Arkwright’s Cromford Mills, says:

“This project is a remarkable initiative to reinstate waterpower at Cromford Mills, which was the birthplace of the modern factory system and the first successful water-power cotton spinning mill in the world. As part of our drive to transform Cromford Mills into a more sustainable and greener site, we hope this project will spark more interest in sustainable energy sources and inspire people working on other heritage sites to play a part in shaping the future of our world.”

This project has been made possible by the many funders and partners. Derbyshire County Council’s Green Entrepreneurs Fund, Severn Trent Community Fund, , The Wolfson Foundation, Valliant, the Rural Community Energy Fund, DHPL, Gilbert Gilkes & Gordon Ltd, and James Boon Architects, and many others have supported Cromford Mills in the return of hydro power to the local area.

For further information about the project visit www.cromfordmills.org.uk/hydro-power-project/.

For more information contact AUMA Actuators Ltd | +44 (0) 1275 871141 | www.auma.co.uk

About AUMA Actuators Limited

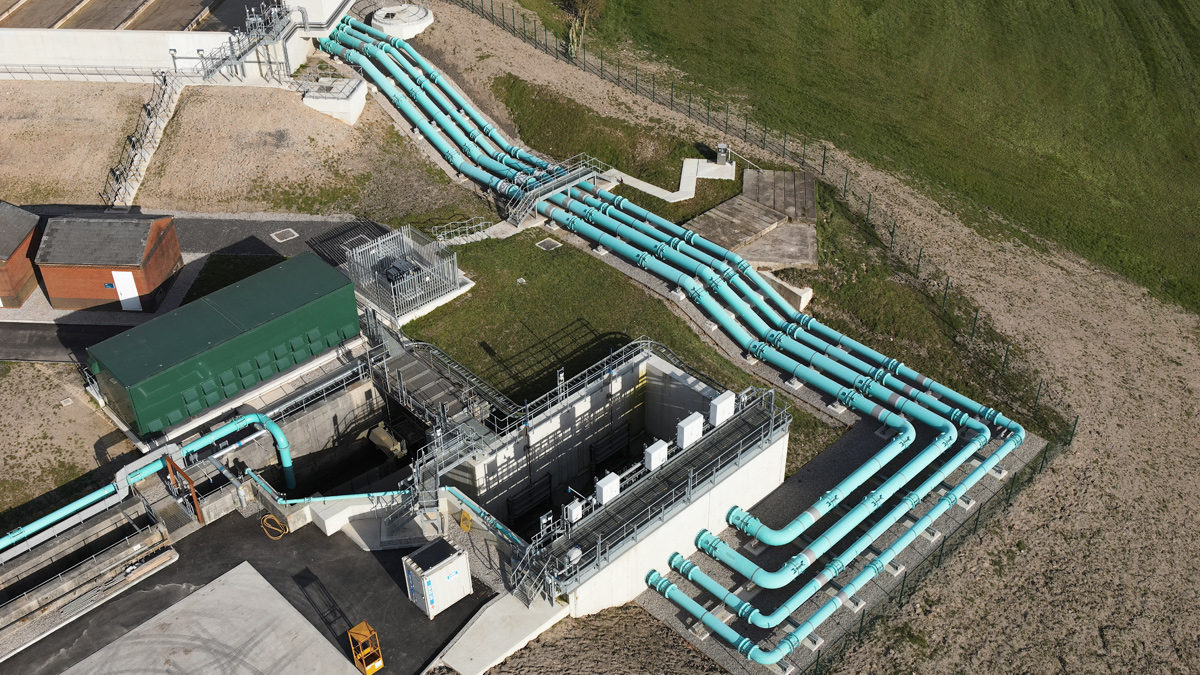

