AUMA Actuators Limited

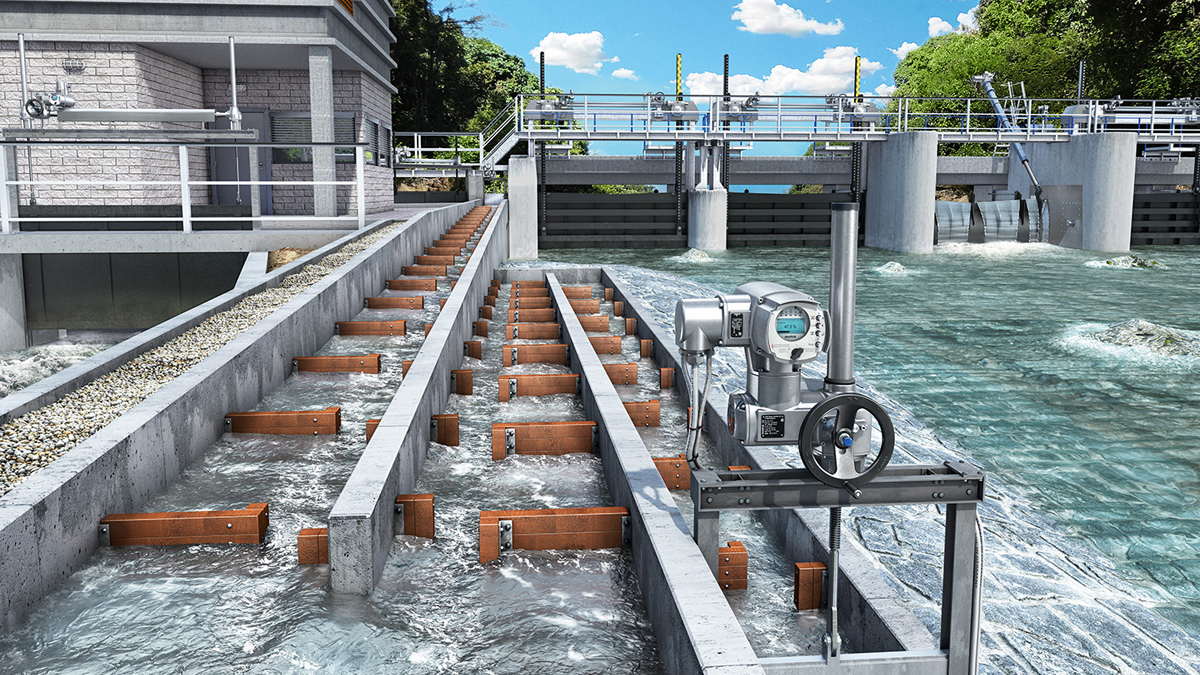

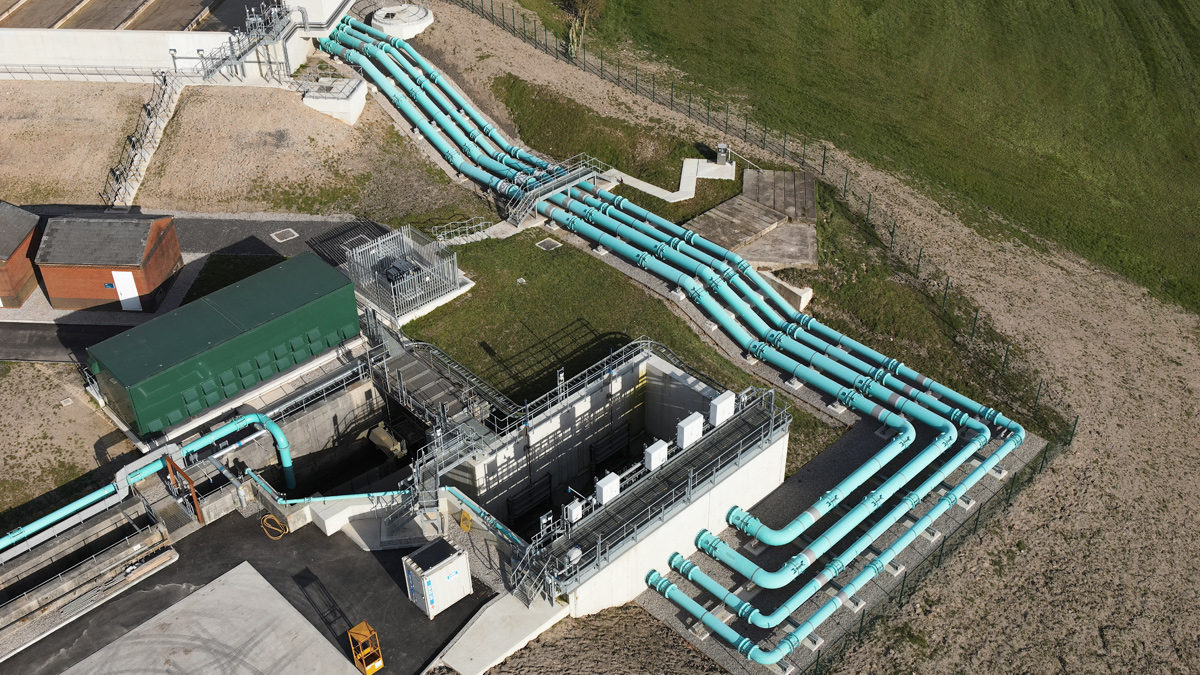

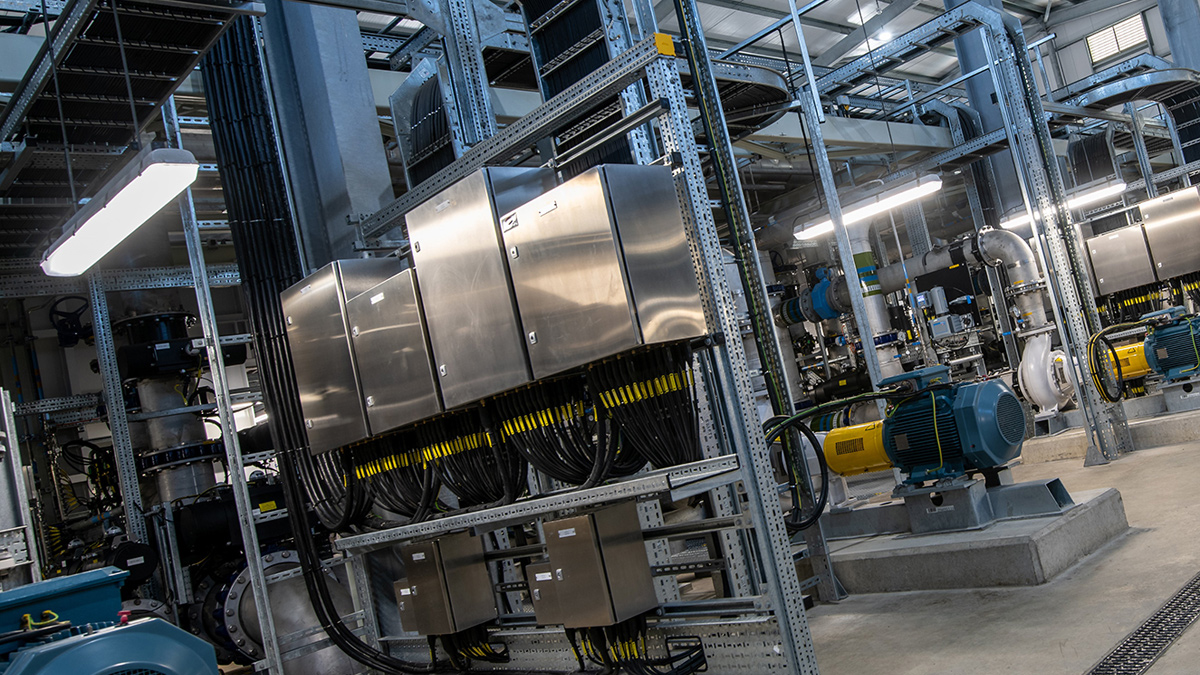

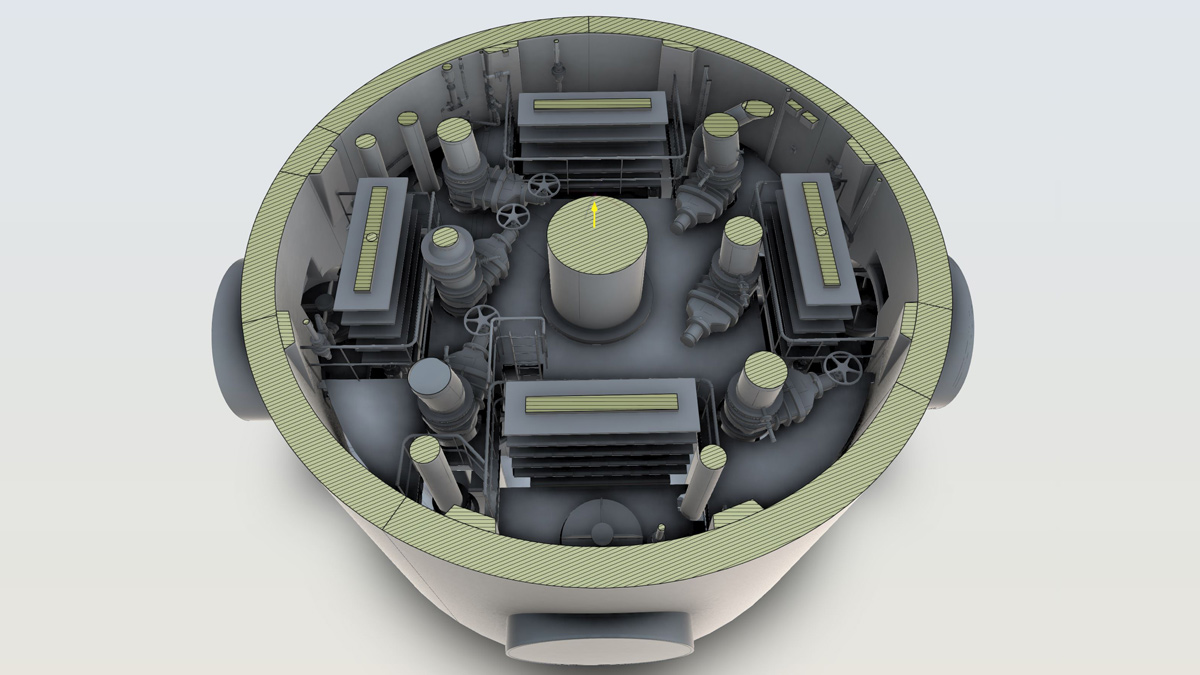

