AUMA Actuators Limited

AUMA Actuators Wins 2-Year Service & Actuator Repair Framework with United Utilities

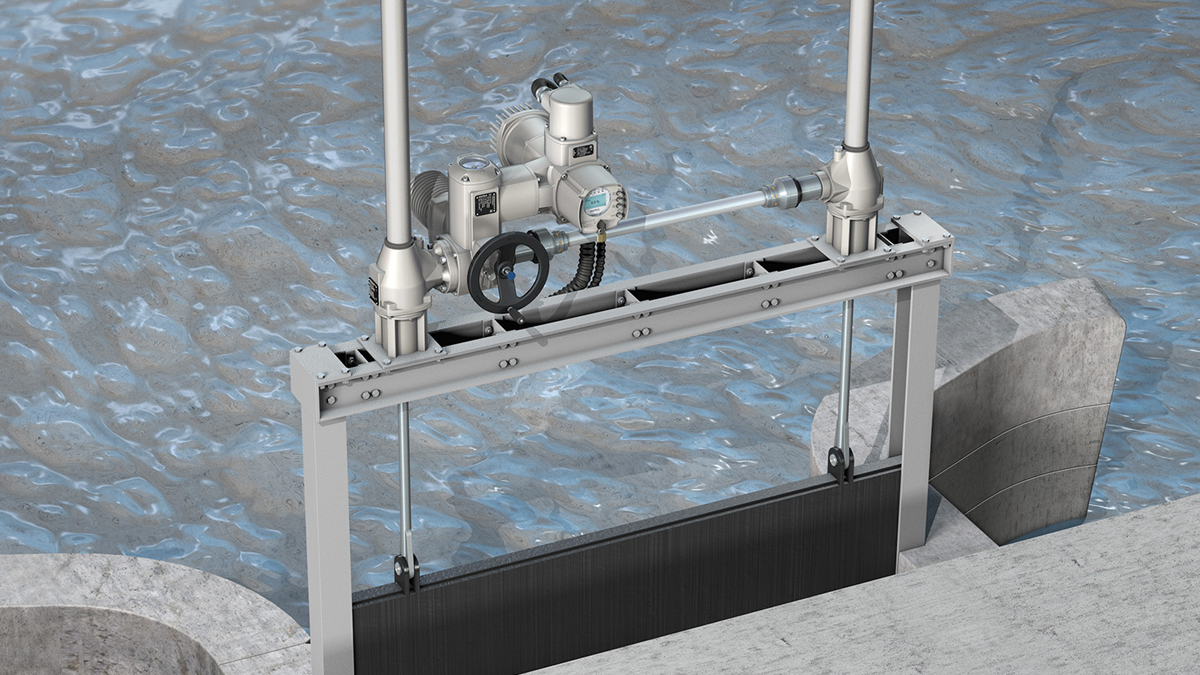

Courtesy of AUMA Actuators Limited

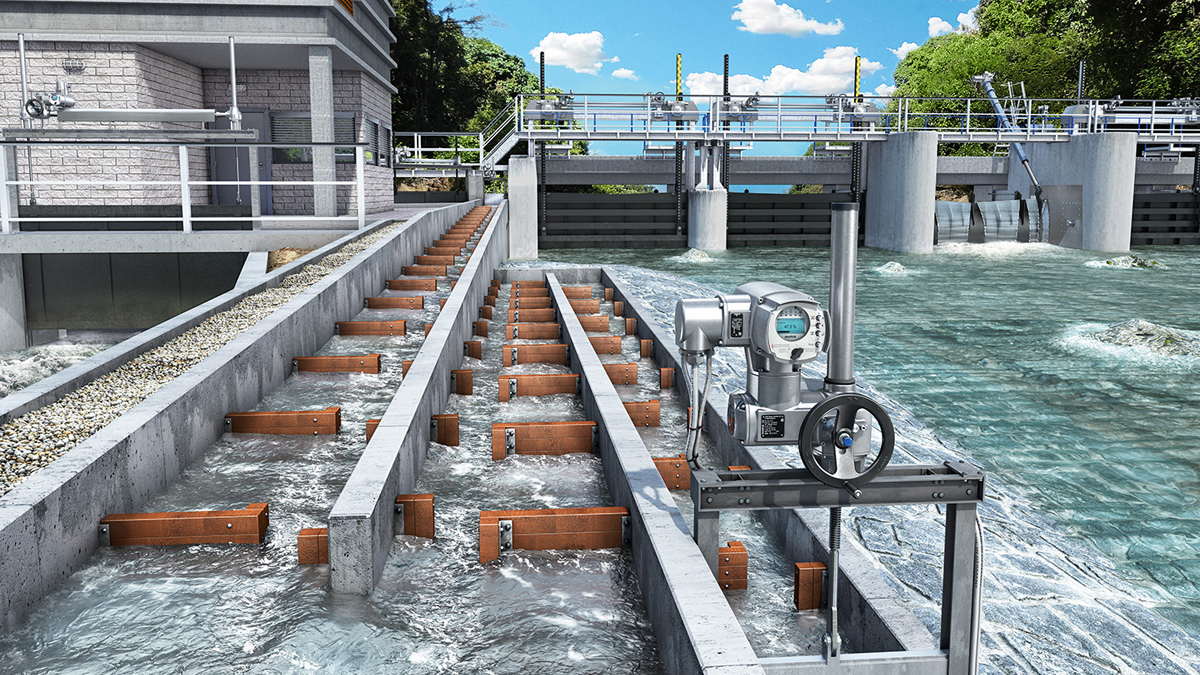

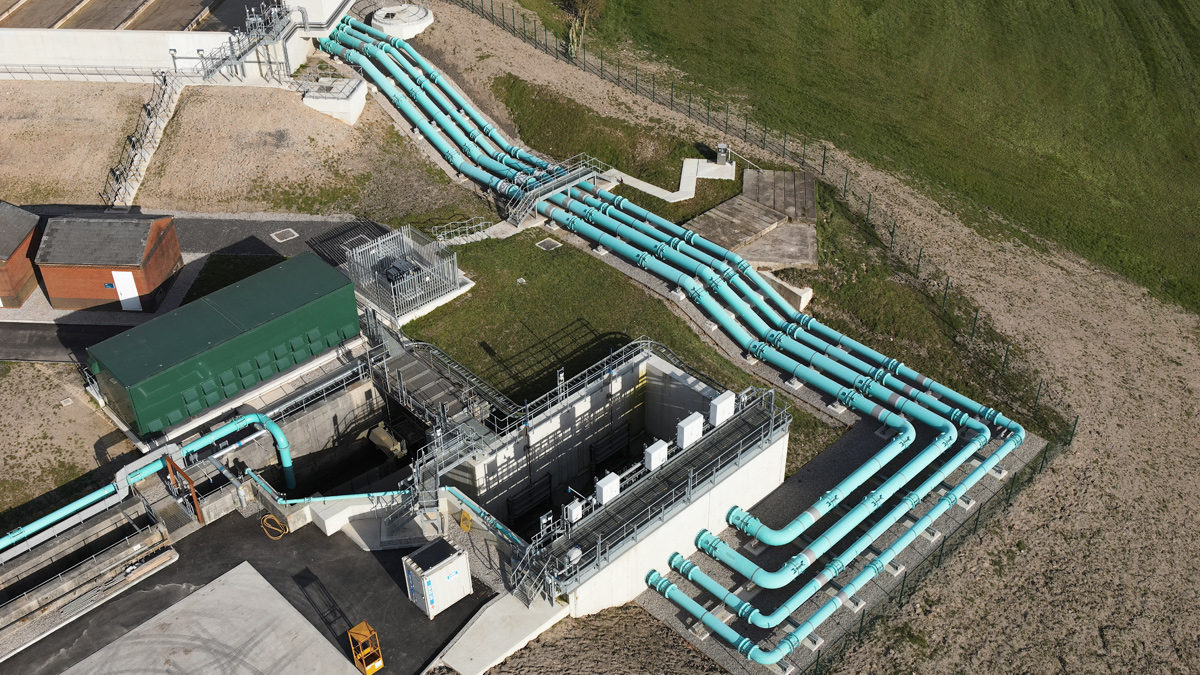

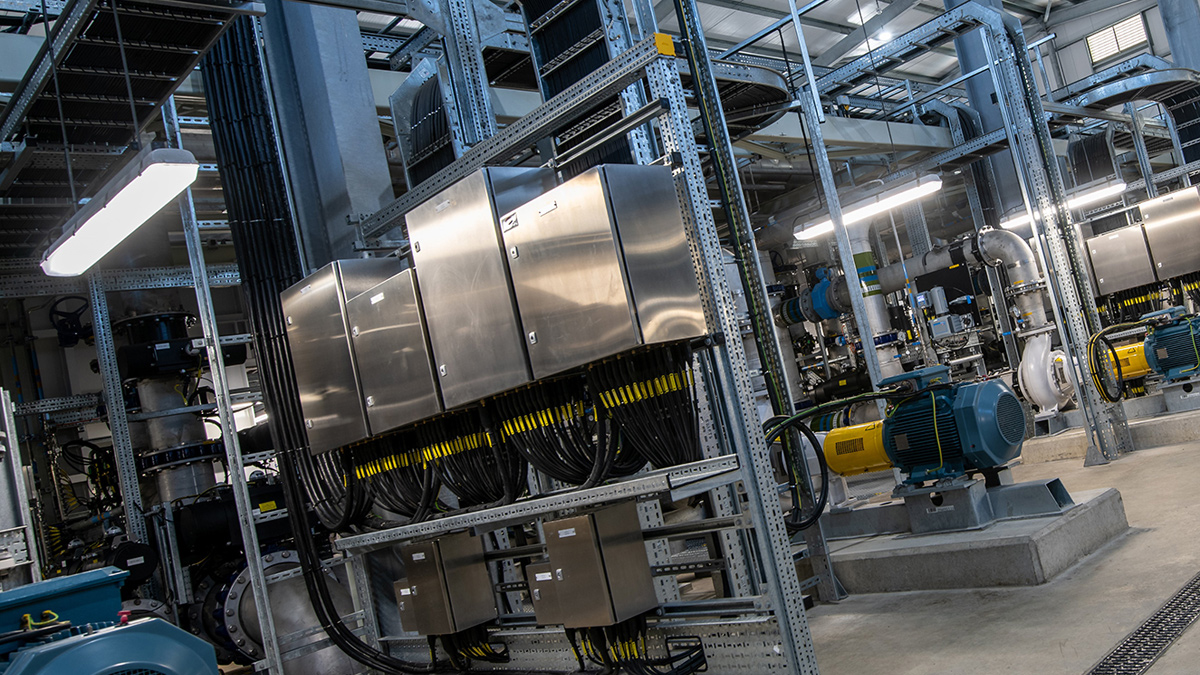

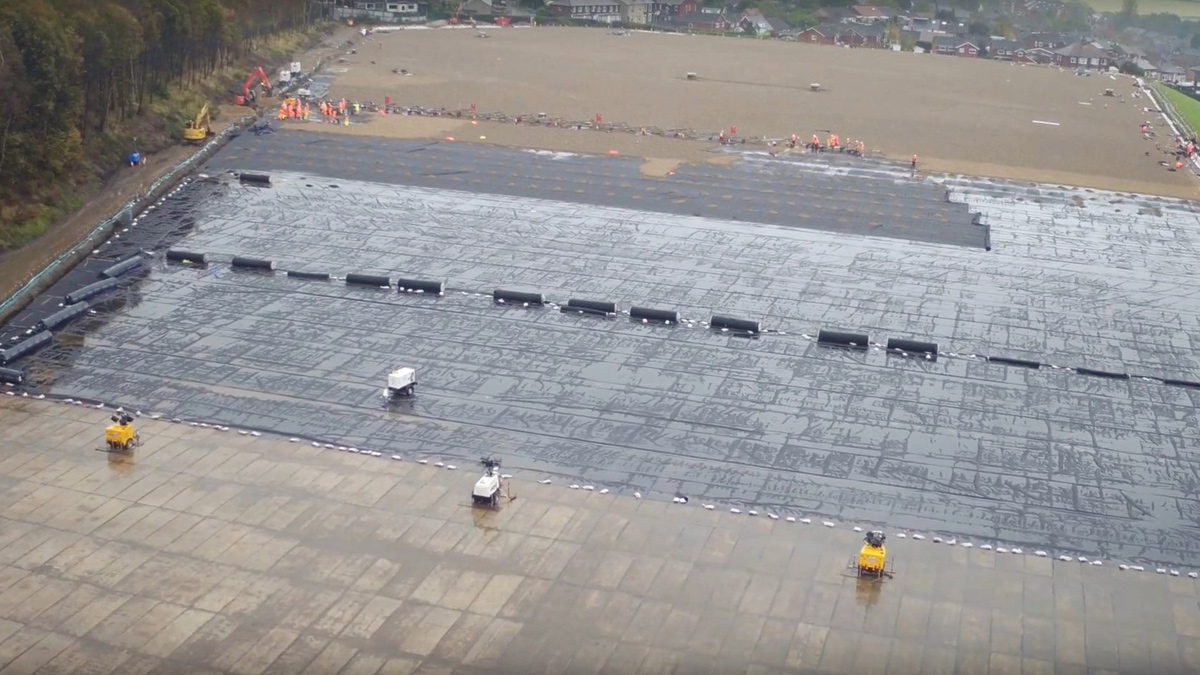