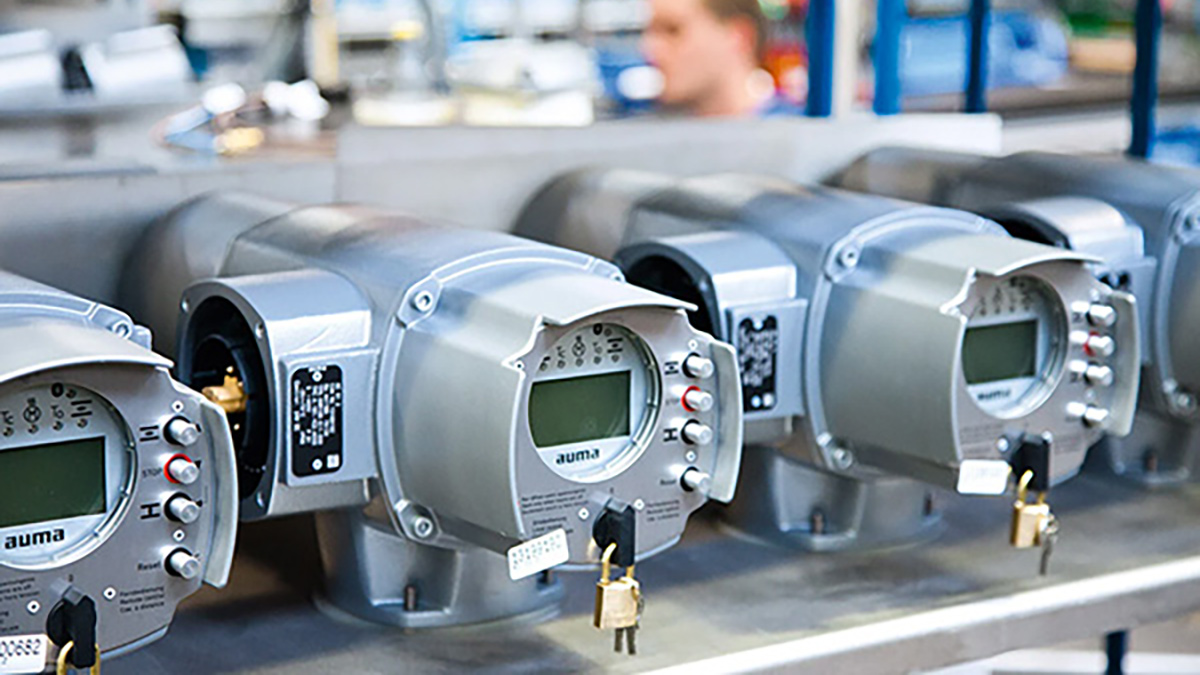

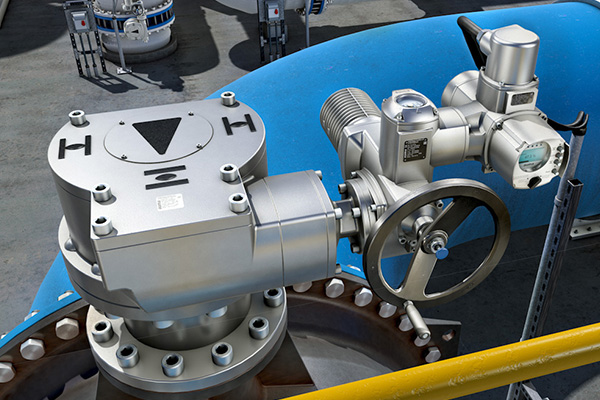

Based in Clevedon, near Bristol, AUMA Actuators Limited is the UK subsidiary of the global AUMA Reister GmbH and Co., the world’s largest manufacturer of electric valve actuators, operating on every continent, with 2,300 employees in 30 locations.

AUMA is the world leader in modular electric valve actuators and gearboxes, supplying a full range of actuators right across the process, water, petrochemical and energy sectors. AUMA manufactures robust, reliable equipment with sophisticated control and connectivity options, backed up with exceptional service support.

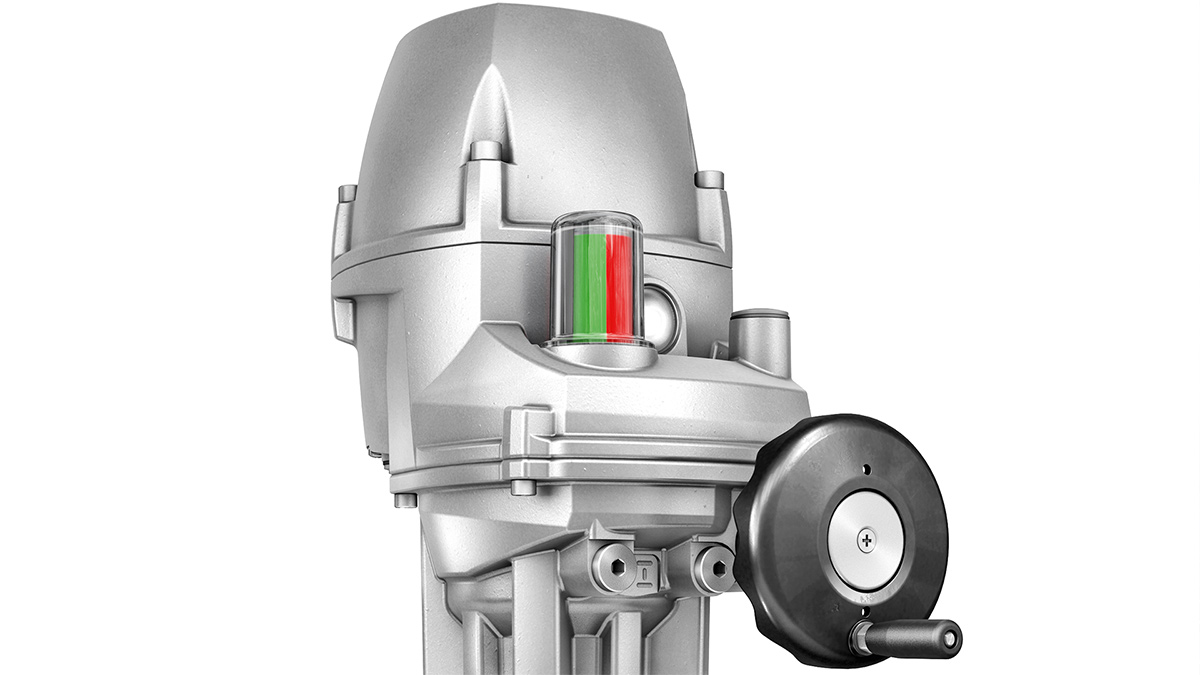

AUMA benefits include:

- Rugged and reliable products.

- Double-sealed actuator housing to protect the electronics.

- Tough and resilient finish.

- Powerful, with multi-turn actuators from 7 to 59,000 ft lb (10 to 80,000 Nm) and thrust acceptance up to 900,000 lbs (4,000 kN) and part-turn actuators from 18 to 498,000 ft lb (25 to 675,000 Nm).

- Worldwide availability and support.

- Modular, user-friendly design.

An AUMA SA07.6-F10 actuator in action at Cromford Mills Derbyshire