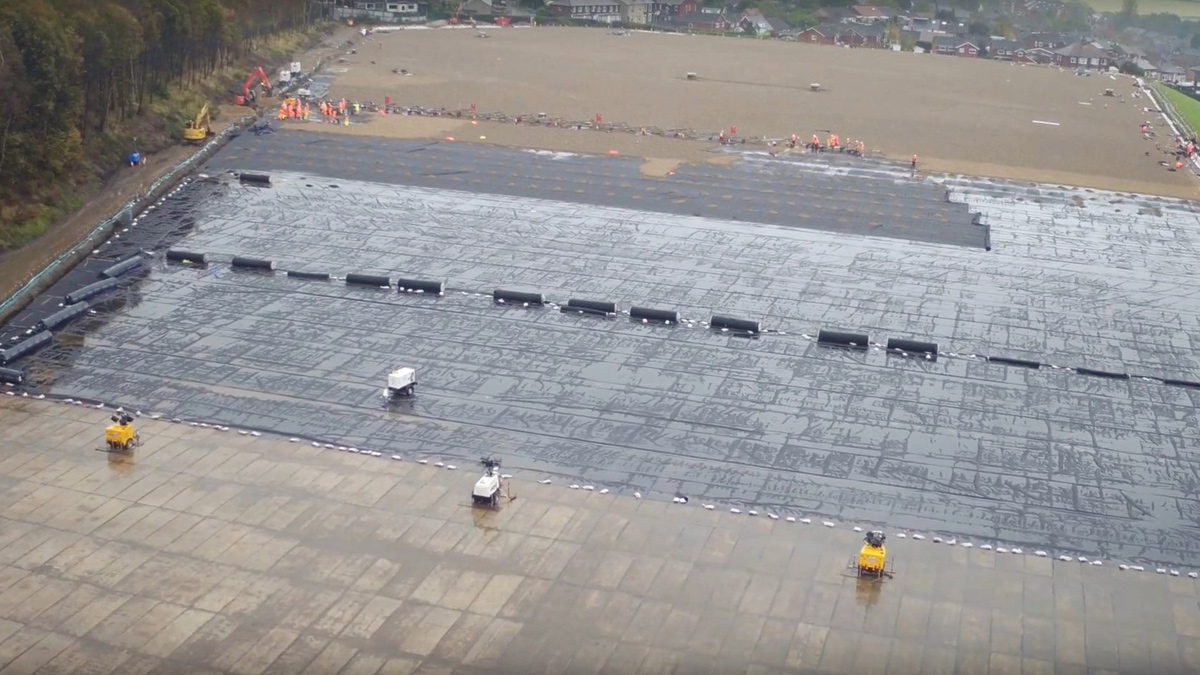

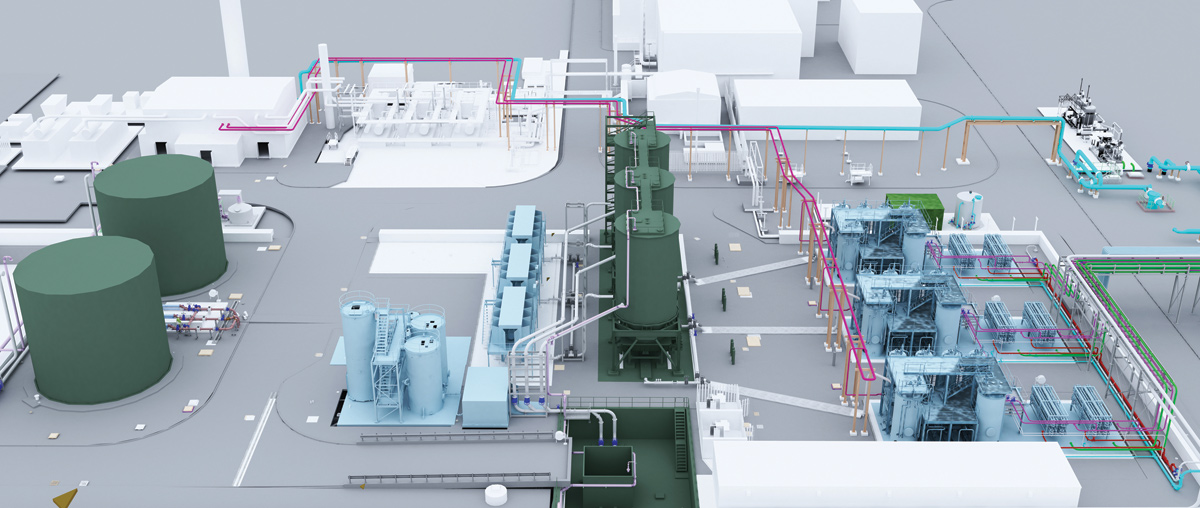

AUMA supplies, services and maintains electric actuators and gearboxes across all sectors, holding frameworks, service level and supply agreements with leading UK utility providers.

Quick quotation turnaround, excellent customer service and telephone triage combines with locally-based support. AUMA also provides FastTrack deliveries, including replacements for other actuator brands, and project installation and commissioning meeting CDM regulations.