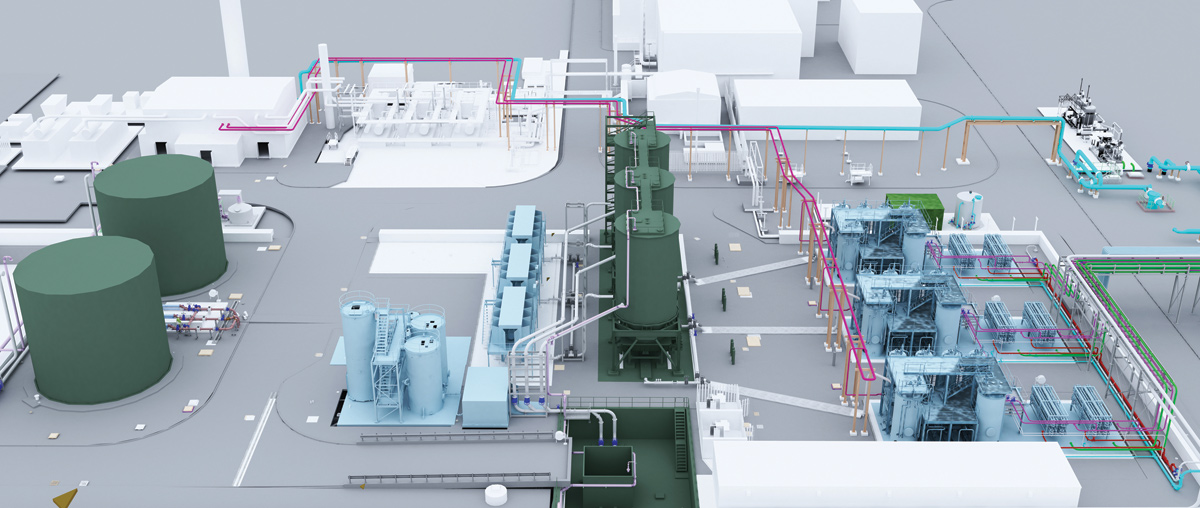

United Utilities delivers 1.8 billion litres of water a day to more than three million homes and businesses across the North West. A two year framework for actuator service and repair has been won by AUMA Actuators Limited (AUMA UK), a world leader in electric valve actuation technology, following a competitive tendering process issued by water and wastewater services provider United Utilities.

Paul Hopkins, Managing Director, AUMA UK, says:

“AUMA is well placed to deliver this prestigious framework. As part of the AUMA Group, we are able to leverage our strong European manufacturing and logistics capabilities, combined with our comprehensive local component stockholding, to provide fast turnaround on all repairs.

“United Utilities is committed to reliability-centred maintenance, increasing the availability of critical assets, whilst at the same time reducing the costs associated with reactive maintenance. This aligns perfectly with AUMA’s approach to condition-based monitoring and maintenance. As the framework progresses we will work closely with United Utilities to achieve these goals.”

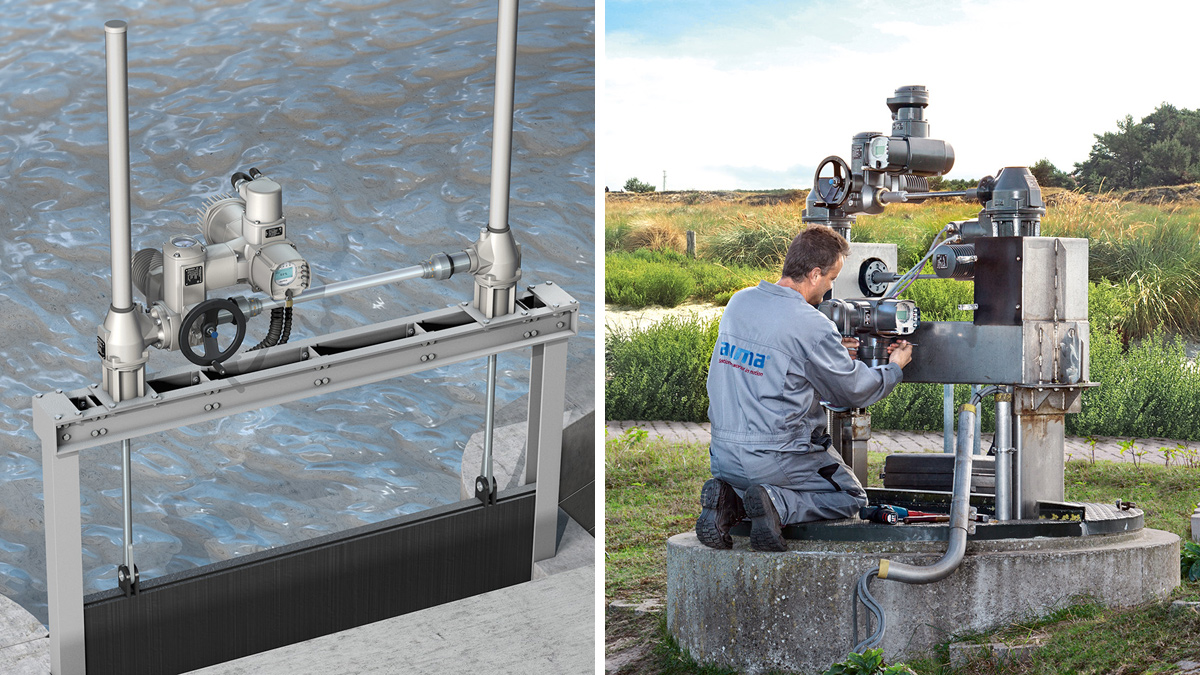

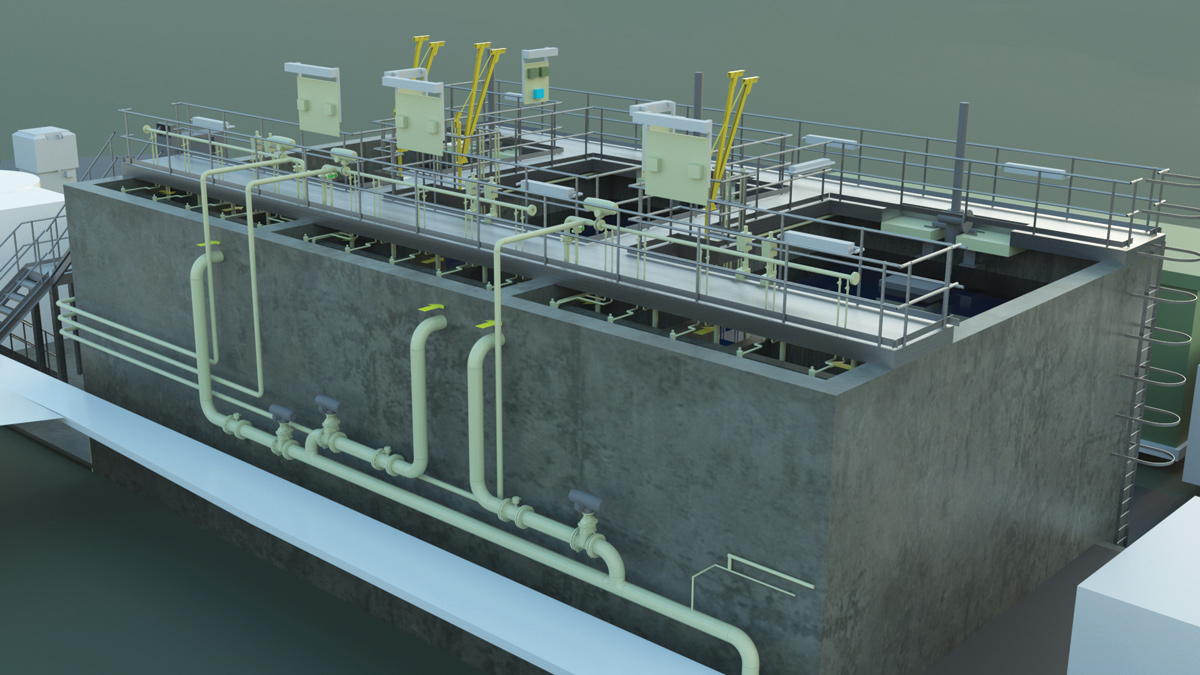

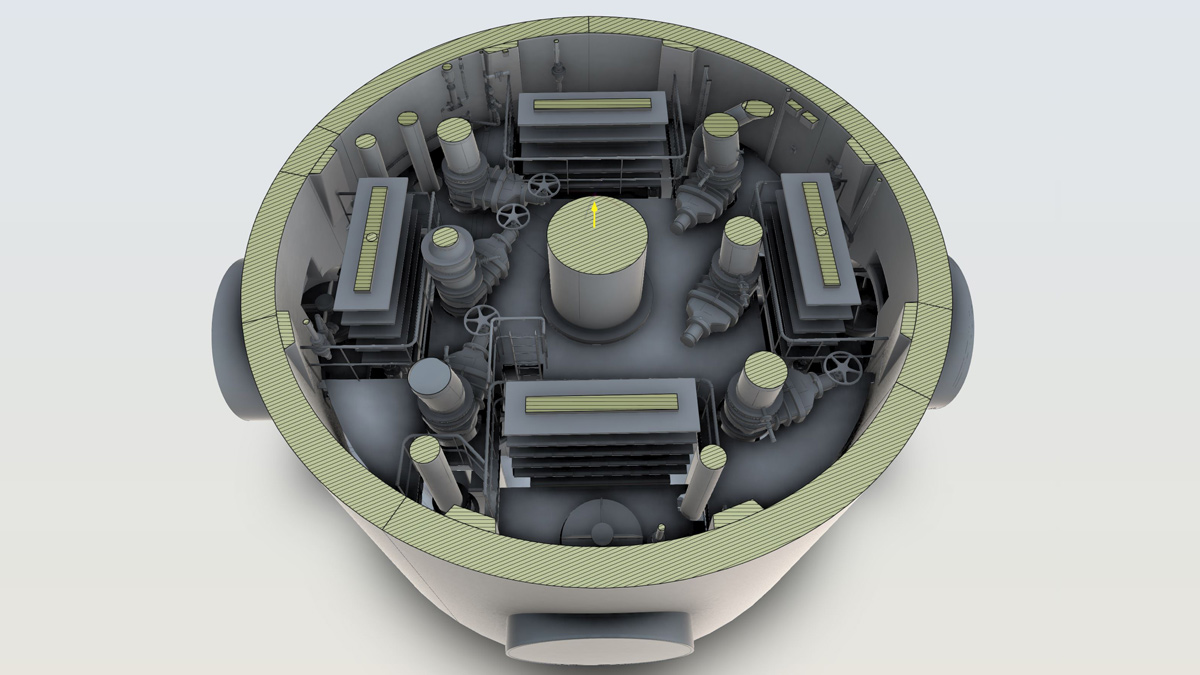

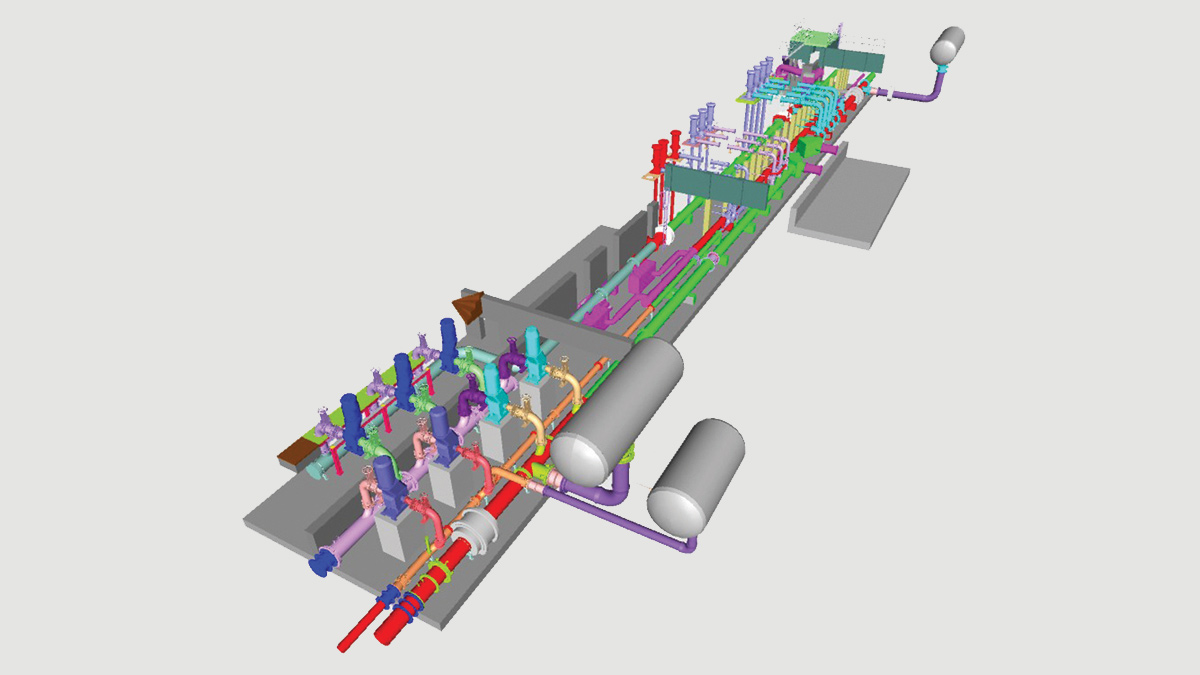

United Utilities’ Maintenance Sourcing team is dedicated to providing the best end-to-end service for engineers to enable them to return assets to service as quickly and cost-effectively as possible. AUMA’s extensive range of high performance actuators is designed using a modular approach to actuator components. Actuators can be quickly combined to provide a bespoke actuator assembly constructed to the exact requirements of applications.