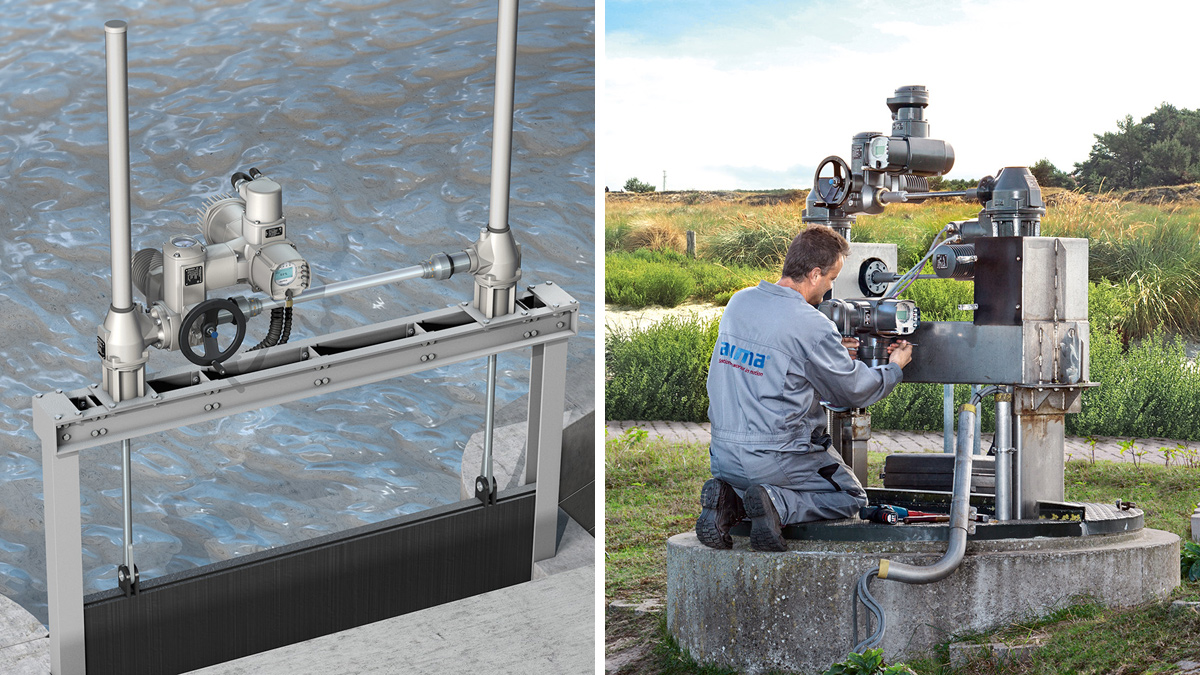

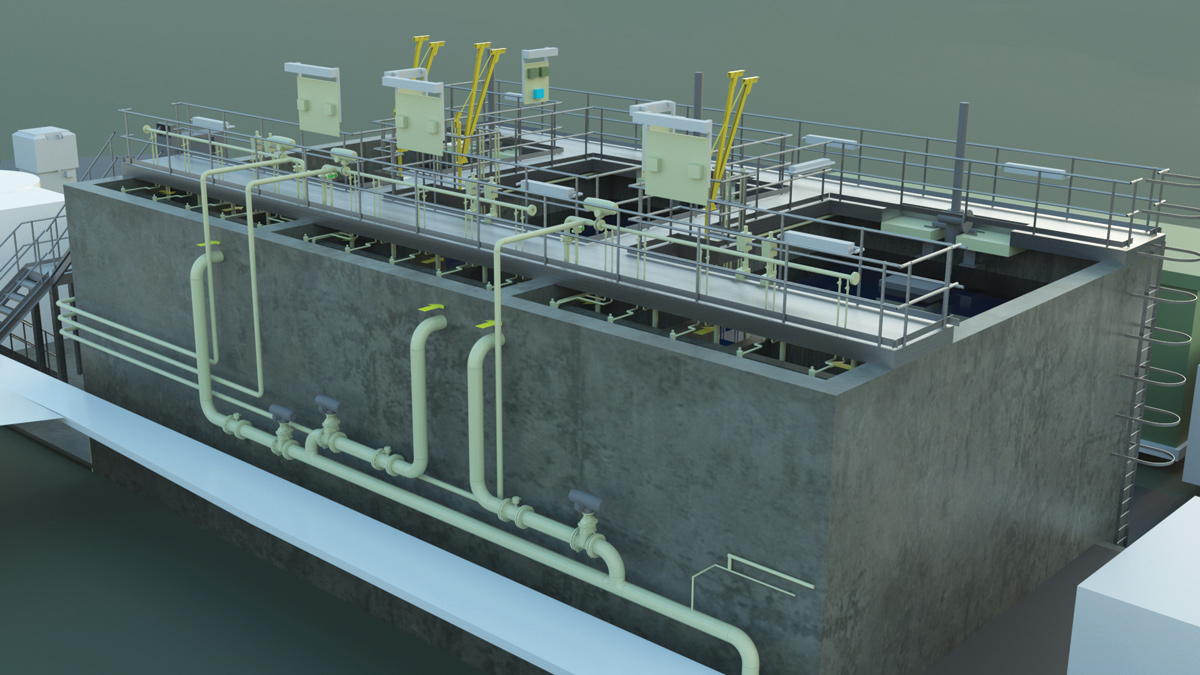

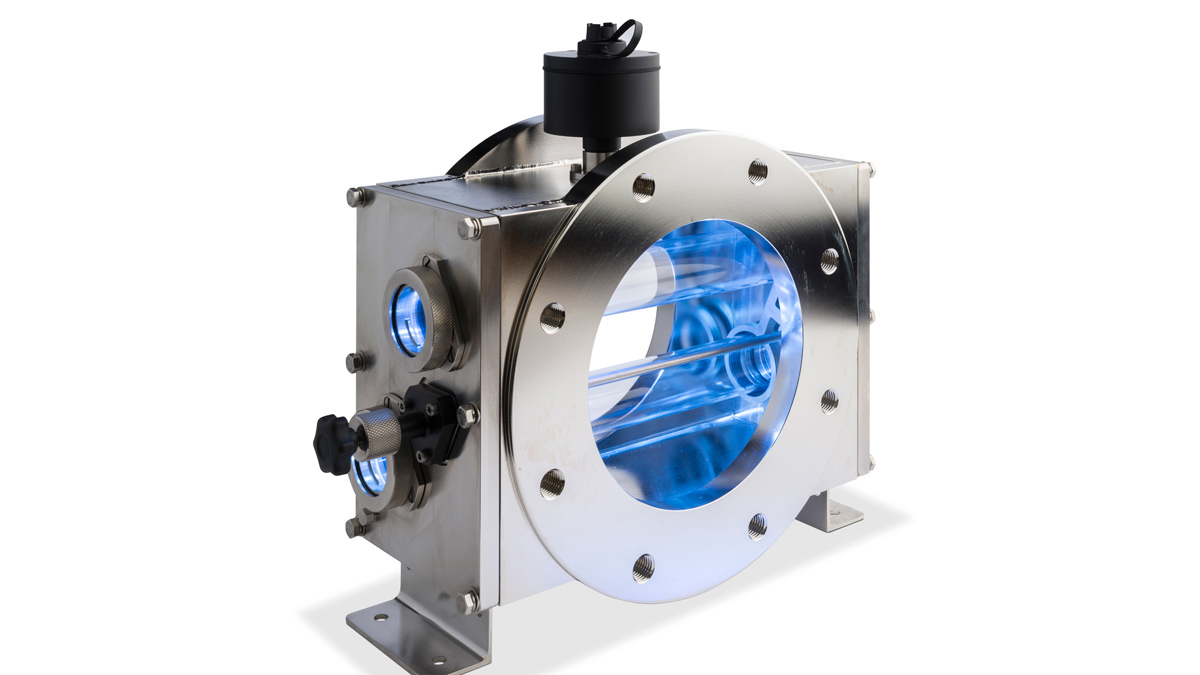

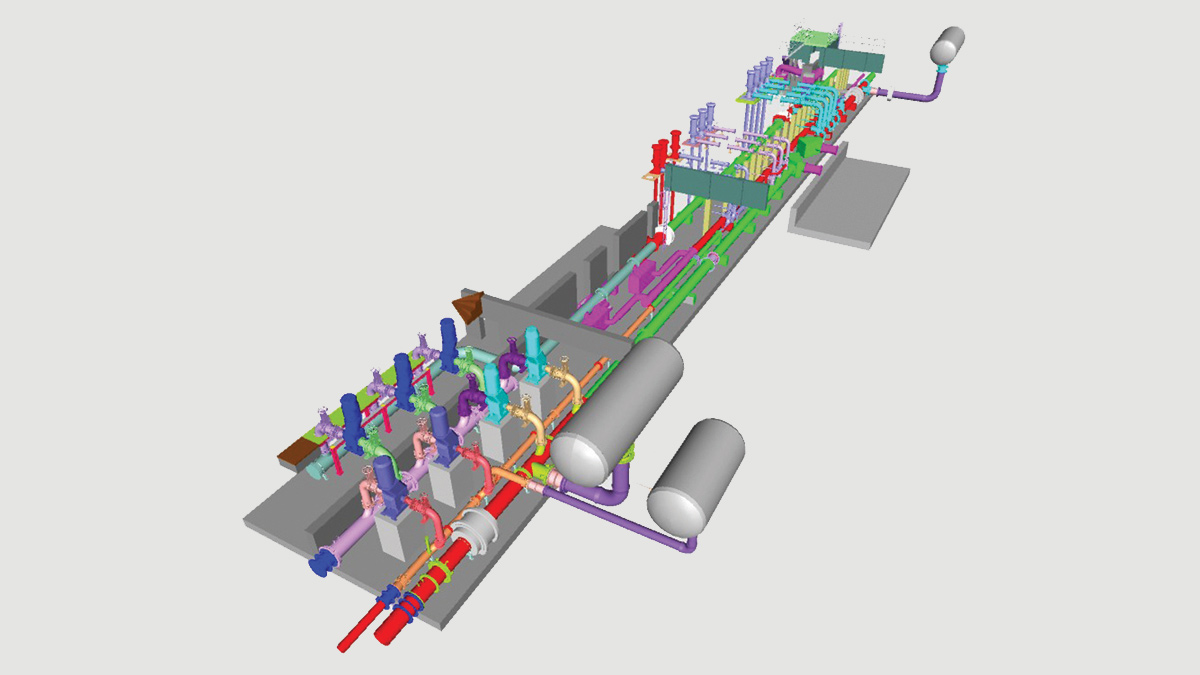

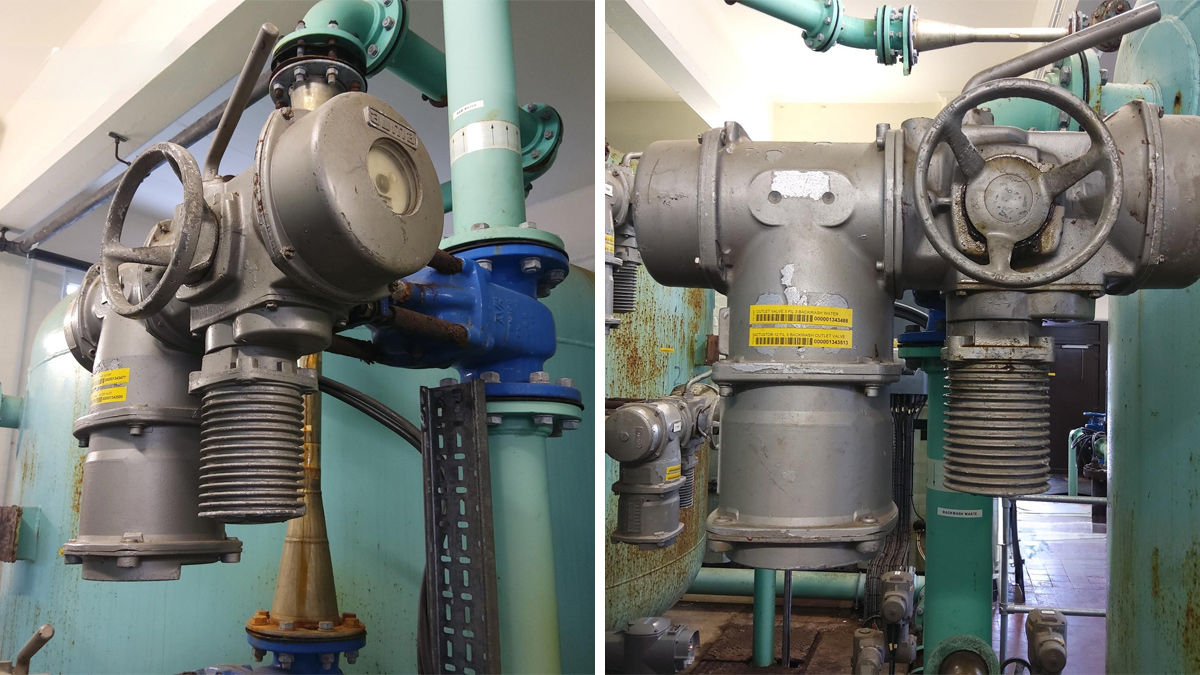