Colin Borrows, Operations Manager, AUMA UK, says:

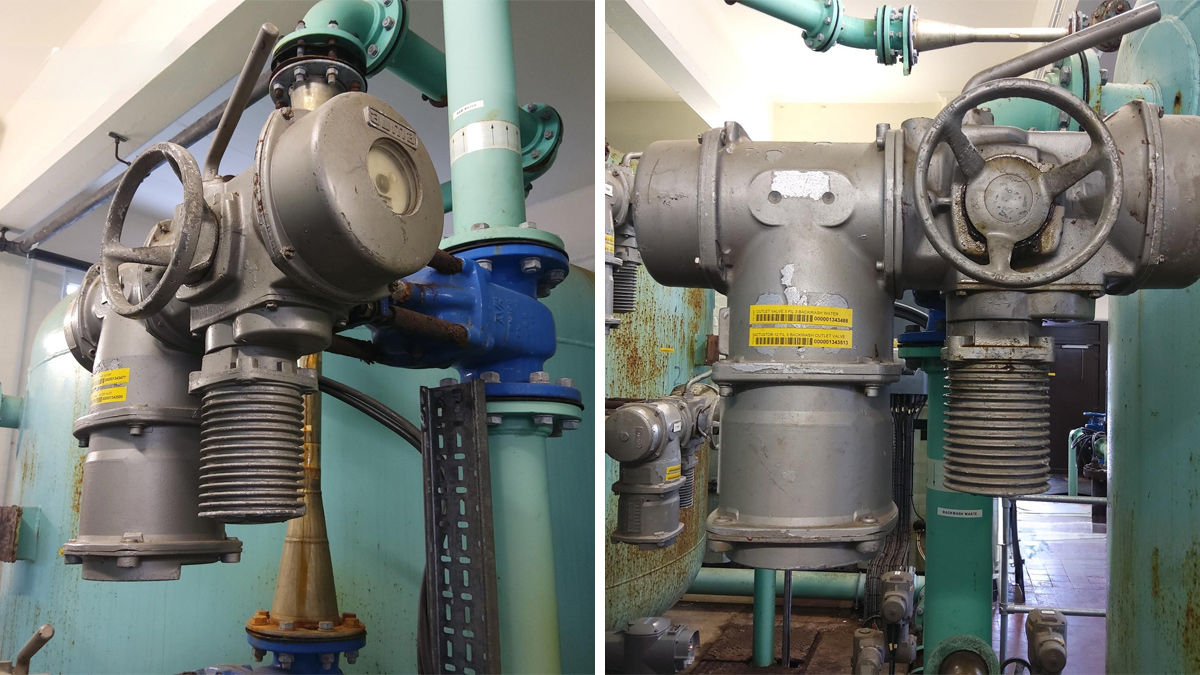

“This two year framework has a facility to extend by up to a further two years. It’s all about delivering an efficient Maintenance Sourcing service that supports United Utilities’ engineers in returning critical assets back to service.

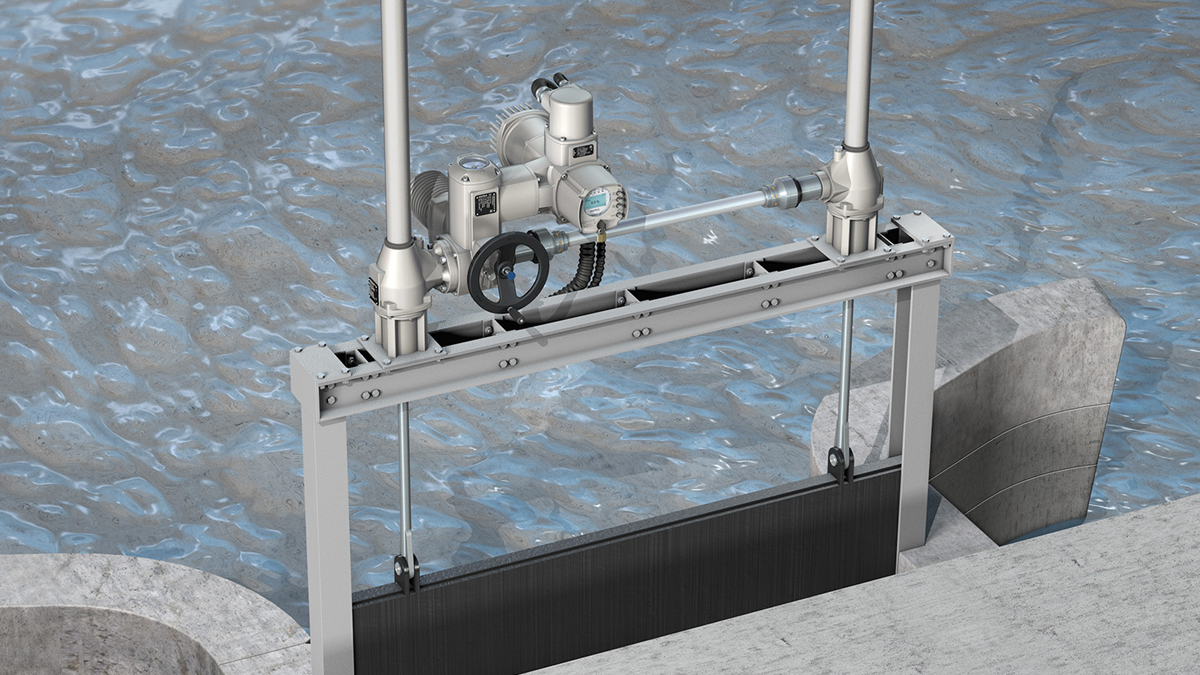

“AUMA has demonstrated its considerable technical capability and competence, in terms of disconnecting and removing actuators from valves and penstocks. This, combined with our expertise in both on and off-site repair, and reinstallation, testing and commissioning makes the company an aligned partner in this important service framework.”

AUMA is also providing training to United Utilities’ maintenance staff through its AUMA Certified Engineering (ACE) training. Delivered on-site, on-line or in AUMA’s dedicated training suite at its head office in Clevedon, Somerset, ACE is a structured programme that trains technicians to install, operate, maintain and troubleshoot AUMA actuators, meeting asset management obligations to maintain equipment in line with the manufacturer’s recommendations. Accredited ACE Technicians are provided with ID cards to prove their level of competency.

For more information contact AUMA Actuators Ltd | +44 (0) 1275 871141 | www.auma.co.uk

About AUMA Actuators Limited

Based in Clevedon, near Bristol, AUMA Actuators Limited is the UK subsidiary of the global AUMA Reister GmbH and Co., the world’s largest manufacturer of electric valve actuators, operating on every continent, with 2,300 employees in 30 locations.

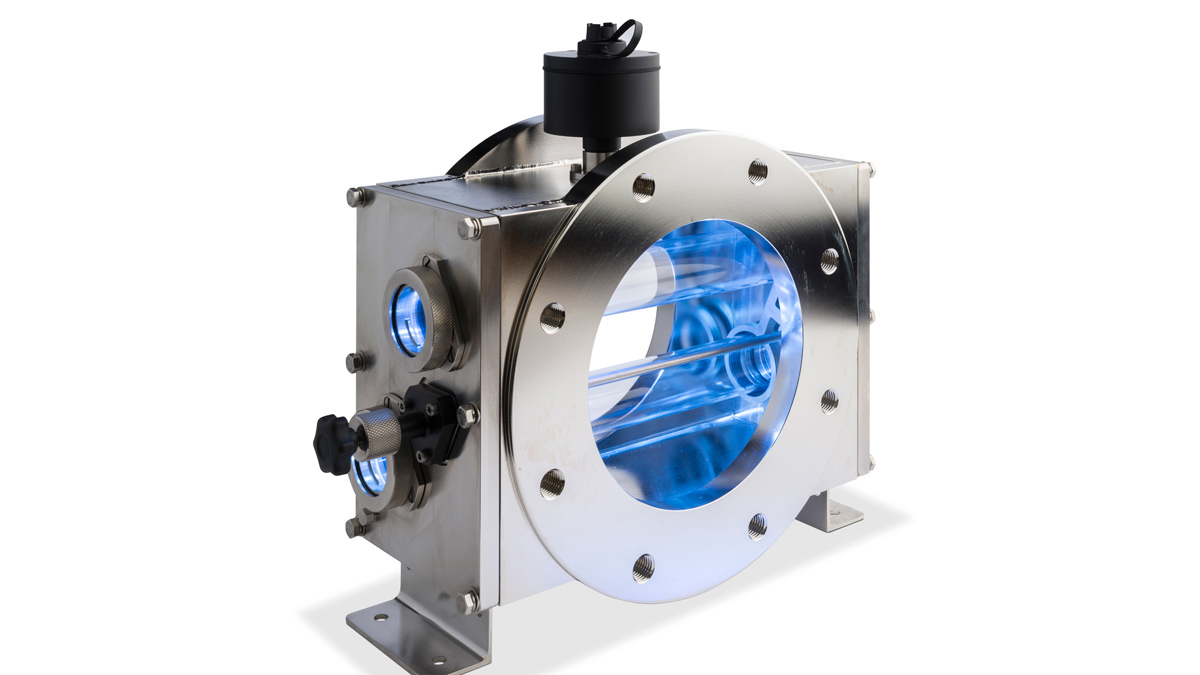

AUMA is the world leader in modular electric valve actuators and gearboxes, supplying a full range of actuators right across the process, water, petrochemical and energy sectors. AUMA manufactures robust, reliable equipment with sophisticated control and connectivity options, backed up with exceptional service support.

AUMA benefits include:

- Rugged and reliable products.

- Double-sealed actuator housing to protect the electronics.

- Tough and resilient finish.

- Powerful, with multi-turn actuators from 7 to 59,000 ft lb (10 to 80,000 Nm) and thrust acceptance up to 900,000 lbs (4,000 kN) and part-turn actuators from 18 to 498,000 ft lb (25 to 675,000 Nm).

- Worldwide availability and support.

- Modular, user-friendly design.