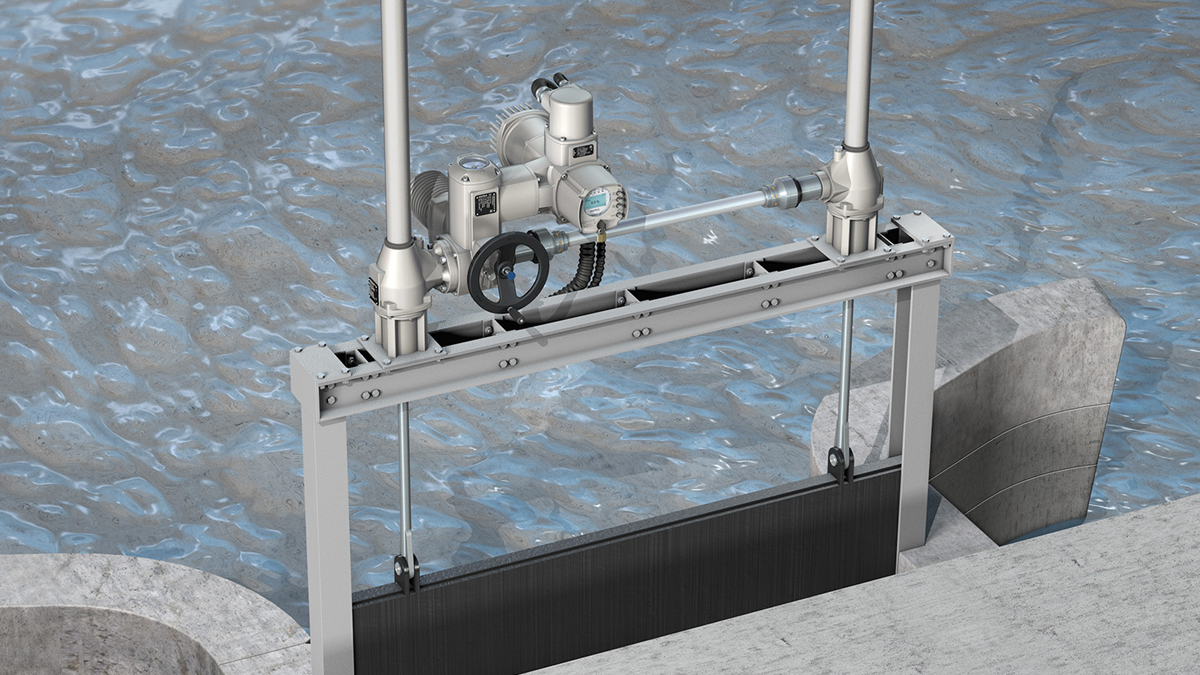

The company’s range of multi-turn and quarter-turn actuators includes state-of-the-art intelligent units with non-intrusive setting and data logging capabilities, plus a full range of bevel, spur and worm gearboxes designed for motorised operation.

AUMA’s unique modular design incorporates smart asset management by condition-based monitoring, with options such as fieldbus, variable speed and continuous underwater. The compact PROFOX range is ideal for lower torque requirements.

AUMA also supports the SIPOS Aktorik actuator range, offering full variable speed output and continuous modulation, plus Siemens legacy actuators.